T

Te

ec

ch

hn

ni

ic

ca

al

l

D

De

es

sc

cr

ri

ip

pt

ti

io

on

n,

,

O

Op

pe

er

ra

at

ti

in

ng

g,

,

M

Ma

ai

in

nt

te

en

na

an

nc

ce

e

a

an

nd

d

R

Re

ep

pa

ai

ir

r

M

Ma

an

nu

ua

al

l

S

Su

up

pp

pl

le

em

me

en

nt

t

Document No.: 304eS/MMSupp

Date of Issue: 11/17

Table of contents Page

0.1 LIST OF EFFECTIVE PAGES ................................................................................ IV

0.2 RECORD OF REVISIONS ......................................................................................V

1. BASIC TECHNICAL DATA ............................................................................1-0

1.1 BASIC TECHNICAL DATA ..................................................................................1-1

1.2 TECHNICAL DESCRIPTION................................................................................1-1

1.2.1 Fuselage ...................................................................................................1-1

1.2.2 Wing..........................................................................................................1-1

1.2.3 Horizontal Tail Unit....................................................................................1-2

1.2.4 Vertical Tail Unit........................................................................................1-2

1.2.5 Water ballast system.................................................................................1-2

1.2.6 Power-plant...............................................................................................1-2

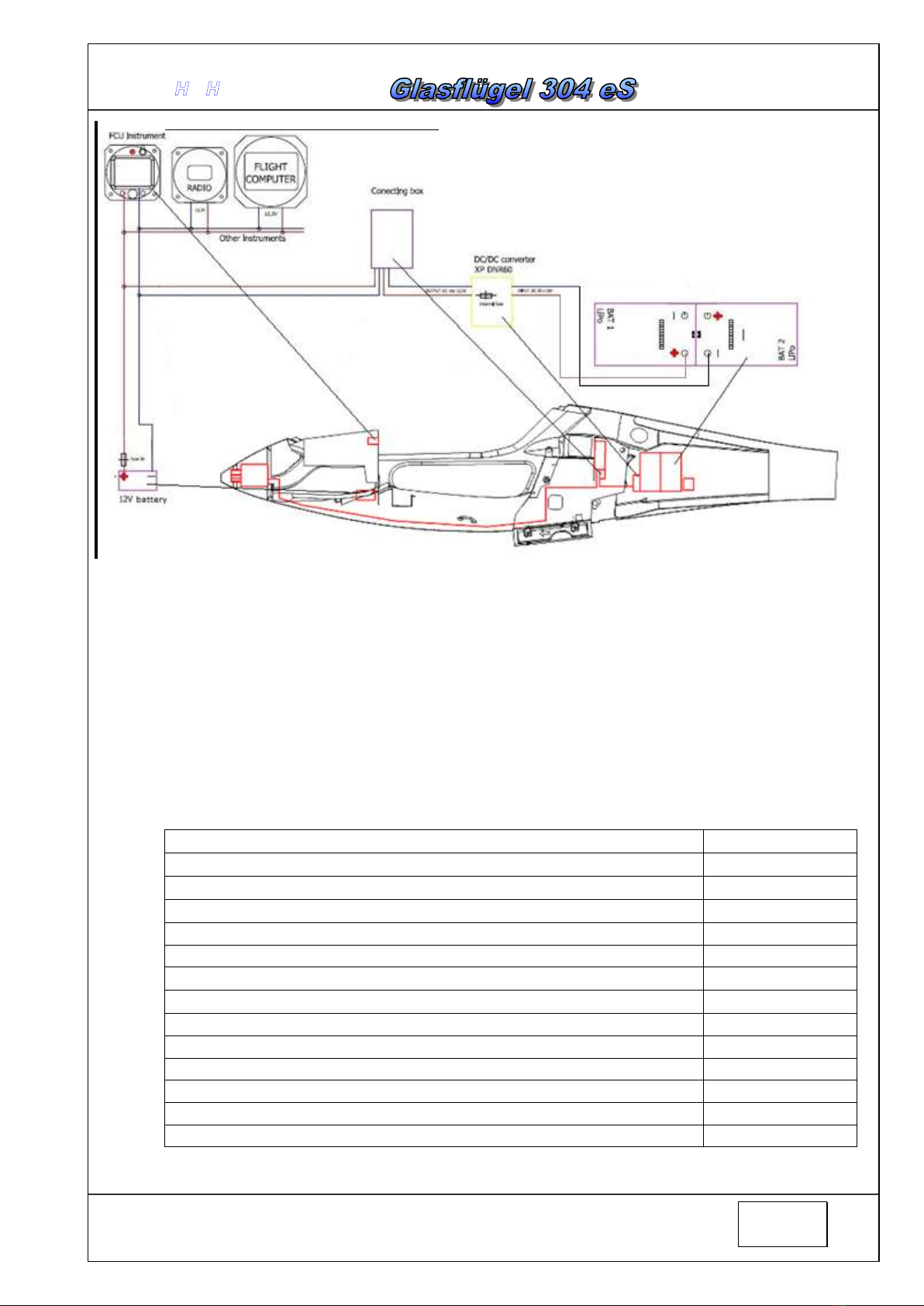

1.3 SAILPLANE SYSTEMS.....................................................................................1-10

1.3.1 Control systems in the fuselage ..............................................................1-10

1.3.2 Control systems in the wing ....................................................................1-10

1.3.3 Rudder control system ............................................................................1-10

1.3.4 Main landing gear system .......................................................................1-10

1.3.5 Control surface deflections and dimensions............................................1-10

1.3.6 Electric system........................................................................................1-10

2. HANGARING, TRANSPORT, RIGGING ........................................................2-0

2.1.1 Hangaring, Parking, and Ground Handling ...............................................2-1

2.2 RIGGING ........................................................................................................2-2

2.3 DE-RIGGING ...................................................................................................2-3

3. MAINTENANCE .............................................................................................3-0

3.1 MANDATORY MAINTENANCE ............................................................................3-1

3.1.1 Inspections periods ...................................................................................3-1

3.1.2 Inspection after every 100 flight hours ......................................................3-1

3.1.3 Propeller....................................................................................................3-1

3.1.4 Motor –Propeller ......................................................................................3-2

3.2 REGULAR MAINTENANCE.................................................................................3-2

3.2.1

Annual inspection

......................................................................................3-2

3.2.2 Inspection at the end of flight season........................................................3-2

3.2.3 Adjustments ..............................................................................................3-2

3.2.4 Motor maintenance ...................................................................................3-3

3.2.5 Propeller maintenance ..............................................................................3-4

3.2.6 Battery packs maintenance.......................................................................3-4

3.3 SPECIAL INSPECTION PROCEDURE...................................................................3-6

3.3.1 After hard landing, ground loops and battery pack impact ........................3-6

3.4 FREE PLAY IN THE CONTROL CIRCUITS ............................................................3-7

3.5 FREE PLAY IN WING AND TAIL PLANE ATTACHMENTS .........................................3-7

3.6 PRIMARY AND SECONDARY STRUCTURES ..........................................................3-7

3.7 DAMAGE ........................................................................................................3-7

3.8 REPAIRS ........................................................................................................3-7

3.9 REMOVAL AND RE-INSTALLATION OF RELEASES ................................................3-8

3.10 CONTROL SURFACE MOMENTS ........................................................................3-8

3.11 PLACARDS AND MARKINGS IN THE COCKPIT.......................................................3-8

3.12 CLEANING AND CARE ......................................................................................3-8