North Star 2820 User manual

Other North Star Paint Sprayer manuals

North Star

North Star 282805 User manual

North Star

North Star M268180M User manual

North Star

North Star 2681022 User manual

North Star

North Star 999883 User manual

North Star

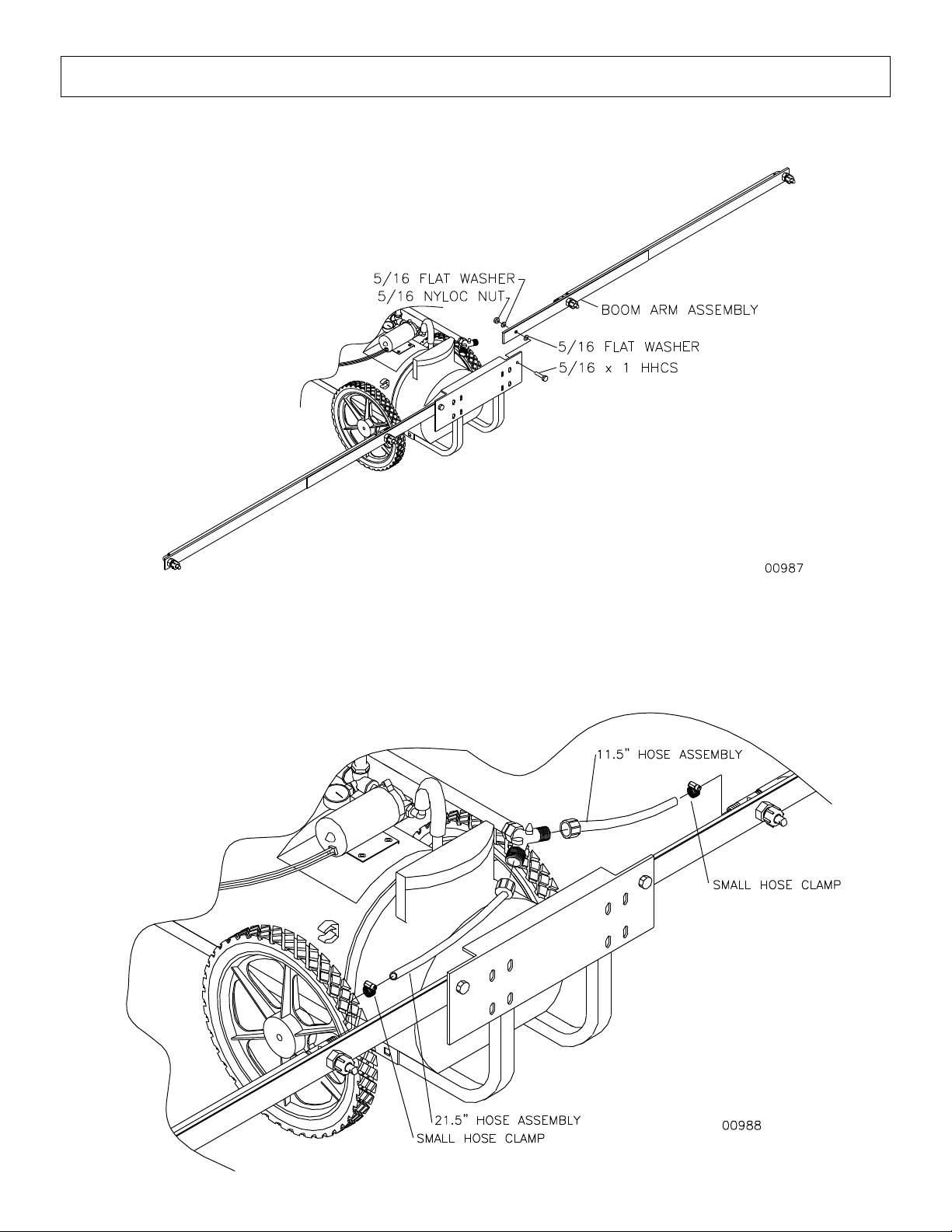

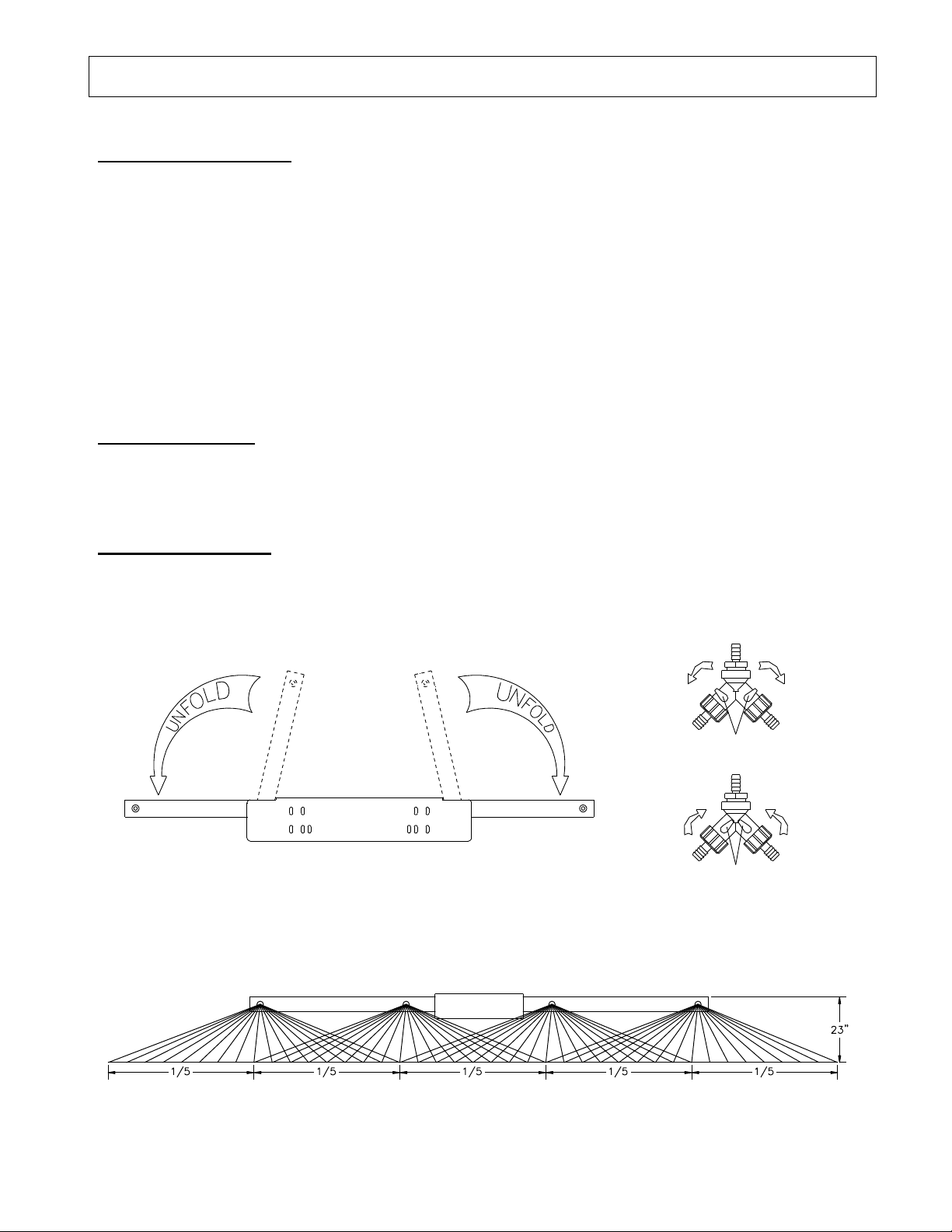

North Star M2681781B User manual

North Star

North Star M2681791A User manual

North Star

North Star MTBSL User manual

North Star

North Star 2851701 User manual

North Star

North Star 5042373 User manual

North Star

North Star 282795 User manual

Popular Paint Sprayer manuals by other brands

zogics

zogics Z-DAS instruction manual

KISANKRAFT

KISANKRAFT KK-KBS-165 Operation manual

Matrix

Matrix SG 650 Translation of the original instructions

Anest Iwata

Anest Iwata SGA-3 Installation, use & maintenance instruction manual

paasche

paasche VV Instructions and parts list

Carlisle

Carlisle DeVilbiss JGA-510 Service manual