IntelliSense TI-002226 User manual

INSTALLATION MANUAL

Addressable Device

GENERAL DESCRIPTION

The resettable call point is a device that allows the general user to trigger an alarm in case of a fire emergency occurrence in the protected

site. This particular model can be successively reset and made ready for other activations as needed.

REQUIREMENTS

This device works only with control panels employing the Vega protocol.

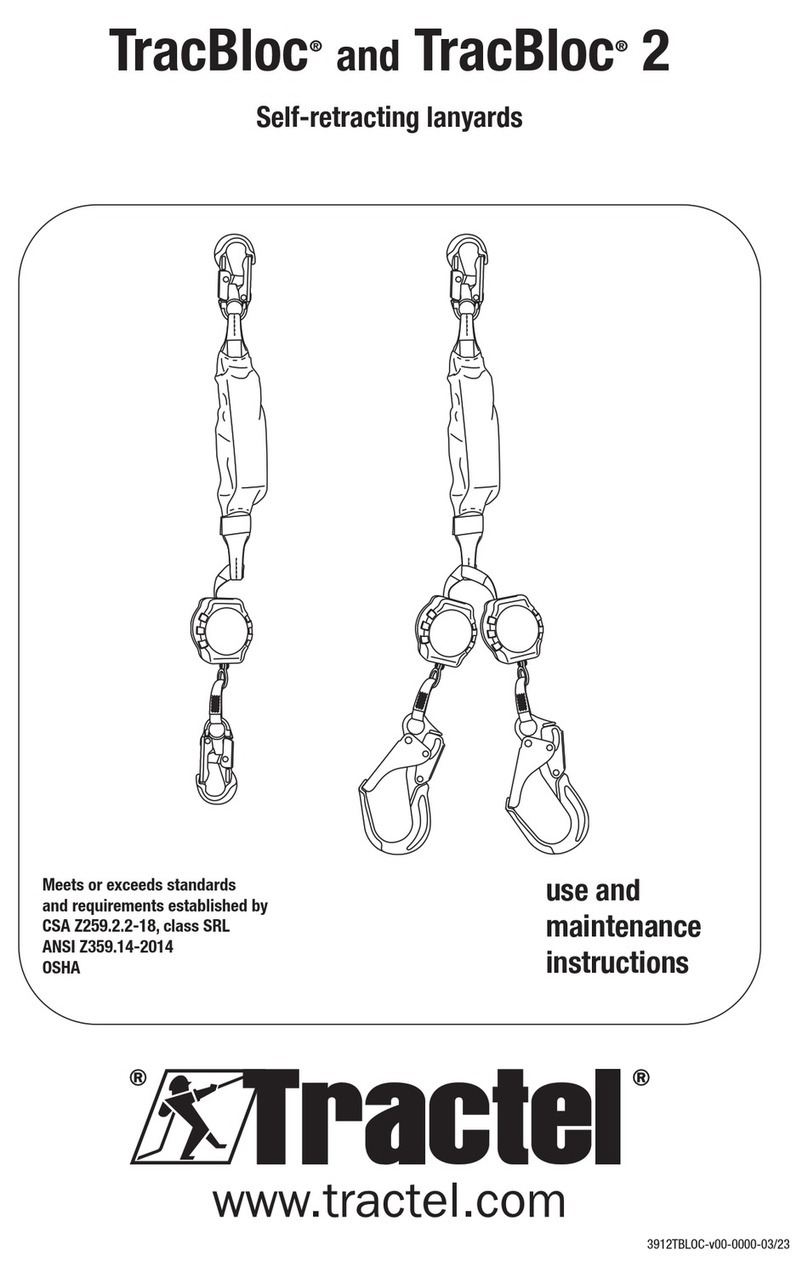

VISUAL INDICATOR LIGHT

This device is equipped with a visual indicator light (picture 1) providing information on its status.

Since this indicator is controlled by the control panel, consult your control panel’s documentation

or your system supplier for further specific information.

SHORT CIRCUIT ISOLATORS

This device is equipped with short circuit isolators.

Isolators limit the consequences that can be caused by short circuits on the analogue loop.

Remember that the “shorted“ loop section is switched out by the isolators as long as the short

persists.

INSTALLATION NOTES

This device must be used only with control panels employing Vega protocol.

Follow recognised codes of practice.

This device is intended only for indoor use.

Disconnect the loop before installing the devices.

Wire the loop connectors to the correct device’s terminal blocks: follow precisely the instructions given in this manual.

Electrostatic sensitive device: observe precautions when handling.

GIVING THE DEVICE AN ADDRESS

This call point must be given an address; you have two options:

- Programming the address through a hand-held Vega programming tool connected to the call

point’s front block.

Consult the Vega programming tool manual for further instructions on how to operate.

- Performing automatic addressing from the control panel.

This can be done if the control panel you are using has this feature and after you have physically

installed all the devices on the loop. Consult your control panel’s manual on how to operate.

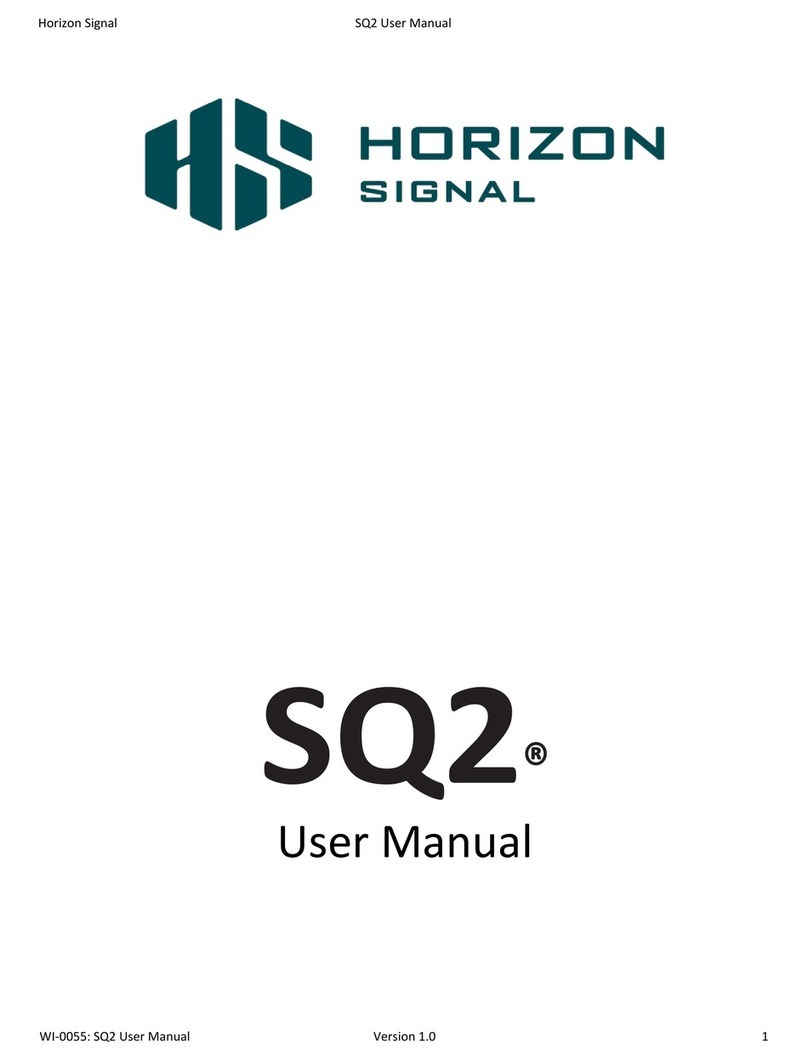

INSTALLATION - POSITIONING

1) Select the installation position.

2) The call point’s installation base has 3 openings, 2 of them are suitable for conduit adaptor

installation (picture 2).

3) Introduce the loop cables into the inside of the installation base.

4) Fix the installation base to the wall; use the supplied screws and anchors (picture 3).

5) Give a suitable length to the loop’s cables inside the base.

TI-002226

INTELLIGENT ANALOGUE RE-SETTABLE MANUAL CALL POINT

WITH SHORT CIRCUIT ISOLATOR 928h/01

CEASEFIRE INDUSTRIES PRIVATE LTD., E6, UPSIDC Industrial area, Selaqui, Dehradun, Pin Code - 248001, Uttarakhand, India

Visual indication

light

Pic. 1

Pic. 2

Pic. 3

INSTALLATION - WIRING

The scheme for wiring the call point’s front block to the loop is represented in (picture 4).

INSTALLATION - HOW TO FIT THE FRONT BLOCK

To install the front block to the installation base fixed to the wall proceed as illustrated in picture 5.

HOW TO REMOVE THE FRONT BLOCK

Insert the two pins at the top of the supplied reset key in the two

holes positioned at the bottom of the front block.

Push the key into the holes until the front block unlocks from the

installation base (picture 6).

CALL POINT ACTIVATION

To activate the call point press the black button positioned on the front of the device; an activation flag

appears on the top left side of the front window (picture 7).

CALL POINT RESET

1) Insert the reset key into the hole located on the bottom side of

the front block.

2) Turn the key counter-clockwise (picture 8).

L20-VCP100-7200 (vA.1)

Pic. 5

Pic. 6

Pic. 7

Pic. 8

+ IN - IN

+ OUT - OUT Pic. 4

+ IN - IN

+ OUT - OUT

TESTING

Apply scrupulously your recognised regulations concerning testing.

Nevertheless, test all devices after completing installation; additionally, we suggest you to test all devices on a periodic basis.

1) Activate the call point.

2) Check that:

- the control panel goes into alarm;

- the activation flag appears;

- the visual indicator light switches on.

3) Test fails if at least one of the above checks fails; test succeeds if all above checks succeed.

4) Reset the call point.

5) Reset the system from the control panel.

WARNINGS AND LIMITATIONS

Our devices use high quality electronic components and plastic materials that are highly resistant to environmental

deterioration. However, after 10 years of continuous operation, it is advisable to replace the devices in order to

minimize the risk of reduced performance caused by external factors. Ensure that these devices are only used with

compatible control panels. Detection systems must be checked, serviced and maintained on a regular basis to

confirm correct operation.

Smoke sensors may respond differently to various kinds of smoke particles, thus application advice should be

sought for special risks. Sensors cannot respond correctly if barriers exist between them and the fire location and

may be affected by special environmental conditions. Refer to and follow national codes of practice and other

internationally recognized fire engineering standards.

Appropriate risk assessment should be carried out initially to determine correct design criteria and updated periodi-

cally.

WARRANTY

All devices are supplied with the benefit of a limited 3 years warranty relating to faulty materials or manufacturing

defects, effective from the production date indicated on each product. This warranty is invalidated by mechanical or

electrical damage caused in the field by incorrect handling or usage. Product must be returned via your authorized

supplier for repair or replacement together with full information on any problem identified.

Full details on our warranty and product’s returns policy can be obtained upon request.

CEASEFIRE INDUSTRIES

PRIVATE LTD.

E6, Upsidc Industrial Area,

Selaqui, Dehradun, Pin Code

-248001, Uttarakhand, India

19

VE0310CPR20130701

EN 54-11:2001+A1:2005

EN 54-17:2005

TI-002226

For use in compatible fire

detection and alarm system

Type A

CEASEFIRE INDUSTRIES PRIVATE LTD., E6, UPSIDC Industrial area, Selaqui, Dehradun, Pin Code - 248001, Uttarakhand, India

TECHNICAL SPECIFICATIONS *

Power supply voltage range from 18 Vdc to 40 Vdc

Average current consumption 70 uA

Operating temperature range from -20 °C to +65 °C

Humidity (no condensation) 95% RH

Dimensions (w/o back box) 87 x 87 x 23 mm

Maximum wire gauge 2.5 mm2

*Check latest version of document TDS-VCPXX for further data, obtainable from

your supplier.

2831

L20-VCP100-7200 (vA.1)

+2*(+!#5/&$5$!.$%'-$5!,,5

$!.$%'-$5*#0./-'$.5 -'1!/$5')'/$#5

(+/5+55 $"+*#5 (++-5 $"/+-55

+'#!5 -$!/$-5 +'#!5 3,-$..2!45

+'#!5 55 //!-5 -!#$.&5*#'!5

/55 55

2225"$!.$%5'5-$2+-(#5"+)5+((+250.5+*5

!((5+0-5 -$$5 +/('*$55

55 555555

+-5"!((5555

Table of contents