Sovereign M1Q-DD7-55BD User guide

450W JIGSAW

Item No. 594446

Model No. M1Q-DD7-55BD

HHGL Limited, MK9 1BA; HHGL (ROI) Limited, D02 X576 Mar 21

ORIGINAL INSTRUCTION MANUAL

Please read these instructions fully before starting assembly.

www.coreservice.co.uk

Technical Support & Parts

01904 727509

Mon-Fri 9am-5pm Sat-Sun 11am-4pm

2

CONTENTS

Contents 2

General safety warnings 3

Warning symbols 10

In the box 11

Operation 12

Maintenance and storage 16

Technical data 17

Recycling and disposal 19

UK plug 19

Getting help 20

Warranty 20

3

GENERAL SAFETY INFORMATION

WARNING! Read all safety warnings,

provided with this power tool.

Failure to follow all instructions listed below

injury.

Save all warnings and instructions for future

reference.

The term "power tool" in the warnings refers to your

mains-operated (corded) power tool or battery-

operated (cordless) power tool.

1) Work area safety

a. Keep work area clean and well lit. Cluttered or

dark areas invite accidents.

b. Do not operate power tools in explosive

atmospheres, such as in the presence of

flammable liquids, gases or dust. Power tools

create sparks which may ignite the dust or fumes.

c. Keep children and bystanders away while

operating a power tool. Distractions can cause

you to lose control.

2) Electrical safety

a. Power tool plugs must match the outlet. Never

modify the plug in any way. Do not use any

adaptor plugs with earthed (grounded) power

4

tools. Unmodified plugs and matching outlets will

reduce risk of electric shock.

b. Avoid body contact with earthed or grounded

surfaces, such as pipes, radiators, ranges and

refrigerators. There is an increased risk of electric

shock if your body is earthed or grounded.

c. Do not expose power tools to rain or wet

conditions. Water entering a power tool will

increase the risk of electric shock.

d. Do not abuse the cord. Never use the cord for

carrying, pulling or unplugging the power tool.

Keep cord away from heat, oil, sharp edges

or moving parts. Damaged or entangled cords

increase the risk of electric shock.

e. When operating a power tool outdoors, use an

extension cord suitable for outdoor use. Use of

a cord suitable for outdoor use reduces the risk of

electric shock.

f. If operating a power tool in a damp location

is unavoidable, use a residual current device

(RCD) protected supply. Use of an RCD reduces

the risk of electric shock.

3) Personal safety

a. Stay alert, watch what you are doing and

use common sense when operating a power

tool. Do not use a power tool while you are

tired or under the influence of drugs, alcohol

5

or medication. A moment of inattention while

operating power tools may result in serious

personal injury.

b. Use personal protective equipment. Always

wear eye protection. Protective equipment, such

as a dust mask, non-skid safety shoes, hard hat, or

hearing protection used for appropriate conditions

will reduce personal injuries.

c. Prevent unintentional starting. Ensure the

switch is in the 'off' position before connecting

to power source and/or battery pack, picking

up or carrying the tool. Carrying power tools

with your finger on the switch or energising power

tools that have the switch on invites accidents.

d. Remove any adjusting key or wrench before

turning the power tool on. A wrench or a key left

attached to a rotating part of the power tool may

result in personal injury.

e. Do not overreach. Keep proper footing and

balance at all times. This enables better control

of the power tool in unexpected situations.

f. Dress properly. Do not wear loose clothing or

jewellery. Keep your hair, clothing and gloves

away from moving parts. Loose clothes, jewellery

or long hair can be caught in moving parts.

g. If devices are provided for the connection of

dust extraction and collection facilities, ensure

these are connected and properly used. Use of

these devices can reduce dust-related hazards.

6

h. Do not let familiarity gained from frequent use

of tools allow you to become complacent and

ignore tool safety principles. A careless action

can cause severe injury within a fraction of a

second.

4) Power tool use and care

a. Do not force the power tool. Use the correct

power tool for your application. The correct

power tool will do the job better and safer at the

rate for which it was designed.

b. Do not use the power tool if the switch does

not turn it on and off. Any power tool that cannot

be controlled with the switch is dangerous and

must be repaired.

c. Disconnect the plug from the power source

and/or the battery pack from the power tool

before making any adjustments, changing

accessories, or storing power tools. Such

preventive safety measures reduce the risk of

starting the power tool accidentally.

d. Store idle power tools out of the reach of

children and do not allow persons unfamiliar

with the power tool or these instructions

to operate the power tool. Power tools are

dangerous in the hands of untrained users.

e. Maintain power tools. Check for misalignment

or binding of moving parts, breakage of parts

and any other condition that may affect the

power tools operation. If damaged, have the

7

power tool repaired before use. Many accidents

are caused by poorly maintained power tools.

f. Keep cutting tools sharp and clean. Properly

maintained cutting tools with sharp cutting edges

are less likely to bind and are easier to control.

g. Use the power tool, accessories and tool bits,

etc., in accordance with these instructions,

taking into account the working conditions and

the work to be performed. Use of the power tool

for operations different from those intended could

result in a hazardous situation.

h. Keep handles and gripping surfaces dry, clean

and free from oil and grease. Slippery handles

and gripping surfaces do not allow for safe

handling and control of the tool in unexpected

situations.

5) Service

a) Have your power tool serviced by a qualified

repair person using only identical replacement

parts. This will ensure that the safety of the power

tool is maintained.

8

ADDITIONAL SAFETY WARNINGS FOR JIGSAWS

a. Hold the power tool by insulated gripping

surfaces, when performing an operation where

the cutting accessory may contact hidden

wiring. Cutting accessory contacting a “live “wire

may make exposed metal parts of the power tool

“live” and could give the operator an electric shock.

b. Use clamps or another practical way to

secure and support the workpiece to a stable

platform. Holding the workpiece by hand or

against your body leaves it unstable and may lead

to loss of control.

c. Keep hands away from the sawing range. Do

not reach under the workpiece. Contact with the

saw blade can lead to injuries.

d. Apply the machine to the workpiece only

when switched on. Otherwise there is danger

of kickback when the cutting tool jams in the

workpiece.

e. When sawing, the base plate must always

face against the workpiece. The saw blade can

become wedged and lead to loss of control over

the machine.

f. When the cut is completed, switch off the

machine and then pull the saw blade out of the

cut only after it has come to a standstill. In this

manner, you can avoid kickback and can put down

the machine securely.

9

g. Use only undamaged saw blades that are in

perfect condition. Bent or dull saw blades can

break, negatively influence the cut, or lead to

kickback.

h. Do not brake the saw blade to a stop by

applying side pressure after switching off.

The saw blade can be damaged, break or cause

kickback.

i. Do not support the workpiece with your hand

or foot. Do not touch objects or the floor with the

saw running: Danger of kickback.

j. Use suitable detectors to determine if utility

lines are hidden in the work area or call the

local utility company for assistance. Contact

with electric lines can lead to fire and electric

shock. Damaging a gas line can lead to explosion.

Penetrating a water line cause property damage or

may cause an electric shock.

k. When working with the machine, always hold

it firmly and provide a secure stance.

10

WARNING SYMBOLS

Warning!

Read the instructions

Wear ear protection

Wear eye protection

Wear a dust mask

Class II tool

The product complies with the applicable European

directives, and an evaluation method of conformity

for these directives was done.

Recycle unwanted materials instead of disposing

of them as household waste. All tools, hoses

and packaging should be sorted, taken to the

local recycling centre and disposed of in an

environmentally safe way.

The product complies with the applicable UK

directives, and an evaluation method of conformity

for these directives was followed.

11

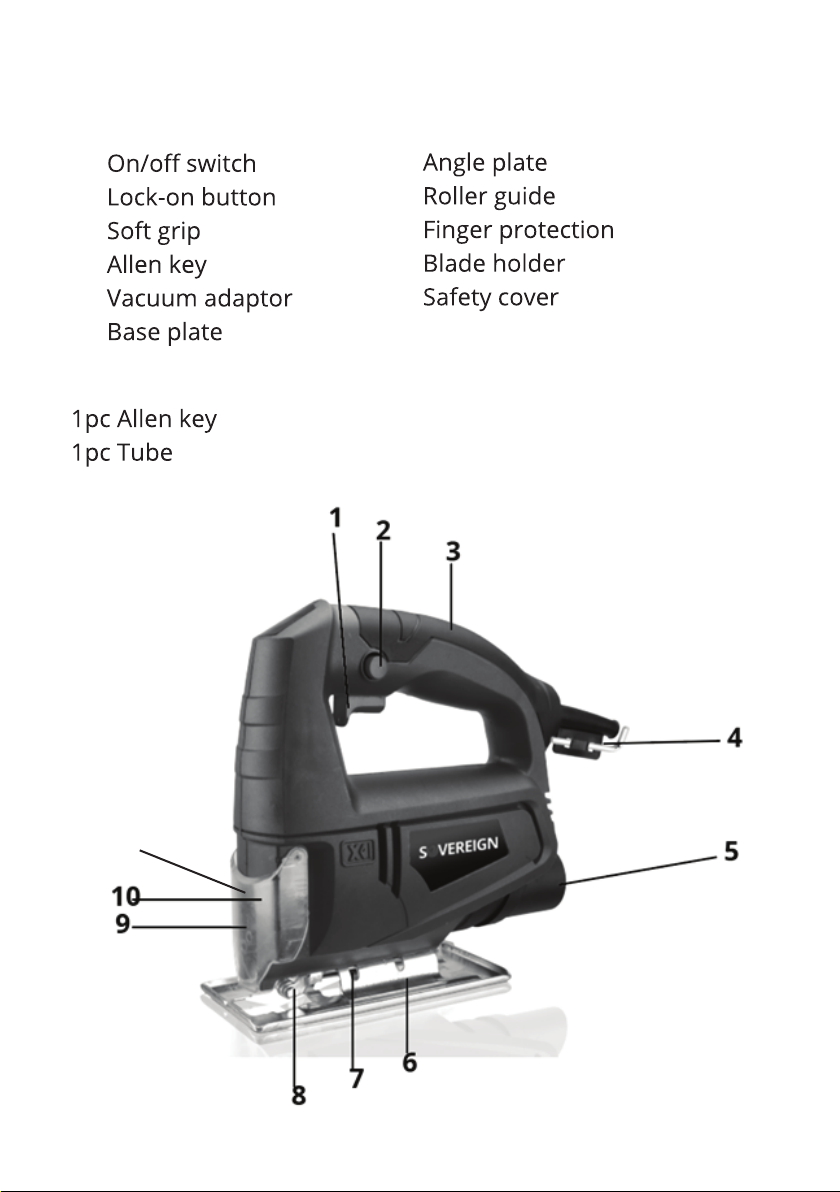

IN THE BOX

Description

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

Accessories

11

12

OPERATION

NOTE: Before using the tool, read the

instruction book carefully.

Intended Use

The machine is intended for sawing wood, plastic, metal and

building materials while resting firmly on the workpiece. It is

suitable for straight and curved cuts with bevel angles to 45°.

The saw blade recommendations are to be observed.

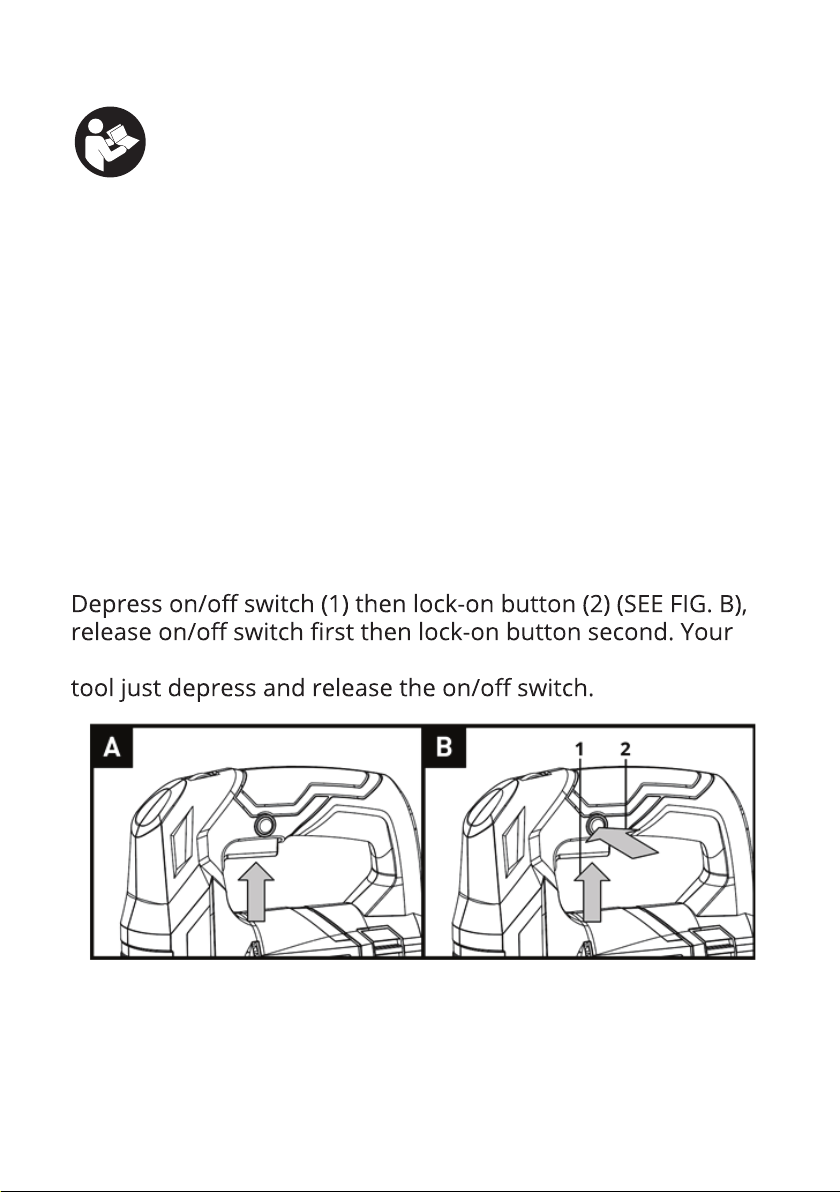

1. ON/OFF SWITCH

Depress to start, and release to stop your tool. (SEE FIG. A)

2. SWITCH LOCK-ON BUTTON

switch is now locked on for continuous use. To switch off your

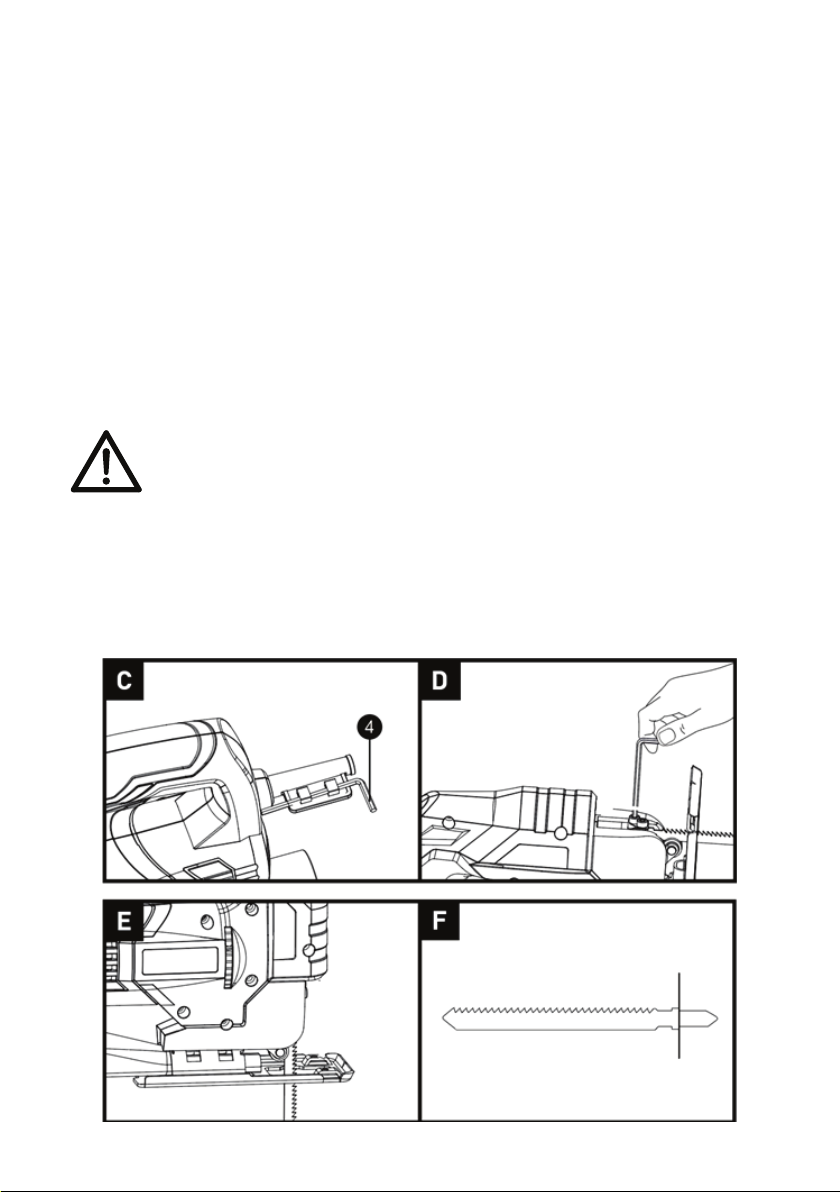

3. ALLEN KEY STORAGE

The Allen key is located at the power cable sheath (SEE FIG. C).

13

4. BLADE FITTING (SEE FIG. D)

NOTE: Remove the plug from the socket before carrying out

any adjustment, servicing or maintenance.

To fit the blade, firstly raise the finger protection and use the

Allen key provided to loosen the blade set screws on the blade

holder. The blade’s cutting edge should be facing forward.

Insert the blade’s mounting portion into the groove in the

blade holder until it touches the bottom of the holder. Then

firmly tighten the set screw, as shown in Fig. D.

NOTE: To fit the blade firmly, do not insert the blade over the

line (SEE FIG. F).

WARNING! Blade teeth are very sharp. For best

cutting results, ensure you use a blade suited to the

material and cut quality you need.

5. ROLLER GUIDE (SEE FIG. E)

Ensure the blade is located and runs smoothly in the groove

(SEE FIG. E).

14

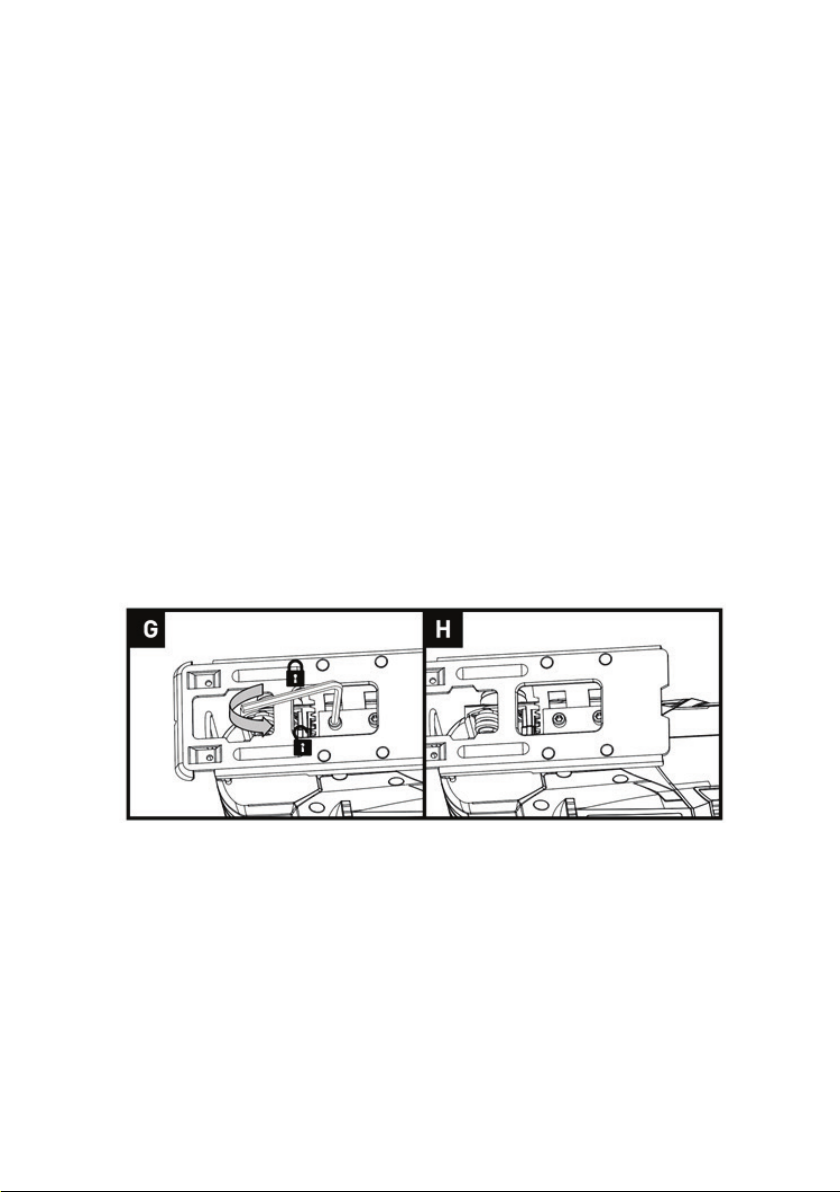

6. BASE PLATE ANGLE ADJUSTMENT

Adjusting the angle of the base plate enables bevel cutting.

The base plate must always be held firmly against the

materials being cut to reduce saw vibration, blade jumping or

blade breakage.

Use an Allen key (4). Loosen the bolts securing the base plate

(SEE FIG. G). For preset angles, rotate so the lines of the angle

on the base plate and angle plate (8) superposition at the

desired angle (0°, 15°, 30°, 45°) (SEE FIG. H). For other mitre

angles, rotate to your desired angle (use a protractor scale).

Following one of the above procedures, hold the base plate in

position and firmly tighten the bolts to clamp the base plate at

that angle. Finally, check the angle and ensure the base plate

is firmly clamped. The angle markings on the base plate are

accurate for most general purposes, but it is recommended

for accurate work to set the angle with a protractor and make

a test cut on other material.

15

7. DUST TUBE (SEE FIG. I)

Mount the dust tube (5) into the opening of the base plate

(6). Make sure that the plastic tip of the vacuum connection

engages into the corresponding opening on the housing (as

shown in the figure I).

8. METAL CUTTING

Use a finer tooth blade for ferrous metals, and a coarse tooth

blade for non-ferrous metals.

When cutting thin sheet metals, always clamp wood on both

sides of the sheet to reduce vibration or tearing of the sheet

metal. Both wood and sheet metal must be cut. Do not force

the cutting blade when cutting thin metal or sheet steel, as

they are harder materials and will take longer to cut. Excessive

blade force may reduce the life of the blade or damage

the motor. To reduce heat during metal cutting, add a little

lubricant along the cutting line.

16

MAINTENANCE AND STORAGE

IMPORTANT:

Make sure that the tool has been thoroughly cleaned

before storing it in a clean, dry and safe place, out of

the reach of children.

1. Switch the product 'OFF' and disconnect it from the power

supply before transporting it anywhere.

2. Always carry the product on its gripping surfaces.

3. Protect the product from any heavy impact or strong

vibrations which may occur during transportation in

vehicles.

4. Secure the product to prevent it from slipping or falling

over.

17

TECHNICAL DATA

Model M1Q-DD7-55BD

No-load speed

Max. cutting depth 55mm wood, 6mm metal

Protection class

Weight 1.7kg

Noise and vibration data

A weighted sound pressure (LpA) 90 dB(A), k=3dB(A)

A weighted sound power (LwA) 101 dB(A), k=3dB(A)

Vibrations ah,B

2 2

ahM

2 2

The sound intensity level for the operator may exceed 80

dB(A) and ear protection measures are necessary.

The declared vibration value has been measured in

accordance with a standard test method (according to EN

62841) and may be used for comparing one product with

another. The declared vibration value may also be used in a

preliminary assessment of exposure.

WARNING!

The vibration emission value during actual use of

the power tool can differ from the declared value

depending on the ways in which the tool is used and

dependant on the following examples and other

variations on how the tool is used:

How the tool is used and the materials being cut or

drilled.

The tool being in good condition and well maintained.

The use the correct accessory for the toolandensuring

it is sharp and in good condition.

The tightness of the grip on the handles and if any

anti-vibration accessories are used.

18

And the tool is being used as intended by its design

and these instructions.

This tool may cause hand-arm vibration syndrome

if its use is not adequately managed.

WARNING! To be accurate, an estimation of exposure

level in the actual conditions of use should also take

account of all parts of the operating cycle, such as

the times when the tool is switched off and when it is

running idle but not actually doing the job. This may

significantly reduce the exposure level over the total

working period.

Helping to minimise your vibration exposure risk.

Maintain this tool in accordance with these instructions

and keep well lubricated (where appropriate).

If the tool is to be used regularly then invest in anti-

vibration accessories.

Plan your work schedule to spread any high vibration

tool use across a number of days.

19

RECYCLING AND DISPOSAL

Waste electrical products should not be disposed with

household waste. Please recycle where facilities exist.

Check with your local authority or retailer for recycling

advices.

UK PLUG

instructions below.

IMPORTANT: The wires in the mains lead are coloured in

accordance with the following code: Blue–Neutral, Brown–Live

WARNING! Never connect live or neutral wires to the

BS1363/A plug and the correct rated fuse.

As the colours of the wire in the mains lead of this product

may not correspond with the coloured markings identifying

the terminals in your plug, proceed as follows: The blue wire

must be connected to the terminal marked N or coloured

black. The brown wire must be connected to the terminal

marked L or coloured red.

5

20

GETTING HELP

Our dedicated UK-based customer helpline is open 7 days a

week to assist you with assembly, parts queries and technical

are here to get you back enjoying your garden in no time.

For useful assembly, starting and maintenance videos, and

ordering spares, please visit www.coreservice.co.uk.

WARRANTY

This product is covered by a 1 year warranty.

The warranty covers any manufacturing defect in materials,

Any claim under this warranty must be made by going to your

nearest Homebase store, taking your proof of purchase with

you, and claims must be made within 12 months of the date

of purchase.

under the Consumer Rights Act 2015.

This warranty is given by HHGL Limited, MK9 1BA; HHGL (ROI)

Limited, D02 X576.

Please note: This warranty does not apply to products

misused or neglected and only covers domestic use. It does

not apply to commercial use of the product. In addition, the

warranty will be void for the following reasons: Any damage

resulting from product misuse or product neglect.

This manual suits for next models

1

Table of contents

Other Sovereign Power Tools manuals