DRIVE CHAINS FIG. 17 furnished

as

replacements,

are complete with connecting

links.

1.

Drain

oil

from gear box and remove

gear

box

cast-

ing.

Disconnect

link,

install

new

chain

around

sprockets

and

connect

link.

SHIFTER

FIG. 13. Drain

oil

and remove

cover.

Loose

n

shifter

for k

screw,

screw

in

gear

box which

holds large

collar,

and remove

shifter

assembly.

the

slinger

disc

will

have to be bent toward

the

gear. Use amallet

or

block

of

wood and

tap the

disc

around

the

circumference

until

the proper

clearance

is

obtained.

4.

When

functioning properly,

the

slinger

carries

the

oil

up

to the cutterhead

worm

and intermediate

gear.

5.

Replace

sprockets,

chains,

gear box and cover.

6.

Fill

with

oil.

SEE LUBRICATION.

Figure

18

~LOCKPLATE

\.~

SCREW

5.

Remove

retainer

ring and

thrust

bearing.

6.

Install

new gear. NOTE: Complete

assembly

is

available

as

a

replacement,

see

parts

list.

2. Remove

chains

and

sprockets.

3. Remove both

screws

in

lockplateS,

Fig.

18.

4. Remove both gear

assemblies

Fig.

19.

1. Remove gear box.

Figure

17

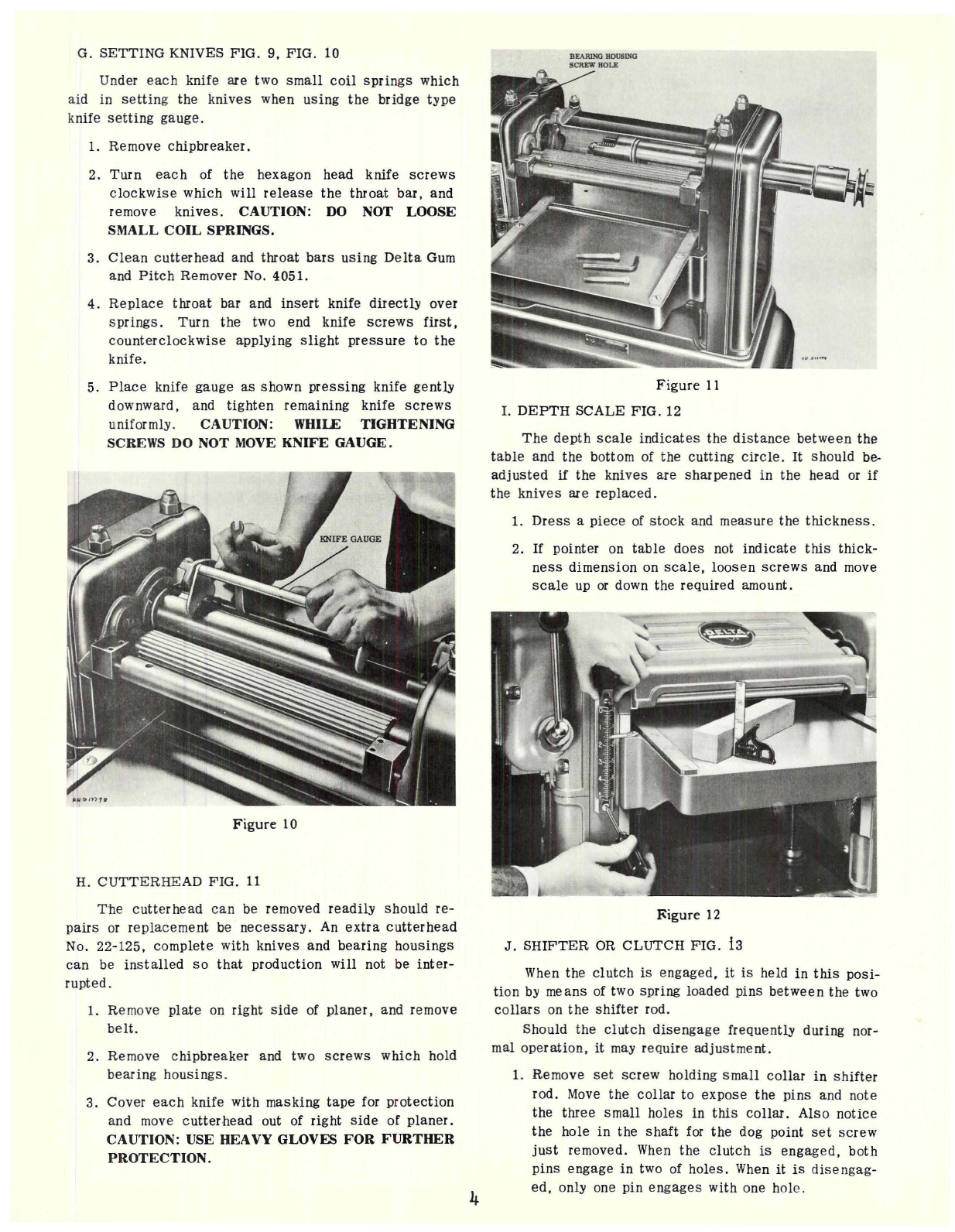

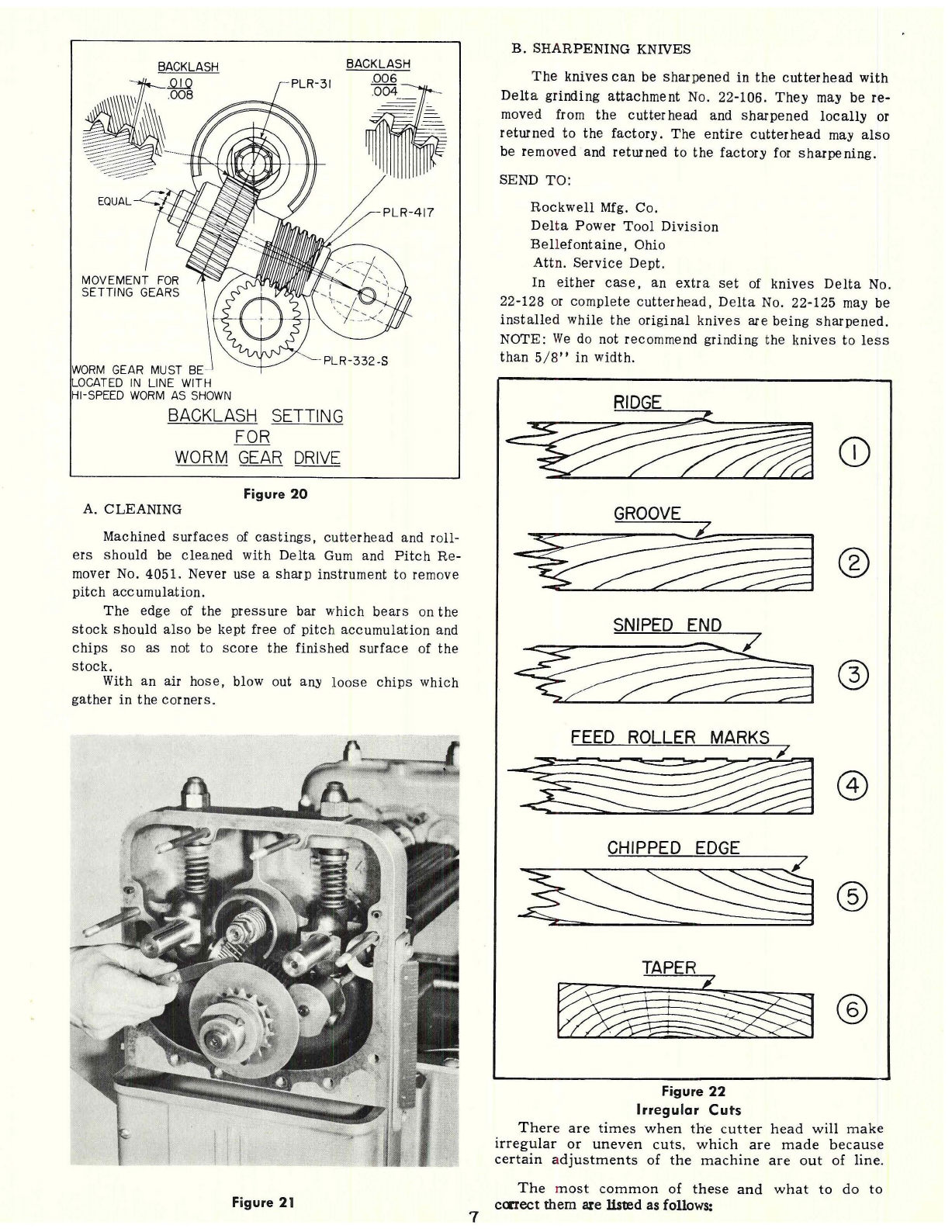

INTERMEDIATE GEAR, FIG.

·18,19,20.

Remove

shifter

as

previously

described.

A

.~.:J~~

Figure

19

6

2. Remove

slinger

using an arbor

press

or

similar

equipment. NOTE: COMPLETE ASSEMBLY

IS

AVAILABLE

AS

REPLACEMENT,

SEE

PARTS

LIST.

3. After gear

assemblies

are

instaHed

in

planer and

adjusted

for

correct

backlash

(Fig.

18),

the oil

slinger

disc

should be

checked

for

clearance,

(Fig.

21).

Use afeeler gauge

.010"

to

measure

the

clearance

between

the

slinger

and the inter-

mediate

gear.

If

the

clearance

is

more than

.010",

7.

Check

cutter

head worm.

It

is

advisable

to

replace

this

part when replacing the

intermediate

gear.

8.

Replace

the two gear

assemblies.'

INTERMEDIATE

GEAR

NOTE:

BEFORE

TIGHTENING

LOCKPLATE

C~~t:f':~~"ii~~

SCREWS,

MAKE

SUR.E

THE

BACKLASH

IS

EQUALIZED, SEE FIG.

20~

CLUTCH SPROCKET GEAR

AND

SLINGER FIGS.

18. 19, 20.

To

remove.

it

is

necessary

to

first

remove

the

oil

slinger

disc.

1. Remove

retainer

ring, bearing and

sprocket.