SOVAL 811-SS-OSY1SPDT Manual

Date:Apr. 7th, 2021

Rev. A

OPERATION&MAINTENANCEINSTRUCTION MANUAL

SUPERVISORYSWITCH FOROS&YGATE VALVE

1

GeneralDescription

ThisSupervisorySwitchisusedtomonitortheopenpositionofanOS&Y (outsidescrew and yoke)typegate

valve.Theseswitchesmount convenientlytomostOS&Y valvesranginginsizefrom2 to24 (50mm to

600mm).Thecoverisheldinplacebytwotamperresistant screwsthat requireaspecialtooltoremove.The

toolisfurnishedwitheachdevice.

Features

•All partshavecorrosionresistant finishes

•TwoConduitEntrances

•AdjustableLengthTripRod

•Three PositionSwitchDetectsTamperingand ValveClosure

•Fineadjustment featureforfast,easyinstallation

•OneortwoSPDT contact models(-1,-2,-3)

•UL Listedand FM Approved

TechnicalSpecifications

Testing

TheoperationoftheSupervisorySwitchand itsassociatedprotectivemonitoringsystemshallbeinspected,

tested,andmaintainedinaccordancewithall applicablelocaland nationalcodesand standardsand/orthe

AuthorityHavingJurisdiction(manufacturerrecommendsquarterlyormorefrequently).Aminimumtest

Model 811-SS-OSY1SPDT,811-SS-OSY2SPDT,811-SS-OSY3SPDT

Enclosure Cover: DieCast Finish: RedPowderCoat

Base: DieCast

All partshavecorrosionresistant finishes

CoverTamper

TamperResistant Screws

OptionalCoverTamperSwitchAvailable

3Amps/5 Ampsat 125/250VAC

Covertamperswitchwithtwoleadsand InsulatingPlate5KV

Contact

Ratings

811-SS-OSY1SPDT: OneSet ofSPDT

811-SS-OSY2SPDT: TwoSetsofSPDT

811-SS-OSY3SPDT: TwoSetsofSPDT andCoverTamperSwitch

10 Ampsat 125/250 VAC

2.5 Ampsat 30VDCResistive

Environmental

Limitations

-40°Cto60°COperatingTemperatureRange

IndoororOutdoorUse

IP67

Conduit EntrancesOneKnockoutsand oneholefor1/2 conduitprovided

ServiceUse NFPA13,13D,13R,72

Date:Apr. 7th, 2021

Rev. A

OPERATION&MAINTENANCEINSTRUCTION MANUAL

SUPERVISORYSWITCH FOROS&YGATE VALVE

2

shall consist ofturningthevalvewheeltowardstheclosedposition.TheSupervisorySwitchshall operate

withinthefirst tworevolutionsofthewheel. Fullyclosethevalveand ensurethattheSupervisorySwitch

doesnot restore.Fullyopenthevalveand ensurethattheSupervisorySwitchrestorestonormalonlywhen

thevalveisfullyopened.

Theory ofOperation

TheSupervisorySwitchisa3 positionswitch.Thecenterpositionisthenormalinstallationposition.Normal

iswhentheswitchisinstalledontheOS&Y valve,thevalveisfullyopenand thetriprodoftheSupervisory

Switchisinthegrooveofthevalvestem.Closingthevalvecausesthetriprodtorideup out ofthegroove

and activatestheswitches.RemovingtheSupervisorySwitchfromthevalvecausesthespringtopull thetrip

rodintheotherdirectionandactivatestheswitches.

Installation

No.1

a.WiththevalveintheFULL OPENposition,locatetheSupervisorySwitchacross thevalveyokeas far as

possiblefromthevalvegland sothatthespringloadedtriprodofit ispulledagainst thenon-threaded

portionofthevalvestem.PositiontheSupervisorySwitchwiththebracketnear thehandwheelas shownin

Fig. 6 ifpossibletoavoidcreatingapinchpoint betweenthewheeland theSupervisorySwitch.

b.Loosenthelockingscrew thatholdsthetriprodinplaceand adjusttherodlength.Whenadjusted

properly,therodshouldextend pastthevalvescrew,but notsofarthatit contactstheclampbar.Tighten

thelockingscrew to5in-lbsminimumtoholdthetriprodinplaceand properlysealtheenclosure.

NOTE: Iftriprodlengthisexcessive,loosenthelockingscrew and removethetriprodfromthetriplever.

Usingpliers,break off theone(1)inchlongnotchedsection.

Reinstall triprodand repeat Step3procedure.

c.MounttheSupervisorySwitchlooselywiththecarriagebolts

and clampbar supplied.Onvalveswithlimitedclearanceuse

J-hooks suppliedinsteadofthecarriageboltsand clampbar to

mount theSupervisorySwitch.

Date:Apr. 7th, 2021

Rev. A

OPERATION&MAINTENANCEINSTRUCTION MANUAL

SUPERVISORYSWITCH FOROS&YGATE VALVE

3

d.Deburr and smooththeedgesofthegroovetoprevent damagetothevalvepackingand toallowthetrip

rodtomoveeasilyinand out ofthegrooveas thevalveisoperated.

e.Finaladjustment canbemadebyslightlylooseningthetwoscrewsonthebracket and usingthefine

adjustment feature(see Fig. 5).Theadjustment iscorrect whentheplungers ontheswitchesaredepressed

bytheactuatorandthereisnocontinuitybetweentheCOM and NOterminalsontheswitches.

f.Tightentheadjustment screwsand all mountinghardwaresecurely(20 in-lbsminimum).Checktoinsure

that therodmovesoutofthegrooveeasilyand that theswitchesactivatewithintwoturnswhenthevalveis

operatedfromtheFULLOPENtowardstheCLOSEDposition.

g.Reinstallthecoverand tightenthecoverscrewsto15 in-lbsminimumtoproperlysealtheenclosure.

No.2

a.WiththevalveintheFULL OPENposition,locatetheSupervisorySwitchacross thevalveyokeas far from

thevalvegland as possiblesothatthespringloadedtriprodofit ispulledagainst thenon-threadedportion

ofthevalvestem.PositiontheSupervisorySwitchwiththebracketnear thehandwheel. Ifpossibletoavoid

creatingapinchpoint betweenthewheeland theSupervisorySwitch.

b.Mount theSupervisorySwitchlooselywiththecarriageboltsand clampbar supplied.

c. Loosenthelockingscrew thatholdsthetriprodinplaceand adjusttherodlength.Whenadjusted

properly,therodSupervisorySwitchshouldextend past thevalvescrew,butnotsofar thatit contactsthe

clampbar.Tightenthelockingscrew to5in-lbsminimumtoholdthetriprodinplaceand properlysealthe

enclosure.

d.Theremainingstepssuchas No.1.

No.3

Ifinstalledin14" andabove,Pleaseindicatespecialwhenbuy,we cancustomizeaccordingtotheactualsize

intheattachment.

Date:Apr. 7th, 2021

Rev. A

OPERATION&MAINTENANCEINSTRUCTION MANUAL

SUPERVISORYSWITCH FOROS&YGATE VALVE

4

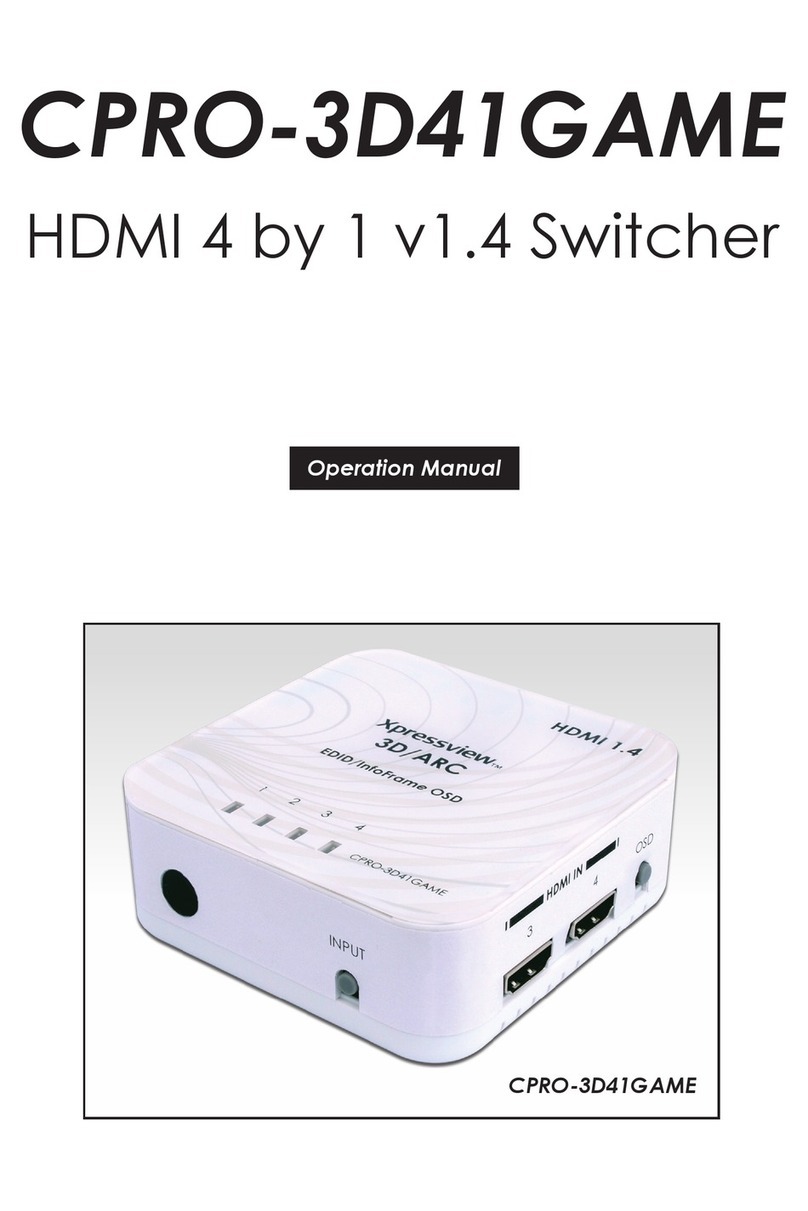

StructuralDrawing

TypicalElectricalConnections(See Fig1)

Fig2

Fig1

Fig3

•WHENOS&YGATEVALVENORMALLYOPEN (See Fig2)When the

•WHENOS&YGATEVALVECLOSEORREMOVETHE

SUPERVISORYSWITCH(See Fig3)

COVERTAMPERSWITCHFig4

WHENREMOVETHECOVERCOMTO NC(See Fig4)

Covertamperswitch withthree leads.

This manual suits for next models

2

Table of contents