– 2 – P/N SCM2-0111

Model SCM Air to Water Heat Pump — Installation, Operation & Maintenance Manual

Hazard denitions

The following terms are used throughout this manual to bring

attention to the presence of potential hazards or to important

information concerning the product.

Indicates an imminently hazardous situation which,

if not avoided, WILL result in death, serious injury or

substantial property damage.

Indicates an imminently hazardous situation which,

if not avoided, COULD result in death, serious in-

jury or substantial property damage.

Indicates an imminently hazardous situation which,

if not avoided, MAY result in minor injury or property

damage.

Used to notify of special instructions on installation,

operation or maintenance which are important to

equipment, but not related to personal injury haz-

ards.

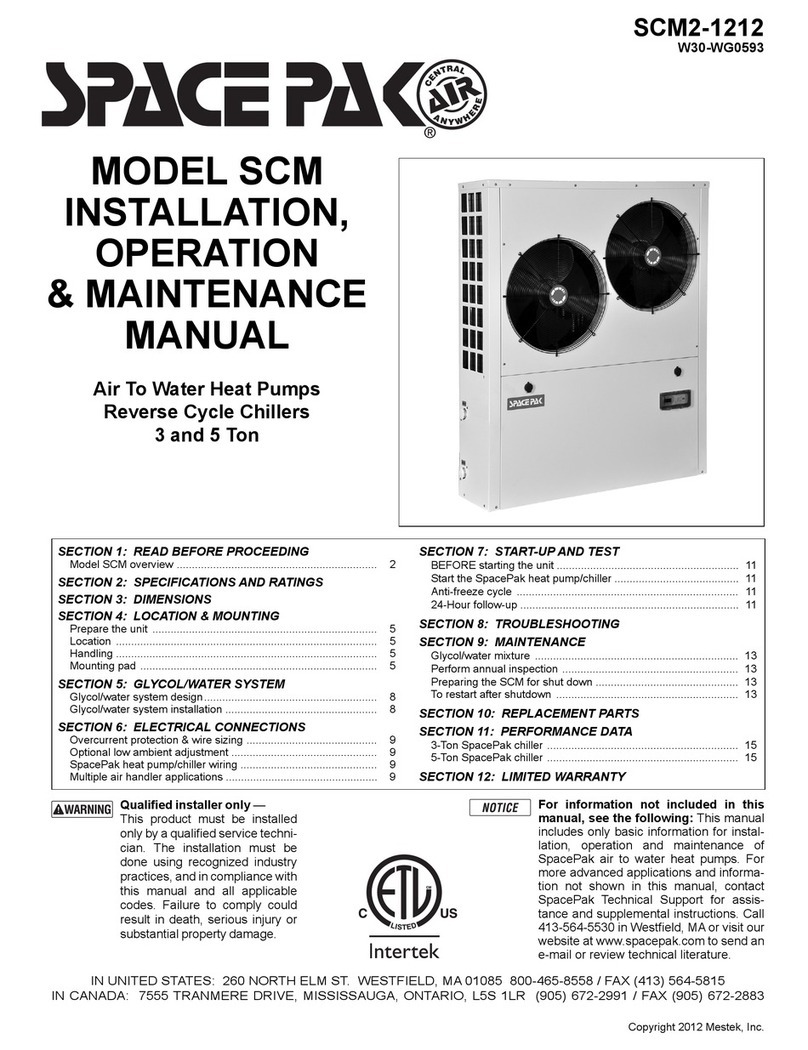

Model SCM overview

The SPACE PAK Model SCM Heat pump/chiller is a self

contained reverse-cycle heat-pump that provides a continuous

supply of heated or chilled water for various purposes, such as:

residential or small commercial building heating and cooling;

and specialty applications, such as computer room cooling or

industrial/agricultural conditioning and dehumidication.

Model SCM Chillers are available in three- and ve-ton nominal

capacities. Both use the same general design and operating

principals.

Each chiller contains TWO isolated refrigeration systems of

equal size to cool or heat the delivered water supply. The two

systems can operate individually or in tandem to achieve 50%

or 100% capacity. The major components of each system are:

• A hermetically sealed refrigeration compressor & motor.

• An outside coil to reject heat (in cooling) or absorb heat (in

heating) from the surrounding ambient air.

• A fan and motor to force air over the outside coil; a shell-

and-tube refrigerant-to-water heat exchanger to absorb heat

(in cooling) or supply heat (in heating) to the delivered water

ow.

• An electronic expansion valve to throttle the refrigerant ow

in both heating and cooling modes of operation, responding

to varying load on the system.

• Additionally, each system contains a reversing valve (to se-

lect between heating and cooling operation) and sensors

and safety circuits to monitor and protect the equipment from

potentially damaging or dangerous operating conditions.

A single water circuit connects both internal heat exchangers,

and contains sensors to measure entering and leaving water

temperatures. A mechanical ow switch safety ensures

continuous water ow while either of the two refrigerant systems

is operating. All components are contained within a supporting

structure and enclosure sufcient to allow stand-alone outdoor

installation in all temperate climates.

All operation and protections are managed by a microprocessor

controller which operates the individual systems, determines

all operating parameters, and monitors the condition of each

system. A simple interface communicates with the indoor air

handler, heat exchanger, or other load.

• This product must be installed in accordance with all appli-

cable codes. Where instructions in this manual differ from

specic local requirements, defer to the local codes.

• The electrical installation must also comply with the latest

edition of: in the U. S. — National Electrical Code ANSI/

NFPA No. 70; in Canada — CSA C22.1 Canadian Electrical

Code Part 1. Wiring must be N.E.C. Class 1. Use only cop-

per wire, rated for 120°F and sized for the load listed in this

manual.

• Electrical shock hazard — Disconnect all electrical power

before servicing the unit. Also, the unit must be grounded in

accordance with the Electrical Code listed above.

• Refrigeration system is factory charged with R410A refriger-

ant, and requires no additional service during installation. Any

repair, diagnosis or maintenance service to the refrigeration

system must be performed by a qualied technician. No alter-

nate refrigerants, lubricants or additives are approved for this

unit. Any use of alternate or non-approved materials in the re-

frigeration system may result in personal injury or equipment

damage, and will void the manufacturer’s warranty.

• The uid in the liquid side of the Model SCM must be

an anti-freeze/water mix. The antifreeze percentage must

be at least 10%. Follow guidelines in this manual to nd the

required antifreeze mix for the application. Thoroughly ush

the system before lling.

• The system must be supplied with a pump sized to provide

the minimum ow rates specied in this manual. Pump selec-

tion must consider the pressure loss through the system and

its components plus the pressure loss through the SCM’s

heat exchanger and internal components. The pump must

be rated for use with chilled water/glycol mixture.

• Install a y-strainer at the liquid input of the heat pump as

shown in this manual to prevent damage to the heat ex-

changer from sediment.

• DO NOT use for potable water heating. The single-wall

heat exchanger is not suitable for the application.

• See information in this manual for heating and cooling per-

formance versus ambient temperature.

• For applications requiring cooling at outdoor temperatures

below 55°F, contact SpacePak Technical Support for assis-

tance.

• DO NOT disconnect power in cold temperatures. Power

must be on to allow the anti-freeze cycle to operate.

• The SCM electronic controller is factory congured. DO NOT

adjust the control settings. If special operating characteris-

tics are required, contact SpacePak Technical Support for

availability and instructions.

Failure to comply with all of the guidelines BE-

LOW could result in death, serious injury or

substantial property damage.