Southwest Microwave INTREPID MicroTrack II User manual

Version 0

Southwest Microwave, Inc.

Security Systems Division

INTREPID™

MicroTrack™ II

A BURIED TERRAIN-FOLLOWING

OUTDOOR PERIMETER INTRUSION DETECTION SYSTEM

MicroTrack II Installation

and Operation Manual

INTREPID MicroTrack II Manual

Version 0

INTREPID™ MicroTrack™ II Software

Southwest Microwave Inc. thanks you for your purchase of the INTREPID MicroTrack II System. Please

refer to the Universal Installation Service Tool (UIST) for the software setup of this sensor.

There is one disk required to setup the system.

1. Universal Installation Service Tool II (UIST II) Software

This software is used to configure and set-up the system as well as being used for maintenance and

troubleshooting the system.

Software provided by Southwest Microwave, Inc. is subject to the license agreement terms of the

individual product. A copy of the license agreement is available by contacting Southwest Microwave, Inc.

Basic Tools Required for Installing the MicroTrack II System

The basic tools and materials required for installing the MicroTrack II system are:

•Laptop computer running Windows XP Pro, Vista Pro or 7 Pro™

•Basic hand tools (screwdrivers, wrenches, cutters, etc.)

•Soldering gun (100 watt minimum)

•Inverter with battery or AC source for the soldering gun

•Multi-meter

•Goo Gone, WD40, Xylene, Kerosene or Mineral Spirits to remove the flooding compound on the

MicroTrack II sensor cable

•Trencher, shovels and bobcat

•Marking paint, string, stakes and tape measure

•Tools for installing conduit in a metal enclosure

•Pole to un-spool the MicroTrack II sensor cable

INTREPID MicroTrack II Manual

Version 0

Trademark and Regulatory Notice

INTREPID, MicroPoint and MicroTrack are registered trademarks of Southwest Microwave, Inc.

Copyright 1995 and 2009 Southwest Microwave Inc. All rights Reserved.

Windows, EXCEL, WORDPAD and NOTEPAD are a registered trademark of Microsoft Corporation.

FCC Notice

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant

to part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial environment. This equipment generates,

uses, and can radiate radio frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio communications. Operation of this equipment

in a residential area is likely to cause harmful interference in which case the user will be required to

correct the interference at his/her own expense. FCC ID: CA6MTP

NOTE: changes or modifications not expressly approved by the party responsible for compliance could

void the user’s authority to operate the equipment.

CE Notice

This equipment has been designed and tested to meet EN 6950-1, EN 300-330-1, EN 300-330-1-7.2, EN

300-330-1-7.4.2 and EN 300-330-1-8.2.

Patent Notice

Southwest Microwave Inc. intellectual property in INTREPID and MicroTrack is protected by the

following patents:

USA 6,577,236,B2

Patents are pending in many counties of the world.

Copyright Southwest Microwave, Inc. June, 2011

Southwest Microwave, Inc.

9055 South McKemy Street

Tempe, Arizona 85284-2946

Tel: (480) 783-0201

Fax: (480) 783-0401

Email: infossd@southwestmicrowave.com

Web: www.southwestmicrowave.com

INTREPID MicroTrack II Manual

Version 0

i

TABLE OF CONTENTS

1. Introduction............................................................................................................................................... 1-1

1.1 Theory of Operation............................................................................................................................ 1-1

1.2 Target Processing................................................................................................................................ 1-3

1.3 Features and Benefits .......................................................................................................................... 1-5

2. MicroTrack™ II Detection Characteristics............................................................................................ 2-1

2.1 Detection Requirements and Expectations.......................................................................................... 2-1

2.2 MicroTrack II Typical Detection Pattern ............................................................................................ 2-1

2.2.1 Detection Field ............................................................................................................................ 2-1

2.2.2 Detection Pattern Width.............................................................................................................. 2-3

2.2.3 Detection Pattern Height ............................................................................................................. 2-3

2.2.4 Sensor Cable Maximum Length.................................................................................................. 2-4

3. MicroTrack II System Components ........................................................................................................ 3.1

3.1 Hardware Components........................................................................................................................ 3-1

3.1.1 MicroTrack Processor II (MTP II) .............................................................................................. 3-1

3.1.2 MicroTrack Sensor Cable Assembly........................................................................................... 3-2

3.1.3 MicroTrack End of Line Termination Kit (MTT)....................................................................... 3-2

3.1.4 MicroTrack In Line Termination Kit (MTI) ............................................................................... 3-3

3.1.5 MicroTrack Enclosure - Metallic (MTE-ME)............................................................................. 3-3

3.1.6 MicroTrack Enclosure - Stainless Steel (MTE-SS)..................................................................... 3-3

3.1.7 MicroTrack Splice Kit (MTS)..................................................................................................... 3-4

3.1.8 MicroTrack - Sensor Cable ........................................................................................................ 3-4

3.1.9 MicroTrack Lead-in Cable Assembly ......................................................................................... 3-4

3.1.10 JB70 Lightning/Surge Protection Module................................................................................... 3-4

3.1.11 Power Supplies............................................................................................................................ 3-5

3.2 Control Modules ................................................................................................................................. 3-5

3.2.1 Relay Control Module II (RCM II)............................................................................................. 3-5

3.2.2 Control Module II (CM II).......................................................................................................... 3-5

3.2.3 Craphic Control Module II (GCM II) ......................................................................................... 3-5

3.2.4 Perimeter Security Manager........................................................................................................ 3-6

3.2.3 INTREPID™ Polling Protocol II (IPP II)................................................................................... 3-6

3.3 Software Components ......................................................................................................................... 3-6

3.3.1 Universal Installation / Service Tool........................................................................................... 3-6

4. Site Planning / System Configuration ..................................................................................................... 4-1

4.1 Basic MicroTrack II Configuration Parameters .................................................................................. 4-1

4.2 MTP II System Architecture Example................................................................................................ 4-1

4.3 Site Survey.......................................................................................................................................... 4-5

5. System Design............................................................................................................................................ 5-1

5.1 Burial Medium .................................................................................................................................... 5-1

5.2 Site Environment and Occurrence of Frost ......................................................................................... 5-1

5.3 Animals and the Detection Field......................................................................................................... 5-2

5.4 Accomodating Grass, Trees and Shrubs ............................................................................................. 5-2

5.5 Uneven Terrain ................................................................................................................................... 5-3

5.6 Rain, Standing Water and Run-off...................................................................................................... 5-4

5.7 Positioning MicroTrack II Components on the Perimeter .................................................................. 5-5

5.8 Selecting the Optimum Sensor Cable Spacing.................................................................................... 5-7

5.9 Promimity to Fences ........................................................................................................................... 5-9

5.10 Double Fences, Concertina and Razor Tape ....................................................................................... 5-9

5.11 Cable Spacing Near Buildings .......................................................................................................... 5-10

INTREPID MicroTrack II Manual

Version 0

ii

6. Installation of the Sensor Cable............................................................................................................... 6-1

6.1 Burying Sensor Cables in Soil ............................................................................................................ 6-1

6.2 Burying Sensor Cables in Concrete/Asphalt, Thickness of 4 in. (10cm) or more............................... 6-3

6.3 Burying Sensor Cables in Concrete/Asphalt, Thickness of 4 in. (10cm) or less …............................ 6-3

6.4 Burying Sensor Cables in Different Mediums .................................................................................... 6-4

6.5 Bypassing Large Non-metallic Pipes and Culverts............................................................................. 6-5

6.6 Buried Electrical Cable, Conduits and Wires...................................................................................... 6-6

6.7 Overhead Electrical Cable and Conduits ............................................................................................ 6-6

6.8 Arranging Lead-in and Sensor Cables for Detection Field Startup..................................................... 6-6

6.9 Locating an MTP Near a Fence Corner .............................................................................................. 6-8

6.10 Making Turns with Sensor Cable........................................................................................................ 6-9

6.11 Terminating the Sensor Cable Near Buildings.................................................................................. 6-10

6.12 Terminating the Sensor Cable........................................................................................................... 6-11

6.13 Splicing the Sensor Cable ................................................................................................................. 6-16

7. Installing the MicroTrack™ Processor (MTP) ...................................................................................... 7-1

7.1 Positioning the MTP II........................................................................................................................ 7-1

7.2 Installing the MicroTrack II Enclosure (MTE) ................................................................................... 7-1

7.3 Grounding the MTP II......................................................................................................................... 7-2

7.4 Power and Data Connections ............................................................................................................. 7-2

7.5 Connecting the PC using RS232 ......................................................................................................... 7-3

7.6 Connecting the Controller using RS422.............................................................................................. 7-3

7.7 Connecting the Power Supply to the MTP II ...................................................................................... 7-3

7.8 Connecting Sensor Cables to the MTP II............................................................................................ 7-5

8. Alarm Reporting ....................................................................................................................................... 8-1

8.1 Relay Outputs...................................................................................................................................... 8-1

8.2 Graphic Map and Relays..................................................................................................................... 8-1

8.3 Serial Communications - Polling Protocol II ...................................................................................... 8-1

9. Maintenance ............................................................................................................................................... 9-1

INTREPID MicroTrack II Manual

Version 0

1-1

1. Introduction

Welcome to Southwest Microwave Inc.’s new buried cable outdoor perimeter intrusion detection system

– MicroTrack™ II – the most advanced buried cable sensor system available. MicroTrack II is the first

buried cable sensor that is truly site-adaptive and can both detect and locate intruders. It is patented and it

is the first outdoor intrusion detection sensor to use ultra wide band FS/PCM (frequency stepped, phase

code modulated) technology.

MicroTrack II communicates with all INTREPID™ Series II devices using the INTREPID Polling

Protocol II (IPP II). It also incorporates Sensitivity Leveling™, Free Format Zoning and security level

settings. MicroTrack II is terrain following with the ability to go up and down hills and around corners. It

provides a large invisible volumetric detection field as shown in Figure 1.1, and operates in difficult

environmental conditions with a very high probability of detection and low false and nuisance alarm rate.

MicroTrack II uses Multi-Segment Target Analysis (MSTA) – a new concept in sensor design enabling

each sensor cable to be divided into small cells, each 6.6 feet (2.0 meters) in length, to be independently

adapted to site conditions and analyzed. These new concepts allow MicroTrack II to overcome numerous

limitations of past generation buried cable sensors.

The system utilizes Microsoft Window XP (.net framework required), Vista or Windows 7™ based

software called Universal Installation Service Tool II (UIST II) for installation setup and service.

Figure 1.1 - MicroTrack II Terrain Following Detection Field

1.1 Theory of Operation

The MicroTrack II processor uses a technique known as FMCW (Frequency Modulated Continuous

Wave) to determine the location of an intruder along each pair of 200-meter sensor cables. The RF

transmission consists of a stepped frequency sweep. The receiver uses a combination of analog and digital

processing to determine alarms and alarm location. A system overview block diagram, Figure 1.2 is

provided to illustrate the detection process. The MicroTrack II processor supports two cable pairs; the

processing is the same for both cable sets.

INTREPID MicroTrack II Manual

Version 0

1-2

Remove

Clutter

Alarm

Processing

Process

Clutter

Location

Process

Target

Location

Target

Filters

Stored

Calib.

Target

Location

Display

A/D

Convert

Analog

Receiver

Clutter

Location

Display

Alarm

Display

Thresh.

Control

Cable

Fault

Detection

Clutter

Input

Display

Calib.

Display

Transmiter

Target

Input

Display

Subcell AttenuationTarget Gain

Cable Fault

Alarm

Sensor

Alarm

I

Q

Clutter + Target

Target

System Gain Set

0-255

Termination

200m Max.

System

Tamper

Figure 1.2 - MicroTrack II Block Diagram

A volumetric detection field is developed between cables as the processor transmits the RF sweep as

shown in Figure 1.3.

Figure 1.3 - Static Coupling between Transmit and Receive Cables

Transmit Receive

INTREPID MicroTrack II Manual

Version 0

1-3

The volumetric detection field is comprised of two components, defined here as clutter and target. Clutter

is the static field that is developed between the cables without a target present as shown in Figure 1.4. The

target component is the change in the static clutter as an intruder enters the volumetric field. The target

component is extremely small compared to the size of the clutter. The clutter is the coupling along the

entire length of the cable pair whereas an intruder tends to change the coupling about a single point.

Figure 1.4 - Static Coupling along the Cable Pair

There are two waveforms on the Clutter Input screen of the UIST II representing the quadrature signals I

& Q. The two waveforms are used so that magnitude and phase of the received signal may be processed

in the detection algorithm. The sole purpose of this screen is to ensure that the system gain (see block

diagram) of the processor is adjusted properly for the site. Since each site has individual characteristics,

the MicroTrack™ II system, upon start up, adjusts the gain of the system to optimum for the receive

signal level. The system gain set value may be observed on the Quadrature Clutter screen in the upper

right hand corner. The system gain level range is 0-255. A typical gain level would be between 30 and

200. The waveforms represent the clutter returned from all locations along the cable for each frequency.

The next process is to determine the locations where the clutter originates.

Once the Clutter Input levels have been properly adjusted the system then processes the input signal into

range data. This is accomplished using a mathematical process known as the Fast Fourier Transform

(FFT). The Clutter Location screen displays the coupling between the cables as a function of distance.

The blue trace represents the actual clutter values while the red lines represent the cable fault thresholds.

The Clutter levels for sites will vary and are determined based on the soil type, burial depth of the cables

and mean distance between cables, as well as other factors.

1.2 Target Processing

The predominant coupling term is the static clutter. Through the use of digital signal processing, the

clutter term is calculated and removed thus leaving only the target to be processed. The Quadrature Target

displays the result of this process which is the noise of the system. The peak-to-peak level of the system

noise should be adjusted to between +/- 256 and +/- 1024 counts (target range of +/- 512 counts) for

optimum performance.

An intruder entering the volumetric field, as shown in Figure 1.5, will change the coupling at a single

point producing a sine wave on the Target Input Display. The number of cycles that are produced on the

Quadrature Target Display is a function of the distance from the processor to the disturbance. The closer

the disturbance is to the processor, the fewer number of cycles are produced. Thus if a target was close to

the termination as many as 17 cycles would be produced compared to a close in target that may only

produce 2 cycles.

INTREPID MicroTrack II Manual

Version 0

1-4

Figure 1.5 - Intruder Entering the Volumetric Detection Field

The next step is to process the Target Input values into location data. Again the Fast Fourier Transform is

employed to perform this function. With no target present the resulting output is the noise level of the

system as a function of range.

As the target enters the detection field the system responds by increasing the magnitude of the signal at

the location of the disturbance. After further processing, the target is located to a single cell.

Calibration of the system begins with the user performing a calibration walk along the length of the cable

as shown in Figure 1.6.

Figure 1.6 - Calibrating the System

INTREPID MicroTrack II Manual

Version 0

1-5

With the system in Calibrate mode, the signal level is recorded for each position along the cable.

The calibration is saved in the processor and the threshold defined. The user has the ability to adjust the

threshold either globally or incrementally. Additionally sections of the cable may be completely disabled.

Figure 1.7 is an example of an intruder entering the detection field.

Figure 1.7 - Intruder entering the Detection Field

The alarm information is available by polling the MicroTrack™ II sensor. The Southwest Microwave

MicroTrack II SDK -Polling Protocol Specification allows alarm, fault & tamper status to be easily

accessed over RS422 data lines or direct connection by RS232 to the processor.

Additional features include the internal logging of alarms, providing magnitude & location of the alarm as

well as a time/date stamp.

1.3 Features and Benefits

MicroTrack II provides a combination of features and performance benefits unequalled in other outdoor

sensors. These include:

•Invisible Detection Field – unobtrusive and covert

•Wide Detection Field Pattern – volumetric high-security detection

•Terrain Following – follows ground contours and goes around corners

•Target Location – the ability to locate intruders anywhere along the cable

•Sensitivity Leveling™ – the sensor adapts precisely to its installed environment so detection

sensitivity is uniform along the entire length of sensor cable

•Free Format Zoning – each sensor cable set will have the capability of 100 zones per 210 meters

of sensor cable, or approximately 200 zones per processor

•Remote Diagnostics via Networks – for quick problem resolution and lower support costs

•Uniform Sensor Cable – the sensor cable is identical from one end to the other for easy repair

•Factory-Made Connections – for high reliability. Eliminates the need to install cable connectors

in the field

•Sensor Cable Configuration – fewer components make it easier to configure and install

INTREPID MicroTrack II Manual

Version 0

2-1

2. MicroTrack™ II - Detection Characteristics

The MicroTrack II Sensor consists of the MicroTrack Processor II (MTP II) and either one or two sets of

buried sensor cables (MTC400) with MicroTrack End of Line Termination (MTT) units or MicroTrack In

Line Termination (MTI) units on the ends of each cable assembly.

A detection field is created around each set of sensor cables, each set having a maximum length of 200

meters (656 feet), for a total of 400 meters (1,312 feet) of coverage per MTP II. The cables are buried in

sand, soil, asphalt, concrete or other burial medium. The processor uses ultra wide band FMCW

transmission to create an invisible electromagnetic detection field around and along the sensor cables. The

MicroTrack II Processor not only detects the presence of a disturbance to this field, but actually locates

the target, allowing for such features as Sensitivity Leveling™ and Free Format Zoning. This approach

provides a far superior probability of detection (Pd) and a lower false and nuisance alarm rate

(FAR/NAR) compared to other sensors.

MicroTrack II is designed to detect walking, running, crawling, jumping, and rolling intruders.

MicroTrack II will locate intruders to within approximately 10 feet (3.0 meters) along the length of the

sensor cable set(s). It will also operate in unfavorable and changing environmental conditions including

rain, wind, and fog, blowing sand, seismic effects, snow and hail. The processor unit transmits radio

frequencies between 19 and 25 MHz through one of the sensor cables which acts as a transmit antenna,

releasing energy along its entire length. The second sensor cable acts as a receive antenna and provides

information about the transmit signal back to the processor. This process creates an electromagnetic

surface wave moving above the ground surface and along the cables. An intruder crossing the cables

changes the surface wave, thus altering the return signal on the receive cable. The processor unit

compares the transmitted and received signals in terms of phase and amplitude and declares an alarm

when changes occur which match a human intruder.

The shape of the detection field of the MicroTrack II sensor is determined by several factors, which

includes the cable spacing, burial depth, burial mediums conductivity, and the sensitivity setting desired

on the MTP II. These four items, when combined, will determine the maximum cable length

recommended. Note that on high-security sites, the typical maximum zone lengths are 100 meters (328

feet).

2.1 Detection Requirements and Expectations

It is very important to begin the system design process by fully understanding the customer’s security

requirements. Make sure that this is the right product to meet their requirements and insure that the

customer has the correct expectations. MicroTrack II is designed as a ground crossing sensor that will

detect an unaided person attempting to walk, run, jump, crawl, or roll across the detection field. This

product is not designed to detect bridging attempts that are above the detection field. For that, you would

add microwave or IR sensors above the MicroTrack II detection field to obtain the desired detection

height, while using the MicroTrack II Sensor to detect all low-level crossing attempts.

2.2 MicroTrack II Typical Detection Pattern

2.2.1 Detection Field

It is important to identify a characteristic of all volumetric detection sensors, which includes MicroTrack

II. MicroTrack II is designed to detect human intruders crossing its primary detection field, as shown in

Figure 2.1. It can also detect larger objects, such as moving vehicles, with its secondary detection field.

INTREPID MicroTrack II Manual

Version 0

2-2

This is because a small target close to the cables will appear to be the same “size” as a larger target

further away from the cables.

Figure 2.1 - MicroTrack can Detect Large Targets in Secondary Field

It is important to recognize the existence of this secondary field because it governs the safe distance from

which MicroTrack™ II can be positioned from fences, buildings and roads without interference and

potential nuisance alarms. For the remainder of this manual, the “primary detection field” will simply be

referred to as the “Detection Field”, which is the area in which a human intruder will be detected.

It is also important to understand the RF fields’ characteristics as it travels along the cable set. The RF

field begins to form where the lead-in cables are factory-connected to the sensor cables. The RF Field

builds to full strength in the first 16 feet (5 meters). This is known as the “Detection Field Startup” area.

The RF Field will follow the sensor cables around corners and over uneven terrain until it reaches the

MicroTrack Termination. This is known as the “Detection Field”. When the RF Field reaches the

MicroTrack Termination, the RF Field begins to diminish. This is known as the “Detection Field

Shutdown” area. The MTT shutdown is also 16 feet (5 meters) long (does not apply to MTI). The

detection field startup and shutdown is shown in Figure 2.2

MTP

Sensor Cables

Lead in Cable

Detection Field

Detection

Field Startup

Detection Field

Shutdown

Figure 2.2 – Detection Field Startup and Shutdown (with MTT)

INTREPID MicroTrack II Manual

Version 0

2-3

When two cable sets from the same MTP II or adjacent MTP II’s meet at a common point, they will be

connected and terminated with two MTI In Line Termination units to allow the Detection Fields to

slightly overlap, forming a continuous detection zone.

2.2.2 Detection Patterns Width

Cable spacing is the main determining factor that controls the width of the detection pattern (wider cable

spacing = wider detection pattern). The cables should be spaced out far enough to detect a jumping

intruder, without making the pattern so wide that it detects the fence or other nuisance sources. In

protecting an open area where a jumping intruder can get a running start, you will want a wider detection

pattern, and therefore wider cable spacing. If the cables are between two fences that are close together,

then the intruder will not be able to get a running start, so the threat has changed, allowing for a narrower

detection pattern that will help to avoid nuisance sources while still maintaining the required detection

level.

The cable burial depth and the burial mediums conductivity do not have a significant affect on the

detection patterns width. These factors can be ignored when selecting the desired pattern width since the

cable spacing is the dominating factor.

It is important to note that the Detection Patterns Width is also affected by the MTP II’s Threshold

setting. A lower threshold setting (which makes it more sensitive) will increase the detection patterns

width, as well as height.

2.2.3 Detection Patterns Height

The MTP II’s Threshold Setting has the greatest effect on the detection patterns height (lower the

threshold setting to increase the detection height). The cable spacing will limit the maximum pattern

height that can be obtained (the closer the cables are, the smaller the maximum detection height).

The MTP II’s Threshold Setting will have more affect on the detection patterns height than on its width.

Figure 2.3 shows a typical example of how the detection pattern changes as the Threshold setting is

adjusted. The cables in this figure were spaced at 5 feet (1.5 meters). Using the -18dB setting in this

figure, the pattern width would be 8.2 feet (2.5 meters) and the pattern height would be approximately 3.3

feet (1.0 meter).

As a rule of thumb, with the MTP II at default settings (Threshold = -12 dB), the detection field for a

slow walking person is approximately 1/2 to 1 foot (.15 to .3 meters) beyond each cable. This means

that a cable set with 5 foot (1.5 meter) spacing will have a default detection field approximately 6 to 7

feet (1.8 to 2.1 meter) wide. The detection patterns width will increase approximately 1 foot (.3 meters)

for every 6 dB drop in the Threshold setting.

INTREPID MicroTrack II Manual

Version 0

2-4

Figure 2.3 –Typical Detection Fields Cross Sectional Shape for 5 Foot (1.5m) Spacing

The cable burial depth and the burial mediums conductivity do not have a significant affect on the

detection patterns height.

As a rule of thumb, with the MTP II at default settings (Threshold = -12 dB) and the cables spaced 5 feet

(1.5 meters) apart, the detection field for a slow walking person crossing on a wooded plank is

approximately 1.3 feet (.4 meters) high at the center. The detection patterns height will increase

approximately 1 foot (.3 meters) for every 6 dB drop in the Threshold setting.

2.2.4 Sensor Cable Maximum Length

There are several factors that all affect the maximum cable length. This includes the burial mediums

conductivity, the expected MTP II Threshold setting, the cable burial depth, detection requirements and

the cable spacing. The most important factors are the burial mediums conductivity and the threshold

setting. It is recommended that low conductivity sand be used in the cable trenches to minimize

attenuation.

Since the sensor cables are buried directly in the soil (or other burial medium); the soil becomes part of

the system. The signal that is transmitted on one cable must pass through the soil and into the air above,

then back through the soil to the receive cable. If the soil is very conductive, then it will attenuate the

signal as it passes through. This attenuation adds up along the length of the cable, resulting in a weaker

signal at the far end. If the soil is highly conductive, it is recommended that the soil in the trenches be

replaced with low conductivity sand. This would have been determined during the site survey or design

phase of the project. This will help to extend the maximum cable length for the installation. Soil samples

obtained from along the proposed path of the sensor cables should have been examined. See the

MicroTrack™ II Application Guide for testing soils.

INTREPID MicroTrack II Manual

Version 0

2-5

The next important factor is the MTP II’s Threshold setting. The default setting is –12 dB and is the

nominal setting for most applications. At this or any setting, the concern is with the difference between

the calibration profile and the noise level. When calibrating the cables, a graph will be generated that

represents a walking target at each location along the cable. This calibration line is adjusted by the

Threshold setting (-12 dB default) and becomes the Alarm Threshold. Concern must be taken with the

background noise level. If the Alarm Threshold is lowered too much, then the background noise may

generate alarms. Since the Calibration Profile will tend to drop down as the calibrator moves further down

the cable and at the same time, the noise level is flat or rising; the far end of the cable will have the

smallest Alarm Threshold to Noise margin and therefore may generate unwanted alarms towards the far

end of the cables. Highly conductive soils will cause the calibration profile to drop faster as the calibrator

moves towards the end of the cables. If the site has heavy clay soil and / or requires a more sensitive

detection pattern, then shorter cable lengths are required

Burial depth also has an affect on the maximum length, for the same attenuation reasons stated above. If

the cables will be installed below grass and there is a chance that an aerator may be used over the cables,

then the cables need to be buried deep enough that they can’t be damaged. This may be 6 to 9 inches (150

to 230 mm) or more, depending on the equipment. If installed between fences where there is no

reasonable chance of damage, then they can be buried shallower, for example, 4 inches (101mm) deep.

When the cables are buried deeper, the signals must pass through more soil, adding more attenuation.

Raising the cables from 9 inches (230mm) up to 4 inches (101mm) may increase the detection level by up

to 6 dB without increasing the noise level.

The cable spacing has only a minimal affect on the maximum cable length.

Table of contents

Popular Measuring Instrument manuals by other brands

AquaMaster Tools

AquaMaster Tools Combo meter P700 Pro 2 user manual

HP

HP 3562A Service manual

Trident

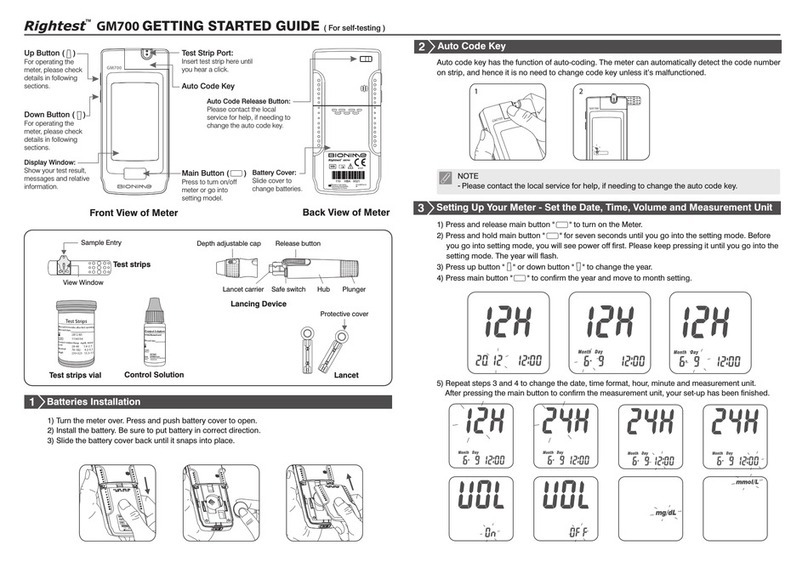

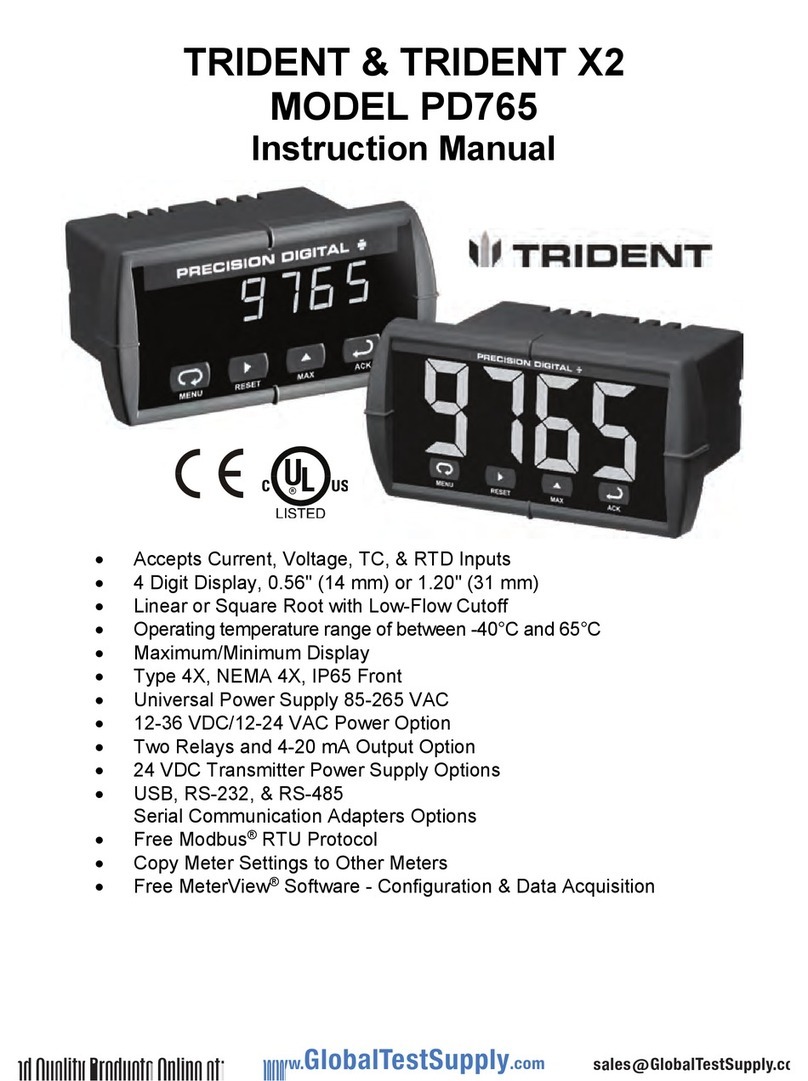

Trident PD765-6R0-00 instruction manual

Tuthill

Tuthill FILL-RITE TN700 Series Owners installation, operation, and safety manual

SUPMEA

SUPMEA SUP-1158-J user manual

montwill

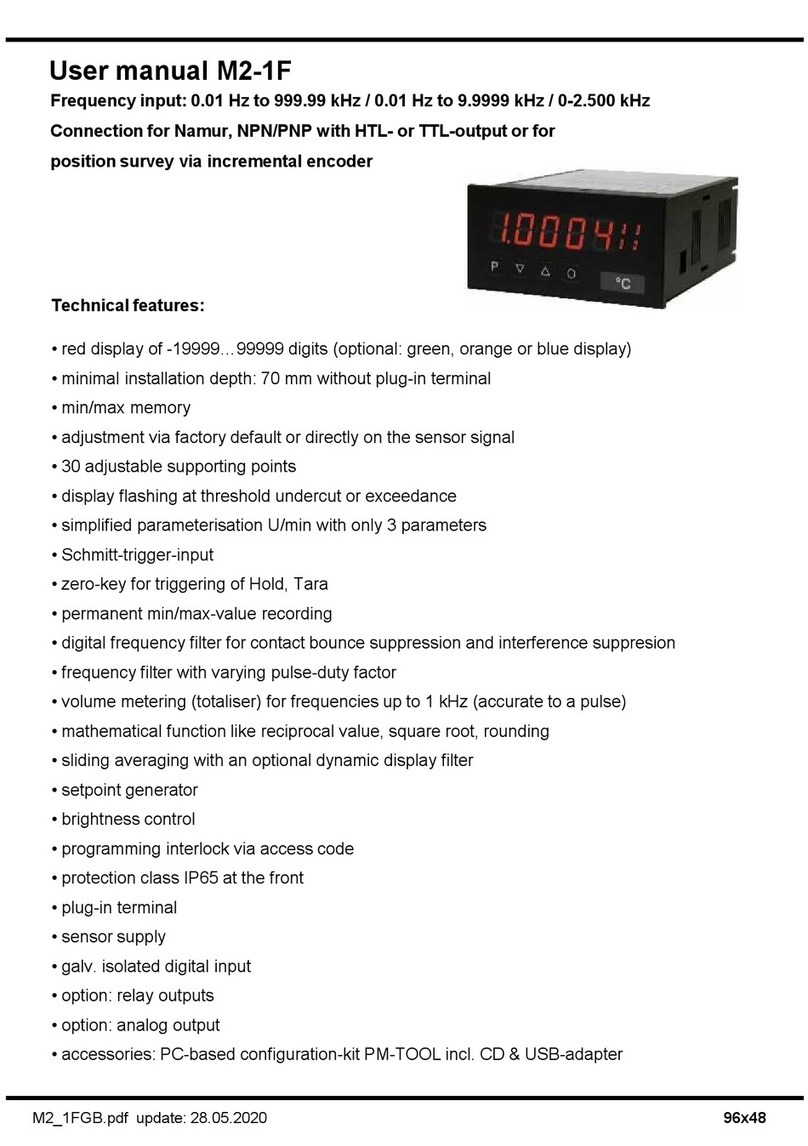

montwill M2-1F Series user manual

Worldcast Systems

Worldcast Systems audemat GOLDENEAGLE ATSC user manual

Spectro-UV

Spectro-UV Spectroline AccuMAX Series Operator's manual

ADLINK Technology

ADLINK Technology PCIe-9834P quick start guide

Kyowa Medex Co., Ltd.

Kyowa Medex Co., Ltd. HM-JACK Series Operation manual

Spectra-Physics

Spectra-Physics Pulseo user manual

RS PRO

RS PRO IPM 241 instruction manual