17 18

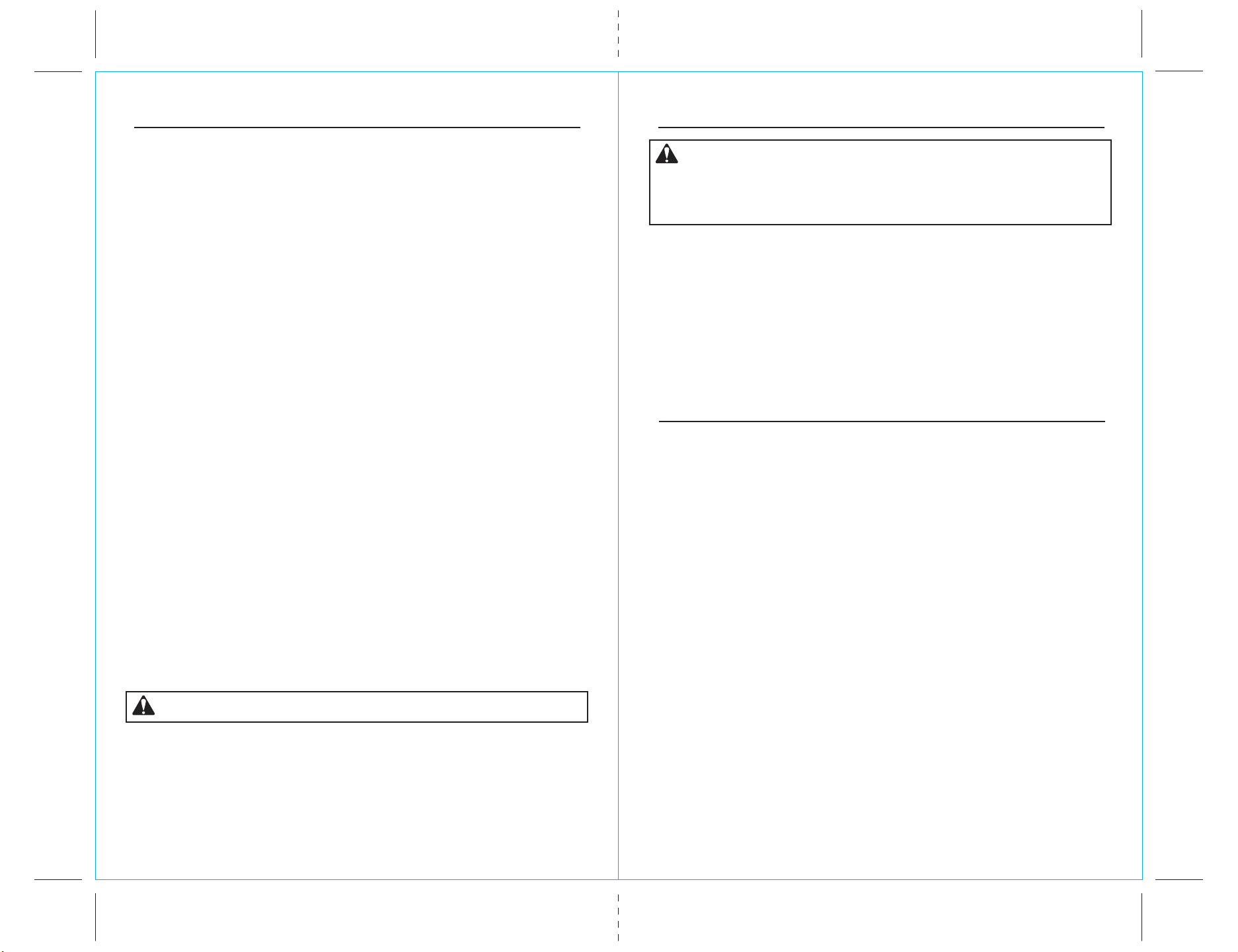

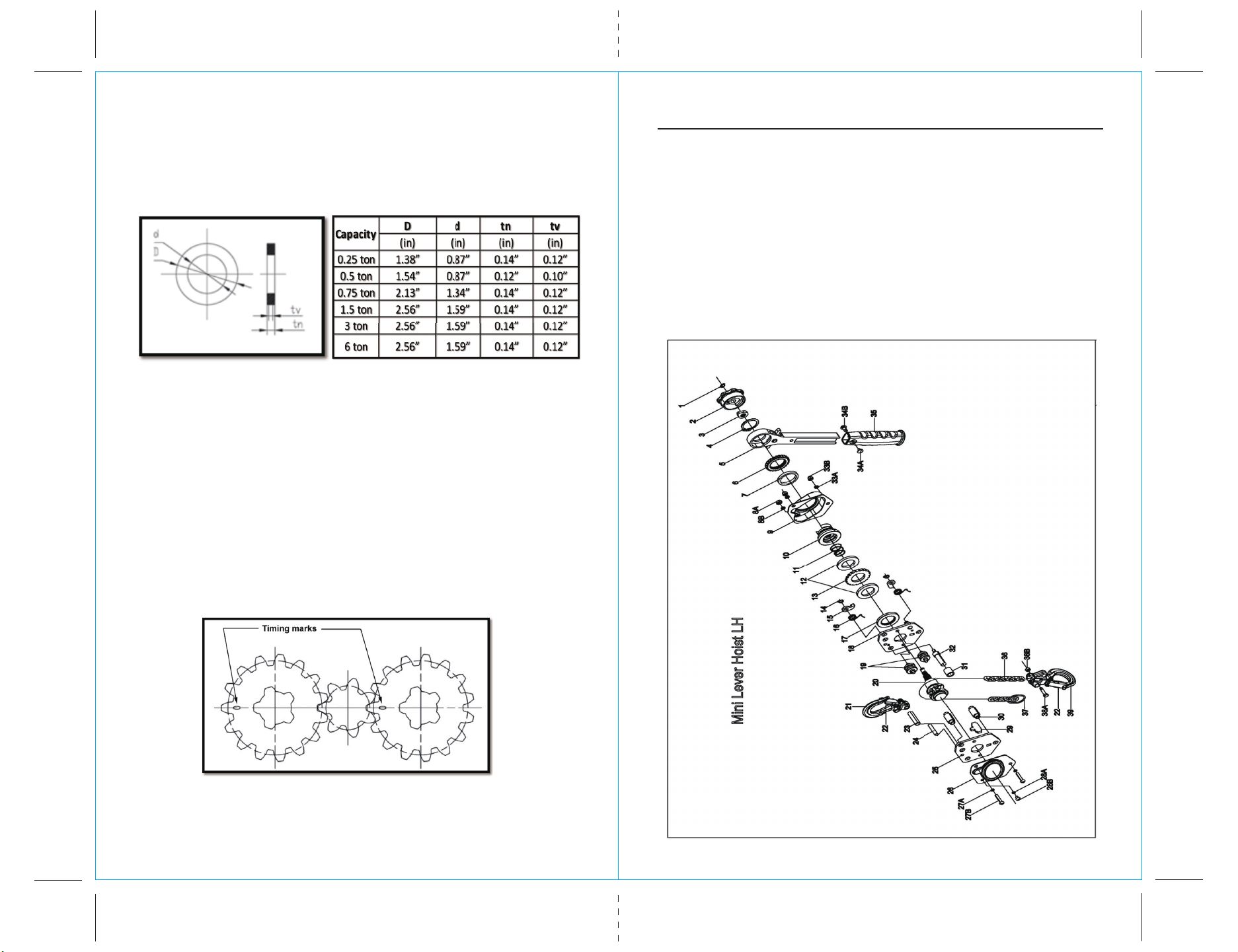

LH025 Quanty Stock # Reference MODEL DESCRIPTION UPC

1 1 788200McMaster

90967A115KX050-29 Snap Ri ng 661165882001

2 1 788201KX050-28 Hand Wheel661165882018

3 1 788202KX025-27 Stop Knob 661165882025

4 1 788203McMaster

90967A270YAL025-4 Snap Ring 661165882032

5 1 788204 YAL050-5 Lever Handle Assembly 661165882049

6 1 788205KX050-23 Change Over Gear 661165882056

7 1 788206KX050-22 Bushing 661165882063

8A 1 788207McMaster

90591A255YAL050-8A Hexagon Nut = Zinc-Plated Steel Hex Nut, Medium-

Strength, Class 8, M4 x 0.7 mm Thread 661165882070

8B 1 788208McMaster

91202A230YAL050-8B Lock Washer = Zinc-Plated Steel Split Lock Washer

for M5 Screw Size, 5.4 mm ID, 9.2 mm OD 661165882087

9 1 788209 YAL025-9 Brake Cover 661165882094

10 1 788210KX050-33 Disc Hub 661165882100

11 1 788211KX050-18 Twisng Spring 661165882117

12 2 788212 YAL025-12 Fricon Disc 661165882124

13 1 788213KX050-17 Ratchet Disc 661165882131

14 2 788214McMaster

90967A110KX050-16 Snap Ri ng 661165882148

15 2 788215KX050-15 Pawl 661165882155

16 2 788216KX050-14 Pawl Spri ng 661165882162

17 1 788217 YAL025-17 Brake Seat 661165882179

18 1 788218 YAL025-18 Lever Side Pl ate Assembly 661165882186

19 2 788219 YAL025-19 Guide Roller 661165882193

20 1 788220 YAL025-20 Load Sheave 661165882209

21 1 788221 YAL025-21 Top Hook Assembly 661165882216

22 2 788222 YAL025-22 Safety Latch Assembly 661165882223

23 1 788223KX025-3 Top Hook Sha661165882230

24 1 788224 YAL025-24 Pin 661165882247

25 1 788225 YAL025-25 Gear Si de Plate 661165882254

26 1 788226 YAL025-26 Gear Cover 661165882261

27A 2 788227McMaster

91202A230YAL025-27A Lock Washer 661165882278

27B 2 788228McMas ter

94387A341YAL025-27B Phillips Pan Head Screw = JIS Steel Pan Head

Phillips Screws, M5 x 0.8 mm Thread, 35 mm Long 661165882285

28A 1 788227McMaster

91202A230YAL025-27A Lock Washer 661165882278

28B 1 788229McMas ter

92095A210YAL025-28B

Socket Head Screw = Buon Head Hex Drive Screw,

Passivated 18-8 Stainless Steel, M5 x 0.80 mm

Thread, 12mm Long

661165882292

29 1 788230 YAL025-29 Stripper 661165882308

30 2 788231 YAL025-30 Stay Bolt 661165882315

31 1 788232 YAL025-31 Support 661165882322

32 1 788233 YAL025-32 Stay Bolt II 661165882339

33A 2 788227McMaster

91202A230YAL025-27A Lock Washer 661165882278

33B 2 788234McMas ter

91180A037YAL025-33B Acorn nut = Low-Strength Steel Cap Nut, Zinc-

Plated, M5 x 0.8 mm Thread 661165882346

34A 1 788235 KV016-27A Steel Pan Head Phillips Screw, M3.5 x 0.6 mm

Thread, 6 mm Long 661165882353

34B 1 788236KX025-30B Barrel Nut - M3 x 11.5 x 5Ф661165882360

35 1 788237KX050-31 Rubber Grip 661165882377

36 As Req'd

Per Foot 788238Φ4×12 Load Chai n 661165882384

37 1 788239 YAL050-37 End Chain Ring 661165882391

38A 1 788240 YAL025-38A Load Pin 661165882407

38B 1 788241 YAL050-38B Lock Nut 661165882414

39 1 788242 YAL025-39 Boom Hook Assembly 661165882421

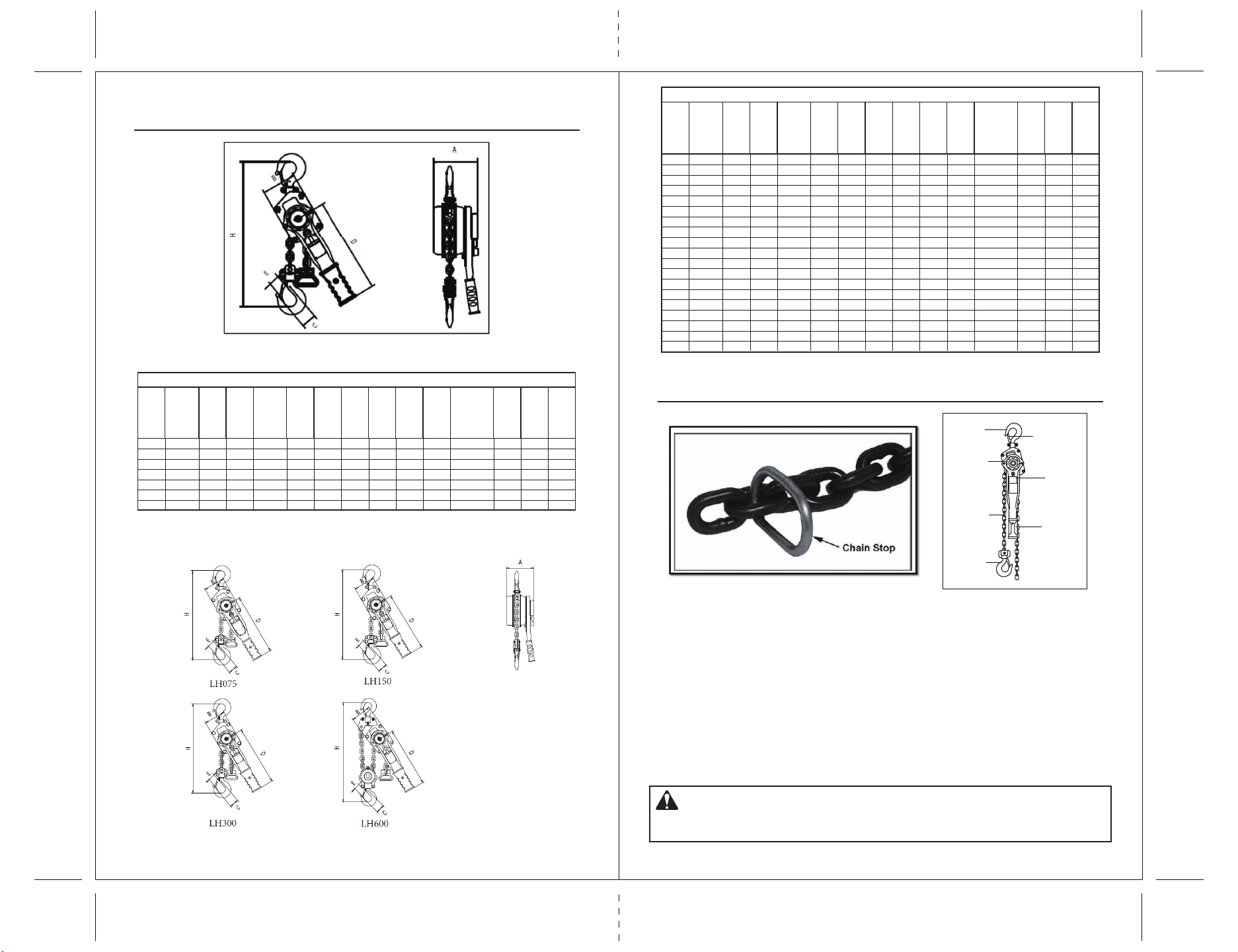

LH050 Quanty Stock # Reference MODEL DESCRIPTION UPC

1 1 788200

KX050-29 Snap Ring 661165882001

2 1 788201KX050-28 Hand Wheel661165882018

3 1 788243 YAL075-1 Stop Knob 661165882438

4 1 788244

YAL050-4 Snap Ring 661165882445

5 1 788204 YAL050-5 Lever Handle Assembly 661165882049

6 1 788245 YAL050-6 Change Over Gear 661165882452

7 1 788246 YAL050-7 Bus hing 661165882469

8A 1 788207McMaster

90591A255YAL050-8A Hexagon Nut = Zinc-Plated Steel Hex Nut,

Medium-Strength, Cl ass 8, M4 x 0.7 mm Thread 661165882070

8B 1 788208McMaster

91202A230YAL050-8B

Lock Washer = Zinc-Plated Steel Split Lock

Washer for M5 Screw Size, 5.4 mm ID, 9.2 mm

661165882087

9 1 788247 YAL050-9 Brake Cover 661165882476

10 1 788248 YAL050-10 Disc Hub 661165882483

11 1 788249 YAL050-11 Twisng Spring 661165882490

12 2 788250 YAL050-12 Fricon Di sc 661165882506

13 1 788251 YAL050-13 Ratchet Disc 661165882513

14 2 788214

KX050-16 Snap Ring 661165882148

15 2 788215KX050-15 Pawl 661165882155

16 2 788216KX050-14 Pawl Spring 661165882162

17 1 788252 YAL050-17 Brake Seat 661165882520

18 1 788253 YAL050-18 Lever Si de Plate Assembly 661165882537

19 2 788254 YAL050-19 Guide Roller 661165882544

20 1 788255 YAL050-20 Load Sheave 661165882551

21 1 788256 YAL050-21 Top Hook Assembly 661165882568

22 2 788257 YAL050-22 Safety Latch Assembly 661165882575

23 1 788258KX050-3 Top Hook Sha661165882582

24 1 788259 YAL050-24 Pin 661165882599

25 1 788260 YAL050-25 Gear Side Plate 661165882605

26 1 788261 YAL050-26 Gear Cover 661165882612

27A 2 788262

YAL050-27A Lock Was her 661165882629

27B 2 788263McMaster

92095A248YAL050-27B

Socket Head Screw = Buon Head Hex Drive

Screw, Passi vated 18-8 Stainless Steel, M6 x 1

661165882636

28A 1 788262

YAL050-27A Lock Was her 661165882629

28B 1 788264McMaster

92095A224YAL050-28B

Socket Head Screw = Buon Head Hex Drive

Screw, Passi vated 18-8 Stainless Steel, M6 x 1

661165882643

29 1 788265 YAL050-29 Stripper 661165882650

30 2 788266 YAL050-30 Stay Bol t 661165882667

31 1 788267 YAL050-31 Support 661165882674

32 1 788268 YAL050-32 Stay Bol t II 661165882681

33A 1 788262

YAL050-27A Lock Was her 661165882629

33B 1 788269

YAL050-33B

Acorn nut = High-Strength SteelCap Nut, Class

10, Zinc-Plated, M6 x 1 mm Thread

661165882698

34A 1 788235 KV016-27A

Steel Pan Head Phillips Screw, M3.5 x 0.6 mm

Thread, 6 mm Long

661165882353

34B 1 788236KX025-30B Barrel Nut - M3 x 11.5 x 5Ф661165882360

35 1 788270 YAL050-35 Rubber Grip 661165882704

36

788271Φ4.3×12 Load Chain 661165882711

37 1 788239 YAL050-37 End Chai n Ring 661165882391

38A 1 788272KX050-39A Load Pi n 661165882728

38B 1 788241 YAL050-38B Lock Nut 661165882414

39 1 788273KX050-40 Boom Hook Assembly 661165882735