SP Systems Yard Tender 189 User manual

1618 Stanford Street, Suite "C", Santa Monica, CA 90404 (310) 449-1492 FAX: (310) 449-6912

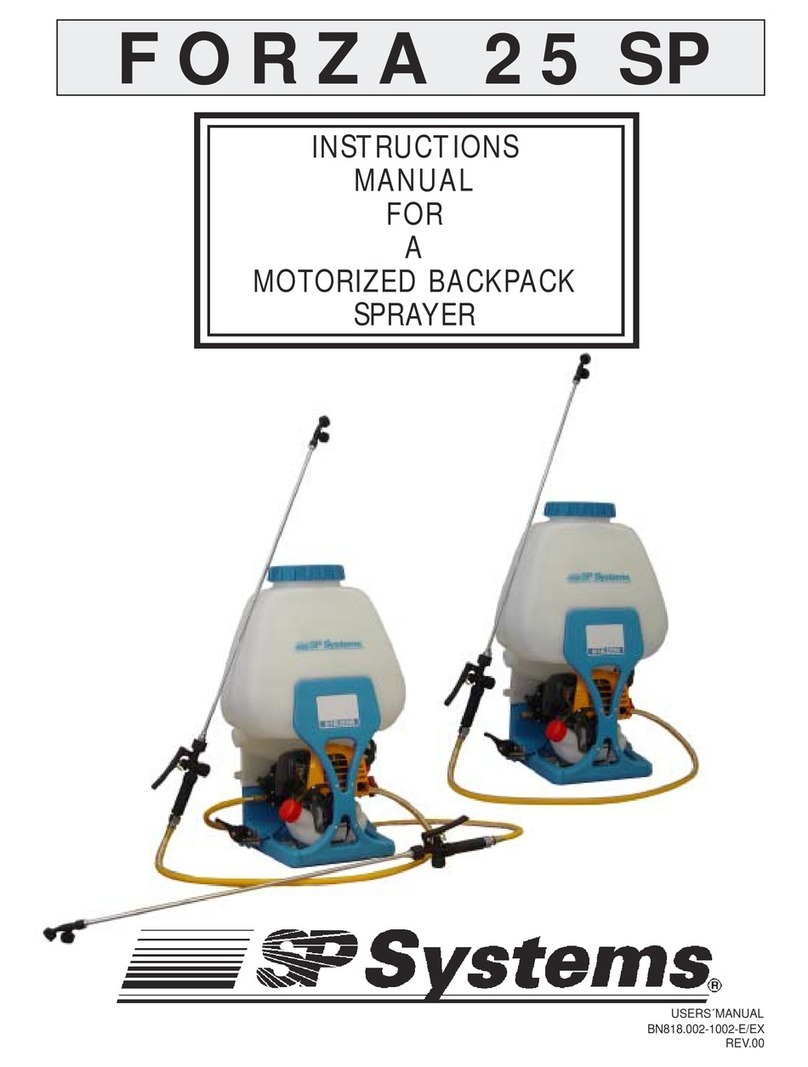

INSTRUCTIONS

Yard Tender 189

Congratulations on the purchase of the

Yard Tender 189

. These sprayers allow the easiest and most

comfortable way for all spraying projects. These units have been skillfully engineered to all but eliminate

the problems inherent in most sprayers. It is strongly recommend you carefully read and follow all the

information on this sheet before using, and then save for future reference.

Included in the box, please find the following:

1) PUMP HANDLE & PUMP LEVER.

2) SPRAYER (Pump Module installed).

3) SPARE PARTS (bag with locking pins & washer).

The pump handle is made of a tubular steel with a plastic grip

on one end, and a round tube welded to the opposite side at

right angle. The flat bar has a hole 1/2" in diameter. This hole

is located 2 1/4" from the round tube. (See figure 1).

Thepumpleverismadeofa1/2"solidroundsteelbarwithtwo

bends, one on either side of the bar. (See figure 1).

Pump module is installed in the sprayer. Now proceed to

install pump handle and lever.

Pull sprayer, pump lever, pump handle, spray wand, plastic

bag (with washers and pins), etc. out of box. Place parts in

front of you. Take the pump lever, there are bends on either

side. (See figure 2). Place one washers through the bar, then

push lever through opening on pump, place washer on pump

lever and then place hairpin lock and push through.

On the same side where the pump is located, place the round

portionof the pumphandle through thehole on thebase of the

sprayer. When it is almost through, place the bent portion of

the pump lever through the hole on the flat portion of the

handel. Once through, place on one washer and then the

lockingpin. (Seefigure3). Theroundtubecomesthroughthe

baseof the unitand extendsout 1/4", exposingthe holedrilled

through the tube. Place on the other washer and the other

holding pin. The pump handle assembly is now complete.

PUMPHANDLE

PUMP LEVER

PUMP MODULE

ASSEMBLY OF

PUMPHANDLE

PUMP LEVER &

PUMP MODULE

STRAPS

SPRAYWAND

AND NOZZLE

HOW TO PREPARE YOUR UNIT FOR USE:

1. Always oil the seal inside the cap of unit before using, as well as the check valve. This will extend life

of seal, and it is important for obtaining a leakproff barrier.

Hook the plastic clip attached to the shoulder straps into the appropriate lateral

opening on the base of unit.

Attach spray wand to spray gun and firmly tighten. To adjust nozzle, tighten (turn

clockwise), cap for a fine atomized spray, or loosen (turn counter-clockwise), for a

coarser spray or solid stream.

THE SPRAYER IS NOW READY TO USE.

A unit that has been used with herbicides should never be used to spray insecticides, unless the sprayer has

been properly cleaned and all other chemicals neutralized. Failure to do this could cause you to kill plants

sprayed. Consult with the manufacturer of the chemicals in use for proper instructions.

Remove cap.

Mix solution in a separate receptacle, following manufacturer's directions on the container.

Pour pre-mixed solution into sprayer and fasten cap securely.

Place sprayer on back and pressurize by pumping approximately 5 to 11 times.

Normal working pressure should be from 25 psi to 40 psi. Too much pressure will waist chemical and over

apply, as well as causing potential damage to pump tube.

Pump occasionally to maintain the desired spraying pressure.

2.

3.

4.

5.

6.

7.

8.

1.

2.

3.

Remove cap and pour out any remaining spray solution. Rinse all parts thoroughly with clean water.

Leaving approximately one gallon of fresh water in the tank, pressurize and flush pumping system by

depressing trigger for at least 2 minutes. Then drain all remaining water from tank, and repeat this process

twotimes. Toproperlyneutralizechemicals,aneutralizingsolutionmentionedinthe"Trouble-Shooting"guide

should be used.

Always store tank clean and empty in a dry shaded location.

HOW TO CLEAN AND MAINTAIN:

1. Pullpumpmoduleoutofsprayer,emptypumpandwipeclean. Turnpumpmoduleupsidedown. Pistonisheld

in by a plastic screw, turn counter clockwise to unscrew. Remove old piston, place new piston on the plastic

supportpiece. Putpistoninplaceandhandtightenthescrew. Makesurenottolosethestainlesssteelorplastic

ball inside the pump module.

HOW TO CHANGE OUT THE PUMP PISTON:

DYT1890396T

Foraccuratemeasuredsprayoutput,askadistributorordealerabouttheminiatureregulatorwithgauge(KitB40).

With proper application of chemicals, the monies saved will pay for the regulator.

CAUTIONS

Failure to follow

manufacturers

recommendation

onuseandcareof

unit will void any

expressed or im-

plied warranty.

Please read and follow all instructions before using sprayer.

Before using, filling or cleaning any sprayer, read all parts of the operating instructions.

Makesuretosetupthesprayerexactlyasexplainedintheprintedoperatinginstructions,remindertagsand/or

stickers.

Wear protective clothing, respirator, gloves, eye protection, etc. whenever using, filling, or cleaning sprayer.

Periodically re-grease lid gasket as well as lid vent and pump cylinder, where applicable.

To ensure good performance, keep lid vent free of obstruction. Before and after each use, make sure all

connections are well tightened. Service and replace worn parts as required.

Read and follow all instructions of the chemical suppliers.

As a rule, mix your chemicals in a separate container from which to fill the sprayer. Do not mix formulas inside

thesprayer.Whereanexceptionismade(e.g.withliquidfertilizers),fillsprayerwithwaterBEFOREaddingthe

activeingredient.

Always sift formula through the screen. If there is no built-in strainer, use a screened funnel.

Never fill the sprayer with hot liquids. Max. 30ºC, or 85ºF.

Thissprayerismadetohandleagrichemicalsintheirusualwateroroilsolutions.Donotuseflammable,corrosive

or caustic solutions.

Never use gasoline or other flammable materials.

Before cleaning or servicing the sprayer, allow all pressure to escape. Do not store or transport sprayer under

pressure.

Aftereachuse,washthesprayer—includinghose,lanceandshut-offvalve—withplentyoffreshwater. Unless

sprayingistobecontinuedwithinhours,drainchemicalformulaandthoroughlyrinsethetankandallliquidducts.

Never store chemicals in your sprayer for any length of time.

Use the sprayer only for the kind of jobs for which it was designed. When in doubt, ask your dealer.

Do not leave the sprayer in reach of children or persons not qualified to handle it in proper fashion.

Whennotinuse—andespeciallyduringprolongedstorage—keepyoursprayerinaprotectedplaceawayfrom

direct solar heat.

Make sure the spray hose loops freely without kinking or squeezing.

Always use SP Systems original replacement parts.

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

Table of contents

Other SP Systems Paint Sprayer manuals