1. The DP G3 Spec-R is NOT A TOY. Treat it with

the same respect and care you would a rearm.

2. Carelessness, misuse, and failure to adhere

to the warning and guidelines printed in this

Owner’s Manual may result in property damage,

injury, or death. User assumes all risks

associated with use of the DP G3 Spec-R.

3. Always ensure that proper safety gear - eyes,

face, ear, and head protection - conforming to

ASTM standard F1776 (USA) or CE (Europe)

are worn at all times when paintballs are within

range.

4. Persons under the age of 18 must have adult

supervision at all times during use of the G3

Spec-R, or any paintball ring device.

5. Observe all local and national laws regarding

rules and regulations.

6. The G3 Spec-R should only be used on a

permitted and regulated paintball eld where

safety rules and guidelines are strictly enforced.

7. Only use compressed air or nitrogen. DO NOT

USE CO2!

8. Only use high quality, .68 caliber paintballs.

9. Never point your G3 Spec-R at an unintended

target.

10. Always treat your G3 Spec-R as if it were

loaded.

11. Keep your G3 Spec-R turned OFF until ready to

use.

12. Always measure the velocity of paintballs from

your G3 Spec-R with a suitable chronograph

device before play.

13. Never look down the barrel or breech area of the

G3 Spec-R without rst ensuring that the marker

is switched to the OFF position, with NO AIR in

the marker.

NOTE- SEE NOTE ON PAGE 3 FOR DIRECTIONS ON

REMOVING RESIDUAL AIR FROM A POWERED ‘OFF”

MARKER.

WARNING

IMPORTANT SAFETY INSTRUCTIONS AND GUIDELINES!

14. Never put any body parts or foreign objects into

the breech or feed tube.

15. Always use the supplied barrel cover when your

G3 Spec-R is not in use at the eld. Doing so

will help secure the safety of yourself and those

around you.

16. Never allow pressurized gas to come into

contact with your body. Serious harm, injury, or

death may occur.

17. When not in use, always turn your G3 Spec-R to

the OFF position.

18. Promptly remove any paintballs from your G3

Spec-R when not in use.

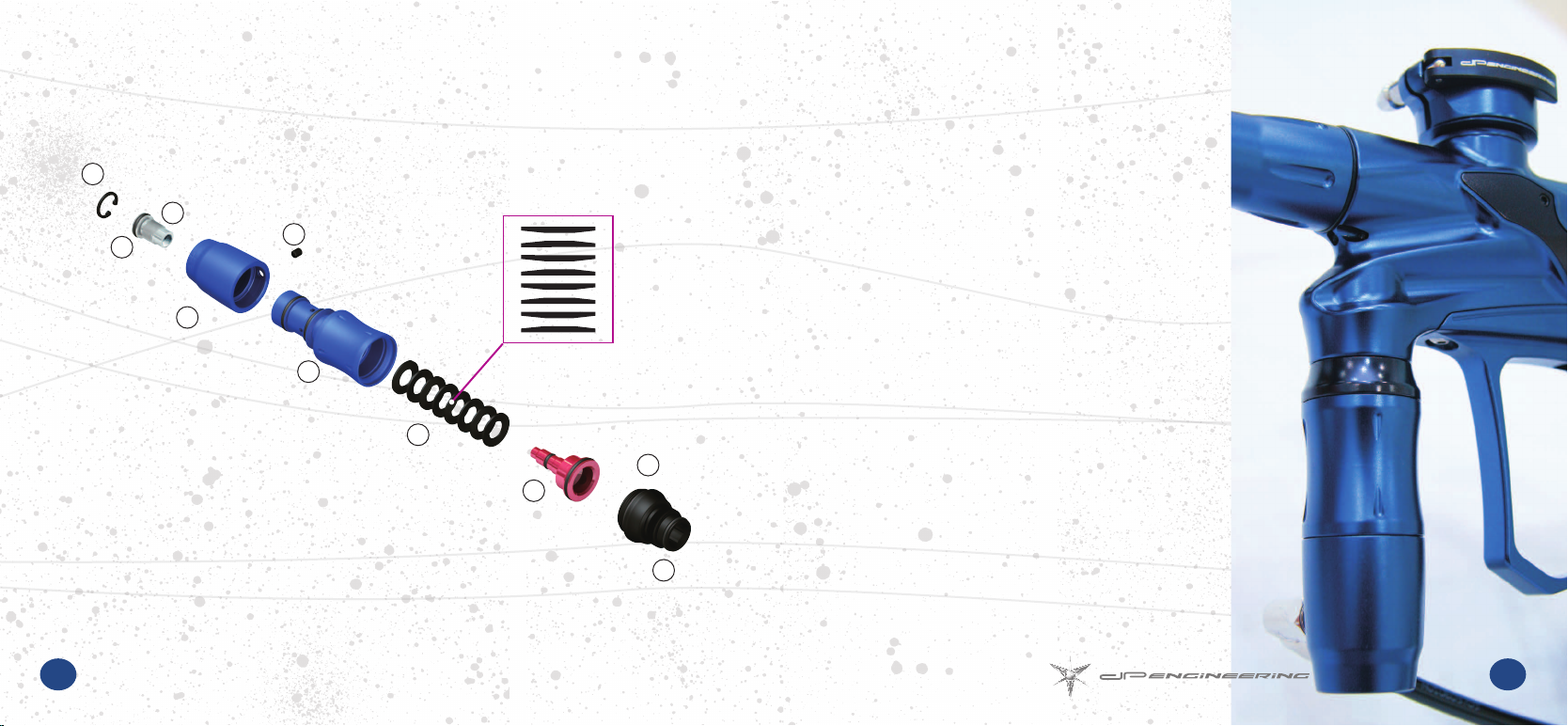

19. Always remember to remove residual air from

your G3 Spec-R before attempting maintenance

or service.

20. Always remember to remove residual air from

your G3 Spec-R before storage or

transportation.

NOTE- POWERING ‘ OFF’ THE MARKER WILL NOT

AUTOMATICALLY REMOVE RESIDUAL AIR. TO

SAFELY REMOVE RESIDUAL AIR, PLEASE DO THE

FOLLOWING:

A. Remove loader and paintballs from marker.

B. Turn Eye Sensors to the OFF position.

C. Point marker in a safe direction.

D. Fire marker until all residual gas is removed.

21. Always store your G3 Spec-R in a safe place.

22. Do not discard the Owner’s Manual. In the event

of transfer or resale, this guide must accompany

the marker.

23. When in doubt, ALWAYS seek expert advice

by contacting a reputable airsmith familiar with

paintball markers, or by contacting

DP Engineering’s Customer Service Staff.

WARNING

IMPORTANT SAFETY INSTRUCTIONS AND GUIDELINES!

WWW.DANGEROUSPOWER.COM

02 03