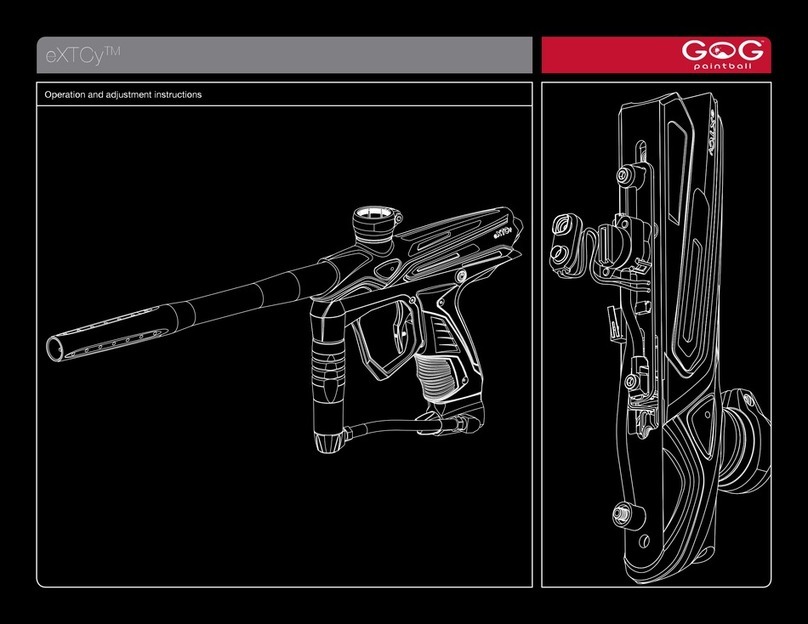

GOGpaintball.com

The EnvyTM has been designed with

simplicity in mind so that you can

concentrate on your game instead of your

marker. It has only one major moving part

in its valve system, with a minimal number

of seals. This DOES NOT mean that you

should neglect your EnvyTM. If you take care

of it off the eld, your EnvyTM will take care

of you on the eld. For best performance,

clean and grease your EnvyTM frequently.

Many players disassemble and clean their

EnvyTM after every day of use. While this

may seem a bit extreme, being vigilant in the

upkeep of your EnvyTM will extend its useful

life considerably, and catch any problems

when there is time to correct them before

the next game. Playing in the rain will not

damage your EnvyTM. In fact, the EnvyTM.

has been tested and proven to function

underwater. However, long-term exposure

to moisture can cause rust damage to some

of the EnvyTM’s screws, so if your EnvyTM

should become waterlogged, remove the

barrel, stock and rubber grips and allow

it to dry out, then follow the disassembly

instructions for full cleaning. Clean out mud

and paint with a damp cloth and alcohol.

Lubricate the EnvyTM ONLY with GR33SETM

pneumatic grease. Use fresh, high quality

paintballs for best performance.

REQUIRED ITEMS FOR MAINTENANCE

STATISTICS MAINTENANCE

WEIGHT:

OPERATING PRESSURE:

POWER SOURCE:

PROPELLANT:

RATE OF FIRE:

OPERATION:

MODES OF FIRE:

ANTI CHOP SYSTEM:

BARREL THREAD:

LUBRICANT:

1 lb. 11oz.

160 psi

9-volt Alkaline Battery

CO2 or Nitrogen/Compressed air

11 bps

Low pressure electropneumatic

Semi-Automatic, Billy-BallTM, PSP and Select Fire

Low-Force bolt

GOG®

For proper and consistent operation, the EnvyTM should

only be lubricated with GR33SETM lubricating grease.

• 0.050-inch Allen Wrench (included) Trigger Adjustment

• 5/64-inch Allen Wrench (included) - Battery Change

• 7/64-inch Allen Wrench (included)- Clamping Feedneck

• 1/8-inch Allen Wrench (included) - Stock/Backplate, Trigger

Adjustment, ASA, Grip, Breech and Circuit Board Screws

• 5/32-inch Allen Wrench (included) - Velocity Adjustment

• 5/16-inch Allen Wrench (included) - Bolt Sleeve

• Snap-Ring Pliers (purchase seperately) - Regulator

Disassembly (Advanced Maintenance)

• GR33SETM (purchase seperately) - Paintball Marker

Lubricant

GETTING FAMILIAR PLEASE READ CAREFULLY

02

REQUIRED ITEMS FOR USE

• 5/32-inch Allen Wrench (included) - Velocity Adjustment

• Chronograph (provided for use at commercial paintball

eld) - Velocity Adjustment

• Barrel Blocker (included)

• CO2 or HPA tank (purchase seperately)

• ASTM Compliant Paintball Goggles with Mask

(purchase seperately)

• 68 Caliber Paintballs

• Paintball Hopper/Loader (purchase seperately)

• 9-Volt Alkaline Battery