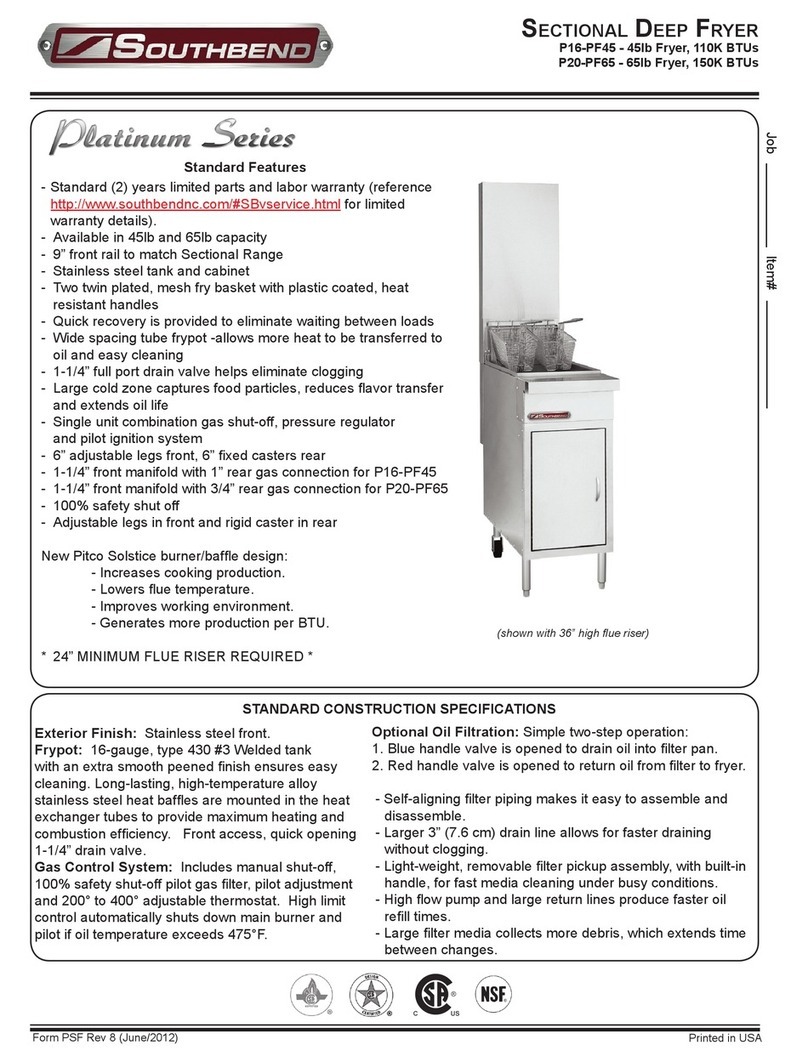

Southbend P16-PF45 User manual

MANUAL 1189468 REV 1 (8/19) $21.00

Owner’s Manual

IMPORTANT FOR FUTURE REFERENCE

Please complete this information and retain

this manual for the life of the equipment:

Model #:

S

erial

#:

D

ate

P

u

r

chased:

Sectional Fryers

Model P16-PF45 & P20-PF65

WARNING

Improper installation, adjustment, alteration, service, or maintenance can cause property damage, injury, or death.

Read installation, operation, and maintenance instructions thoroughly before installing or servicing this equipment.

1100 Old Honeycutt Road Fuquay-Varina, North Carolina 27526 USA •www.southbendnc.com

OWNER’S MANUAL 1189468 REV 1 (8/19)

PAGE 2of 50

SECTIONAL FRYERS SAFETY PRECAUTIONS

SAFETY PRECAUTIONS

Before installing and operating this equipment, be sure everyone involved in its operation is fully trained and aware of

precautions. Accidents and problems can be caused by failure to follow fundamental rules and precautions.

The following symbols, found throughout this manual, alert you to potentially dangerous conditions to the operator,

service personnel, or to the equipment.

DANGER

WARNING

CAUTION

NOTICE

This symbol warns of immediate hazards that will result in severe injury or death.

This symbol refers to a potential hazard or unsafe practice that could result in injury or death.

This symbol refers to a potential hazard or unsafe practice that could result in injury, product

damage, or property damage.

This symbol refers to information that needs special attention or must be fully

understood, even though not dangerous

WARNING FIRE HAZARD FOR YOUR

SAFETY

DO NOT store or use gasoline or other flammable vapors and liquids in the vicinity of cooking

appliances. Keep area around cooking appliances free and clear of combustibles.

Purchaser of equipment must post in a prominent location detailed instructions to be followed in the event the

operator smells gas. Obtain the instructions from the local gas supplier.

WARNING BURN HAZARD

Contact with hot surfaces will cause severe burns. Always use caution when operating cooking appliances.

W

ARNING EXPLOSION AND ASPHYXIATION HAZARD

In the event a gas odor is detected, shut down equipment at the main gas shut-off valve and immediately call the

emergency phone number of your gas supplier.

Improper ventilation can result in headaches, drowsiness, nausea, and could result in death. Do not obstruct the

flow of combustion and ventilation air to and from cooking appliances.

WARNING ELECTRIC SHOCK HAZARD

For appliances that use electric power, disconnect the power to the appliance before cleaning. Do not remove

panels that require tools to remove.

NOTICE

Southbend appliances are intended for commercial use only. Not for household use.

Warranty will be void if service work is performed by other than a qualified technician, or if other than genuine

Southbend replacement parts are installed.

Give this Owner’s Manual and important papers to the proper authority to retain for future reference.

Copyright © 2019 by Southbend. All rights reserved. Published in the United States of America.

OWNER’S MANUAL 1189468 REV 1 (8/19)

PAGE 3of 50

SECTIONAL FRYERS INSTALLATION

I

NSTALLATION

C

HECKING

YOUR NEW

F

R

YER

Your new fryer has been carefully packed into one crate. Every effort has been made to ensure that your fryer is delivered

to you in perfect condition. As you unpack your new fryer, inspect each of the pieces for damage. If something is

damaged, DO NOT sign the bill of lading. Contact the shipper immediately, the shipper is only responsible for 15 days

after delivery. Check the packing list enclosed with your fryer to ensure that you have received all of the parts to the fryer.

If you are missing any parts, contact the dealer from whom the fryer was purchased.

CAUTION

To prevent equipment damage, don’t tilt the fryer onto any two of its casters or pull the unit by the flue

vents.

L

EG/

C

ASTER

I

NSTALLATION

AND

A

DJUSTMENT

Installing the legs and leveling the fryer is done with a 7/16" wrench, socket, and a large pair of water pump pliers. The

legs/ casters must be installed to provide the necessary height to meet sanitation requirements and assure adequate air

supply to the burner. Attach the legs by performing the following procedure.

a. Lay the fryer on its side being careful not to damage the flue by pulling on it. Protect the outside of the fryer

with cardboard or a drop cloth when laying it down.

b. Attach each leg/caster with the hex head cap screws supplied with the fryer. Each leg/caster requires four

1/4-20 x 5/8" cap screws.

c. Mount the screws from the inside of the fryer with the nut on the outside. The nuts have lock washers

attached to them, therefore it is not necessary to use lock washers.

d. When all four legs/casters are mounted, stand the unit up being careful not to put too much weight on any one

leg/ caster. Adjust the height and level the fryer by adjusting the leveling devices on the leg/caster with the

water pump pliers.

e. On units with casters, move the fryer to the desired location and lock the wheels using the locking devices

on the front of the casters.

WARNING

The fryer must be

properly restrained

to prevent movement or tipping. This

restraint

must prevent the fryer

fr

o

m

movements that would splash hot liquids on personnel, which could cause severe burns or

injuries.

Always wear oil proof gloves when moving or handling equipment or hot

liquids.

I

NSTALLATION

C

LEARANCES

The fryer needs clearance around it for proper operation. Adequate clearances allow for servicing and proper burner

operation. The clearances shown below are for cooker installation in combustible and noncombustible construction.

Combustible

Non-Combustible

Construction

Construction

Back

6"

0"

Sides

6"

0"

Floor - Combustible

9"

9" (Needed for Combustion)

OWNER’S MANUAL 1189468 REV 1 (8/19)

PAGE 4of 50

SECTIONAL FRYERS SPECIFICATIONS

S

PECIFICATIONS

GAS

C

ONNECTION

Your fryer will give you peak performance when the gas supply line is of sufficient size to provide the correct gas flow.

The

gas line must be installed to meet the local building codes or National Fuel Gas Code ANSI Z223.1 Latest Edition.

In Canada, install the fryer in accordance with CAN/CGA-B149.1 or .2 and local codes. Gas line sizing requirements

can be determined by your local gas company by referring to National Fuel Gas Code, Appendix C, Table C-4

(natural gas) and Table C-16 (propane). The gas line needs to be large enough to supply the necessary amount of

fuel to all appliances without losing pressure to any appliance.

WARNING

NEVER supply the fryer with a gas that is not indicated on the data plate. Using the

incorrect

gas type will

cause

improper operation.

If you need to convert the fryer to

another

type of fuel, contact your

dealer

.

FUEL TYPES

Each fryer is equipped to work with one type of fuel. The type of fuel with which the appliance is intended to operate

is stamped on the data plate attached to the inside of the door.

NOTICE

NEVER use an

adaptor

to make a smaller gas supply line fit the cooker connection. This

may

not allow

proper

gas flow for optimum

burner operation, resulting

in poor

cooker

performance.

Q

UICK

D

ISCONNECT

G

AS

C

ONNECTION

Gas fryers equipped with casters must be installed with connectors that comply with the Standard for Connectors for

Movable Gas Appliances, ANSI Z223.1 Latest Edition, and Addenda Z21.69A Latest Edition. This connection should

include a quick disconnect device that complies with the Standard for Quick Disconnect Devices for Use With Gas Fuel ,

ANSI Z223.1 Latest Edition. When installing a quick disconnect you must also install a means for limiting the movement

of the fryer. This

device will

prevent the gas line or the quick disconnect from being strained. The restraining device

should be attached to the cooker on the back panel.

F

UEL

S

UPPLY

L

INE

L

EAK AND

P

RESSURE

T

ESTING

The fuel supply system must be tested before the fryer is used. If the fuel line is going to be tested at a pressure

greater than (>)1/2 PSIG (3.45 kPa), make sure that the fryer is disconnected from the fuel line. If the fuel line is to be

tested at a pressure equal to or less than (<) 1/2 PSIG (3.45 kPa), the fryer can be connected but the unit’s gas valve

must be shut. Test all gas line connections for leaks with a solution of soap and water when pressure is applied.

E

LECTRICAL

C

ONNECTION

The electrical service used by the fryer must comply with local codes. If there are no local codes that apply, refer to the

National Electrical Code (NEC), ANSI/NFPA 70 to install the service. In Canada refer to CSA Standard C22.1 and local

codes. Wiring diagrams are provided inside the fryer control box.

V

ENTILATION AND

F

IRE

S

AFETY

S

YSTEMS

Your new fryer must have proper ventilation to function safely and properly. Exhaust gas temperatures can reach as high

as 1000°F. Therefore, it is very important to install a fire safety system. Your ventilation system should be designed to

allow for easy cleaning. Frequent cleaning of the ventilation system and the fryer will reduce the chances of fire. Table 1-2

provides a list of reference documents that provide guidance on ventilation and fire safety systems. This table is not

necessarily complete. Additional information can be obtained from the CSA-International, 8501 East Pleasant Valley Road,

Cleveland, OH 44131.

OWNER’S MANUAL 1189468 REV 1 (8/19)

PAGE 5of 50

SECTIONAL FRYERS SPECIFICATIONS

Excessive ventilation causes drafts, which will interfere with the proper operation of the pilot and the burner. Leave at

least 18 inches of open space between the fryer’s flue vent opening and the intake of the exhaust hood.

CAUTION

Ensure that your ventilation system does not cause a down draft at the fryer’s flue

opening.

Down drafts will not allow the fryer to exhaust

properly

and will cause

overheating

which

may

cause

permanent

damage. Damage caused by down drafts will not be covered under

equipment

warranty.

NEVER allow anything to

obstruct

the flow of combustibles or

ventilation

exiting

from

the fryer flue. DO NOT put anything on top of the flue

ar

ea.

NOTICE

NEVER connect the blower directly to the flue openings. The direct flow of air will cause

poor temperature

r

ecover

y, poor ignition, inefficient

operation

of the fryer, and could

extinguish

the

pilot.

G

AS

L

INE

R

EQUIREMENTS

A properly installed gas supply system will deliver 7.0 ± 2.0" w.c. natural gas (12.0 ± 2.0" w.c. LP) to all appliances

connected to the line, operating at full demand.

NOTICE

Do NOT exceed 13.5" W.C.

pressure

as damage may occur to the gas valve.

TOPIC

UNDERWRITERS

LABORA

T

O

R

Y

DOCUMENT

NATIONAL FUEL GAS CODE

DOCUMENT

EXHAUST HOODS

ANSI/UL 710

ANSI/NFPA 96

POWER VENTILATORS

ANSI/UL 705

ANSI/NFPA 96

FILTER UNIT

ANSI/UL 586

ANSI/UL 900

ANSI/NFPA 96

TYPES OF FIRE EXTINGUISHERS

AND DETECTION EQUIPMENT

CO2

ANSI/UL 154

ANSI/NFPA 12

DRY CHEMICAL

ANSI/UL 299

ANSI/NFPA 17

WATER

ANSI/UL 626

ANSI/NFPA 13

FOAM

ANSI/UL 8

ANSI/NFPA 11

SPRINKLERS

ANSI/UL 199

ANSI/NFPA 13

SMOKE DETECTORS

ANSI/UL 268

ANSI/NFPA 72

FIRE DETECTION THERMOSTATS

ANSI/UL 521

ANSI/NFPA 72

IF MAINTENANCE IS REQUIRED, CONTACT YOUR LOCAL FACTORY SERVICER, LOCAL

FACTORY REPRESENTATIVE, OR THE FACTORY TO OBTAIN SERVICE.

OWNER’S MANUAL 1189468 REV 1 (8/19)

PAGE 6of 50

SECTIONAL FRYERS OPERATION

OPERATION

L

IGHTING

I

NSTRUCTIONS

1. Fill kettle before lighting.

2. Turn combination gas valve knob to “PILOT” position.

3. Depress valve knob and light pilot. With pilot burning, hold knob depressed for 60 seconds. d. Release knob,

pilot should remain lit.

4. DO NOTTURN COMBINATION GAS VALVE KNOB TO THE “ON”POSITION UNTIL VESSEL IS FULL OF

WATER OR SHORTENING. TURNING THE KNOB TO “ON”WITH VESSEL EMPTY WILL DAMAGE THE

VESSEL OR COMPONENTS AND VOID WARRANTY.

5. Relighting - wait 5 minutes before attempting to relight the pilot to allow for any gas in the fryer to dissipate.

WARNING

Gas units installed with casters must have a

restraining

device. This device must be connected at all

times that

the fryer

is connected to the gas supply. If it is disconnected for any

reason,

it must be

r

econnected.

I

NITIAL

C

LEANING

When the fryer is shipped, many of its parts are covered with a thin coat of oil for protection. Before the fryer is ready

for cooking it must be cleaned. This will remove oil coating and any foreign matter that may have accumulated during

storage and shipment. Perform the cleaning as described below.

1. Fill the vessel with water.

2. Turn the fryer gas valve knob to the “ON” position. Allow the fryer to bring the water to a low boil and add one

3. Packet of fryer cleaner or a mild, low sudsing detergent and allow water to continue to boil for a minute,

making sure the water does not boil over.

4. Turn the gas valve knob to the “PILOT” position and allow fryer to soak with the hot water for 15 minutes.

NOTICE

Do not leave the fryer unattended during cleaning. Never let the water level go below the “Min Level” mark

on the back of the tank.

5. Using the fryer cleaning brush, scrub the inside of the fryer to remove protective coating.

6. When cleaning is complete, turn the gas valve knob to the “OFF” position and drain the water into a container

suitable for hot water and dispose of it.

7. When the tank has cooled, rinse it thoroughly with cool water. Continue to rinse the tank until the cleaner has

been rinsed thoroughly from the tank.

8. Using a clean dry cloth, wipe out all of the water. Be very thorough removing the water, because any residual

water will cause hot oil to splatter out of the fryer. Close the drain valve and remove container.

9. Now that the tank is clean, you are ready to fill and operate the fryer. Refer to instructions on adding shortening

to the fryer.

OWNER’S MANUAL 1189468 REV 1 (8/19)

PAGE 7of 50

SECTIONAL FRYERS OPERATION

T

HERMOSTAT

C

ALIBRATION

C

HECK

NOTICE

Thermostat calibration requires

that the

temperature

of the fryer be raised above

boiling.

Therefore,

you will need to drain the water

from

the fryer and fill it with oil. Before

r

emoving

the

water, perform

the Initial Cleaning of the

fryer.

Cleaning the fryer now will prevent

you

from

having to drain the oil

and

r

efill

with water

late

r

.

To

perform

the

calibration

check detailed below, you will need a digital

thermometer

.

1. Place the tip of the thermometer in the shortening approximately 1" above the temperature sensors.

2. Set the thermostat at 325°F and wait for the temperature reading on the thermometer to rise. As the

temperature rises toward 325°F watch the thermometer closely.

3. If the shortening temperature reaches 350°F and the burners DO NOT turn off, turn the thermostat down. Keep

lowering the thermostat setting until the burners go out.

CAUTION

If the

burners

do not turn off at the lowest

thermostat

setting, the

thermostat

could

be

defective.

Contact your

representative

immediately

.

4. Let the fryer cycle 4 to 6 times before checking the temperature. Compare the thermometer temperature

against the thermostat setting. If the values are more than 5°F apart, calibrate the thermostat using the

appropriate calibration procedure in this manual.

T

HERMOSTAT

C

ALIBRATION

Millivolt

thermostats

1. Set the thermostat dial to 325°F.

2. Remove the thermostat dial by pulling the knob straight out. DO NOT rotate the dial.

3. Hold the outside of the shaft so it does not move. Use the tip of a small, flat tip screw driver to scrape away the

sealing compound from the adjustment screw.

4. Turn the adjustment screw clockwise to lower the temperature setting and counterclockwise to raise the

temperature. One quarter turn changes the temperature approximately 25°F.

5. Turn the adjustment until the burners turn on at 325°F. Replace the knob and allow the fryer to cycle 4 to 6

times. Check the temperature of the thermometer against the thermostat dial. If it is greater than 5° F

difference, repeat the calibration procedure.

6. When the calibration is correct, remove the thermometer and replace the tube screen.

F

RYER

O

PERATION

Filling the Fryer with Liquid

Shortening

1. Make sure the drain valve is completely closed.

2. Fill the fryer with oil to the “Oil Level”line marked on the back of the tank.

OWNER’S MANUAL 1189468 REV 1 (8/19)

PAGE 8of 50

SECTIONAL FRYERS OPERATION

Filling the Fryer with Solid

Shortening

1. Make sure the drain valve is completely closed.

2. Remove the screen covering the tubes.

3. Cut the shortening into cubes no larger than 1". ALWAYS pack the shortening below, between, and on top of the

burner tubes. DO NOT leave any large air gaps. Use care when packing the solid shortening in the tank. DO NOT

bend or break the temperature sensor probes. If these are damaged the fryer will not function properly.

4. Once the fryer is packed with shortening, the shortening must be melted.

5. To melt shortening, manually pulse the burners ON and OFF using the thermostat until the shortening is liquidized

enough to cover the heat tubes. This will protect the tank and components from damage and extend the life of the oil.

Fryer Shut-Down

There are two shutdown modes of fryer operation, STANDBY and COMPLETE. The Standby mode removes the ability

for the fryer’s main burners to cycle. Complete shutdown turns off the gas supply to the fryer. Shut down the fryer by:

STANDBY

Turn the thermostat to OFF. Turn the gas valve clockwise to the PILOT position. The cooker is now in Standby mode

and can remain this way for only brief periods of time. NEVER leave the cooker in Standby overnight.

COMPLETE

To completely shut down the cooker, push and turn the gas valve counterclockwise to the OFF position. The fryer is

now completely shut down and can be cleaned and filtered.

F

ILTER

P

ROCEDURES

NOTICE

When working with hot oil ALWAYS wear oil-proof, insulated

gloves.

WARNING

NEVER •Run the filter system without a filter

bag/paper

.

NEVER •Empty the oil from the fryer before

turning

OFF the fryer

burners.

NEVER •Store the UFM Filter Unit anywhere other than in the fryer filter

cavity

.

1. Slide the filter pan out. Carefully remove filtered residue off the filter media. Examine the filter media for clogged

or torn areas. Refer to filter media replacement instructions following this section. Reinstall the pan.

2. Turn the fryer that is to be filtered OFF (See Standby Shutdown). Remove the baskets from the fryer

tank(s).

3. Use the clean out brush to lift out the tube screens. If there are excess crumbs in the fryer tank, remove them

with the crumb scoop.

4. If you have replaced the filter media or remove crumbs and debris, sprinkle Pre-Coat Filter Aid on the filter paper.

5. Check the drain spout to ensure that it is in the drain tower and over the filter pan opening.

6. Slowly open the green handled drain valve for the tank being filtered. If necessary use the clean-brush to clear

the crumbs from the drain. Use the brush to clean the sides of the tank as the oil drains.

OWNER’S MANUAL 1189468 REV 1 (8/19)

PAGE 9of 50

SECTIONAL FRYERS OPERATION

WARNING

This filter pan is only large enough to hold the

contents

of ONE (1) tank at a time,

during the filter

pr

ocess.

7. When the tank is empty, close the green handled drain valve. Open the red handled return valve to the tank you

are filtering. This will start the pump and return the oil to the bottom of the fry tank.

8. When bubbles are seen coming out of the oil return spout, close the red handled valve to turn the pump off. If

necessary add more oil to the tank to return the oil level to the fill mark. The fryer is now ready for use.

DRAINING A TANK

Note -The filter system is also used to drain the fryers. You will need a container capable of holding 400°F oil and

protective gloves.

1. Rotate the drain down spout so that it extends in the container that you want to drain the shortening into.

2. Open the green handled drain valve for the tank to be drained. The oil will drain into the container you have

chosen. When the container is full or the fry tank is empty, close the green handled drain valve. If the container

was full repeat this step until fryer tank is empty.

3. Once tank is completely empty add new shortening and follow fryer start up procedures.

WARNING

The power supply must be disconnected before servicing or cleaning

the

appliance.

FILTER MEDIA REPLACEMENT

The filter module stores neatly under the fryer when not in use. The unit is very easy to use and allows for quick

installation and filtration, even under the busiest conditions. Follow the procedures below to change the filter media.

WARNING

At

operating temperature,

the

shortening

in the fryer may be hotter

than

375°F (190°C). This hot, melted

shortening

will cause severe burns. DO NOT

let

the hot

shortening

touch your skin or clothing. Always wear

insulated

oil p

roof gloves when working on the filter system. It will be easier and safer if the

filter

assembly has

cooled to

room temperature

before handling any filter

par

ts.

1. With the filter pan empty of oil, remove the filter media by grasping the filter pan handle and gently pull the

assembly toward the front of the fryer.

2. Separate the filter pickup tube from the filter pickup screen assembly by pulling up on the pickup tube just above

where it connects to the pickup screen assembly. Lift pickup tube and swing it to the left, until it rests on the left

hand side of the filter pan.

3. Grab filter screen pickup assembly lift handles and carry it to a trash barrel and shake off heavy discard any debris

that may be built upon the top of the assembly.

4. Unscrew the filter paper clip bracket from the filter paper support screen and slide the filter paper support screen

out of the filter paper clip bracket.

OWNER’S MANUAL 1189468 REV 1 (8/19)

PAGE 10 of 50

SECTIONAL FRYERS OPERATION

5. Remove filter paper support screen from the filter envelope.

6. All of the filter pick up assembly parts can be washed in a dish washer or a pot sink. Flush out the suction tube

assembly with hot water. After cleaning, it is very important to thoroughly dry the parts before reassembling. Water

and oil do not mix. Water in hot oil will cause the oil to splatter.

7. Start reassembling the filter pick up assembly by sliding the new filter paper on to the filter paper support rack.

Ensure that the hole in the filter paper goes over the pickup tube assembly threaded connector.

8. Fold the open end of the bag in two folds. The first fold should be approximately 1 inch from the end and the

second should be over the edge of the rack assembly.

9. Slide the clip screen over the folded end of the filter paper. Ensure the opening of the clip screen goes over the

pickup tube connection. Screw the suction tube connection onto the threaded connection.

10. Place the filter pickup assembly into the filter pan and slide the filter pan assembly back into the fryer cabinet.

11. Filter unit is now ready for use.

OWNER’S MANUAL 1189468 REV 1 (8/19)

PAGE 11 of 50

SECTIONAL FRYERS CLEANING AND MAINTENANCE

C

LEANING AND

M

AINTENANCE

WARNING

Disconnect the power supply to the appliance before cleaning. Do not remove panels that require tools to remove.

WARNING

Adjustments and service work should be performed only by a qualified technician who is experienced in, and

knowledgeable with the operation of commercial gas cooking equipment. To assure confidence, contact your

authorized service agency for reliable service, advice and other assistance with your appliance. Insist upon genuine

factory parts to be used for any repair or service of your appliance.

Southbend appliances are sturdily constructed of the best materials and are designed to provide durable service when

treated with ordinary care. To expect the best performance, your equipment must be maintained in good condition and

cleaned daily. Naturally, the periods for this care and cleaning depend on the amount and degree of usage.

Following the daily and periodic maintenance procedures will enhance long life for your equipment. Climatic

conditions (such as salt air), may require more thorough and frequent cleaning or the life of the equipment could be

adversely affected.

Keep exposed, cleanable areas clean at all times.

I

NITIAL

C

LEANING -

See Page 6

D

AILY

C

LEANING AND

M

AINTENANCE

Cleaning should be performed daily to maintain peak operation and appearance.

1. Wipe up any shortening that spills onto the exterior of the fryer. This should be done with a clean soft cloth while the

oil is still warm.

2. Use warm water with a mild detergent to clean surfaces. Be careful not to get water in the shortening and to remove

any detergent from the fry tank.

3. Use a nonabrasive scouring powder or pad to clean stains if necessary.

4. Perform the weekly boil out cleaning of your fryer described below.

W

EEKLY

F

RYER

C

LEANING AND

M

AINTENANCE

This cleaning should include a complete draining of the fryer and a boil out.

1. You will need a container large enough to hold 1 1/2 times the oil in one tank. This container should also be able to

withstand 400° F oil temperatures.

2. Shut fryer gas system OFF completely before performing procedures to ensure unit does not come on during any

part

of the cleaning operation.

3. Drain the oil from the fryer and discard or save for reuse. Remove tube rack/mesh tube screens and remove any

large debris from the bottom of the fry tank. Once clean, return tube rack/mesh screens to the fry tank. Close the

drain valve and fill the fry tank with water and non-caustic detergent.

OWNER’S MANUAL 1189468 REV 1 (8/19)

PAGE 12 of 50

SECTIONAL FRYERS CLEANING AND MAINTENANCE

4. Relight gas system pilot, following the lighting instructions.

5. Turn the fryer gas valve knob to the “ON” position. Allow the fryer to bring the water to a low boil and add one packet

of fryer cleaner or a mild, low sudsing detergent and allow water to continue to boil for a minute, making sure water

does not boil over.

6. Turn the gas valve knob to the “PILOT” position and allow fryer to soak with the hot water for 15 minutes.

7. Using the fryer cleaning brush, scrub the inside of the fryer to remove protective coating.

8. When cleaning is complete, turn the gas valve knob to the “OFF” position and drain the water into a container

suitable for hot water and dispose of it.

9. When the tank has cooled, rinse it thoroughly with cool water. Continue to rinse the tank until the cleaner has been

rinsed, thoroughly from the tank.

10. Using a clean dry cloth, wipe out all of the water. Be very thorough removing the water, because any residual water

will cause hot oil to splatter out of the fryer. Close the drain valve and remove container.

11. Now that the tank is clean, you are ready to fill and operate the fryer. Refer to instructions on adding shortening to

the fryer.

OWNER’S MANUAL 1189468 REV 1 (8/19)

PAGE 13 of 50

SECTIONAL FRYERS

This Page Left Blank for Notes:

OWNER’S MANUAL 1189468 REV 1 (8/19)

PAGE 14 of 50

SECTIONAL FRYERS PARTS LISTS AND DRAWINGS

PARTS LISTS P16-PF45 ONLY

TANK & FLUE

Tank & Flue Drawing A - Parts List

ITEM #

PART #

PART DESCRIPTION

1

B3322601-C

TANK WELDMENT MODULAR SST SG14R

2

1405556

36” DEEP FLUE ASSEMBLY

1405559

42” DEEP FLUE ASSEMBLY

60131002

BALL VALVE 1-1/4 FULL PORT REVERSIBLE LUG RIGHT HAND

4

A8030407

DRAIN LINE PIPING ADAPTER SG, SGM (NON-FILTER)

5

B6700604-C

WIRING PROBE SERVICE KIT SG

B6700608-C

WIRING PROBE SERVICE KIT (BACK UP THERMOSTAT)

10

A3525901

FLUE GASKET SG14T

11

P7036726

STEEL TANK PLUG 1/4NPT

12

60130101

TANK REAR ADAPTER 37.5 FLARE SWIVEL X 1/2NPT

P7036729

STEEL TANK PLUG 1/2NPT

13

A1406702

CLAMP HIGH LIMIT THERMOSTAT SG MILLIVOLT

16

PP11366

SCREW 10-24 X 5/8 PAN HEAD SST THREAD FORMING

18

P0076100

SCREW 10-24 X 3/4 SELF TAPPING

19

P0092300

NUT HEX 10-24 KEP ZN

OWNER’S MANUAL 1189468 REV 1 (8/19)

PAGE 15 of 50

SECTIONAL FRYERS PARTS LISTS AND DRAWINGS

P16-PF45 ONLY

Tank & Flue Drawing A

OWNER’S MANUAL 1189468 REV 1 (8/19)

PAGE 16 of 50

SECTIONAL FRYERS PARTS LISTS AND DRAWINGS

P16-PF45 ONLY

BURNER ASSEMBLY

Burner Assembly Drawing B - Parts List

ITEM #

PART #

PART DESCRIPTION

1

B8039101

BURNER MANIFOLD WELDMENT CENTER-TAP SG14, SG14R (REPLACES B8029701)

2

B8042001

SELF-CLEANING BURNER RUNNER TUBE SG14, SG14R

3

60147801

THERMAL-LIMIT SWITCH WITH MANUAL RESET

4

A8028401

GASKET BURNER BRACKET SG14R,SGM1824

3M SUPER 77 MULTIPURPOSE HIGH TACK SPRAY ADHESIVE

(REQUIRED WHEN INSTALLING NEW ITEM #4)

DO NOT SPRAY ADHESIVE ACROSS BURNER FACES

5

A8027701

BURNER FLAME JUMPER SG14,SG14R,SG18,SG18F,SGC

8

B8037301-C

BURNER SLOTTED-FACE NATURAL

B8037302-C

BURNER SLOTTED-FACE LP

B8041901

BURNER INCONEL 601 WIRE-FACE SCREEN NATURAL SCB & LP

(REPLACES B8030001)

9

60127501

FITTING ADAPTER FLARED 15/16-16 UN-2A X 1/2 FNPT BRASS

10

60129701

FITTING 1/4 MNPT X .344-32 UNS ORIFICE TIP BRASS

11A

60132801

FITTING TEST PRESSURE PLUG 1/8-27 (CE)

11B

N/A

PLUG 1/8 NPT 3/16 HEX SOCKET STEEL

12

A7513701

ORIFICE TIP 1.45mm DIA

P6071309

ORIFICE TIP 1/16 DIA

P6071336

ORIFICE TIP #36 DIA

P6071337

ORIFICE TIP #37 DIA

P6071338

ORIFICE TIP #38 DIA

P6071339

ORIFICE TIP #39 DIA

P6071340

ORIFICE TIP #40 DIA

P6071341

ORIFICE TIP #41 DIA

P6071342

ORIFICE TIP #42 DIA

P6071343

ORIFICE TIP #43 DIA

P6071344

ORIFICE TIP #44 DIA

P6071353

ORIFICE TIP #53 DIA

P6071354

ORIFICE TIP #54 DIA

P6071355

ORIFICE TIP #55 DIA

PP10859

ORFICE TIP 1.51 mm DIA

13

PP10023

SCREW 10-24 X 3/8 SELF TAPPING

14

PP10687

SCREW 6-32 X 5/16 TRUSS HEAD PHILLIPS ZN

15

A8028001

BURNER BRACKET SG14R

16

A2036904-C

SELF-CLEANING BURNER HIGH-LIMIT BRACKET SG14, SG14R, SG18

17

P0075300

SCREW 10-16 X 5/8 HEX HEAD SELF-DRILLING

19

B8031702

BURNER ASSEMBLY SLOT FACE NATURAL SG14R

B8031705

BURNER ASSEMBLY INCONEL 601 WIRE-FACE SG14R

NOT SHOWN

OWNER’S MANUAL 1189468 REV 1 (8/19)

PAGE 17 of 50

SECTIONAL FRYERS PARTS LISTS AND DRAWINGS

P16-PF45 ONLY

Burner Assembly Drawing B

OWNER’S MANUAL 1189468 REV 1 (8/19)

PAGE 18 of 50

SECTIONAL FRYERS PARTS LISTS AND DRAWINGS

P16-PF45 ONLY

GAS TRAIN

Gas Train Drawing C1 - Parts List

ITEM#

PART#

PART DESCRIPTION

1

60125901

TUBE, VENT GAS VALVE

2

60127601

FITTING,ADAPTER FEMALE SWIVEL X 1/2 MPT

3

A8029001-C

PIPING, VALVE SHIELD SG, SGC, SG18F

4

60127401

FITTING, ELBOW MALE FLARE X MPT

5

P0007300

SCREW, 8-32 X 1/4 HEX HEAD SLOTTED ZN

9

A8029105

COUPLING, GAS SUPPLY SHORT SG, MKG (PRIOR TO 2/05: USE A8029103)

10

60128101

VALVE, GAS SUPPLY SHUTOFF

11

60128015

TUBING, FLEXIBLE WITH FITTINGS 22 GAS (SG AFTER 2/05)

OWNER’S MANUAL 1189468 REV 1 (8/19)

PAGE 19 of 50

SECTIONAL FRYERS PARTS LISTS AND DRAWINGS

P16-PF45 ONLY

Gas Train Drawing C1

OWNER’S MANUAL 1189468 REV 1 (8/19)

PAGE 20 of 50

SECTIONAL FRYERS PARTS LISTS AND DRAWINGS

P16-PF45 ONLY

GAS TRAIN

Gas Train Drawing C2 - Parts List

ITEM#

PART#

PART DESCRIPTION

2

60125201-C

VALVE, GAS VS820 NAT SG, SGC, SG18F

60125202-C

VALVE, GAS VS820 LP SG, SGC, SG18F

5

A8035302

PIPING, PILOT BRACKET SG14 SG14R SG18

10

60128801

PILOT, REVERSE STANDING NAT SG

60128802

PILOT, REVERSE STANDING LP SG

11

60119001

TUBE, FLEXIBLE WITHOUT FITTINGS 18 X 1/4 OD SG, SG18F, SGC

12

60088001

SCREW, 10-32 X 1/4 HEX HEAD SST

14

60125501

THERMOPILE, MILLIVOLT

23

2908-0940501

ORIFICE, PILOT RUNNER TUBE #52 NAT SG14, SG14R, SG14T

2908-0940502

ORIFICE, PILOT RUNNER TUBE #68 LP SG

28A

B6783401

WIRING, IGNITION CABLE WITH GROUND WRAP 20" SG*

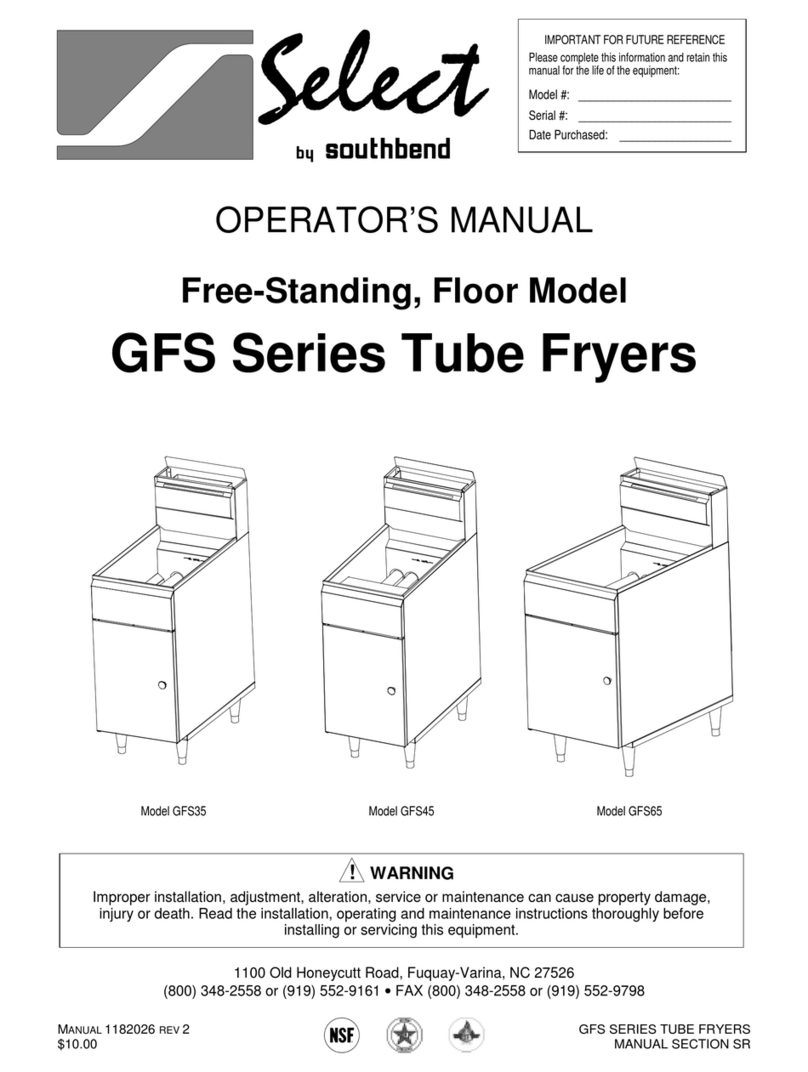

Other manuals for P16-PF45

4

This manual suits for next models

1

Table of contents

Other Southbend Fryer manuals

Southbend

Southbend P16-PF45 Installation and operation manual

Southbend

Southbend 35-Pound Fryer User manual

Southbend

Southbend 14-36 User manual

Southbend

Southbend P16-PF45 User manual

Southbend

Southbend 14-36 User manual

Southbend

Southbend FF-21-36 User manual

Southbend

Southbend P16-PF45 User manual

Southbend

Southbend 4FR-45 User manual

Southbend

Southbend P16-PF45 User manual

Southbend

Southbend Select GFS35 User manual