Sovereign YT9757 User manual

2

CONTENTS

CONTENTS 2

GENERAL SAFETY WARNINGS 3

WARNING SYMBOLS 9

IN THE BOX 10

OPERATION 11

MAINTENANCE AND STORAGE 19

TECHNICAL DATA 20

RECYCLING AND DISPOSAL 22

UK PLUG 22

GETTING HELP 23

WARRANTY 24

3

GENERAL SAFETY WARNINGS

WARNING! Read all safety warnings,

instructions, illustrations and specifications

provided with this power tool. Failure to

follow all instructions listed below may result

in electric shock, fire and/or serious injury.

Save all warnings and instructions for

future reference. The term "power tool" in

the warnings refers to your mains-operated

(corded) power tool or battery-operated

(cordless) power tool.

1) Work area safety

a) Keep work area clean and well lit. Cluttered or

dark areas invite accidents.

b) Do not operate power tools in explosive

atmospheres, such as in the presence of

flammable liquids, gases or dust. Power tools

create sparks which may ignite the dust or fumes.

c) Keep children and bystanders away while

operating a power tool. Distractions can cause

you to lose control.

2) Electrical safety

a) Power tool plugs must match the outlet. Never

modify the plug in any way. Do not use any

adaptor plugs with earthed (grounded) power

tools. Unmodified plugs and matching outlets will

reduce risk of electric shock.

b) Avoid body contact with earthed or grounded

4

surfaces, such as pipes, radiators, ranges and

refrigerators. There is an increased risk of electric

shock if your body is earthed or grounded.

c) Do not expose power tools to rain or wet

conditions. Water entering a power tool will

increase the risk of electric shock.

d) Do not abuse the cord. Never use the cord

for carrying, pulling or unplugging the power

tool. Keep cord away from heat, oil, sharp edges

or moving parts. Damaged or entangled cords

increase the risk of electric shock.

e) When operating a power tool outdoors, use an

extension cord suitable for outdoor use. Use of

a cord suitable for outdoor use reduces the risk of

electric shock.

f) If operating a power tool in a damp location

is unavoidable, use a residual current device

(RCD) protected supply. Use of an RCD reduces

the risk of electric shock.

3) Personal safety

a) Stay alert, watch what you are doing and

use common sense when operating a power

tool. Do not use a power tool while you are

tired or under the influence of drugs, alcohol

or medication. A moment of inattention while

operating power tools may result in serious

personal injury.

b) Use personal protective equipment. Always

wear eye protection. Protective equipment such

5

as a dust mask, non-skid safety shoes, hard hat, or

hearing protection used for appropriate conditions

will reduce personal injuries.

c) Prevent unintentional starting. Ensure the

switch is in the off-position before connecting

to power source and/or battery pack, picking

up or carrying the tool. Carrying power tools

with your finger on the switch or energising power

tools that have the switch on invites accidents.

d) Remove any adjusting key or wrench before

turning the power tool on. A wrench or a key left

attached to a rotating part of the power tool may

result in personal injury.

e) Do not overreach. Keep proper footing and

balance at all times. This enables better control

of the power tool in unexpected situations.

f) Dress properly. Do not wear loose clothing or

jewellery. Keep your hair, clothing and gloves

away from moving parts. Loose clothes, jewellery

or long hair can be caught in moving parts.

g) If devices are provided for the connection of

dust extraction and collection facilities, ensure

these are connected and properly used. Use of

these devices can reduce dust-related hazards.

h) Do not let familiarity gained from frequent use

of tools allow you to become complacent and

ignore tool safety principles. A careless action

can cause severe injury within a fraction of a

second.

6

4) Power tool use and care

a) Do not force the power tool. Use the correct

power tool for your application. The correct

power tool will do the job better and safer at the

rate for which it was designed.

b) Do not use the power tool if the switch does

not turn it on and off. Any power tool that cannot

be controlled with the switch is dangerous and

must be repaired.

c) Disconnect the plug from the power source

and/or the battery pack from the power tool

before making any adjustments, changing

accessories, or storing power tools. Such

preventive safety measures reduce the risk of

starting the power tool accidentally.

d) Store idle power tools out of the reach of

children and do not allow persons unfamiliar

with the power tool or these instructions

to operate the power tool. Power tools are

dangerous in the hands of untrained users.

e) Maintain power tools. Check for misalignment

or binding of moving parts, breakage of parts

and any other condition that may affect the

power tools operation. If damaged, have the

power tool repaired before use. Many accidents

are caused by poorly maintained power tools.

f) Keep cutting tools sharp and clean. Properly

maintained cutting tools with sharp cutting edges

are less likely to bind and are easier to control.

g) Use the power tool, accessories and tool bits,

7

etc., in accordance with these instructions,

taking into account the working conditions and

the work to be performed. Use of the power tool

for operations different from those intended could

result in a hazardous situation.

h) Keep handles and gripping surfaces dry, clean

and free from oil and grease. Slippery handles

and gripping surfaces do not allow for safe

handling and control of the tool in unexpected

situations.

Service

a) Have your power tool serviced by a qualified

repair person using only identical replacement

parts. This will ensure that the safety of the power

tool is maintained.

8

Planer safety warnings

1. Wait for the cutter to stop before setting

the tool down. An exposed rotating cutter may

engage the surface leading to possible loss of

control and serious injury.

2. Hold the power tool by insulated gripping

surfaces only, because the cutter may contact

its own cord. Cutting a “live” wire may make

exposed metal parts of the power tool “live” and

could give the operator an electric shock.

3. Use clamps or another practical way to

secure and support the workpiece to a stable

platform. Holding the workpiece by your hand or

against the body leaves it unstable and may lead

to loss of control.

9

WARNING SYMBOLS

Warning!

Read the instructions

Wear ear protection

Wear eye protection

Wear a dust mask

Class II tool

The product complies with the applicable

European directives, and an evaluation method

of conformity for these directives was done.

Recycle unwanted materials instead of

disposing of them as household waste. All tools,

hoses and packaging should be sorted, taken to

the local recycling centre and disposed of in an

environmentally safe way.

The product complies with the applicable UK

directives, and an evaluation method of conformity

for these directives was followed.

10

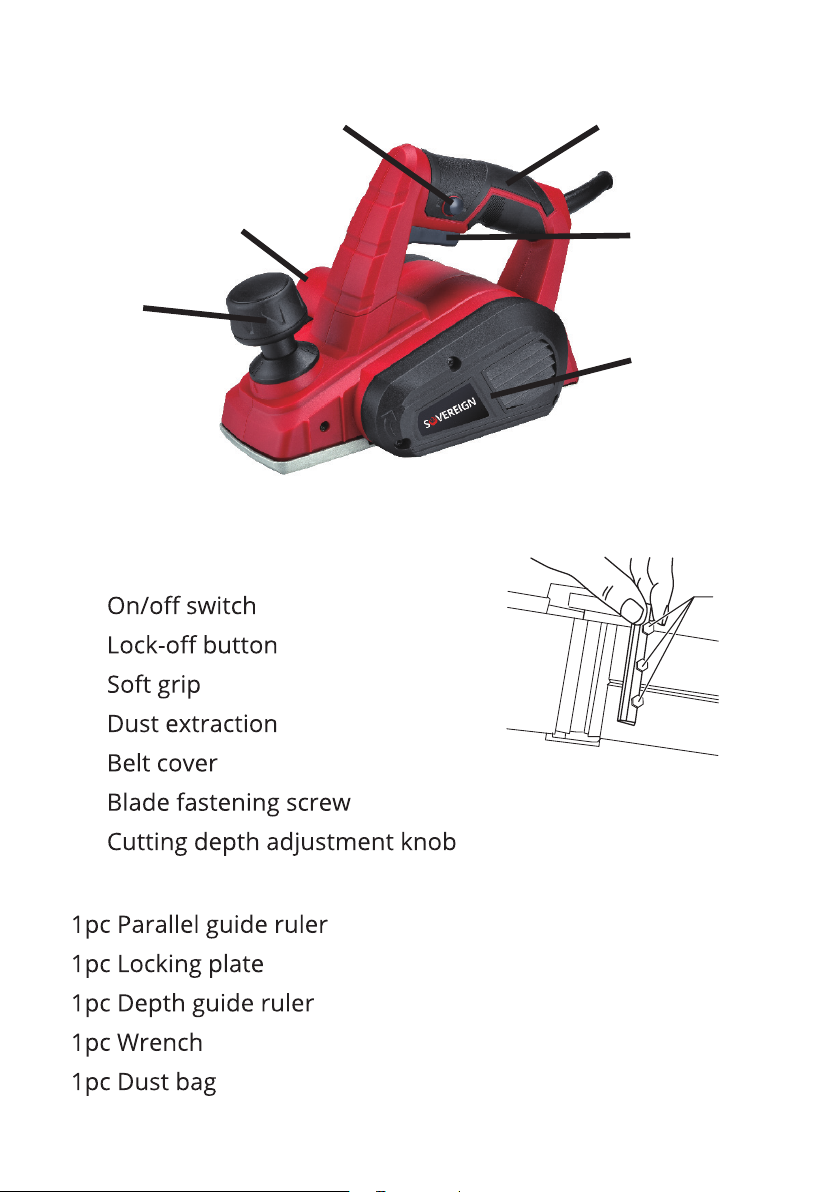

IN THE BOX

Description

1.

2.

3.

4.

5.

6.

7.

Accessories

6

7

4

23

1

5

11

OPERATION

NOTE: Before using the tool, read the instruction book

carefully.

INTENDED USE

The tool is intended for planing of firmly supported wooden

materials, such as beams and boards. It is also suitable for

bevelling edges and rebating.

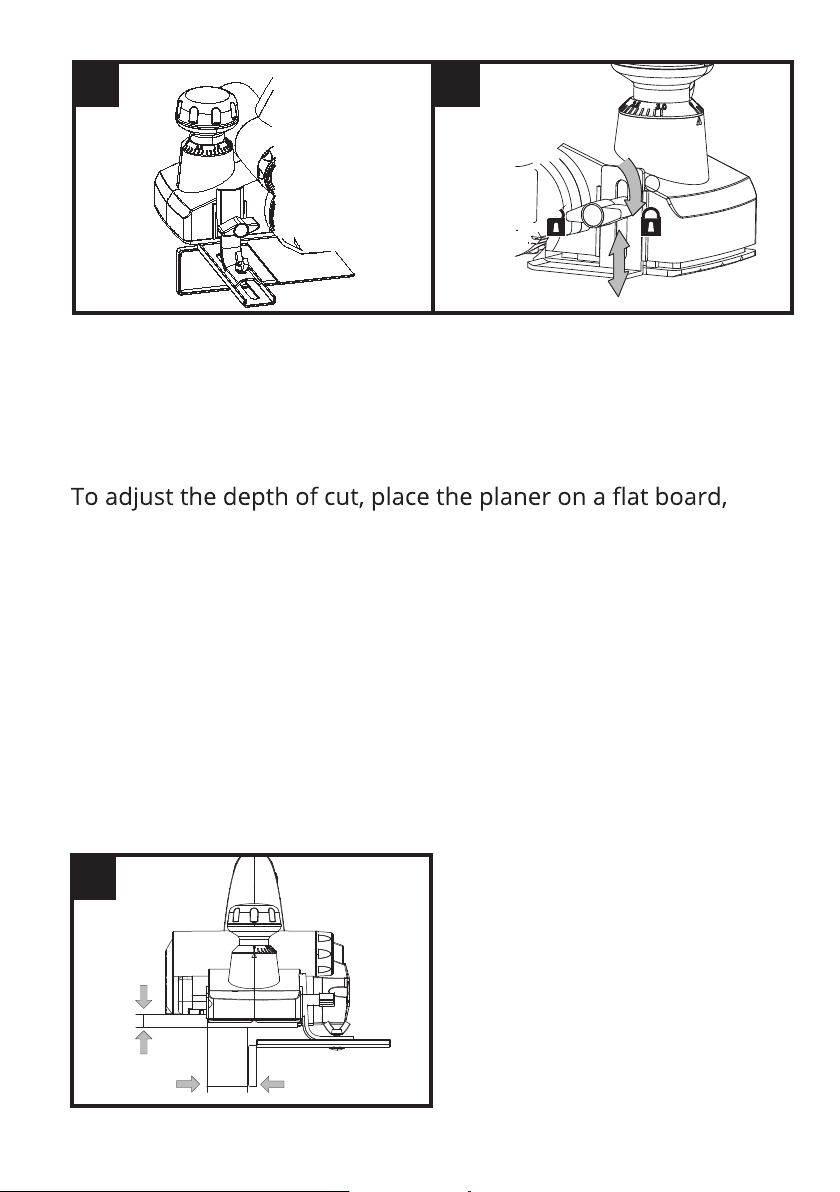

1. SAFETY ON/OFF SWITCH (SEE FIG. A)

The switch is locked off to prevent accidental starting. Depress

the lock-off button then the on/off switch and release the lock-

off button. To switch off, just release the on/off switch.

WARNING! Danger of kickback! Apply the tool to the

work piece only when switched on.

2. CUTTING DEPTH ADJUSTMENT (SEE FIG. B)

The planing depth can be adjusted from 0 to 2mm. Rotate

the cutting depth adjustment knob to set the required cutting

depth with the scale. Clockwise rotation increases the planing

depth; anticlockwise rotation reduces the planing depth.

It is recommended that test cuts be made in scrap wood after

each adjustment to make sure that the desired amount of

wood is being removed by your planer.

NOTE: To protect blades during storage, transporting, etc., set

the blade depth adjustment knob to 0.

12

3. STANDARD SURFACE PLANING (SEE FIG. C)

Set the desired cutting depth. Position the front part of the

base plate flat onto the work surface. Make sure that the

blades are not touching the workpiece. Switch the tool on

and push your planer forward and it will start cutting. Always

maintain all of the base plate flat on the work surface to

prevent the cutting blade jumping. Move the plane evenly over

the work surface.

Be careful to avoid hitting nails during operation. It could nick,

crack, or damage blades. We suggest that you always keep an

extra set of blades on hand for replacement.

AB

C

13

4. EDGE CHAMFERING (SEE FIG. D, E)

CAUTION: Always use both hands on the tool for any

operation. It assures you maintain control and avoids

the risk of serious personal injury. The workpiece must

always be properly supported and clamped so that

both hands will be free to control the planer.

Using the V-groove in the base plate, you can make a chamfer

on the workpiece edge. Guide the planer along the edge and

maintain a constant angle and force to produce a good finish.

You can control the angle of the chamfer with your hands.

Make a test chamfer on a scrap piece of wood. Maintain

downward pressure to keep your planer flat at the beginning

and the end of the work surface.

5. USING THE PARALLEL GUIDE (SEE FIG. F)

Insert the screw provided through the hole on the support of

parallel guide (7). Turn the screw into the nut on the housing.

Fix the parallel guide on the support of parallel guide with the

screw and nut. Ensure the screws are tightened securely.

NOTE: The parallel guide should be fitted on the left of

housing.

To adjust the required width of cut, loosen the nut and slide

the parallel guide to the required position. Retighten the nut

fully. Use the parallel guide while cutting. The guide should be

held firmly against the edge of the workpiece.

D

45o

E

14

6. USING THE REBATE (SEE FIG. G)

Insert the screw provided through the slot on the Rebate.Turn

the screw into the nut on the housing.

The cut depth adjustment can be set from 0 to 10mm.

then loosen the screw and slide the cut depth adjustment

guide up and down for required depth. Tighten the thumb

screw fully.

7. REBATING (SEE FIG. H)

The width of rebating cut (a) is adjustable by moving the

parallel guide. The depth of rebating cut (b) is determined by

moving the rebate, and the number of passes made along the

workpiece. Make sure that the plane is guided with a lateral

supporting pressure.

F G

H

b

a

15

8. USING THE DUST BAG

Your planer is equipped with a dust bag for collection of wood

chips in the work area. Make sure the zipper on the bag is fully

closed. To fit the dust bag, simply insert the tube end of the

bag into the dust extraction outlet.

Then switch on and start planing.

CLEANING DUST EXHAUST OUTLET & EMPTYING

THE DUST BAG

After using your planer for an extended period of time or

when planing wet greentimber, chips may build-up in the dust

exhaust outlet and require clearing. Chip build-up restricts air

flow and causes the motor to overheat. Turn off the planer

and remove the dust bag from the dust exhaust outlet. Clean

the chip and dust exhaust outlet of your planer with a small

piece of wood. Do not use your hands or fingers. Unzip the

dust bag and empty all chips from it. Ensure the collar is free

from debris.

We recommend emptying the dust bag every 3-6 minutes.

9. BLADE FITTING AND CHANGING (SEE FIG. I, J, K, L)

WARNING! Remove the power cord from the socket

before carrying out any adjustments or changing

blades. Always put on gloves when replacing blades.

NOTE: Dull and worn blades cannot be reground and must be

replaced. Always replace blades in pairs.

Using the blades spanner provided, loosen the three

installation screws approximately 1/2 rotation anticlockwise.

NOTE: Do not over-loosen the screws. If the screws are too

loose, the alignment of the new blade will not be accurate.

Before removing the old blades, take notice of the direction

of cut as well as how the tapered edge of the old blade is

oriented. The tapered edge of the new blade must be in the

same orientation as the original blade.

16

Press the safety cover down with your finger. Push the blade

out with the tip of a spanner (or a screwdriver) and then

remove.

NOTE:There is no needto remove the blade clamp, as this will

change the factory settings for cutting blade height control.

NOTE: If a blade cannot be pushed out easily after loosening

the screws, use a piece of wood to pry the blade loose from

the blade clamp, with a short sharp blow. Then push with a

screwdriver to remove the blade. If necessary, tap the piece of

wood sharply with a small hammer to break the blade loose.

Before reinserting a new or reverse blade, always clean both

the blade and the blade seat if dirty. Slide the blade into

the clamp with a spanner (or a screwdriver) in the correct

orientation.Check the blade is equal with the clamp.Retighten

the three blade screws with the spanner.

K

I J

L

17

Repeat the above procedure to change the other blade.

After the blades are replaced, check if the blades are parallel

and aligned to the rear base plate with a ruler. If not, you

can adjust the blades with the hexagonal wrench provided.

Firstly, loosen the three screws on the blade clamp. Turn the

socket head screw clockwise, the blade will be risen. Turn it

anticlockwise, the blade will be lowered down.

Finally retighten the three screws fully.

10. REPLACING A DRIVE BELT (SEE FIG. M, N)

WARNING!

1. Remove the plug from the socket before carrying out any

adjustment, servicing or maintenance.

2. The cutting blades will be turning and may cause injury.

Loosen the screws and remove the belt cover. Remove the

worn drive belt from the large pulley and the pinion and clean

them. Lace the new belt on the top of the pinion and turn it

manually, press it on the large pulley. Make sure that the drive

belt runs exactly along the length of the grooves of the pinion

and the pulley. Replace the belt cover. Install the cover screw

and tighten fully.

N

M

18

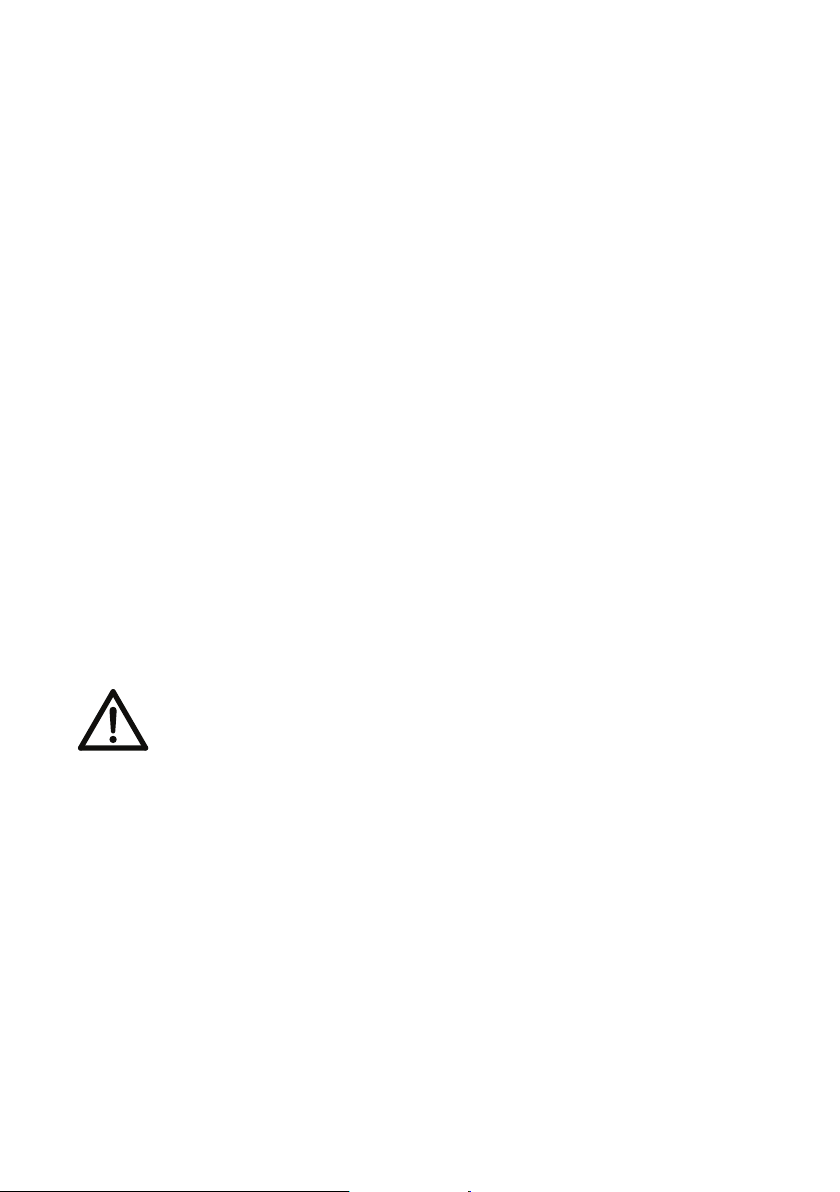

11. CORRECT PLANER BLADE SETTING (SEE FIG. O)

Your planing surface will end up rough and uneven, unless the

blade is set properly and securely.

The blade must be mounted so that the cutting edge is

absolutely level, that is, parallel to the surface of the rear base.

FIG. P shows some examples of proper and improper settings.

(A) Front base (moveable shoe)

(B) Rear base (stationary shoe)

1) Correct setting

Although this side view cannot show it, the edges of the blade

run perfectly parallel to the rear base surface.

2) Nicks in surface

Cause: one or both blades fail to have edge parallel to rear

base line.

3) Gouging at start

Cause: one or both blade edges fail to protrude enough in

relation to rear base line.

4) Gouging at end

Cause: one or both blade edges protrude too far in relation to

rear base line.

P

O

19

MAINTENANCE AND STORAGE

IMPORTANT:

Make sure that the tool has been thoroughly cleaned

before storing it in a clean, dry and safe place, out of

the reach of children.

1. Switch the product 'OFF' and disconnect it from the power

supply before transporting it anywhere.

2. Always carry the product on its gripping surfaces.

3. Protect the product from any heavy impact or strong

vibrations which may occur during transportation in

vehicles.

4. Secure the product to prevent it from slipping or falling

over.

20

TECHNICAL DATA

Model YT9757

Voltage/power 220-240V~ 50Hz/710W

No-load speed 16500/min

Max. cutting width 82mm

Max. cutting depth 2mm

Max. rebating depth 10mm

Protection class / II

Weight 2.8kg

NOISE AND VIBRATION DATA

A weighted sound pressure (LpA) 83.1dB(A), k=3dB(A)

A weighted sound power (LwA) 94.1dB(A), k=3dB(A)

Vibrations 6.96 m/s² K=1.5 m/s²

The sound intensity level for the operator may exceed 80

dB(A) and ear protection measures are necessary.

The declared vibration value has been measured in

accordance with a standard test method (according to EN

62841) and may be used for comparing one product with

another. The declared vibration value may also be used in a

preliminary assessment of exposure.

WARNING!

The vibration emission value during actual use of

depending on the ways in which the tool is used and

dependant on the following examples and other

variations on how the tool is used:

How the tool is used and the materials being cut or

drilled.

The tool being in good condition and well maintained.

Using the correct accessory for the tool and ensuring it

is sharp and in good condition.

The tightness of the grip on the handles and if any

anti-vibration accessories are used.

This manual suits for next models

1

Table of contents