18 SHOCKER CVO WWW.SHOCKERPAINTBALL.COM 19

PLEASE READ CAREFULLY PLEASE READ CAREFULLY

TROUBLESHOOTING TROUBLESHOOTING

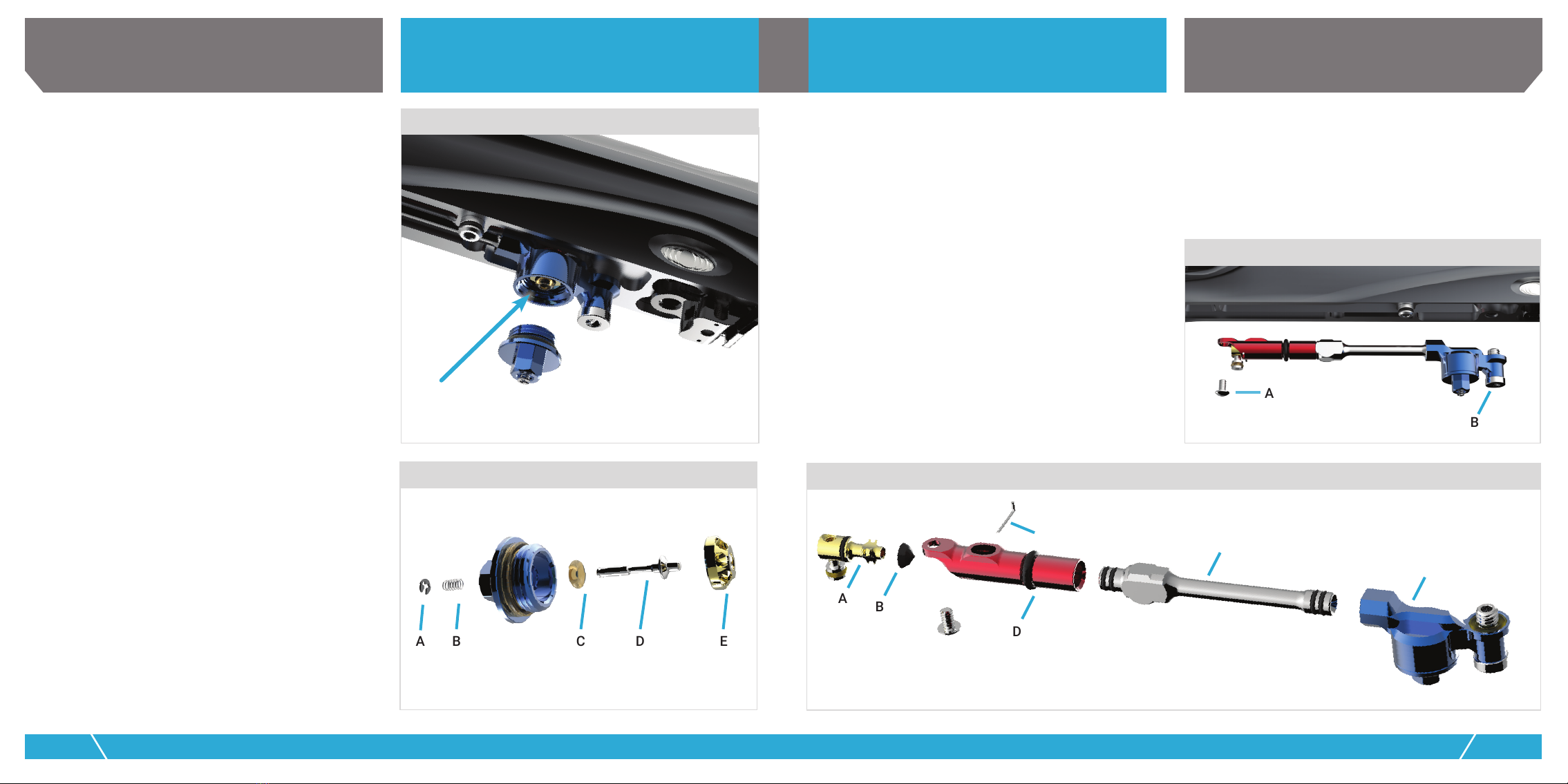

AIR LEAKS OUT THROUGH THE VELOCITY ADJUSTER.

•Damaged or worn seal in spring platform assembly causing

continuous leak - Inspect clean and if necessary replace o-rings

and relief valve seal from spring platform assembly following

the instructions in the Regulator section of this manual.

•Damaged or worn regulator piston or regulator base o-rings or

regulator seat causing intermittent leak - Damaged components

causing the regulator to “run hot” will result in the relief valve

repeatedly venting excess pressure through the velocity

adjuster. Inspect, clean and if necessary replace all regulator

o-rings and seals.

•Visit shockerpaintball.com for leak point images to identify

cause of leak.

AIR LEAKS OUT THROUGH THE MIDDLE REGULATOR VENT HOLE.

•One of the following o-rings is damaged or worn: regulator

piston o-ring, inner or lower outer regulator base o-ring - Clean

inspect and if necessary replace bad o-rings following the

instructions in the Regulator section of this manual.

•Visit shockerpaintball.com for leak point images to identify

cause of leak.

AIR LEAKS OUT THROUGH THE TOP REGULATOR VENT HOLE.

•One of the upper two regulator base o-rings is damaged or worn

- Clean inspect and if necessary replace bad o-rings following

the instructions in the Regulator section of this manual.

•Visit shockerpaintball.com for leak point images to identify

cause of leak.

AIR LEAKS OUT THROUGH THE LOWER REGULATOR VENT HOLE.

•Damaged or worn outer spring platform o-ring - Clean, inspect

and if necessary replace the outer spring platform o-ring

following the instructions in the Regulator section of this manual.

•Visit shockerpaintball.com for leak point images to identify

cause of leak.

THE TRIGGER DOES NOT MOVE WHEN PULLED.

•Trigger is out of adjustment - Adjust the trigger following the

instructions in the Trigger Adjustment section of this manual

•Loosen trigger pivot pin slightly.

WHEN GASSED UP AIR LEAKS FROM BETWEEN THE GRIP

FRAME AND BODY.

•Manifold assembly o-rings may be damaged or worn - Inspect,

clean and if necessary replace o-rings in the manifold assembly

following the instructions in the Bolt Control section of this

manual.

•Gas through seal is damaged or worn - Inspect, clean and

if necessary replace the gas-through seal following the

instructions in the Grip Frame section of this manual.

•Grip frame is not fully seated into body - Check to make sure the

grip frame is fully seated in the body. An improperly positioned

QEV pin may prevent the grip frame from fully seating.

WHEN GASSED UP, LITTLE OR NO AIR SEEMS TO BE

GETTING TO THE SHOCKER®.

•Bolt cannot move - Follow the Bolt Cleaning section of this

manual to clean and inspect the o-rings of the bolt system.

•Filter is clogged – see the grip frame removal section of this

manual to locate and inspect the lter at the gas through port.

BOLT ASSEMBLY WILL NOT SLIDE SMOOTHLY INTO BODY

OR LOCK IN PLACE.

•O-rings are damaged or un-seated - Follow the bolt cleaning

procedure and make sure all o-rings are in good condition and

properly seated. Also make sure there is no debris inside the

body. Pressing the bolt release button before the Shocker®

CVO has been de-gassed is a common cause of un-seated

o-rings and should be avoided.

WHEN GASSED UP, THE BOLT IMMEDIATELY CLOSES.

•Trigger is stuck in the ring position – Make sure that debris or

dirt has not jammed the trigger into the ring position. Clean

as needed to resolve.

•Trigger is mis-adjusted and is not releasing the pilot valve –

Make sure the trigger moves forward far enough to allow the

front of the activation lever to rise, releasing the pilot valve.

See the trigger adjustment section of this manual.

•QEV diaphragm is damaged or stuck open – See the bolt

control section of this manual.

•Pilot valve is leaking internally – Make sure pilot valve pin is

straight and unblemished, and that the lower internal pilot

valve o-ring is in good repair. See the pilot valve section of this

manual.

AIR LEAKS DOWN THE BARREL WHEN GASSING UP.

•One or more o-rings in the bolt system are damaged are worn

•Clean and inspect, following the instructions in the Bolt

Cleaning section of this manual. Pay special attention to the

inner o-ring of the chamber guide [FIG. 18C].

WHEN GASSED UP AIR LEAKS FROM THE BOTTOM OF THE

GRIP FRAME.

•One of the o-rings or face seal of the air rail seal assembly

is damage, dirty or missing. Inspect, clean and if necessary

replace these seals. See the ASA section of this manual.

SHOCKER®CVO WILL NOT FIRE WHEN TRIGGER IS PULLED.

• System is not pressurized with air – See the quick start section

of this manual.

•Safety is engaged – See the quick start section of this manual.

•Trigger is not engaging activation lever – See the trigger

adjustment section of this manual.

•Activation lever is stopped by post travel adjustment screw

before pilot valve is actuated – See the trigger adjustment

section of this manual.

GRIP FRAME WILL NOT FIT CORRECTLY TO BODY.

•QEV pin incorrectly aligned – Make sure the pin locking the

QEV body in place (see bolt control section of manual) is

correctly aligned. If it is pushed too far into the QEV, it will

extend out the other side and interfere with a ridge in the

grip frame.

•Trigger too far forward. The spring pressure of the activation

lever will push and lock the trigger into a forward position

that prevents the grip frame from tting to the body. Reset

the activation lever and hold the trigger in place following the

instructions in the grip frame section of this manual.

SHOCKER®CVO SUFFERS FROM FIRST SHOT DROP OFF.

•Shocker® CVO res at a low velocity or will not re on the

rst trigger pull after sitting still for a few minutes, but res

at proper velocity on all subsequent shots, this rst shot

drop off may be caused by dirt or under-lubrication. Degas,

disassemble, clean and inspect the bolt assembly following

the instructions in the Bolt Cleaning section of this manual.

SHOCKER®CVO IS BREAKING PAINT IN THE BREECH OR BARREL.

• Paint is too large for barrel - Check paint to barrel t and if

necessary switch to a larger bore FreakTM insert or smaller paint.

•Paint is inconsistent in size or shape - Old paint or paint that

is lumpy and out of round will not shoot well. Switch to fresh,

good quality paintballs.

•Turn bolt speed adjust screw in all the way (clockwise) to slow

down forward bolt speed.

•Ball detents are damaged or dirty - Inspect and clean the ball

detents as described in the Ball Detent section of this manual.

•Paint is brittle - Decreasing the bolt closing force will adapt the

Shocker®CVO to be extra gentle with brittle paintballs. See the

QEV Adjustment section of this manual.

•Loader is too slow - Upgrade to a force-feed loader or increase

the activation lever tension to its maximum setting (see trigger

adjustments).