SP Systems FORZA 25 SP User manual

INSTRUCTIONS

MANUAL

FOR

A

MOTORIZED BACKPACK

SPRAYER

FORZA 25 SP

BN818.002-1002-E/EX

REV.00

USERS´MANUAL

Dear Customer:

Congratulations for purchasing one

of the best motorized

sprayers on the market.

To obtain best results,

we recommend you take a few minutes

to read and understand the instructions

for using the sprayer, as well as its care,

maintenance, and solutions guide to correct

any damages that your sprayer

could get.

Parts diagrams and disassembly of instructions

are also included for you to

order the necessary spare parts, should

your sprayer need them.

We again thank you

for your preference.

FEATURES

Doublepistonpumpthatsuppliesconstantandsufficientpressuretoyour

sprayer;additionally,itconsiderablyreducesvibrationsand pounding.

Centrifugalclutchthatgivesthepumpandthemotorindependenceto

easeignition,fillingof thefueltank,and forotheroperations.

Manufacturedwithaspeedreducingpinionthatextendstheusefullife

ofboththepumpandthemotor.

Flatfan and constantspraying nozzles withone hole only, to avoid

obstruccion,and that also offers good coverage andpenetration even in

densefoliage.

The hose can be placed on the left or the right side of the sprayer, as may be

convenient.Unitcanbeoperatedwithtwohoses(guns)withtwohands.

The center of gravity of the unit is very low; there fore, operator´s fatigue is

reducedtoaminimum.

Theunit´spartsareof thebestquality:

Agrichemicalstank:Highdensitypolyethylene

Back:Cushionedtoabsorbmotorvibrations

Supportstructure:Reinforced plastic,rust-resistantandlighttofacilitate

handling

Motorbase:Metalforlongerusefullife.

Pumpmaintenanceisveryeasy;itcanbetakenapartbylooseningthescrews,

to access the checks. Supply and exhaust valves manufactured of stainless

steeltolastlonger.

Motorwithelectronicignition,reliableeveninveryinclinedpositions;diaphragm

carburetor,fueltankbelow themotorforhigher security.

6.7 gallon, 25 litre, tank for applying herbicides, insecticides, pesticides,

fungicidesandfertilizers,etc.onanycrop.Alsofordisinfectinganimals,stables,

warehouses,etc.

!!

!!

!

!!

!!

!

!!

!!

!

!!

!!

!

!!

!!

!

!!

!!

!

!!

!!

!

!!

!!

!

!!

!!

!

1.- BEFORE IGNITION

1.1 Fillthe fuel tank with gasoline andoil. 4 cycle engines do notrequirean oil or

gasolinemixture.

1.2 Adjustthe hoseand nozzle connectionsperfectly.Make surethereare noseals

missing.

1.3 Verify that the filterand the tankdrain plug are securedbefore filling it.

1.4 Whenpreparing the mix,add water tohalf the tank;addthe chemical, andfill with

water.

2.- IGNITION

2.1 Liftthe choke leverandpump the primer locatednext to the fueltank a few times,

untilthefuel returntransparent hoseis filledup.

2.2 movethe accelerationlever upwards approximately onethird.

2.3 Pullthestartercorduntilthe motorturns on.

2.4 Openthe chokeslowly depending onthe motortemperature.

2.5 Onceturned on,move the chokeslowly toitslimit, whileyouobserve themotor

operation.

2.6 Leave the motor at low speed for some minuts before beginning the spray

work.

2.7 Ifthe motor doesnot turn on easily, takeoffthe sparkplug anddo the following:

a) Ensurethe sparkplugproduces sparks whenstarting.

b) Whenthere is toomuchgasoline flow, the sparkplugdampens. Dry it.

NOTE: Alwaysconsultthe instructionsmanual.

3.- SPRAYING

3.1Elect thedesiredpressure turning the ribbed knobclockwise(high) or

counterclockwise(low), deppending onthework to beperformed. Remember that to

applyherbicides, the pressure mustbelow.For fungicides, insecticides,andfoliaters,

higherpressure can beused.

3.2 Holdthe spray lancewell and begin thespraying operation.

3.3 Whenworking athigh pressures,preferably securethe gunleverwith the

continuousapplicationsafety latch.

4.- EQUIPMENT SHUT-OFF

4.1 Lowertheacceleratorlevercompletely, pushthe shut-offbuttonand themachine

willstop working.

5.-CLEANING

5.1 Emptythe residuesleft in thechemicals tank, usingthe drain outlet.

5.2 Fillthe tankwithcleanwater,runthe motora few minutes,pour outthewater untilit

istransparent. Thenturn themotor offand empty thetank completelyusing thedrain

outlet.This operationwill helpextend the lifeof theseals andpreventany obstruction

ofthe checks.

6.- MAINTENANCE

6.1Disconnectthesupply andreturn hoses fromthe pump looseningthe respective

clamps.

6.2 Takethe capsoffthe cylinder, loosening thescrews.

5.3When theequipment will notbe in usefor some time,emptythe fueltank.

6.3Takethe cylinderoffofthe pump.

6.4 Withdrawthesupplyand exhaustcheck valvesfrom thecylinder (theyare located

nextto the cap);wash the pieces ifnecessary.

6.5Takethe sealsoffthe cylinders(next to thepump);wash the piecesif necessary.

6.6 Replacethe checkvalvesin the sameposition they werelocated previously.

6.7 Replacethe capsand tightenthe screws firmly.

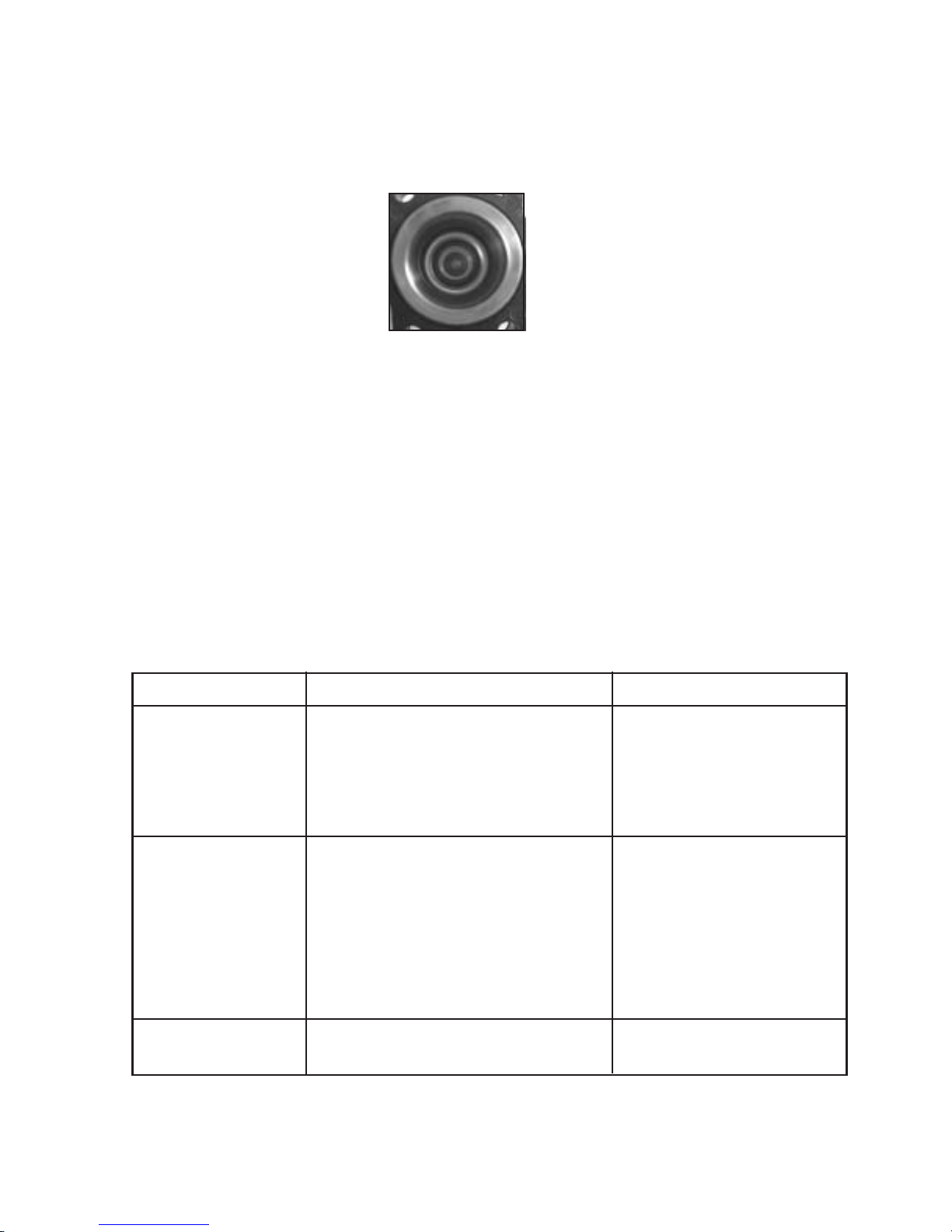

COMMON PROBLEMS AND POSSIBLE CORRECTIONS

PROBLEM CAUSE SOLUTION

1.- The mix does not

move a) Air intake through the supply hose

andcoupling.

b) Air intake in the cylinder, causing

pressureproblems.

c) Valve stuck to the seat.

Tighten the clamp securely to

the hose.

Open the knob for all the air to

come out.

Take the valve offandrepairit

followingthecorrectorder.

2.-Lackofpressure a) The pump does not suck the liquid.

b) Although liquid is suctioned, it does

notproduce a good spray.

c) Whenthe regulator valve or the seat is

scratched or full of dust.

d) The clutch skids.

See item 1:

Check the outflow of liquid. if it

is strong, change the nozzle.

Take the pressure regulator

valve or the seat if it is

scratched.

Increasethespeed of the

motor.

3.-Liquidand/or

Oringsareleaking Leakthrough seals. Change thefaulty seals and

rings.

SPECIFICATIONS

Model

Dimensions (L x A x H)

Weight

Liquid tank capacity

Pump

Type

Maximumflow

Pressure(BAR)

Nozzle type

Consumptionpernozzle

Hose

Motor

Type

Cylindercapacity

Maximumpower

Fuel tank

Carburator

Ignitionsystem

FORZA 25

6.7 gallons 25 litres

Electronic

Diaphragmtype

.30 GMP 1.16 lts./min. per nozzle (at 20 BAR)

NN-D-6(Widecoverage)

Doublepiston

9.9 Kg. with one gun 22.3

41x35x64cm.16.4x14x25.6

Int.diameter 7.5, BP 120 BAR, length 1250 mm

24.5 cc

0.88 kw/7000 RPM

0.6 litres

Duetotheinterestintechnologicalprogress,thecompanyreservesthe

righttomaketechnicalchangeswithoutpreviousnotice.

2.6 GPM 9.6 lts/min.

10-22 BAR (with a limit)

4 cycle air-cooled

www.spsystemsllc.com

1618 Stanford Street, Suite "C", Santa Monica, CA 90404

(310) 449-1492 (800) 457-3440 FAX (310) 449-6912

Table of contents

Other SP Systems Paint Sprayer manuals