Sovereign DM-130B-1 User guide

135W ROTARY TOOL SET

Item No. 594448

Model No. DM-130B-1

HHGL Limited, MK9 1BA; HHGL (ROI) Limited, D02 X576 Mar 21

ORIGINAL INSTRUCTION MANUAL

Please read these instructions fully before starting assembly.

www.coreservice.co.uk

Technical Support & Parts

01904 727509

Mon-Fri 9am-5pm Sat-Sun 11am-4pm

2

CONTENTS

Contents 2

General safety warnings 3

Warning symbols 16

In the box 17

Operation 18

Maintenance and storage 24

Technical data 25

Recycling and disposal 27

UK plug 27

Getting help 28

Warranty 28

3

GENERAL SAFETY INFORMATION

WARNING! Read all safety warnings,

provided with this power tool.

Failure to follow all instructions listed below

injury.

Save all warnings and instructions for future

reference.

The term "power tool" in the warnings refers to your

mains-operated (corded) power tool or battery-

operated (cordless) power tool.

1) Work area safety

a. Keep work area clean and well lit. Cluttered or

dark areas invite accidents.

b. Do not operate power tools in explosive

atmospheres, such as in the presence of

flammable liquids, gases or dust. Power tools

create sparks which may ignite the dust or fumes.

c. Keep children and bystanders away while

operating a power tool. Distractions can cause

you to lose control.

2) Electrical safety

a. Power tool plugs must match the outlet. Never

modify the plug in any way. Do not use any

adaptor plugs with earthed (grounded) power

4

tools. Unmodified plugs and matching outlets will

reduce risk of electric shock.

b. Avoid body contact with earthed or grounded

surfaces, such as pipes, radiators, ranges and

refrigerators. There is an increased risk of electric

shock if your body is earthed or grounded.

c. Do not expose power tools to rain or wet

conditions. Water entering a power tool will

increase the risk of electric shock.

d. Do not abuse the cord. Never use the cord for

carrying, pulling or unplugging the power tool.

Keep cord away from heat, oil, sharp edges

or moving parts. Damaged or entangled cords

increase the risk of electric shock.

e. When operating a power tool outdoors, use an

extension cord suitable for outdoor use. Use of

a cord suitable for outdoor use reduces the risk of

electric shock.

f. If operating a power tool in a damp location

is unavoidable, use a residual current device

(RCD) protected supply. Use of an RCD reduces

the risk of electric shock.

3) Personal safety

a. Stay alert, watch what you are doing and

use common sense when operating a power

tool. Do not use a power tool while you are

tired or under the influence of drugs, alcohol

5

or medication. A moment of inattention while

operating power tools may result in serious

personal injury.

b. Use personal protective equipment. Always

wear eye protection. Protective equipment such

as dust mask, non-skid safety shoes, hard hat, or

hearing protection used for appropriate conditions

will reduce personal injuries.

c. Prevent unintentional starting. Ensure the

switch is in the 'off' position before connecting

to power source and/or battery pack, picking

up or carrying the tool. Carrying power tools

with your finger on the switch or energising power

tools that have the switch on invites accidents.

d. Remove any adjusting key or wrench before

turning the power tool on. A wrench or a key left

attached to a rotating part of the power tool may

result in personal injury.

e. Do not overreach. Keep proper footing and

balance at all times. This enables better control

of the power tool in unexpected situations.

f. Dress properly. Do not wear loose clothing or

jewellery. Keep your hair, clothing and gloves

away from moving parts. Loose clothes, jewellery

or long hair can be caught in moving parts.

g. If devices are provided for the connection of

dust extraction and collection facilities, ensure

these are connected and properly used. Use of

these devices can reduce dust-related hazards.

6

h. Do not let familiarity gained from frequent use

of tools allow you to become complacent and

ignore tool safety principles. A careless action

can cause severe injury within a fraction of a

second.

4) Power tool use and care

a. Do not force the power tool. Use the correct

power tool for your application. The correct

power tool will do the job better and safer at the

rate for which it was designed.

b. Do not use the power tool if the switch does

not turn it on and off. Any power tool that cannot

be controlled with the switch is dangerous and

must be repaired.

c. Disconnect the plug from the power source

and/or the battery pack from the power tool

before making any adjustments, changing

accessories, or storing power tools. Such

preventive safety measures reduce the risk of

starting the power tool accidentally.

d. Store idle power tools out of the reach of

children and do not allow persons unfamiliar

with the power tool or these instructions

to operate the power tool. Power tools are

dangerous in the hands of untrained users.

e. Maintain power tools. Check for misalignment

or binding of moving parts, breakage of parts

and any other condition that may affect the

power tools operation. If damaged, have the

7

power tool repaired before use. Many accidents

are caused by poorly maintained power tools.

f. Keep cutting tools sharp and clean. Properly

maintained cutting tools with sharp cutting edges

are less likely to bind and are easier to control.

g. Use the power tool, accessories and tool bits,

etc., in accordance with these instructions,

taking into account the working conditions and

the work to be performed. Use of the power tool

for operations different from those intended could

result in a hazardous situation.

h. Keep handles and gripping surfaces dry, clean

and free from oil and grease. Slippery handles

and gripping surfaces do not allow for safe

handling and control of the tool in unexpected

situations.

Service

a) Have your power tool serviced by a qualified

repair person using only identical replacement

parts. This will ensure that the safety of the power

tool is maintained.

8

SAFETY INSTRUCTIONS FOR ALL OPERATIONS

Safety Warnings common for grinding, sanding,

wire brushing, polishing, carving or abrasive

cutting-off operations:

a) This power tool is intended to function as a

grinder, sander, wire brush, polisher, carver or

cut-off tool. Read all safety warnings, instructions,

illustrations and specifications provided with this

power tool. Failure to follow all instructions listed

injury.

b) Operations such as polishing is not

recommended to be performed with this power

tool. Operations for which the power tool was not

designed may create a hazard and cause personal

injury.

c) Do not use accessories which are not

specifically designed and recommended by the

tool manufacturer. Just because the accessory can

be attached to your power tool, it does not assure

safe operation.

d) The rated speed of the grinding accessories

must be at least equal to the maximum speed

marked on the power tool. Grinding accessories

running faster than their rated speed can break and

fly apart.

e) The outside diameter and the thickness of your

accessory must be within the capacity rating

of your power tool. Incorrectly sized accessories

cannot be adequately controlled.

9

f) The arbour size of wheels, sanding drums or

any other accessory must properly fit the spindle

or collet of the power tool. Accessories that do not

match the mounting hardware of the power tool will

run out of balance, vibrate excessively and may cause

loss of control.

g) Mandrel mounted wheels, sanding drums,

cutters or other accessories must be fully

inserted into the collet or chuck. If the mandrel is

is too long, the mounted wheel may become loose

and be ejected at high velocity.

h) Do not use a damaged accessory. Before each

use, inspect the accessory, such as abrasive

wheels for chips and cracks, sanding drum for

cracks, tear or excess wear, wire brush for loose

or cracked wires. If the power tool or accessory

is dropped, inspect for damage or install an

undamaged accessory. After inspecting and

installing an accessory, position yourself and

bystanders away from the plane of the rotating

accessory and run the power tool at maximum no-

load speed for one minute. Damaged accessories

will normally break apart during this test time.

i) Wear personal protective equipment.

Depending on application, use a face shield,

safety goggles or safety glasses. As appropriate,

wear a dust mask, hearing protectors, gloves

and workshop apron capable of stopping small

abrasive or workpiece fragments. The eye

protection must be capable of stopping flying debris

10

generated by various operations. The dust mask

or respirator must be capable of filtrating particles

generated by your operation. Prolonged exposure to

high intensity noise may cause hearing loss.

j) Keep bystanders a safe distance away from the

work area. Anyone entering the work area must

wearpersonal protective equipment. Fragments of

workpiece or of a broken accessory may fly out and

cause injury beyond immediate area of operation.

k) Hold the power tool by insulated gripping

surfaces only, when performing an operation

where the cutting accessory may contact hidden

wiring or its own cord. Cutting accessory contacting

a “live” wire may make exposed metal parts of the

power tool “live” and could give the operator an

electric shock.

l) Always hold the tool firmly in your hand(s)

during the start up. The reaction torque of the

motor, as it accelerates to full speed, can cause the

tool to twist.

m) Use clamps to support the workpiece

whenever practical. Never hold a small workpiece

in one hand and the tool in the other hand while

in use. Clamping a small workpiece allows you to use

your hand(s) to control the tool. Round material, such

as dowel rods, pipes or tubing, have a tendency to

roll while being cut, and may cause the bit to bind or

jump toward you.

11

n) Position the cord clear of the spinning

accessory. If you lose control, the cord may be cut

or snagged and your hand or arm may be pulled into

the spinning accessory.

o) Never lay the power tool down until the

accessory has come to a complete stop. The

spinning accessory may grab the surface and pull the

power tool out of your control.

p) After changing the bits or making any

adjustments, make sure the collet nut, chuck

or any other adjustment devices are securely

tightened. Loose adjustment devices can

unexpectedly shift, causing loss of control; loose

rotating components will be violently thrown.

q) Do not run the power tool while carrying it

at your side. Accidental contact with the spinning

accessory could snag your clothing, pulling the

accessory into your body.

r) Regularly clean the power tools air vents. The

motors fan will draw the dust inside the housing

and excessive accumulation of powdered metal may

cause electrical hazards.

s) Do not operate the power tool near flammable

materials. Sparks could ignite these materials.

t) Do not use accessories that require liquid

coolants. Using water or other liquid coolants may

result in electrocution or shock.

12

Further safety instructions for all operations

Kickback and related warnings

Kickback is a sudden reaction to a pinched or

snagged rotating wheel, sanding band, brush or any

other accessory. Pinching or snagging causes rapid

stalling of the rotating accessory which in turn causes

the uncontrolled power tool to be forced in the

direction opposite of the accessory’s rotation.

For example, if an abrasive wheel is snagged or

pinched by the workpiece, the edge of the wheel

that is entering into the pinch point can dig into the

surface of the material, causing the wheel to climb

out or kick out. The wheel may either jump toward or

away from the operator, depending on the direction

of the wheels movement at the point of pinching.

Abrasive wheels may also break under these

conditions.

incorrect operating procedures or conditions and

can be avoided by taking proper precautions as given

below.

a) Maintain a firm grip on the power tool and

position your body and arm to allow you to resist

kickback forces. The operator can control kickback

forces, if proper precautions are taken.

b) Use special care when working corners, sharp

edges, etc. Avoid bouncing and snagging the

accessory. Corners, sharp edges or bouncing have

a tendency to snag the rotating accessory and cause

loss of control or kickback.

13

c) Do not attach a toothed saw blade. Such blades

create frequent kickback and loss of control.

d) Always feed the bit into the material in the

same direction as the cutting edge is exiting from

the material (which is the same direction as the

chips are thrown). Feeding the tool in the wrong

direction causes the cutting edge of the bit to climb

out of the work and pull the tool in the direction of

this feed.

e) When using rotary files, cut-off wheels, high-

speed cutters or tungsten carbide cutters, always

have the work securely clamped. These wheels will

grab if they become slightly canted in the groove, and

can kick back. When a cut-off wheel grabs, the wheel

itself usually breaks. When a rotary file, high-speed

cutter or tungsten carbide cutter grabs, it may jump

from the groove and you could lose control of the

tool.

Safety Warnings Specific for Grinding and

Abrasive Cutting-Off Operations:

a) Use only wheel types that are recommended

for your power tool and only for recommended

applications. For example: do not grind with the

side of a cut-off wheel. Abrasive cut-off wheels are

intended for peripheral grinding, side forces applied

to these wheels may cause them to shatter.

b) For threaded abrasive cones and plugs,

use only undamaged wheel mandrels with an

14

unrelieved shoulder flange that are of correct

size and length. Proper mandrels will reduce the

possibility of breakage.

c) Do not “jam” a cut-off wheel or apply excessive

pressure. Do not attempt to make an excessive

depth of cut. Overstressing the wheel increases the

loading and susceptibility to twisting or snagging of

the wheel in the cut and the possibility of kickback or

wheel breakage.

d) Do not position your hand in line with or

behind the rotating wheel. When the wheel, at the

point of operation, is moving away from your hand,

the possible kickback may propel the spinning wheel

and the power tool directly at you.

e) When the wheel is pinched, snagged or when

interrupting a cut for any reason, switch off the

power tool and hold the power tool motionless

until the wheel comes to a complete stop. Never

attempt to remove the cut-off wheel from the cut

while the wheel is in motion, otherwise kickback

may occur. Investigate and take corrective action to

eliminate the cause of wheel pinching or snagging.

f) Do not restart the cutting operation in the

workpiece. Let the wheel reach full speed and

carefully re-enter the cut. The wheel may bind,

walk up or kickback if the power tool is restarted in

the workpiece.

g) Support panels or any oversized workpiece to

minimise the risk of wheel pinching and kickback.

Large workpieces tend to sagunder their own weight.

Supports must be placed under the workpiece near

15

the line of cut and near the edge of the workpiece on

both sides of the wheel.

h) Use extra caution when making a “pocket

cut” into existing walls or other blind areas.

The protruding wheel may cut gas or water pipes,

electrical wiring or objects that can cause kickback.

Safety Warnings Specific for Wire Brushing

Operations:

a) Be aware that wire bristles are thrown by the

brush even during ordinary operation. Do not

overstress the wires by applying excessive load to

the brush. The wire bristles can easily penetrate light

b) Allow brushes to run at operating speed for at

least one minute before using them. During this

time, no one is to stand in front or in line with

the brush. Loose bristles or wires will be discharged

during the run-in time.

c) Direct the discharge of the spinning wire

brush away from you. Small particles and tiny wire

fragments may be discharged at high velocity during

the use of these brushes and may become imbedded

in your skin.

16

WARNING SYMBOLS

Warning!

Read the instructions

Wear ear protection

Wear eye protection

Wear a dust mask

Class II tool

The product complies with the applicable European

directives, and an evaluation method of conformity

for these directives was done.

Recycle unwanted materials instead of disposing

of them as household waste. All tools, hoses

and packaging should be sorted, taken to the

local recycling centre and disposed of in an

environmentally safe way.

The product complies with the applicable UK

directives, and an evaluation method of conformity

for these directives was followed.

17

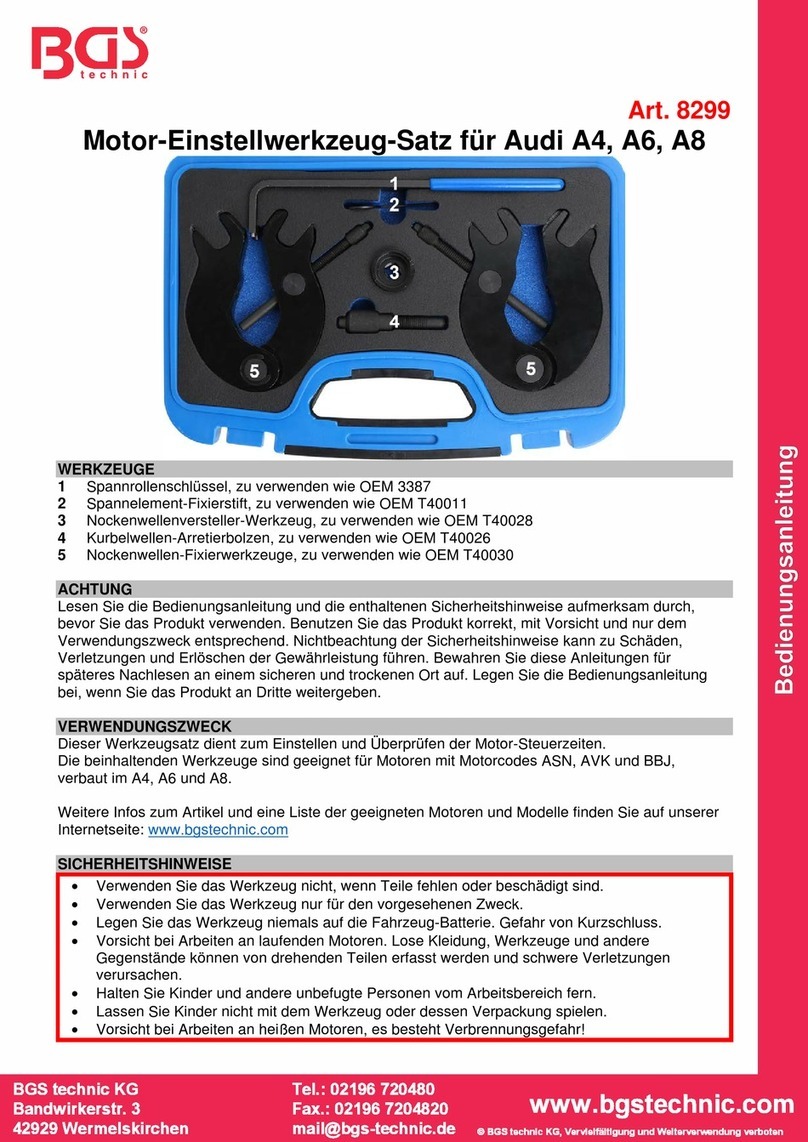

IN THE BOX

Description

1. Collet nut

2. Spindle lock button

3. Carbon brush holder

(on both sides)

4. Speed selector

5. Hook

6.

7. Spanner

8. Flexible shaft

Accessories

10pcs Grinding wheel with shank

2pcs Diamond bits

4pcs Sanding drum

1pc Sanding shank

2pcs Drill bits

2pcs Mandrel

4pcs Felt wheel

8pcs Cutting disk

3pcs Sanding paper

2pcs Collets (3.2mm & 2.3mm)

1pc Spanner

1pc Whet stone

1pc Flexible shaft

18

OPERATION

NOTE: Before using the tool, read the

instruction book carefully.

Intended Use

This tool is intended for grinding and polishing metal, as well

as for cutting metal and drilling into metal and wood.

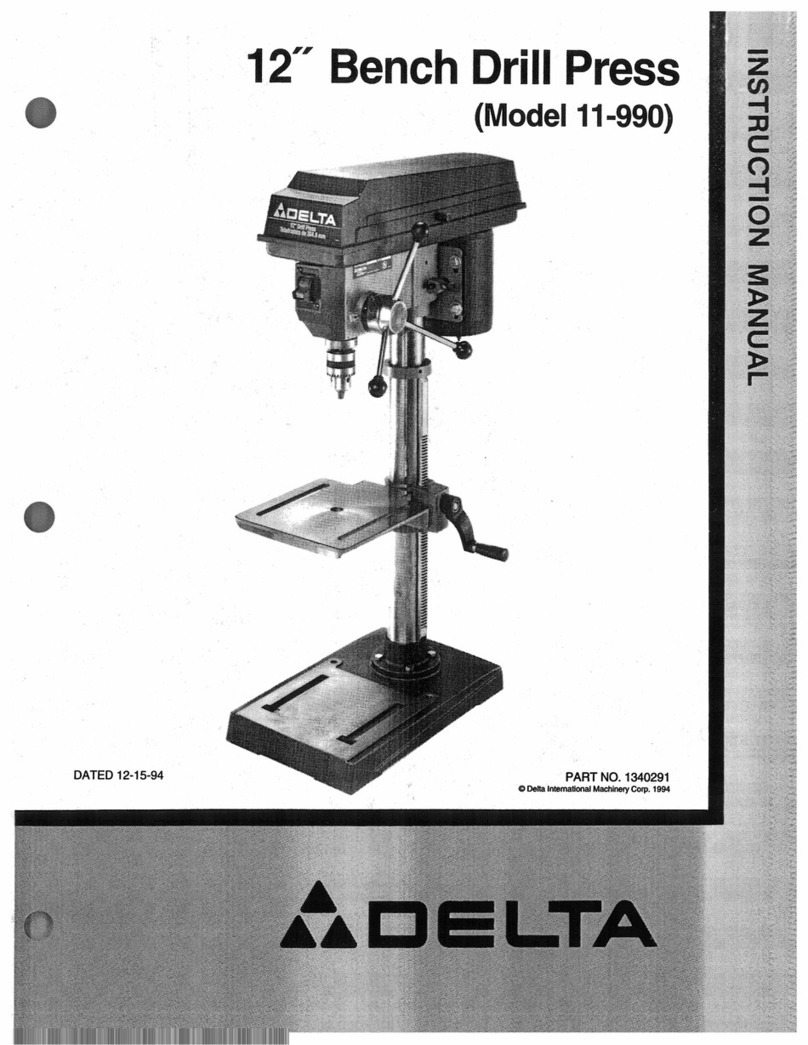

1. CHANGE THE COLLET (SEE FIG. A)

Two sizes (3.2mm pre-assembled, 2.3mm as an accessory) of

collets are provided to accommodate the different accessories

shank sizes.

When using an accessory with a smaller or larger shaft, you

will need to change the collet which matches the shank size of

the accessory, as follows:

Press the spindle lock button. Loosen the collet nut (1) with

the spanner provided. Remove the collet nut (1) and then fully

insert the appropriate size collet into the spindle.

Reinstall the collet nut (1) finger tight. Do not over-tighten the

nut when there is no accessory in the collet.

WARNING! Fully tighten the collet nut before

operation. Always use the collet which matches the

shank size of the accessory you plan to use. Do not

force a larger diameter shank into a smaller collet.

19

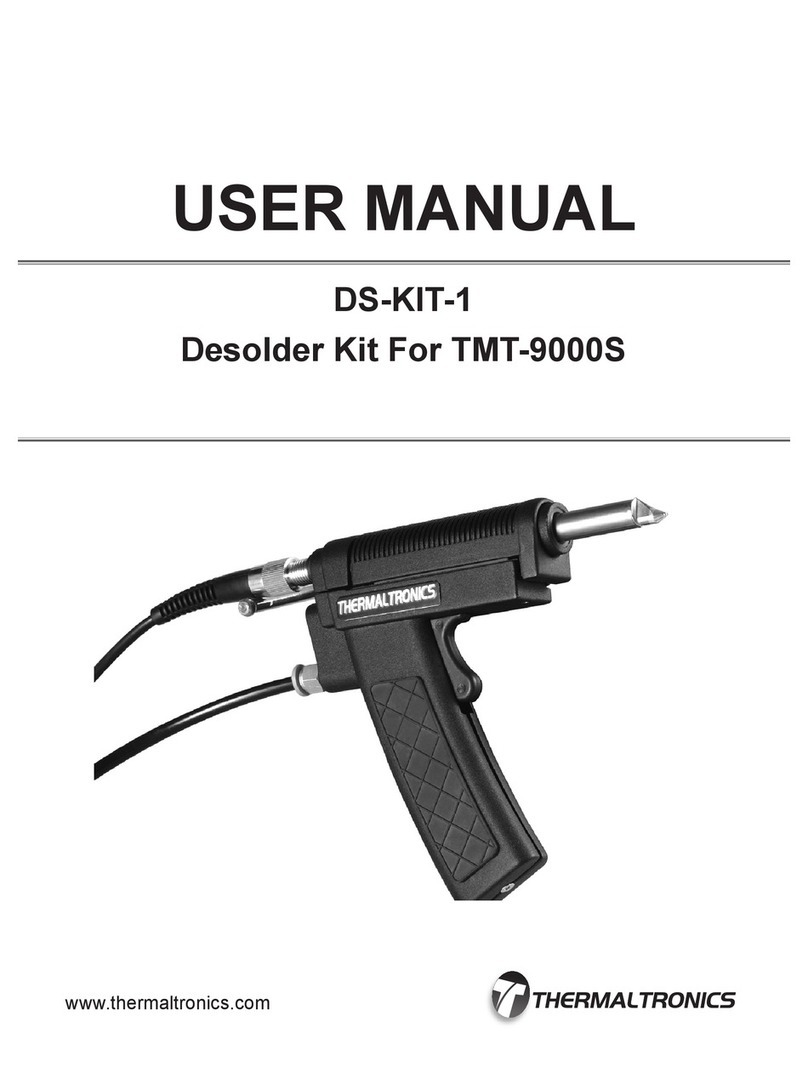

2. FITTING AN ACCESSORY (SEE FIG. B, C)

Press the spindle lock button. Hold down and rotate the

spindle by hand until the spindle lock engages with the

spindle. Loosen the collet nut anti-clockwise using the spanner

if necessary.

Fully insert the tool shank into the collet. Tighten the collet nut

with the spanner but do not over-tighten. Finally release the

spindle lock button.

WARNING! Do not engage the spindle lock button

while the tool is running.

3. FITTING A CUTTING/SANDING WHEEL (SEE FIG. D, E)

First, fit the cutting wheel fixture into the collet. Loosen the

small screw (a) on the cutting wheel fixture with the top of the

collet spanner. Insert the screw through the cutting wheel and

then screw into the cutting wheel fixture. Do not over-tighten,

otherwise the wheel may crack.

20

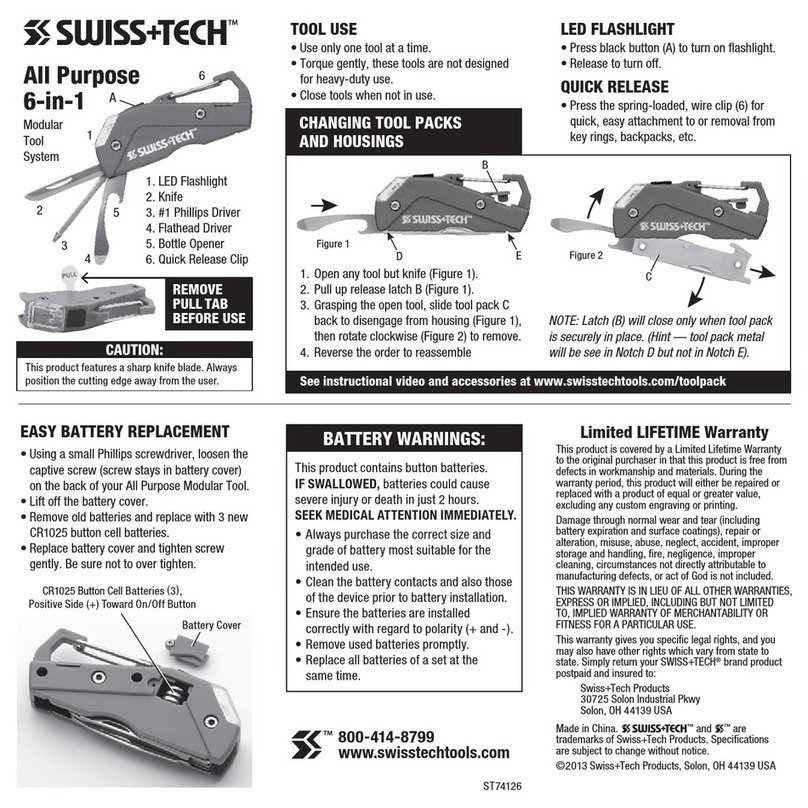

4. ASSEMBLING THE FELT WHEEL (SEE FIG. F)

The felt wheel is used with the mandrel. Thread the wheel on

to the screw carefully.

The felt wheel must thread down straight on the mandrel, and

be turned all the way to the collar.

5. FITTING THE SANDING ROLL (SEE FIG. G1, G2, G3)

To fit the sanding roll, firstly loosen the small screw on top

of the hole for the rubber wheel, this will allow the rubber to

relax. Slide the sanding roll onto the holder.

To secure, simply tighten the screw and the rubber roll will

swell, gripping the sanding drum.

This manual suits for next models

1

Table of contents

Other Sovereign Power Tools manuals