Forbo siegling blizzard HP 160/400 AIR User manual

Siegling – total belting solutions

OPERATING INSTRUCTIONS

BLIZZARD HEATING PRESS

Contents

3 English manual

37 German manual

siegling blizzard

splicing equipment

TM

2

Dieses Gerät darf nur von Personen

in Betrieb genommen werden, die die

nachfolgende Betriebsanleitung gelesen

und verstanden haben.

Този уред трябва да се използва само

от лица, които са прочели и разбрали

следното ръководство за употреба.

本设备仅供阅读并理解以下使用手册

的人员使用

Dette apparat må kun sættes i drift af

personer, som har læst og forstået den

følgende driftsvejledning.

This device should only be used by

those personnel who have read and

understood the following user manual.

Seda seadet tohivad kasutada vaid ini-

mesed kes on lugenud kasutusjuhendit.

Tämä laite on tarkoitettu vain henkilöille,

jotka ovat lukeneet ja ymmärtäneet

kyseisen käyttöoppaan.

Cet appareil ne doit être mis en service

que par des personnes ayant lu et

compris les instructions de service ci-

après.

Αυτή η συσκευή επιτρέπεται να τεθεί σε

λειτουργία όνο από έλη του προσωπι-

κού που έχουν διαβάσει και κατανοήσει

τι οδηγίε χρήση που ακολουθούν.

Questo dispositivo può essere utilizzato

solo da persone che hanno letto e

compreso il seguente manuale.

この装置は、次の取扱説明書をよく読んで

理解した作業員のみが使用するようにして

ください 。

Ovaj uređaj mogu koristiti samo osobe,

koje su pročitale i razumjele upute

za upotrebu.

Šo ierīci drīkst lietot personāls, kurš ir

izlasījis un sapratis lietošanas instrukcijas.

Šį prietaisą leidžiama pradėti eksploatuoti

tik asmenims, perskaičiusiems ir supra-

tusiems toliau pateiktą instrukcijų žinyną.

Dit apparaat mag alleen door personen

in gebruik worden genomen die de

volgende gebruiksaanwijzing hebben

gelezen en begrepen.

To urządzenie może być użytkowane

tylko przez osoby, które przeczytały i

zrozumiały następującą instrukcję obsługi.

Este aparelho só pode utilizado por

pessoas, que tenham lido e compreendi-

do o Manual de instruções que se segue.

Acest aparat poate fi pus în funcţiune

doar de către persoanele care au citit și

au înţeles instrucţiunile de utilizare de

mai jos.

Bara de personer som har läst och

förstått den här bruksanvisningen får

använda den här apparaten.

Toto zariadenie môžu uviesť do prevádz-

ky len osoby, ktoré si prečítali nasledujúci

návod na použitie a porozumeli jeho

obsahu.

To napravo smejo uporabljati samo

osebe, ki so prebrale in razumele

naslednja navodila za uporabo.

Este aparato solo deben emplearlo

las personas que hayan leído y compren-

dido las siguientes instrucciones de uso.

Tento přístroj smějí uvádět do provozu

pouze osoby, které si přečetly následující

návod k obsluze a rozumějí mu.

A készülék üzembe helyezését csak olyan

személyek végezhetik, akik elolvasták az

alábbi használati utasítást és megértették

annak tartalmát.

3

INCORRECT or IMPROPER use of this heating press can cause injuries and damage

to the heating press. These instructions contain important information on how

the product works and safety issues. Please ensure you have read and under-

stood these instructions before you start operating the heating press. Keep this

manual handy for other users and owners so that they can read it before using

the heating press.

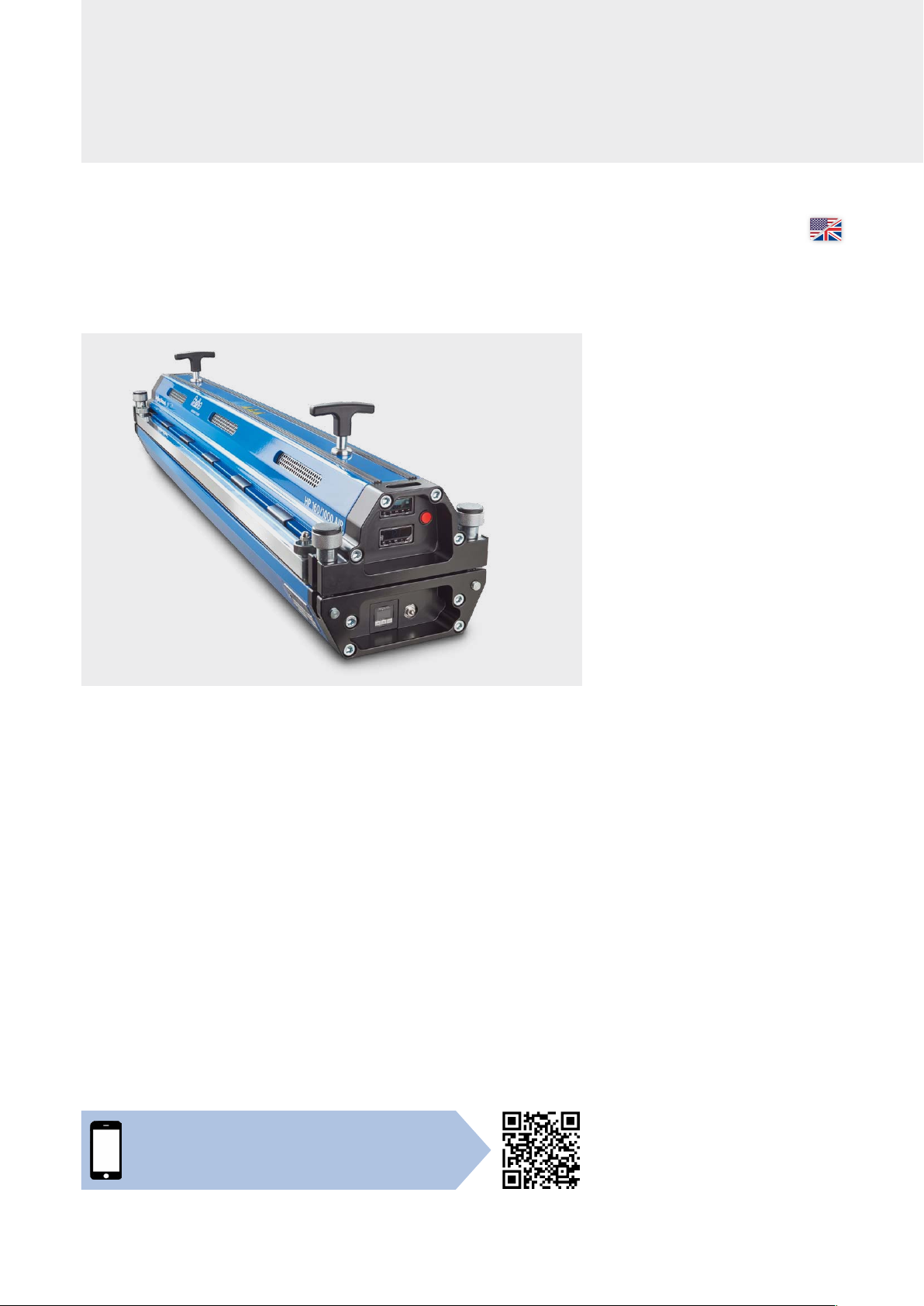

4 Main components

5 Technical information

6 Introduction

7 General safety rules

8 Safe operation

26 Design and diagrams

30 Power supply lead

wiring diagram

32 Wiring diagram

electrical components

36 Manufacturer‘s note/customer service/

EC declaration of conformity

OPERATING INSTRUCTIONS

BLIZZARD HEATING PRESS

Blizzard HP 160/X00 | The web app

Device data, step-by-step instructions, current

belt-specific heating parameters for your work on site

https://blizzard.hp160-x00.forbo.com

4

Top part of the

heating press

Heating press connector screws (4 x)

Clamping bar nuts (4 x)

Clamping bars (2 x)

MAIN COMPONENTS

Connection side

Control

side

Handle

Connection side

Start button

Control side

Timer

Control unit for top part

of heating press

Control unit for bottom part

of the heating press

Pressure relief button

Pressure control switch

Socket to connect the

bottom part of the press

Connection for the main

and power supply leads

Socket to connect with

the top part of the press

Bottom part of the heating press

5

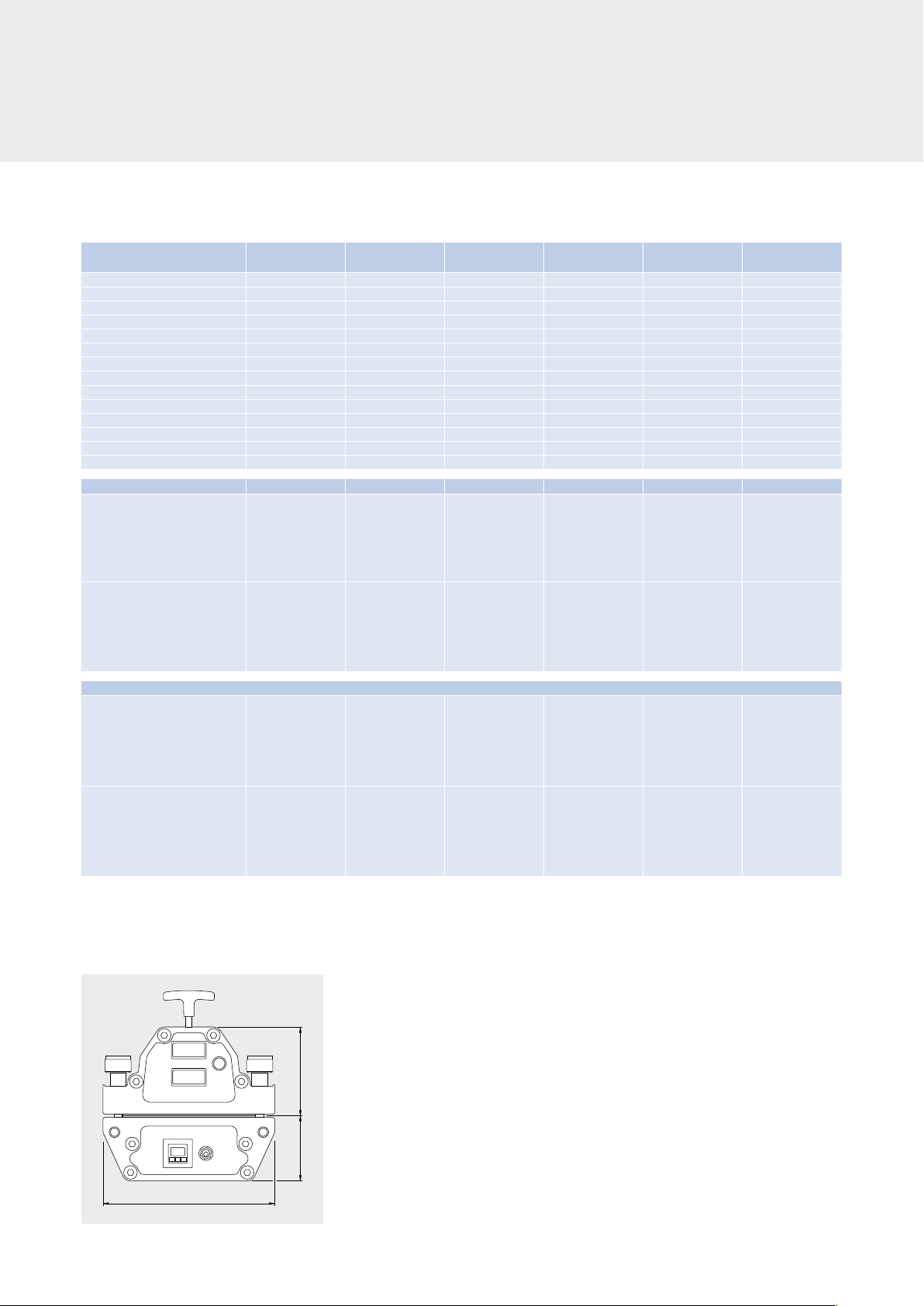

Main dimensions

TECHNICAL INFORMATION

Supplied with the

product and accessories

The following items are included with the heating

press: Leads, transport box and 2 silicone pads.

Embossing mats, glossy or matte release paper

(VEZ) are available as accessories on request.

Blizzard

HP 160/400 AIR

Blizzard

HP 160/600 AIR

Blizzard

HP 160/800 AIR

Blizzard

HP 160/1000 AIR

Blizzard

HP 160/1200 AIR

Blizzard

HP 160/1500 AIR

Effective belt width [mm (in)] 400 (15.7) 600 (23.6) 800 (31.5) 1000 (39.4) 1200 (47.2) 1500 (59)

Effective splice length max.

[mm (in)] 160 (6.3) 160 (6.3) 160 (6.3) 160 (6.3) 160 (6.3) 160 (6.3)

Weight bottom part [kg (lb)] 12 (26.5) 15.8 (34.8) 19.1 (42.1) 22.5 (49.6) 26. 2 (57.8) 31 (68.3)

Weight top part [kg (lb)] 14.6 (32.2) 18.6 (41) 22.7 (50) 26.9 (59.3) 30.9 (68.1) 36.8 (81.1)

Total weight [kg (lb)] 26.6 (58.6) 34.4 (75.8) 41.8 (92.1) 49.4 (108.9) 57.1 (125.9) 67. 8 (149.5)

Length [mm (in)] 590 (23.2) 790 (31.1) 990 (39) 119 0 (4 6.8) 1390 (54.7) 1690 (66.5)

Width [mm (in)] 230 (9.1) 230 (9.1) 230 (9.1) 230 (9.1) 230 (9.1) 230 (9.1)

Height top part [mm (in)] 118 (4.6) 118 (4.6) 118 (4.6) 118 (4.6) 118 (4.6) 118 (4.6)

Height bottom part [mm (in)] 84 (3.3) 84 (3.3) 84 (3.3) 84 (3.3) 84 (3.3) 84 (3.3)

Pressure max. [bar (psi)] 2.5 (36.3) 2.5 (36.3) 2.5 (36.3) 2.5 (36.3) 2.5 (36.3) 2 (29)

Max. temperature [°C (°F)] 200 (392) 200 (392) 200 (392) 200 (392) 200 (392) 200 (392)

Transport sizes (LxWxH) [mm] 875 x 370 x 350 875 x 370 x 350 1275 x 370 x 350 1275 x 370 x 350 1775 x 370 x 350 1775 x 370 x 350

Transport sizes (LxWxH) [in] 34.5 x 14.6 x 13.8 34.5 x 14.6 x 13.8 50.2 x 14.6 x 13.8 50.2 x 14.6 x 13.8 69.9 x 14.6 x 13.8 69.9 x 14.6 x 13.8

Weight when transported [kg (lb)] 42.1 (92.8) 49.9 (110) 61.9 (136.5) 69.5 (153.2) 83.8 (184.8) 94.5 (208.3)

Power requirements basic model

1 Phase [Volt /Ampere/ Watt]

article number

230 V/ 9A / 2200 W

Art. No. 873399

110V /14A / 1520 W

Art. No. 873400

230 V/ 14 A/ 3200 W

Art. No. 873401

110V /14A / 1520 W

Art. No. 873402

230 V/ 16 A/ 3680 W

Art. No. 873403

110V /14.5A /1600 W

Art. No. 873404

230 V/ 16 A/ 3680 W

Art. No. 873405

110V /14A / 1484 W

Art. No. 873406

230 V/ 16 A/ 3680 W

Art. No. 873409

230 V/ 19.5 A /4500 W

Art. No. 873412

230 V/ 16.0 A /3680 W

Art. No. 873413

230 V/ 13.0 A/ 3000 W

Art. No. 873414

3 Phase [Volt /Ampere / Watt]

article number

400 V/ 11A-5.5 A-5.5A

/

7600 W

Art. No. 873407

400 V/ 12 A-6.0 A-6.0 A/

8990W

Art. No. 873408

480V /11 A-5.5 A-5.5 A/

8900 W

Art. No. 873410

400 V/ 16 A-8.0 A-8.0 A/

11072W

Art. No. 873411

480V /13A-6.5 A-6.5 A/

10700 W

Art. No. 873415

Power requirements iCON type

1 Phase [Volt /Ampere / Watt]

article number

230 V/ 9A / 2200 W

Art. No 873417

110V /14A / 1520 W

Art. No 873418

230 V/ 14 A/ 3200 W

Art. No 873419

110V /14A / 1520 W

Art. No 873420

230 V/ 16 A/ 3680 W

Art. No 873421

110V /14.5A /1600 W

Art. No 873422

230 V/ 16 A/ 3680 W

Art. No 873423

110V /14A / 1484 W

Art. No 873424

230 V/ 16 A/ 3680 W

Art. No 873427

230 V/ 19.5 A /4500 W

Art. No 873430

230 V/ 16.0 A /3680 W

Art. No 873431

230 V/ 13.0 A/ 3000 W

Art. No 873432

3 Phase [Volt /Ampere / Watt]

article number

400 V/ 11A-5.5 A-5.5A

/

7600 W

Art. No

873425

400 V/ 12 A-6.0 A-6.0 A

/

8990W

Art. No 873426

480V /11 A-5.5 A-5.5 A/

8900 W

Art. No 873428

400 V/ 16 A-8.0 A-8.0 A/

11072W

Art. No 873429

480V /13A-6.5 A-6.5 A/

10700 W

Art. No 873433

Main dimensions in mm and inches (in).

All Imperial measurements have been

rounded up.

230 (9.1)

84 (3.3)

84 (4.6)

6

INTRODUCTION

The Siegling Blizzard heating press is a compact solution for heating thermoplastic conveyor belts (e.g. PVC, polyurethane).

No extra equipment such as an external control unit box, air pump or water tank are required. Siegling Blizzard heating

presses are heated electrically and air-cooled from inside. The heating procedure is fully automatic.

Problems can occur in thicker belts if the outsides of the belts are kept at the heating temperature for too long until the

inside has reached the required temperature. The melted material could dissolve or discolor and the fabric could shrink. The

pre-heating option can be used to prevent this from happening. This option heats the inside and outside of the belt to a

temperature just below melting point. After the pre-heating stage, the heating temperature on the inside is reached much

more quickly, minimizing the risk of material dissolving, discoloration or fabric shrinkage.

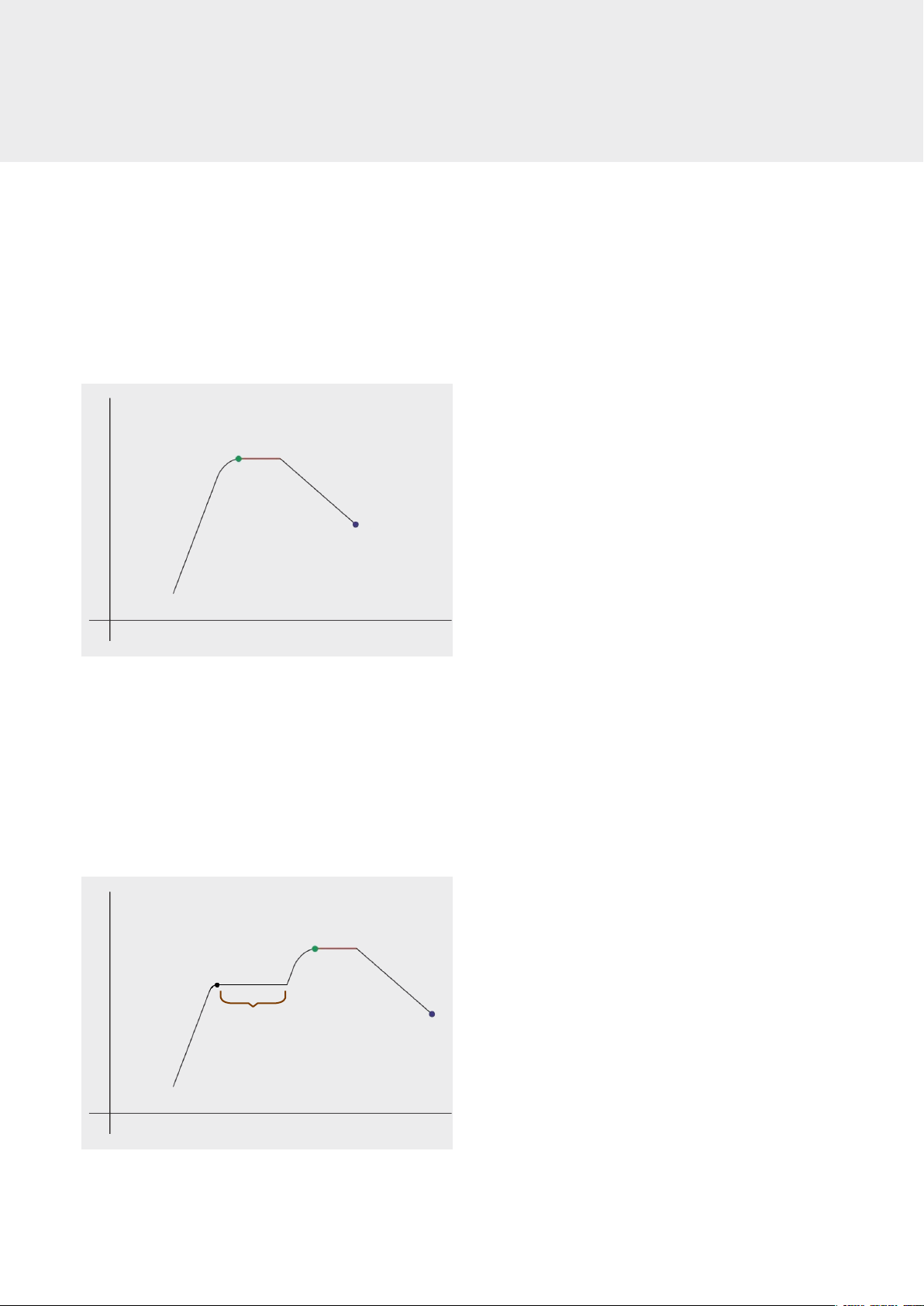

Basic procedure

• Heating pressure of up to 2.5 bar is generated.

Siegling Blizzard HP 160/1500 AIR: max. 2.0 bar

via the integrated compressor

• The heating device creates a heating temperature

of up to 200 °C

• The heating temperature is maintained

(adjustable dwell time)

• Cools down to the cooling temperature

(to a temperature safe enough to remove the belt)

• A pre-heat temperature and pre-heat dwell time

can be applied if belts are thicker.

• The two heating platens’ heating temperatures can be

adjusted so that they are different.

Graph of the procedure, program level 1

Settings:

Temperature

Time

Heating

temperature

Dwell time

Cooling temperature,

fan off

Graph of the procedure, program level 2 with pre-heating

Settings:

Temperature

Time

Heating

temperature Dwell time

Pre-heat

dwell time Cooling temperature,

fan off

Pre-heat

temperature

7

GENERAL SAFETY RULES

Risks

Danger indicates an immediate source of danger, which,

if ignored, may be fatal or lead to serious injuries. This safety

word is only used in exceptionally extreme circumstances.

Warning indicates a potential source of danger, which,

if ignored, could be fatal or result in serious injuries.

Caution indicates an immediate source of danger, which,

if ignored, could cause minor injuries. It can be used to warn

users not to use the device improperly.

Safety symbol

The purpose of this international safety symbol is to

call attention to specific safety issues.

General safety rules

Danger

In order to prevent serious injuries or damage to property,

please ensure you have read and understood this manual

before you start to operate the device.

Danger

Remove the main power supply cable from the socket or

the power outlet at the bottom of the device to rule out any

electrical hazards.

Warning

Press the red pressure relief button to rule out any pressure

hazards.

Caution

The press’s heating platens develop over 5 tons of clamping

force. Tighten the four heating press connector screws man-

ually before starting to operate the heating press.

Caution

To prevent any temperature hazards, only touch the

heating press’s components and the conveyor belt once

they have cooled down.

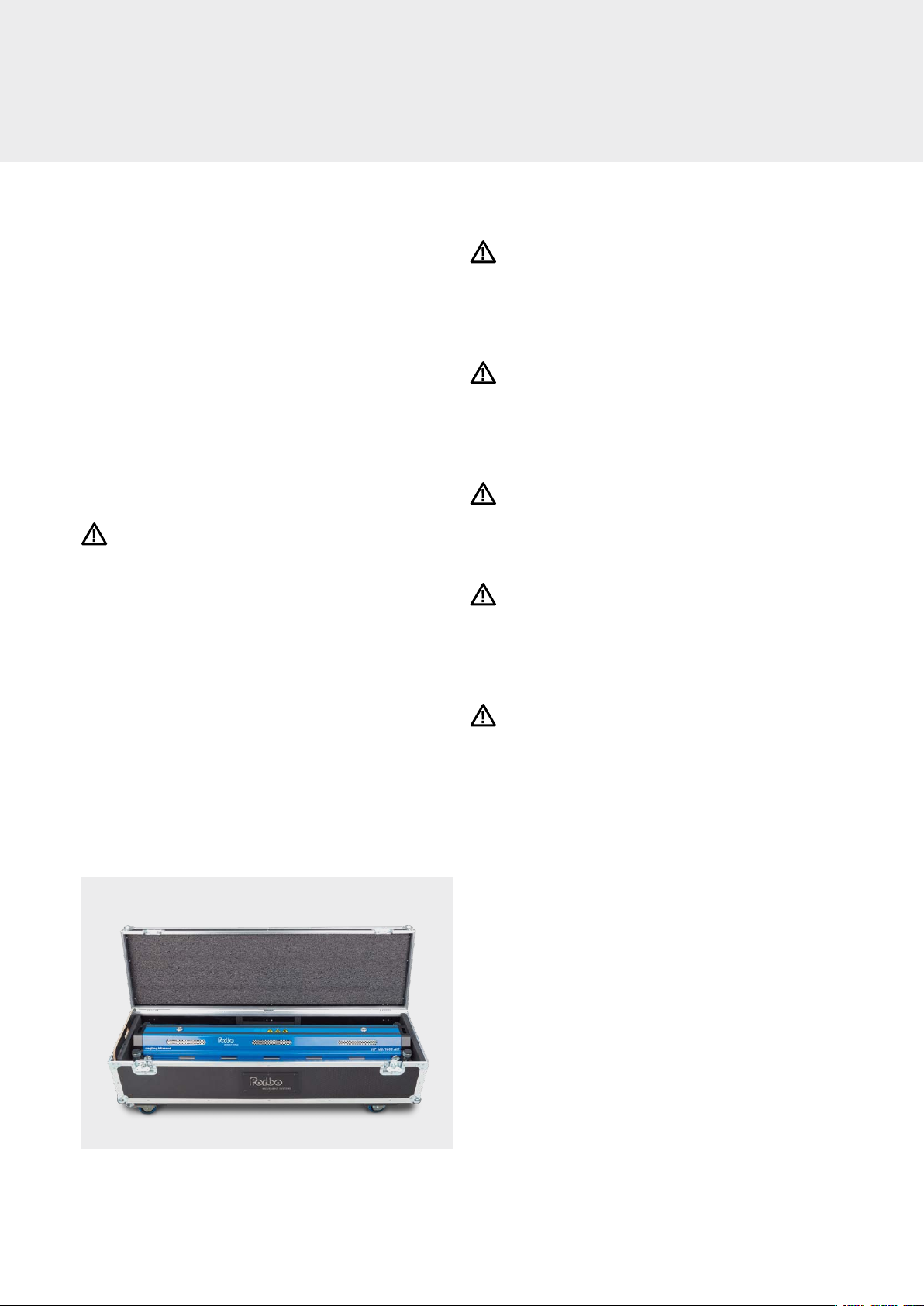

Transport box

• Siegling Blizzard heating presses come with a transport

box for storage purposes and so that the device is easy to

carry on site.

• Siegling Blizzard 400 – 1500 presses are stowed in transport

boxes with four wheels and a pull-out handle.

• The transport boxes can be stacked on top of each other,

but need to be secured during transportation.

• All transport boxes come with a pull-out handle to make

transporting them easier and more practical. Squeeze the

button in the handle to pull the handle out.

8

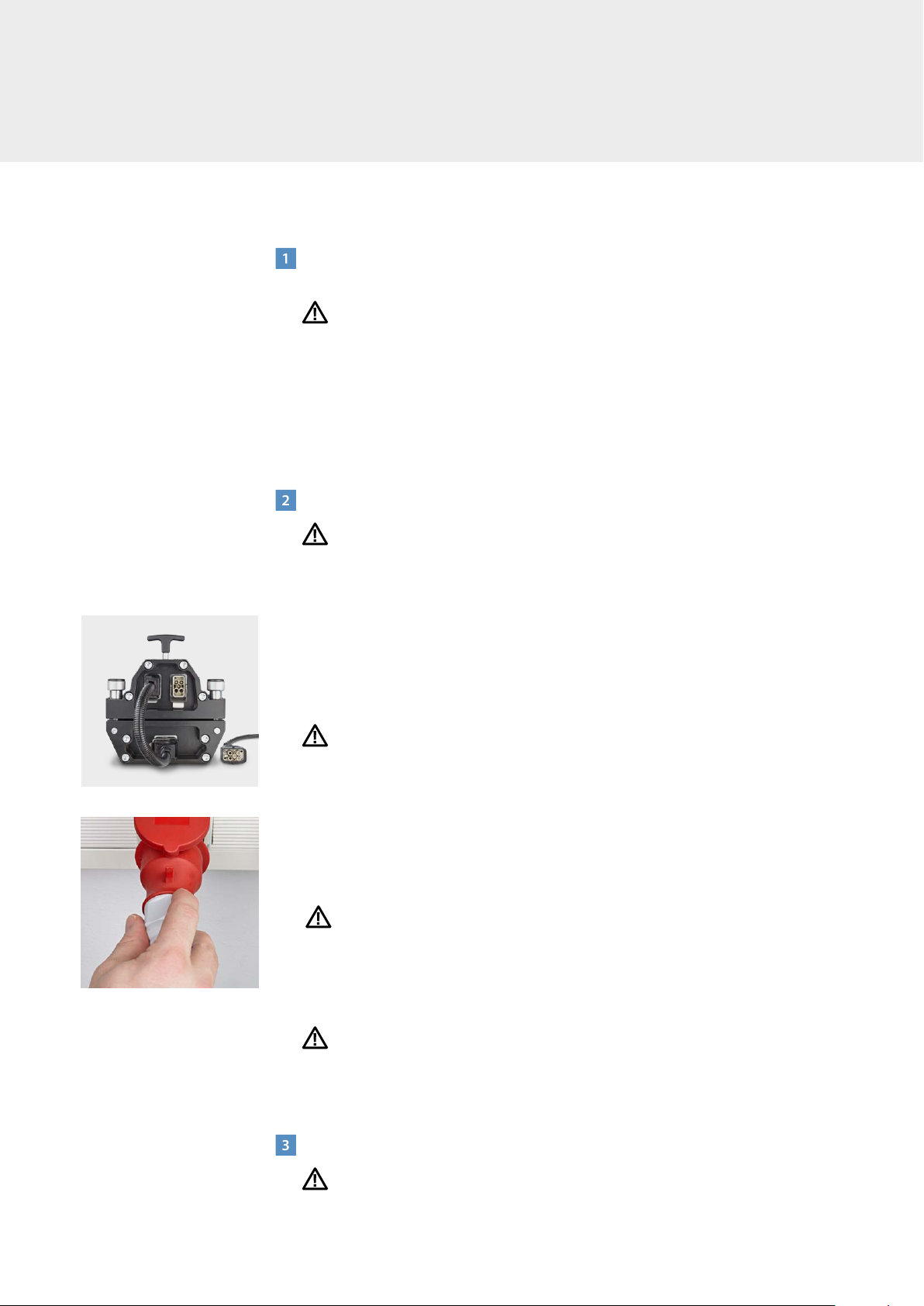

1

To operate the heating press, find somewhere with the right voltage and

connection options

Warning

Operating the heating press at the wrong voltage can cause serious damage and other

risks.

Before starting work, ensure you have enough belt material to cover the edges of the

heating press. The belt material for the edges must be of the same type and thickness

as the rest of the material.

2

Inspecting the power supply lead

Danger

a. Inspect the lead for any damage. Don’t use a damaged power supply lead. Either

replace the lead or ask an electrician to remove the faulty part and reattach the plug.

The electrician must refer to the wiring diagram on page 32 to ensure everything is

wired correctly.

b. Check whether the plug fits in the socket. If this isn’t the case, find another power

outlet or ask an electrician to attach the right plug (refer to the wiring diagram on

page 32).

Danger

c. Don’t plug the power supply lead into the socket yet. As soon as all preparations to

connect to the socket have been carried out, follow these safe instructions:

– Use the connection lead to attach the top and bottom part of the heating press

with one another. (Fig. 1)

– Now attach the power supply lead to the power outlet at the bottom of the device.

– Put the plug into the socket. (Fig. 2)

Danger

– Never leave the power supply lead in the socket when the lead is not attached to the

device because this could be very dangerous if it comes into contact with liquids

such as water.

Danger

d. All the heating press’s electricity outlets and plugs have coded (uniquely shaped)

guide pins and jacks. This means it’s virtually impossible to connect it up wrongly.

3

Remove the heating press from the transport box

Heavy object

Note: Use proper lifting methods to prevent injuries. If you find it hard to lift the heating

press out of the transport box yourself, ask someone to help you.

SAFE OPERATION

Fig. 1

Fig. 2

9

4

Inspect the heating press for damage

Warning

Broken or missing components can make the workspace unsafe and therefore cause

more damage to the heating press or injuries to operatives.

Danger

a. Ensure that all four heating press connector screws are undamaged. Don’t attempt to

operate the heating press if a screw is broken or missing.

b. Inspect the press’s heating platens for damage.

c. Ensure that there are no deposits or dirt on the press’s heating platens. If dirty,

proceed as follows:

– Carefully wipe off any dirt and deposits with a clean cloth and an ammonium-based

cleaning agent.

Warning

– Don’t clean the heating platens with flammable solutions.

Caution

– Do not hose down the heating press with water. Soak a cloth in an ammonia-based

solvent and use it to wipe the heating press. Dry the heating press off with a clean,

dry cloth.

d. Ensure all the leads are in perfect condition. Don’t use the heating press if the leads

are damaged.

5

Checking the heating press works

Forbo Movement Systems recommends checking the heating press twice a year.

Tools required

–

Temperature measurement device (with ±1°C accuracy) including temperature sensor

– Pressure measurement device including pressure sensor

– Straightedge

Use the tools listed to check the temperature, pressure and flatness of your Siegling

Blizzard heating press’s heating platens. If the heating press doesn’t comply with the set

parameters, we recommend sending in the heating press for calibration or repair. Please

get in touch with your Forbo Movement Systems contact for more details.

Warning

– Before attaching the sensors, unplug the heating press from the power supply

– The press’s heating platens can be hot

10

SAFE OPERATION

6

Inspecting the silicone pads

In order to produce a perfect splice, the pads must have no dirt or deposits on them.

The pads can also be cleaned using an ammonia-based, non-flammable cleaning agent

that will not adversely affect the splice.

7

Removing the top part of heating press (Fig. 3)

a. Loosen all four heating press connector screws.

b. Grab the handles on the heating press to lift up the top part of the press

Heavy object

You might need to ask somebody else to help you lift the heating press depending on

its width and weight.

c. Place the bar to one side, without the heating platen facing downward. It’s important

to keep the heating platens in good condition at all times. The top part of the heating

press should lie on its side to protect the heating platens from scratches or getting

dirty. The top part of heating press has a rubber strip on the long side of the heating

press to prevent any scratches. (Fig. 3)

8

Insert the prepared ends of the belt into the heating press

a. Place a clean silicone pad onto the clean bottom heating platen. Ensure the silicone

pad lies flat because any creases will impact the appearance of the splice. The pur-

pose of the silicone pads is to prevent the belt material from sticking to the press’s

heating platens.

b. Place the prepared ends of the belt onto the bottom heating platen.

Note: The area heated is 160 mm wide and situated in the middle of the heating plat-

en. Make sure the area to be heated is correctly centered. Depending on the belt

type, slight heat loss can occur in the outer areas of the heating zone. A prepared fin-

ger splice or layer separation must be within the heating zone because otherwise the

material won’t melt outside the heating zone. (Fig. 4)

Fig. 4

Nominal width + 100 mm

Nominal width 400 – 1500 mm

160 mm

Heating area

Protective

rubber strip

Handle

Handle

Heating press

connector screws (4 x)

Fig. 3

11

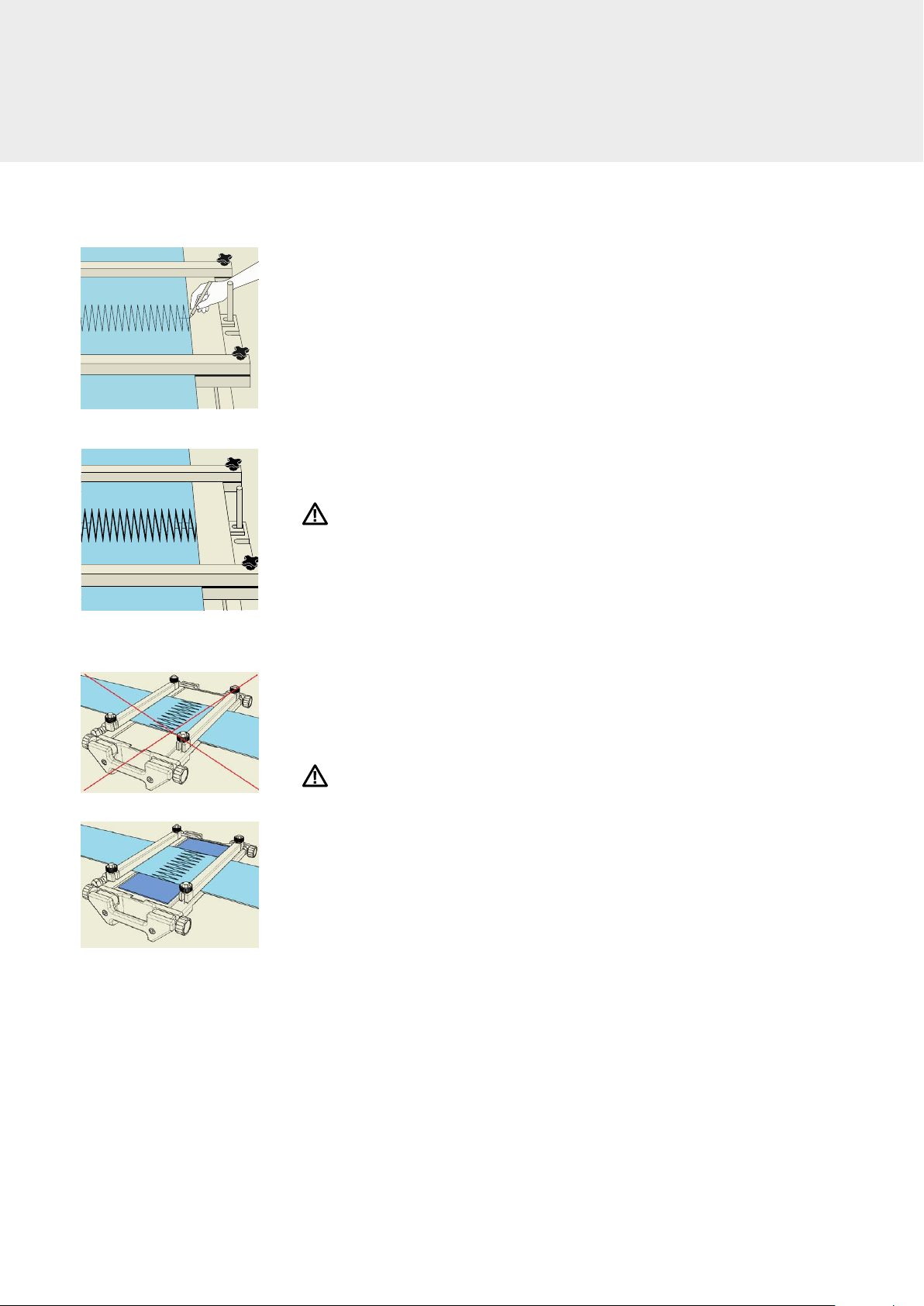

c. Please follow this procedure if you want to make a finger splice:

– For splices without any additional materials:

The fingers must interlock completely and there must be no gaps between the

fingertips. Distance between the fingers = 0 mm

– For splices with film on the top face:

Push the fingers into one another completely and draw a marking line (see Fig. 5).

Then pull the ends of the belt apart again until there is a 6 mm distance between

the lines. The distance between the fingers is 2 mm. (Fig. 6).

d. Apply extra belt material to the edges of the belt to be spliced until all of the heating

press is covered over the entire area to be pressed. This prevents melted material

from being squeezed out.

Caution

Ensure the belt material covers the entire width of the heating press so that even pres-

sure is applied and damage to the press prevented.

e. Apply the clamping bars so that the fingers are secured firmly onto the bottom part

of the press.

f. Depending on the splicing instructions for the material to be prepared, place film/

release paper/silicone pad onto the prepared heating zone. Ensure no creases form.

Incorrect: Area at the edge not covered (Fig. 7)

Correct: Area at the edge covered with extra belt material (Fig. 8)

Caution

Don’t use any metal shim bars due to the risk of thermal bridges forming between the

top and bottom heating platen.

Fig. 7

Fig. 8

Fig. 5

Fig. 6

12

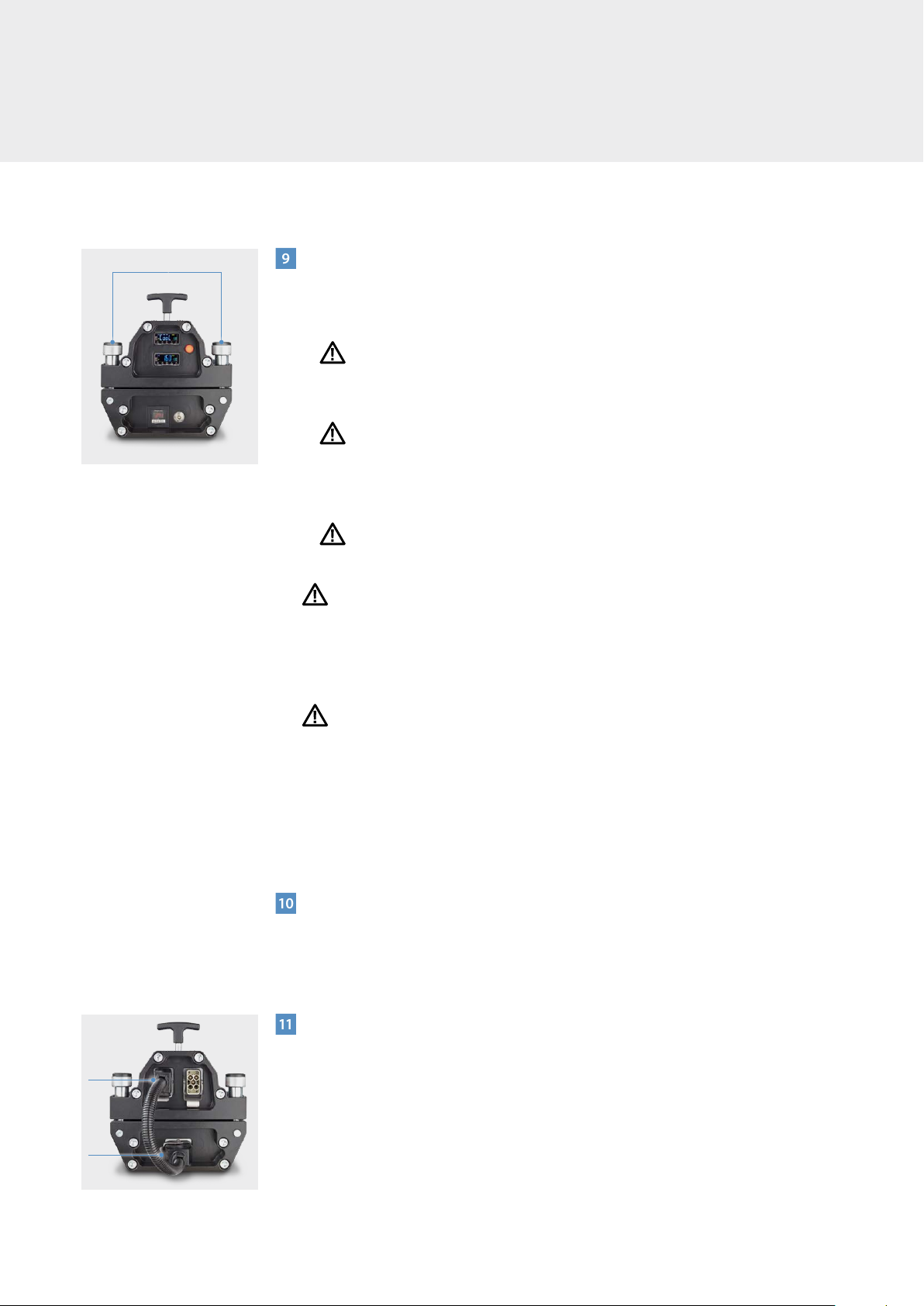

9

Insert the top part of heating press

a. Carefully place the top part of heating press onto the prepared ends of the belt.

Ensure that the prepared ends of the belt or the fingers aren’t separated.

Heavy object

Ask another person to help you if you find it hard to lift the heating press because of

its width or weight.

Danger

b. Center the top bar so that all four connecting screws can easily rotate upward. This is

vital in order to align the heating press correctly. Tighten the screws by hand and

ensure these are positioned properly in the recess on the top bar. (Fig. 9)

Caution

Ensure you don’t get your fingers caught in areas where they could be crushed.

Danger

The heating press can exert pressure of up to 2.5 bar.

Do not operate the heating press if a screw is missing or broken as this could cause seri-

ous injury and/or damage to the press. Missing or broken screws may only be replaced

by parts authorized by the company.

Warning

To ensure the screws engage properly with the thread, the prepared ends of the belt

(including the pads) must not exceed 15 mm (0.59 in). This would not necessarily impair

the heating press’s ability to heat. If this thickness is exceeded, the threads on the con-

necting screws can’t reliably clamp to the heating press, which could damage the heat-

ing press and lead to injuries.

10

Remove clamping bars as soon as the top part of heating press has been secured

If the clamping bars can’t be removed, it is possible that heating might not be even

across the belt width.

11

Using the power lead to connect the top and bottom part of the press (Fig. 10)

a. Put the power lead’s plug into the cable connector at the bottom of the device.

b. Lock the plug in place. If the plug is not locked in place, the power supply to the

controls at the base of the heating press might be temporarily interrupted.

SAFE OPERATION

Lock

Lock

Heating press connector screws (4 x)

Fig. 9

Fig. 10

13

Lock

Fig. 11

Fig. 12

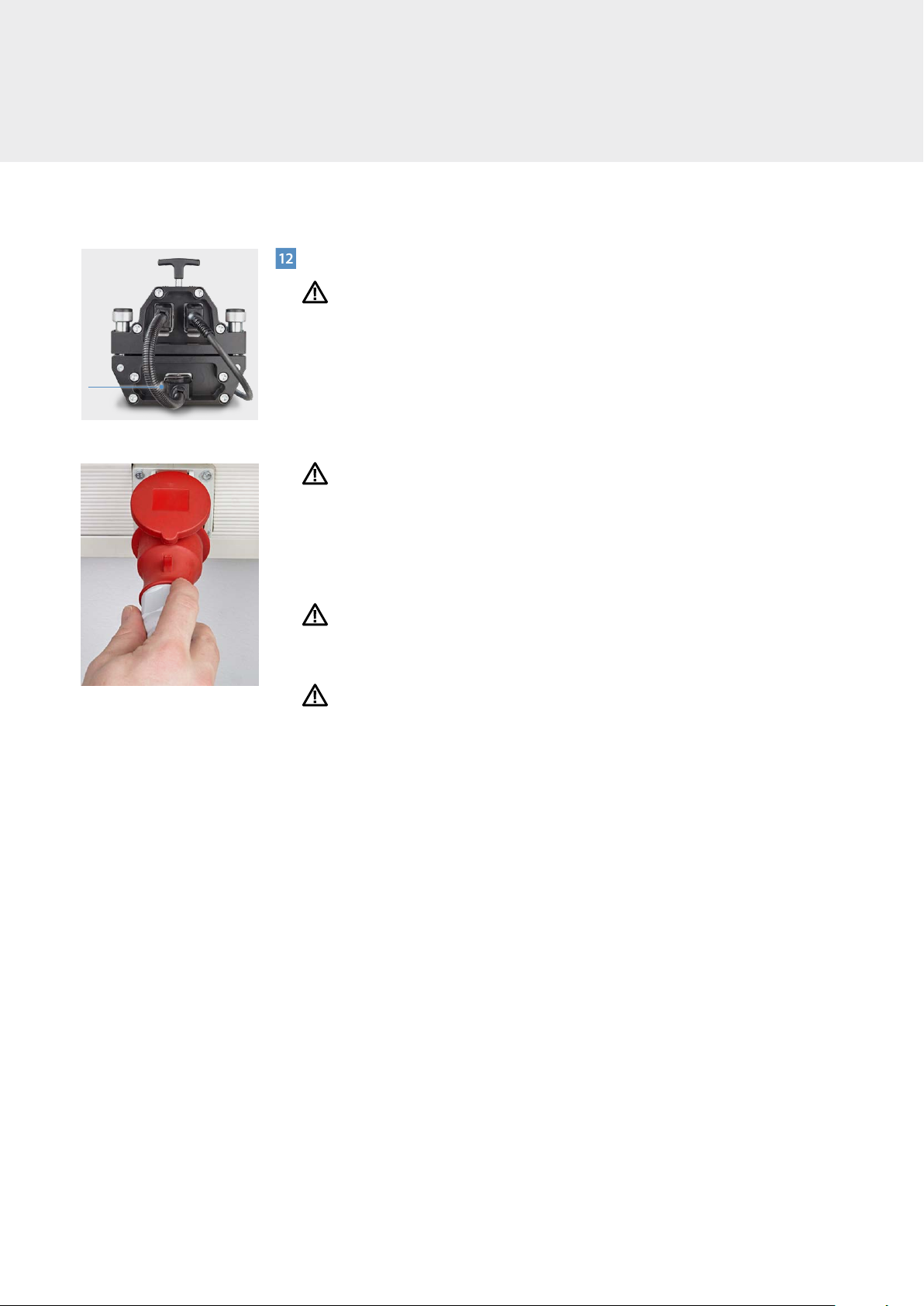

12

Connecting the power supply lead to the heating press (Fig. 11)

Warning

It is very important that the power cable is connected to the heating press first and

then to the socket. Doing this in reverse order could cause a fatal electric shock and

dangerous electrical arcing.

a. Pull the power supply lead’s plug out of the power outlet at the bottom of the

device.

b. Lock the plug in place. If the plug is not locked in place, the power supply to the

heating press might be temporarily interrupted.

Danger

c. Double check to ensure that the voltage and connections are appropriate for the

power supply lead. Incorrect or too much voltage can cause serious damage to the

heating press and accidents (e.g. a short circuit or a fire to break out if a 230-volt

cable is connected to a 460-volt socket).

d. Now insert the power supply lead into the appropriate socket. (Fig. 12)

Important

Only plug the power supply lead into the socket once it has been connected to the

heating press.

Danger

e. If you connect a plug to a bare power lead or a permanently fitted cable, you must

always comply with the wiring diagram for the power supply lead shown on

page 30. Ensure that the right wiring diagram is used for the lead concerned. Ensure

that the right plug is used. This may only be done by qualified personnel.

The heating press has three controls:

1. Temperature control on the top part of heating press to adjust:

The heating temperature at the top (200°C max.), pre-heat temperature at the top.

2. Temperature control on the bottom part of the heating press to adjust:

The heating temperature at the bottom (200°C max), dwell time,

pre-heat temperature at the bottom and cooling temperature.

3. Pressure control switch on the bottom part of the press. This controls the pressure

of up to 2.5 bar.

14

13

Configuring the parameters

The Blizzard heating press has two digital control units, a pressure switch and an air

bleeder knob. These components can be used to set all process parameters. (Fig. 13)

a. Digital control unit on the bottom part of the press

Control functions: – Heating temperature at the bottom and relevant dwell time

– Pre-heat temperature at the bottom and relevant dwell time

– Cooling temperature

Please refer to the following table to set the heating parameters:

b. Digital control unit for the top part of the press

Control functions: – Heating temperature at the top

– Pre-heat temperature at the top and relevant dwell time

– Parameters are entered in the same way as for the bottom part of the press’s digi-

tal control unit. The heating temperature’s dwell time and the cooling tempera-

ture are taken from the settings for the bottom part of the press. This means that

SoAK and AL-1 will not be shown.

c. Pressure switch

Select the required working pressure and maximum pressure deviation, which would

restart the compressor should pressure drop. (Forbo Movement Systems recom-

mends working pressure of -0.2 bar). As soon as the heating press is connected to

the mains, the display shows the current pressure, in other words 0 bar when idle.

Start button

Timer

Top

controller

Bottom

controller

Air bleeder

button

Pressure switch

Fig. 14

Function Key

Mode Key

Digit Key

Minus Key

Plus Key

Display nº 1

Display nº 2

Display 1 on the main screen (Fig. 14) shows the current temperature.

Display 2 shows the heating temperature selected (default: 173°C).

Before pressing the start button, display 1 shows StoP.

Adjusting the heating

temperature

Increasing temperature

Decreasing temperature

Jump to 1, 10 or 100 decimal places

Adjusting the pre-heat

temperature SP-0

LAdj

Use the arrow buttons and to adjust

the pre-heat temperature

Adjusting the dwell time

SoAK Use the arrow buttons and to adjust

the pre-heat temperature and dwell time (default:

240 s)

Adjust the dwell time’s

pre-heat temperature

W60-N

Use the arrow buttons and to adjust

the pre-heat temperature and dwell time

Cooling temperature AL-1 Back to the main screen StoP

Press the arrow buttons and to adjust

the cooling temperature (default: 70°C)

Fig. 13

SAFE OPERATION

15

– Briefly press the SET button to access OUT1 (on). Then select the maximum

working pressure by pressing the + or – buttons (2.5 bar max.). (Fig. 15)

– Then briefly press SET again to access OUT1 (off). Then press the + or –

buttons to adjust the pressure at which the compressor switches on again to

achieve the working pressure set. This figure should be 0.2 bar lower than the

working pressure.

Warning

Make sure that this figure is 0.2 bar lower than the working pressure because the

pressure control could be damaged otherwise.

– Then press SET again for about 3 seconds. The main screen will then show the

current pressure.

The heating press has a pressure relief device that restricts maximum pressure

to 2.7 bar.

Warning

When the main screen is open, don’t press the SET button for a long period of time.

Otherwise, the screen will display Unt. In this case, press SET again for about 3 sec-

onds to return to the main screen.

d. Start button

Once all the parameters have been set and the belt is prepared, start the process

by pressing the button on the top part. This button will light up during the entire

process. (Fig. 16)

– Before pressing the start button, make sure that all the screws have been

tightened.

– As soon as the process has been completed and the fans switch off because the

heating press has reached the cooling temperature, a buzzer will indicate that

the process is finished. The buzzer must be deactivated manually.

e. Air bleeder knob

As soon as the process is finished, press the air bleeder knob to release the pressure.

Danger

Ensure that the start button has been switched off. Otherwise, the air compressor

will switch on again to generate pressure. This can cause injuries or damage the

heating press.

– If you want the press to repeat a process, just press the start button again and the

press will make another splice.

– Once the pressure has been released, carefully remove the top part of the heating

press.

– Once the mains plug has been pulled out of the heating press, the last splice’s

parameters are stored.

Fig. 16

Fig. 15

16

If you’ve chosen a Blizzard HP with an iCON app control, you can leave out step 13

and operate the Blizzard HP via the app. Point 14 describes how to do this. Otherwise

proceed to point 15.

14

Operating the Blizzard HP via the iCON app

a. Connecting with the iCON heating press

The Blizzard heating press with iCON has an extra module that the press uses to

generate a Wi-Fi signal. In order to control the heating press with your mobile device,

connect to the Wi-Fi network belonging to the press which is connected to the

power supply:

Wi-Fi network (SSID) iCON-XXXXXX

Wi-Fi password forboicon

Open a browser on your mobile device and enter the following address:

http://192.168.1.1

Depending on your mobile device’s operating system, we recommend using the

following

iOS: Safari Unix: Chrome

Android: Chrome Windows: Chrome

b. Logging in or creating a new user

Once you’ve entered your address in your browser’s address bar, you’ll be forwarded

to the log-in section (Fig. 17). Click on to choose the language required. The lan-

guage can be changed in the settings (section d). If you already have a user account

on this heating press, enter your e-mail address and click on Submit. Enter your pass-

word in the next screen that appears. If your log-in data is correct, you’ll be forward-

ed to the cockpit.

If you’re logging in for the first time (Fig. 18), enter your e-mail address that you’d like

to log in with in the future and press Submit. Once you’ve read and accepted the

terms of use (by clicking on terms of use)*, enter your name in the window and con-

firm by clicking on Submit. You will now be asked to provide a password. You will

then be able to log on as described above.

* Your data will only be stored in the iCON heating press’s own memory. The data won’t be

stored anywhere else. You can only enter your user data to log onto the heating press for

which you are a registered user.

SAFE OPERATION

Fig. 18

Fig. 17

17

c. Cockpit and options menu

Once you’ve logged in, you’ll be forwarded to the cockpit (Fig. 19). You can enter the

heating parameters here (section e), store them (section f) and retrieve recipes

already stored (section g).

You will find the and symbols in the top right-hand corner. The symbol

will display notifications, e.g. about missing entries. Clicking on will show the

log-out button. By clicking on in the top-left corner, you’ll access the options

menu (Fig. 20). This will give you access to the following menus:

Preferences Section d

Managing recipes Section g

Retrieving reports Section h

Managing belts Section i

Managing splice types Section j

View company account Section h

View current user data Section l

Selecting and managing customers Section m

Fig. 19

Fig. 20

18

d. Settings

You can reach the settings (Fig. 21) via the options menu (section c) and by clicking

on . You can enter the relevant language and time zone here.

To select the language, click on the dropdown menu in the top box under language.

You can choose between the following languages:

German English French Spanish

Italian Chinese Japanese Korean

You can select the time zone in the time zone section. Select the right one from the

dropdown menu.

Save your language and time zone by clicking on the submit button.

e. Configuring the parameters

You can enter the heating parameters in the cockpit (Fig. 22). Each of the parameters

are explained in the table below:

Click on the buttons and a box will appear where you can add your entry (Fig. 23).

Clicking on confirms the entry you have made and sends it to the heating press.

Enter the air pressure for the heating procedure. To do so, click in the appropriate box

(Fig. 24). Please note that for safety reasons, the air pressure must be set manually on

the press control unit. The air pressure entered into the iCON control unit appears on

the heating procedure report (section h).

Name Top/bottom part

of the heating press Meaning

SP

Top part of the press

Heating temperature

SP_0 Pre-heat temperature

W6ON Pre-heat temperature dwell time

SP

Top part of the press

Heating temperature

SP_0 Pre-heat temperature

SOAK Heating temperature dwell time

W6ON Pre-heat temperature dwell time

AL_1 Cooling temperature

SAFE OPERATION

Fig. 21

Fig. 22

Fig. 23

Fig. 24

19

After entering the parameters, click in the belt & splice box to enter the belt type and

relevant splice. A dropdown list (Fig. 25) appears once you have clicked on Belt. You

can select an existing belt type here.

If the belt type is not on the list, click on next to the dropdown list. Now add the

article number and the name of the belt type in the window and click on Save. You

can then select the belt types in the dropdown list. Section i describes how to man-

age the stored belt types.

Proceed in the same way for the splice type. Click on splice on the belt & splice

menu and select the splice type from the dropdown list.

If it’s not there, add it by pressing (Fig. 26). Section j describes how to manage

the splice types.

Before starting the heating, enter your customer’s information or select an existing

customer (see section l). This is the only way of ensuring that these customer data

are displayed correctly on the report.

After entering all the data and parameters in the heating press, you can start the

heating procedure as usual by pressing the press’s start button. You can monitor the

procedure on your mobile device. (Fig. 27)

f. Storing recipes

Heating parameters can be stored for quick and easy retrieval in future. To store the

parameters, enter these into the home screen as described in section e.

Then click on (Fig. 28). A window will then open with a field for the name of the

recipe so that you can find it afterwards (pre-saved recipes are stored with “Article

Number Splice Type”, e.g. 900025 Z 70:11.5). Click on Submit to confirm you want to

save it. (Fig. 29)

Fig. 25

Fig. 26

Fig. 27

Fig. 28

Fig. 29

20

g. Retrieving and managing stored recipes

In order to retrieve recipes that you or the factory have stored, click on in the

cockpit to get to the recipe menu. Or you can click on i in the top left-hand cor-

ner. The options menu will then open (section c). Click on recipes to get to the recipe

menu. (Fig. 30)

This menu provides a list of all recipes stored on the heating press. You can use the

filter to find a recipe easily.

Click on one of the recipes to display all the relevant recipes and information. Click

on to confirm your selection and the data will be sent to the press. You will

then be sent to the home screen automatically. Click on to delete a recipe select-

ed.

After selecting a recipe, you can start the heating procedure as usual by pressing the

press’s start button. You can monitor the heating procedure on your mobile device

(Fig. 27).

h. Retrieving reports

The Blizzard iCON heating press logs every heating procedure in detail and stores it

automatically. Click on in the top left-hand corner to get to the options menu

(section c). Click on Reports to get to the menu required (Fig. 31).

SAFE OPERATION

Fig. 30

Fig. 31

Other manuals for siegling blizzard HP 160/400 AIR

1

This manual suits for next models

39

Table of contents

Languages:

Other Forbo Power Tools manuals

Popular Power Tools manuals by other brands

Edge Craft

Edge Craft Chef'sChoice 490 instructions

Panasonic

Panasonic EY7440 - DRILL DRIVER 14.4V- MULTI-LANG operating instructions

Hakko Electronics

Hakko Electronics FR400-53 instruction manual

Bosch

Bosch PKP 7 Original instructions

MasterCraft

MasterCraft 058-9847-6 operating manual

Skil

Skil SHD77-02 Operating/safety instructions