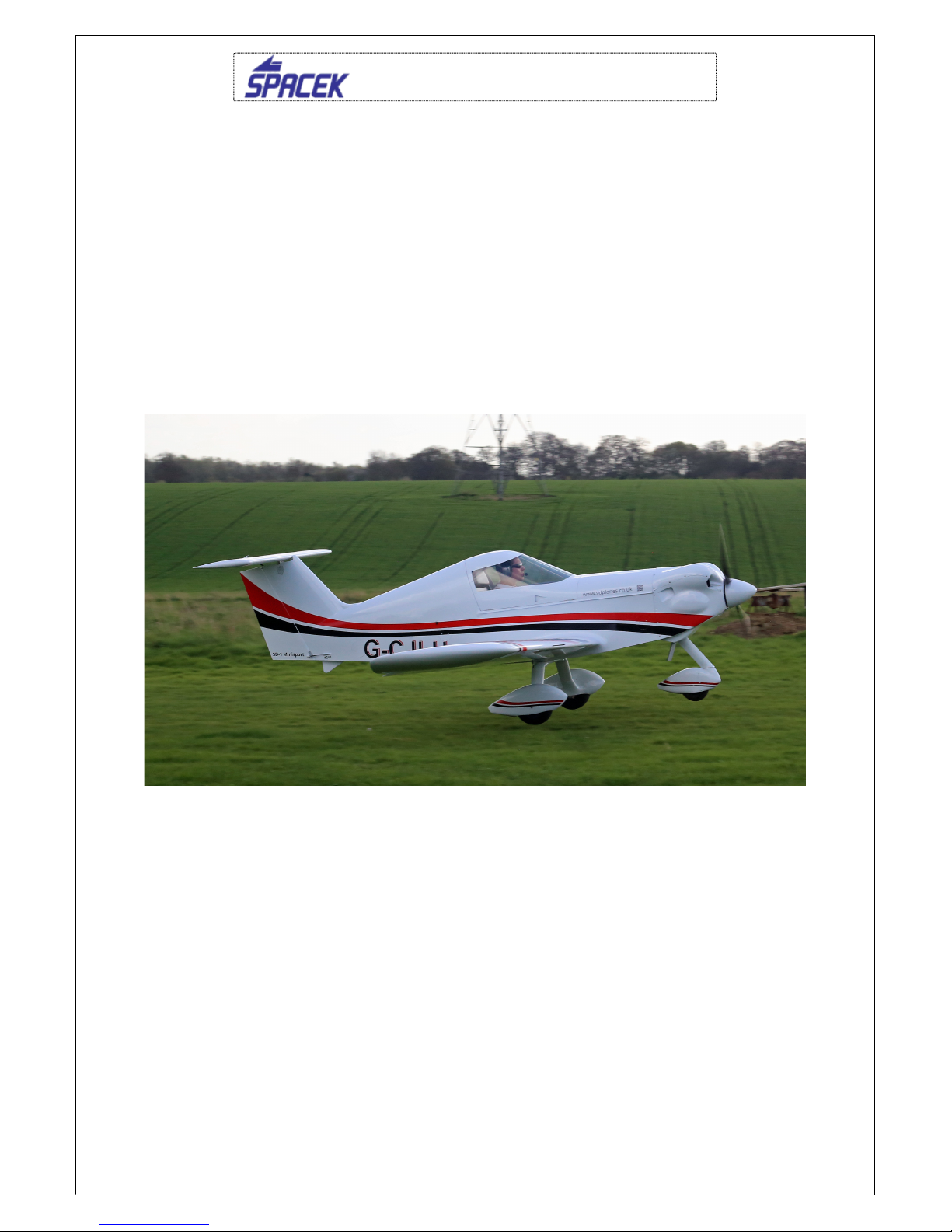

Spacek SD-1 Minisport TG Owner's manual

SD-1 Minisport TG, SE-33, P.O.H

1

Issue 1

PILOT OPERATING HANDBOOK (P.O.H)

FAI UL / SSDR

SD-1 MINISPORT

Type: SD-1 Minisport TG, engine SE-33, propeller Helix H30F

Airplane must be operated in compliance with the information and limitations

stated in this manual.

SD-1 Minisport TG, SE-33, P.O.H

2

Issue 1

CONTENTS

1. General

1.1 Description of airplane

1.2 Warning, cautions notes

1.3. Description of airplane

1.4. Main technical data

1.5. Engine and propeller

1.6. Three-view airplane drawing

2. Operation Limitations

2.1 Airspeed Limits

2.1.2 Air speed indicator marking

2.1.3 Limitation of maximal permitted wind speed

2.1.4 Engine limitation

2.2. Weights

2.3. Loads

2.4. Approved maneuvers

2.5. G-forces

2.6. Other limitations

2.7. Limitations labels

3. Operation data and procedures

3.1 Emergency procedures

3.1.2. Engine failure

3.1.3. Smoke and fire

3.1.4. Emergency and safety landing

3.1.5. Recovery of unintentional spin

4. Normal procedures

4.1. Assembling and Disassembling

4.2 Pre-flight Check

4.3. General procedures and check list

4.3.1 Prior to engine starting

4.3.2 Engine warming, ground test

4.3.3 Taxying

4.3.4 Pre-flight Check

5. Performance

5.1 Take-off distance

5.2 Landing distance

5.3 Climb

5.4 Airspeed

5.5 Glide

5.6 Stall speeds

5.7 Airspeed Indicator Calibration System

SD-1 Minisport TG, SE-33, P.O.H

3

Issue 1

1. General

The airplane SD-1 Minisport belongs to the FAI-UL category, according to the CAA

UK as Single Seat Deregulated microlight (SSDR).

1.1. Important information

Attention!

This product is not liable to be approved by Civil Aviation Authority, and it

is operated at someone’s own risk. Intentional spins, stalls and aerobatic

maneuvers are prohibited.

‘Every damage of airplane must be reported to an approved inspector – technician.

He will recommend the way how repair the damage and then he will provide the

check and technical inspection. In the airplane documentation there must be made a

report about the case’

1.2. Warnings, cautions, notes

The following information applies to warnings, cautions and notes used in the

Flight manual:

WARNING

MEANS THAT NON-OBSERVATIONS OF THE

CORRESPONDING PROCEDURE LEADS TO AN IMMEDIATE

OR IMPORTANT DEGRADATION OF FLIGHT SAFETY.

CAUTION

MEANS THAT NON-OBSERVATIONS OF THE

CORRESPONDING PROCEDURE LEADS TO A MINOR OR

TO A MORE OR LESS LONG TERM DEGRADATION OF THE

FLIGHT SAFETY.

NOTE

Draws the attention to any special item not directly related to

safety but which is important or unusual.

1.3 Description of airplane

The SD-1 Minisport is an ultra-light aerodynamically controlled, low-wing cantilever

single seat monoplane of mixed wood-composite construction, equipped with front

placed engine and fixed undercarriage of taildragger or tri-gear type. The airplane

could be equipped with parachute emergency system.

The airplane is designed according to the LTF-UL and UL-2 regulations, and is

intended for recreational flying in VFR.

SD-1 Minisport TG, SE-33, P.O.H

4

Issue 1

1.4 Main technical data

Measurements

Wing span…...…………………...… ..5,98 m

Fuselage length..………………….. ..4,35 m

Wing area .………………………….. ..6,1 m2

Wing aspect ratio…..…………….… ..5,85

MAC depth bmac………………………1,05 m

Horizontal tail unit span……..………1,96 m

Elevator Area…………………………0,95 m

Vertical tail Area……………………...0,44 m2

Landing gear gauge………………….2,78 m

Wheelbase…………………………….1,08 m

Main landing gear wheel diameter….0,3 m

Diameter of tail wheel………………..0,1 m

Propeller diameter……………………1,2 m

Weight

Empty weight………………………….(118-137) kg

Weight of a wing half ……………..……12 kg

Elevator weight…………………………..3 kg

Maximum take-off weight…………….240 kg

Payload…………………………..........110 kg

Fuel tank volume……………….……….35 l

Unusable fuel volume………………….0,5 l

1.5 Engine and propeller

Engine

SE-33, simple V-twin OHV 4-stroke, air-cooled, direct drive, magneto ignition

Max. continuous power…………………25kW@3600 rpm

Max. take off power……………………..22kW@3100 rpm

Min. CHT…………………………………60°C

Max. CHT……………………………......240 °C

Min. oil temp……………………………..25 °C

Max. oil temp…………………………….140 °C

Oil. pressure……………………………..0,3-2,5 bar – indicated by red light

Oil. quantity………………………………cca 1,4l

Operating outside air temperature……..-10°C / +40°C

Fuel: MOGAS unleaded 98,95

Oil: API SG, SH, SJ, SAE 10W30

Propeller

Helix H30F 1,25 m L-ES-08-2

Typ: 2 blades composite, fixed pitch

Diameter: 1250 mm

Example for the engine monitor

SD-1 Minisport TG, SE-33, P.O.H

5

Issue 1

1.6 Three-view airplane drawing

1. Operation Limitation

2.1 Airspeed limitation

Speed IAS

(km/h)/(kt)

Meaning

VNE Never exceed speed 220 / 119

Do not exceed this speed in

any operation

VA Maximum maneuvering

speed 163 / 88

Do not make full or abrupt

control movement

above this

speed, because under certain

conditions the aircraft may be

overstressed by full control

movement.

V

FE

Maximum flap extended

speed 104 / 57

Do not exceed this speed with

the given flap setting.

SD-1 Minisport TG, SE-33, P.O.H

6

Issue 1

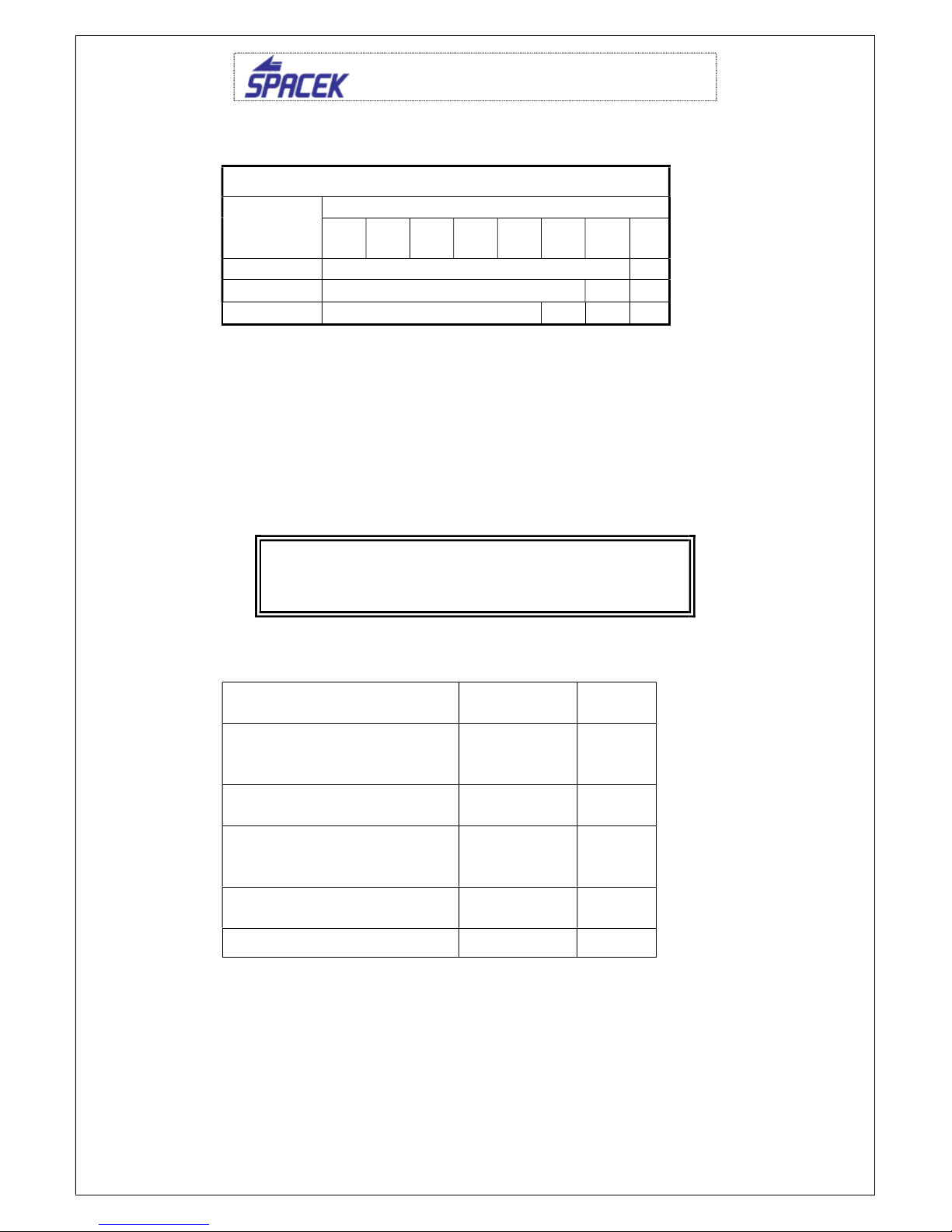

2.1.2 Airspeed indicator marking

Airspeed indicator markings and their color meanings are shown in the table

below:

Marking Value ( IAS )

Range (km/h)/(kt)

Meaning

White arc

64 – 104 / 34 – 57

Operation range with extended flaps.

(The lower limit is 1.1 VSO

in landing

configuration and m

aximum weight. The

upper limit is maximum permitted speed

with extended flaps.)

Green arc

78 – 163 / 46 – 88

Normal operation range. (The lower limit

is 1.1 VS1

when maximum weight,

maximum front position of C.G., and

retracted flaps. The upper limit is

maximum maneuvering speed V

A

.)

Yellow arc 163 – 220 / 88 –

119

Maneuvers must be conducted with

caution and only in smooth air

Yellow line 163 / 88 Maximum maneuvering speed Va

Red line 220 / 119 Maximum airspeed Vne

2.1.3 Limitation of maximum acceptable wind speed

The maximum acceptable wind speed for take-off and landing is 10 m/s (20kts).

The maximum acceptable perpendicular component of wind for take-off and

landing is 5 m/s (10kts).

2.1.4. Power plant limitation

Maximum allowable RPM 3600

Maximum continuous RPM 3600

Maximum CHT 220 ºC

Max. Oil Temp.: 140 °C

2.2. Weight

Maximum take-off weight...…………... 240 kg

Empty weight …………………….…… 130 kg

Approved centre of gravity positions:

Empty airplane C.G. position……......... 13÷18% MAC

Operating C.G. range………………….. 22

34% MAC

Minimum pilot weight………………… 61 kg

Maximum pilot weight………………... 105 kg

Maximum fuel weight……………….... 25 kg = 34 l

Maximum baggage weight……………. 10 kg

SD-1 Minisport TG, SE-33, P.O.H

7

Issue 1

2.3. Load

Maximum allowed filling of the fuel tank in liters

Weight of

baggage

(kg)

Pilot’s weight (kg)

55

60 65 70 75 80 95 10

5

0 Full fuel tank 7

5 Full fuel tank 21

10

Full fuel tank

21

14

2.4. Approved maneuvers

SD-1 is approved as FAI UL. Following maneuvers are approved to be performed:

Steep turns up to bank angle of 60

- recommended entering airspeed is 130

km/h(71kt).

Horizontal eights - recommended entering airspeed is 130 km/h (71 kt).

Climbing turns - recommended entering airspeed is 160 km/h (87 kt).

2.5. Maneuvering load factors

Maneuvering speed Airspeed

km/h / kt

Load

factor

VA- maneuver with maximum

deflection of a control

surface

163 / 88 + 4

VNE – maximum acceptable

airspeed 220 / 119 + 4

VA – maneuver with

maximum deflection of

a control surface

163 / 88 -2

VNE – maximum acceptable

airspeed 220 / 119 -2

VFE – with extended flaps 104 / 57 + 2

Warning

AEROBATICS AS WELL AS INTENTIONAL SPINS

ARE PROHIBITED!

SD-1 Minisport TG, SE-33, P.O.H

8

Issue 1

2.6. Other limitations

SMOKING IS PROHIBITED on the airplane board!

Heavy rain and very high humidity reduce aircraft performance!

In flight under these conditions is recommended to increase take-off and landing

speed by 5 knots.

2.7. Limitation labels

Airspeed IAS

Maximum airspeed VNE 220 km/h / 119 kt

Maximum maneuvering speed VA 163 km/h / 88 kt

Maximum flap extended speed VFE 104 km/h / 57 kt

AEROBATICS AS WELL AS INTENTIONAL SPINS

ARE PROHIBITED!

Flights according to IFR and intentional flights under icing

conditions are prohibited!

SD-1 Minisport TG, SE-33, P.O.H

9

Issue 1

3. Operation data and procedures

3.1 Emergency procedures

3.1.2 Engine failure

Engine failure at take-off below 50 m (150ft)

1. Adopt the glide airspeed to 110 km/h (59kt)

2. Choose an area for landing straight ahead, only in a case to prevent from

frontal crash change the direction

3. Ignition off

4. Fuel valve off

Engine failure during take-off when at least 50 m (150’) above ground

1. Correct the airspeed to 110 km/h (59kt)

2. Choose an area for landing straight forward in a free space without obstacles

3. Ignition off

4. Fuel valve off

5. Flaps for lift increasing according to your need

3.1.3 Smoke and fire

1. Fuel selector OFF

2. Throttle lever FULL

3. When the engine stops master switch OFF

4. Extinguish fire by slip. Do not start the engine again

5. Make a safety landing

3.1.4 Emergency and precautionary landing

Emergency landing

1. Airspeed adjust to 110 km/h (59kt)

2. Choose landing area – free space without obstacles

2. Tighten up the safety harness

3. Flaps – according to your need

4. Fuel selector OFF

5. Ignition OFF

6. Master switch OFF

Precautionary landing

1. Choose an area for landing – against the wind direction

2. In the altitude 50 m (150ft) above ground make a fly-over with extended small

flaps to check the chosen area for its surface and obstacles

3. In the altitude 150 m (500ft) above ground make circle with small flaps. Make

downwind checklist.

4. When lower visibility do not lost the chosen landing area from your view.

5. Approach for landing make in landing configuration with higher engine power.

SD-1 Minisport TG, SE-33, P.O.H

10

Issue 1

6. Correct the glide path to be able to touch-down immediately after flying over

the edge of chosen area.

7. After touch-down use brakes for prompt stop.

8. After stop shut off engine and master switch, close fuel valve and safe the

airplane.

3.1.5 Unintentional spin recovery

Standard procedure of recovery from spin:

1. Throttle lever - idle

2. Control stick - trim, ailerons – neutral position

3. Pedals - push down the pedal against the sense of rotation

4. Control stick - push forward and hold until rotation stops

5. Pedals - immediately after rotation stops return the

pedal from

deflection to the neutral position

6. Control stick - recover the diving by smooth pull back

4. Normal procedures

4.1 Assembly and disassembly

Before mounting clean easy removable hinges and struts. Lubricate them using

grease. Lubricate also hinges bushings placed in beams stubs and main horizontal

tail unit bracket. Push out auxiliary wings hinges and push on the right wing into the

fuselage tunnel. When the wing is enough close to the fuselage mount the linkage of

flaperon control handle to the flaperon stone, and the control handle into the flaperon

slot link. Fix up the auxiliary hinge and push on the main hinges into the stubs circa 1

cm deep using an extension stick. In the same way put the left wing on. Both wings

are on, push the main hinges in and fix them up by pins. Secure the auxiliary hinges

by binding wire.

When mounting the horizontal tail units (HTU), push the control link of trim surface

into the slot of HTU. Insert the hinge into the HTU bracket then insert the hinge

thorough fin bushing to the opposite bracket. Push pin into the hole in bracket of

HTU. Wrench a castle-nut on the pin and fix it up using a pin. Set the trim “heavy on

head” and joint the control link together with HTU by a bolt. Wrench a castle-nut and

secure it by a pin. Join the control link with the anti-servo trim lever and secure it by a

cotter pin.

4.2 Pre-flight check

Make the pre-flight check every flight day or before every first flight when assembled.

Incomplete or reckless check may cause an accident. Make the inspection in the way

described in the check list.

NOTE

Word "condition" in the procedures means visual check of surface for damage,

deformation, scratch, abrasion, corrosion or others events which lower the flight

safety.

Warning

Intentional spins are prohibited!

SD-1 Minisport TG, SE-33, P.O.H

11

Issue 1

ignition - OFF

master switch - OFF

instrument equipment - check on condition

fuel indicator - check on fuel condition

controls -visual check, function, allowance, free

movement

to its stop

- check of lift flaps run

canopy - attachment condition, cleanness

check, if there are free object in the cockpit

condition of engine cowlings,

condition of propeller and spinner,

condition of engine bed and exhaust system,

visual check on fuel and electrical system condition,

other checks according to the engine manufacturer instructions.

wing surface condition,

leading edge condition,

check Pitot tube condition.

wing tip - surface condition, attachment check,

flaperon -

surface condition, attachment, allowance,

free movement.

landing gear - check on wheels

attachment, brakes,

condition and inflation of tires

condition of fuselage and wing bottom surfaces

vertical tail unit -

condition of surface and attachment, free

movement, stops

horizontal tail unit - condition of surface and attachment

, free

movement, stops

SD-1 Minisport TG, SE-33, P.O.H

12

Issue 1

4.3 Normal procedures and check list

4.3.1 Prior to engine starting

CHECK POSITION OF FRONT WHEEL BEFORE ENGINE

STARTING!!! DANGER OF AIRPLANE DAMAGE.

1. Controls ................................................ free movement

2. Canopy ................................................. close and lock

3. Brakes .................................................. push on

4. Safety harness ..................................... fasten

4.3.2 Engine start

It is recommended to open fuel valve and turn propeller 2-3x while all switches OFF

before first start in day to get fuel to carburettor.

1. Starting ................................................. Open fuel valve

Master ON

Ignition ON

Throttle app. 20 % when cold or half

when is engine warm.

Push starter button

2. Choke ................................................... for cold engine open and after engine

starting close slowly

4.3.2 Engine warming and run up

If airplane is not equipped with oil temperature gauge warm up engine at least 5 min.

at 2000 RPM when is air temperature bellow 15 ºC. Prolong warm up time

adequately at lower air temperatures. The CHT should not be below 120 ºC during

run up. At least 3100 RPM static should be achieved at run up.

4.3.3 Taxying

Use the engine power and brakes according to your need. Do not use brakes

continuously. The rudder is efficient from 20 knots speed. Taxi carefully in the strong

wind. Hold the control stick in stick back position.

4.3.4 Before take-off

1. Altimeter ............................................... set (QNH)

2. Trim ...................................................... set to neutral position

3. Controls ................................................ check on free movement

4. Canopy ................................................. check if closed properly

5. Safety harnesses .................................. tighten up

6. Flaps……………………………………….lever in 2nd notch (7°)

4.3.5 Take-off

Set airplane to runway centerline. Apply full throttle. Pull stick back during take-off run

to enlighten front wheel, apply left rudder to compensate yaw effect. Move the stick to

neutral position at rotation speed (app. 83 km/h).

Let build up speed to 110 km/h in ground effect after lift-off and start to climb

thereafter. Check max. CHT during climbing.

SD-1 Minisport TG, SE-33, P.O.H

13

Issue 1

4.3.6 Landing

On downwind leg maintain 110-130 km/h (59-70kt). On base leg slow down to 57

knots and set flaps to first stage. Slow down to 90-100 km/h (49-54kt) and set full

flaps flaps on final. In case of wind from 45º and more to runway centerline or

turbulence do not apply full flaps and land at 100 km/h (54kt). It is advised to apply

some throttle before touch down to slow down speed.

5. Performance

Approved data for airspeed calibration, stall speeds, take-off performance and

additional information useful for operation of the aeroplane.

The data in the charts has been computed from actual flight tests.

If not stated otherwise, the performances given in this section are valid for the max.

take-off weight and flight under ISA conditions.

5.1 Take-off distance

Grass runway:

Take-off roll distance

Distance over 15ft screen hight

130 m 300 m

Paved runway (concrete/asfalt):

Take-off roll distance

Distance over 15ft screen hight

120 m 280 m

5.2 Landing distance

Grass runway:

Landing from 50ft screen height

Landing roll

260 m 120 m

Paved runway (beton/asfalt):

Landing from 50ft screen height

Landing roll

250 m 100 m

5.3 Climb performance

Altitude Rate of

climb

Best rate of climb speed

(km/hod / kt IAS)

0 ft 3,8 m/s 120 / 65

750 ft/min

3000 ft 2,9 m/s 120 / 65

570 ft/min

5.4 Airspeed

Maximum horizontal speed is 180 km/h (100kt), optimal cruise 155 km/h (85kt).

Fuel consumption 4,7 l @ 155 km/h (85kt) / 3100rpm

SD-1 Minisport TG, SE-33, P.O.H

14

Issue 1

5.5 Glide

Best glide speed 110 km/h / 59 kt

Glide ratio @ 110 km/h / 59 kt 1: 13

5.6 Stall Speeds

Stall speed are measured in MTOW and level flight.

Position Stall speed

(km/hod / kt IAS)

Flaps retracted 78 / 42

Flaps – 1. stage T/O (7°) I 70 / 38

Flaps – 2. stage L/D (20°) II 64 / 34

5.7 Airspeed Indicator Calibration System

IAS

[km/h]

CAS

[km/h]

60 61

70 70

80 80

90 89

100 98

110 107

120 116

130 126

140 135

150 144

160 153

170 163

180 172

190 181

200 190

210 200

SD-1 Minisport TG, SE-33, P.O.H

15

Issue 1

6. Weight and balance

Empty weight measured 118-137 kg

C.G. position movement from 22 to 34% MAC

Allowed centre of gravity position range

Front end point 22 % MAC= 231 mm from leading

edge

Rear end point 34 % MAC= 357 mm from leading

edge

MAC 1050 mm

WARNING

IT IS A PILOT RESPONSIBILITY TO OPERATE THE AIRPLANE IN

ALLOWED RANGE OF WEIGHTS AND C.G. POSITIONS.

7. Aircraft description

7.1 FUSELAGE

Fuselage is of wood truss design with prevalent section 15x15 mm covered with

plywood of 0,8-3 mm thickness. The pilot seat back is inclined under 40

. The inside

with of cockpit in shoulder place is 54 cm (21,3"). The plywood tunel with wing and

upper gear legs mounts is under pilot knees. The baggage compartment of 40 l (1,5

ft3) is behind removable seatback. Composite cabin hood with polycarbonate

windshield of 1,5 mm thickness opens to the side. The NACA inlet for ventilation is

on the side of cabine hood.

7.2 WING

It consists of composite main spar with carbon caps on which are glued XPS ribs.

The structure is covered with 1 mm plywood. Wingtips are made of sandwiched glass

composite. Connection of wings to fuselage is made thru two main and two auxiliary

pins. . The connection of flaperons to controls is performed by inserting of control pin

into slot.

7.3 TAIL

The all movable horizontal tail (HT) has anti-servo tab and is statically balanced. Tails

are of similar construction as wings- on composite spar are attached polystyrene ribs

and plywood skin. Spring trimming is under pilot seat. Disassembly of HT is made

thru disconnection of control and tab rods and pulling out of pin. The fin has main

composite spar with carbon caps and HT hinge.

7.4 UNDERCARRIAGE

The legs of main gears are made of pultruded fiberglass rods. The wheels of 12x4

size are braked using mechanically actuated drum brakes. Tail wheel of 100 mm (4")

diameter is controlled via ruder and is attached to the fiberglass spring.

SD-1 Minisport TG, SE-33, P.O.H

16

Issue 1

7.5 CONTROLS

The horizontal tail and flaperons are controlled via pushrods and bellcranks. Flaps

are controlled using mixer placed bellow seat. Rudder is controlled via cables.

7.6 ENGINE

The airplane is driven by SE-33 engine. Engine mount is made of CrMo tubing. Helix

H30F fixed pitch propeller.

7.7 FUEL SYSTEM

The integral tank of 35 l capacity is placed behind fuselage firewall. It is made of

fiberglass-PVC foam sandwich. The ball valve is connected to tank outlet. The

Mikuni pump is connected to crankcase.

7.8 ELECTRICAL SYSTEM

The bus is powered by 12 V/9 Ah lead (lithium ion) battery and is charged by

alternator integrated in stator.

7.9 INSTRUMENTS AND PITOT-STATIC SYSTEM

The airplane is fitted with basic flying instruments-speedmeter, altimeter, compass

and vario*. The RPM´s, total hours, head and exhaust gas temperatures are checked

on the engine. The COM antenna is built in the airframe. The pitot tube is placed on

the leading edge of right wing. The static ports are placed from bothe sides of

fuselage in front of tails.

7.10 RESCUE SYSTEM

The airplane is optionaly equipped with rescue system GRS 4/240. The container of

system is attached behind pilot bulkhead.. The front ropes are attached on upper

engine mount hinges. The auxiliary rope is attached to fuselage behind cabin.

7.11 RUDDER DEFLECTIONS

Rudder: Right/Left 30

, 172 mmm +/- 10 mm

Elevator: Up 11

, 74mm +/- 5 mm

Down 6

, 40mm +/- 5mm

Aileron (Flaps 0): Up 23,5

, 86 mm +/- 5 mm

Down 13,8

, 50 mm +/- 5 mm

Flaps 0: Down 0

,

Flaps 1: Down 7

, 26 mm +/- 5 mm

Flaps 2: Down 20

, 73 mm +/- 5 mm

* depends on builder choice

SD-1 Minisport TG, SE-33, P.O.H

17

Issue 1

8. Handling, treatment and maintenance of the airplane

8.1. FOREWORD

This chapter contains procedures recommended by manufacturer for proper airplane

operation.

8.2. PERIODICAL INSPECTION OF AIRPLANE

The time intervals in which is necessary to perform comprehensive inspections or

maintenance depend on the service and whole airplane condition. Use only original

parts if any exchange is necessary.

Periodical checkings must be performed at least in these intervals:

a) After first 25 hours of sevice

b) After each 50 hours of service

c) After each 100 hours of service or annually.

The engine maintenance system is defined by Engine service manual.

The propeller must be serviced in accordance to its manual.

8.3. The list of work at periodical inspections

8.3.1. Inspection after first 25 hours and after 50 hours

Action

Nr. Description Performed

by Checked by

1

Generaly

Wash whole airframe using wet sponge and suitable

detergent. Remove cowling and covers and check fixing

of all parts (fuel, oil and electrical installation).

Check tightening and securing of all hardware.

2

Controls

Check control cables on damage. Check metal parts for

corrosion. Repair if necessary. Grease moving parts.

Check movement smootheness and its assembly.

3

Undercarriage

Remove covers and check free motion in the pins of

lower main leg consoles. Check free motion in the

tailwheel pin. Lubricate all pins usiing grease.

4

Tyres

Check pressure in tyre, its wear, discs and brake system.

Exchange tyre in case of excessive wear.

5

Engine

Check engine installation, oil, cooling baffles and all

hoses and controls on damage and wear. Check air filter

and wash it in gasoline if necessary.

6

Exhaust system

Check guskets, tubes and exhaust muffler for cracks,

leaks and missing parts.

SD-1 Minisport TG, SE-33, P.O.H

18

Issue 1

Action

Nr. Description Performed

by Checked by

7

Cowling

Check cowling for loosenes, cracks or any damage.

Check completeness of hardware.

8

Propeller

Check tips and leading edge on damage. Repair using

epoxy or varnish..

9

Fuel system

Check tighteness of whole system and condition of all

hoses. Check smoothness of fuel valve run. Check fuel

filter and exchange if necessary.

10

Battery

Check voltage. Charge if necessary.

11

Cockpit

Clean using wet towel. Remove dirty on floor using

vacuum cleaner.

12

Cabine hood

Use agent suitable for cleaning of polycarbonates. Do

not use gasoline, alcohol etc.

7.3.2. Inspection after 100 hours or year examination

Action

Nr. Description Performed

by Checked by

1

Generaly

Clean all outside and inside skin of airplane. Check on

damage, wear and corrosion.

2

Front of the airplane

Check engine (see engine manual), hoses, engine

mount, propeller, battery, exhaust, firewall and rescue

system.

Check tightening and securing of hardware.

3

Fuel system

Check tube on cracks and valve function. Check fuel filter

and exchange it if necessary.

4

Fuselage

Check outside skin on cracks and inside structure on

possible rust.

5

Controls

Check free movement, wear of cable, tubing, bushes in

stick, brackets, mixer and rod ends. Check end stops.

6

Instruments

Check screws, fuses, placards, switches and pitot

system. Assure that all instruments work fine.

SD-1 Minisport TG, SE-33, P.O.H

19

Issue 1

Action

Nr. Description Performed

by Checked by

7

Wing

Check skin for cracks and possible bonding failure.

Check possible free movement in main and auxiliary

assembly pins.

Check flaperon hinges and possible free movement in

control connection pin.

8

Tails

Check skin for cracks and possible bonding failure.

Check possible free movement in all pins and their

securing.

9

Undercarriage

Check in accordance to 25 hours inspection.

10 Lubricate all moving parts-see e plan

11

Check all hinges of control surfaces and moving parts.

Perform repair action if free movement in hinge exceed

0,4 mm. The free play in hinge of horizontal tail should

not exceed 0,1 mm.

Assembly all dismantled parts after performed inspection and/or maintenance

and perform engine test run.

8.3.3. Lubricating plan

a) Lubricant used

Use suitable lubricating grease. (Castrol grease LM, Mobil grease MP etc.)

b) Lubricated places

All bearings

Whole controls of flaperons and horizontal tail

Main pin of HT at every disassembly

Antiservo tab hinges

Rudder hinges

Stick bearings

Pedals

Throttle bowden

Choke bowden

Hinge and pins of cabine hood

Table of contents