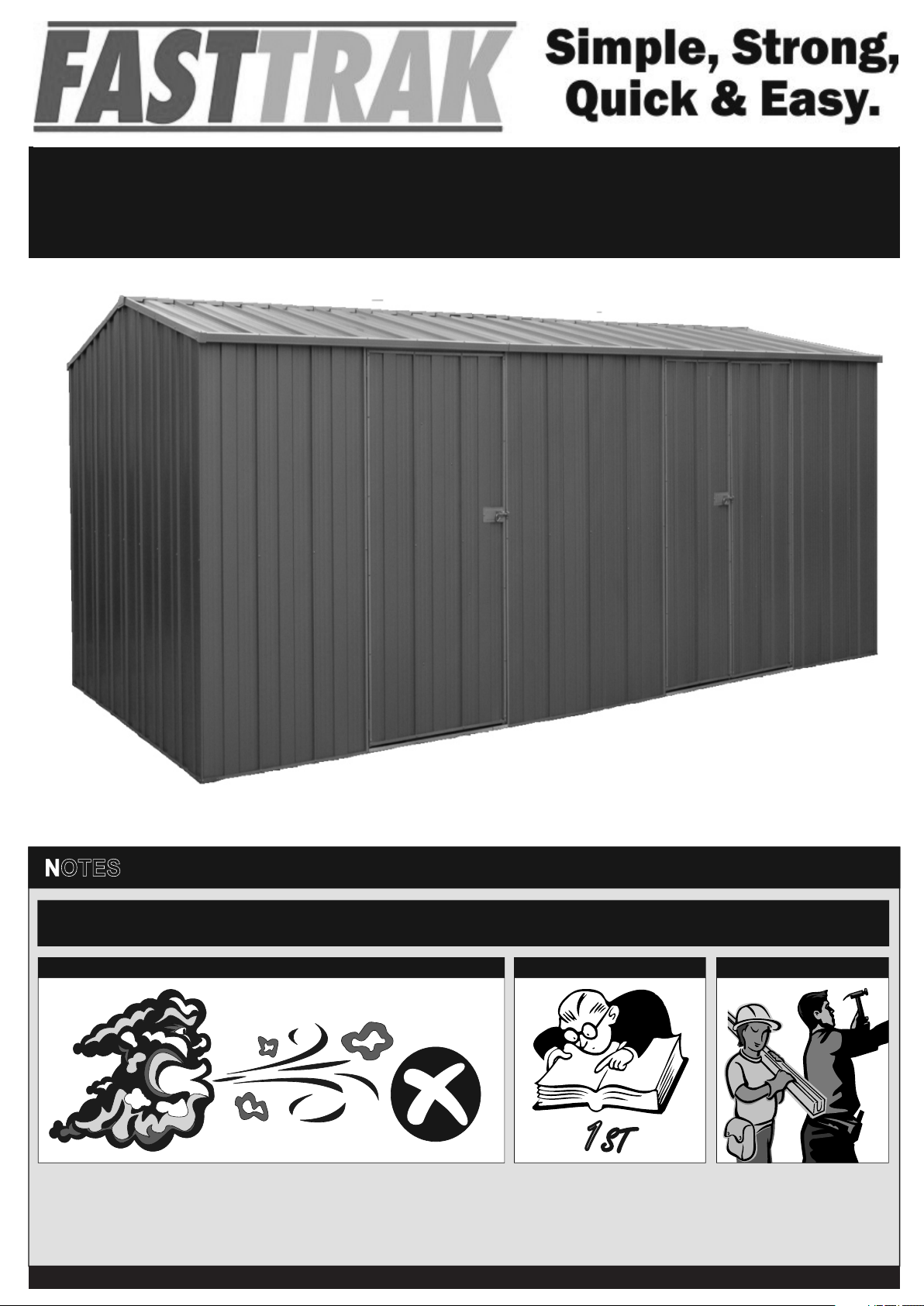

Spanbilt Fasttrak WorkShop 2010 User manual

NOTES

THE MANUFACTURERS CANNOT BE HELD RESPONSIBLE FOR ANY CONSEQUENCES DUE TO SHEDS THAT ARE NOT

INSTALLED PER INSTRUCTIONS OR FOR DAMAGE DUE TO WEATHER CONDITIONS, ACTS OF GOD OR FOR SHEDS THAT

ARE LEFT PARTIALLY ASSEMBLED OVERNIGHT. PARTS MAY CONTAIN SHARP EDGES & CORNERS. CARE MUST BE TAKEN

WHEN HANDLING VARIOUS PIECES TO AVOID A MISHAP, FOR SAFETY SAKE, PLEASE USE A PAIR OF WORK GLOVES, EYE

PROTECTION & PROTECTIVE CLOTHING WHEN ASSEMBLING OR PERFORMING ANY MAINTENANCE ON THE BUILDING.

DO NOT ASSEMBLE IN WINDY CONDITIONS

1ST

READ INSTRUCTIONS FIRST 3 PERSON ASSEMBLY

BEFORE COMMENCING SHED ASSEMBLY, CHECK ALL PARTS. IF THERE IS A DISCREPANCY, PLEASE CALL

YARDSAVER (SEE REAR OF INSTRUCTION BOOK)

ASSEMBLY INSTRUCTIONS

WorkShop 2010

Subject to changes © Spanbild Pty. Ltd.

W5915mm x D2800mm x H2085mm

REVISION 10-03-14

Read instructions and check parts carefully

before assembling the shed.

Do not assemble in windy conditions as panels

may be difficult to handle and damage may result.

Please wear safety gloves and glasses at all

times to protect against sharp metal edges.

MOST PILOT HOLES ARE PRE-PUNCHED AND IN THIS CASE DRILLING

HOLES IS NOT NECESSARY, HOWEVER SOME PILOT HOLES NEED TO BE

DRILLED WITH THE INCLUDED 2.5MM DRILL BIT WHERE INDICATED

Do not back fill against the shed as this will

result in corrosion. Allow drainage from the site.

HANDY HINTS FOR CONSTRUCTION

Electric Drill Cordless Drill Screwdrivers 8mm Masonry

Drill Bit

Sturdy Ladder

(two if possible)

Gloves Rubber Mallet

Protective Eyewear

Measuring Tape

TOOLS REQUIRED

PAGE 2

Builders Pencil

Shifting Spanner Tin Snips

(some models

only)

6mm Drill Bit

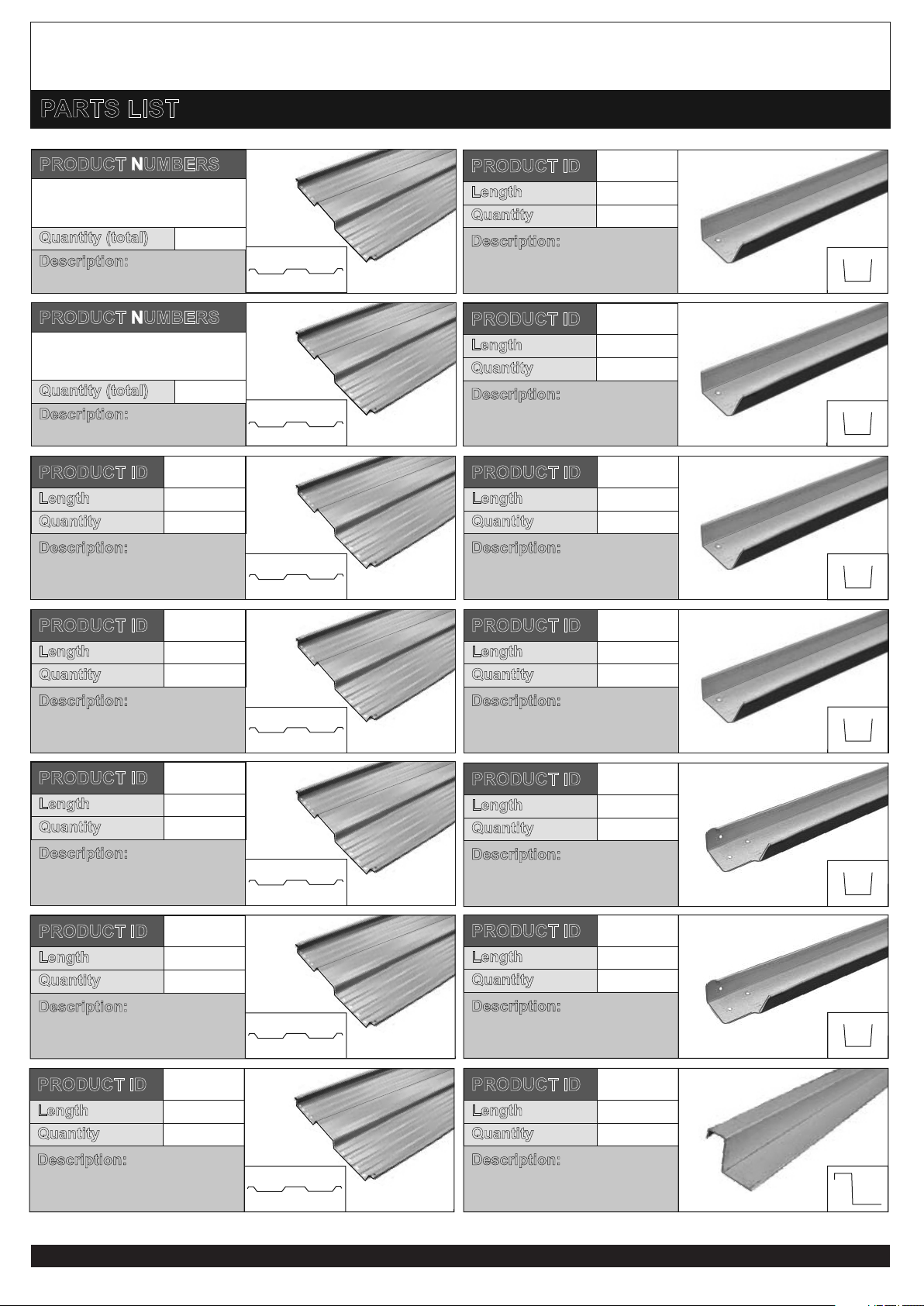

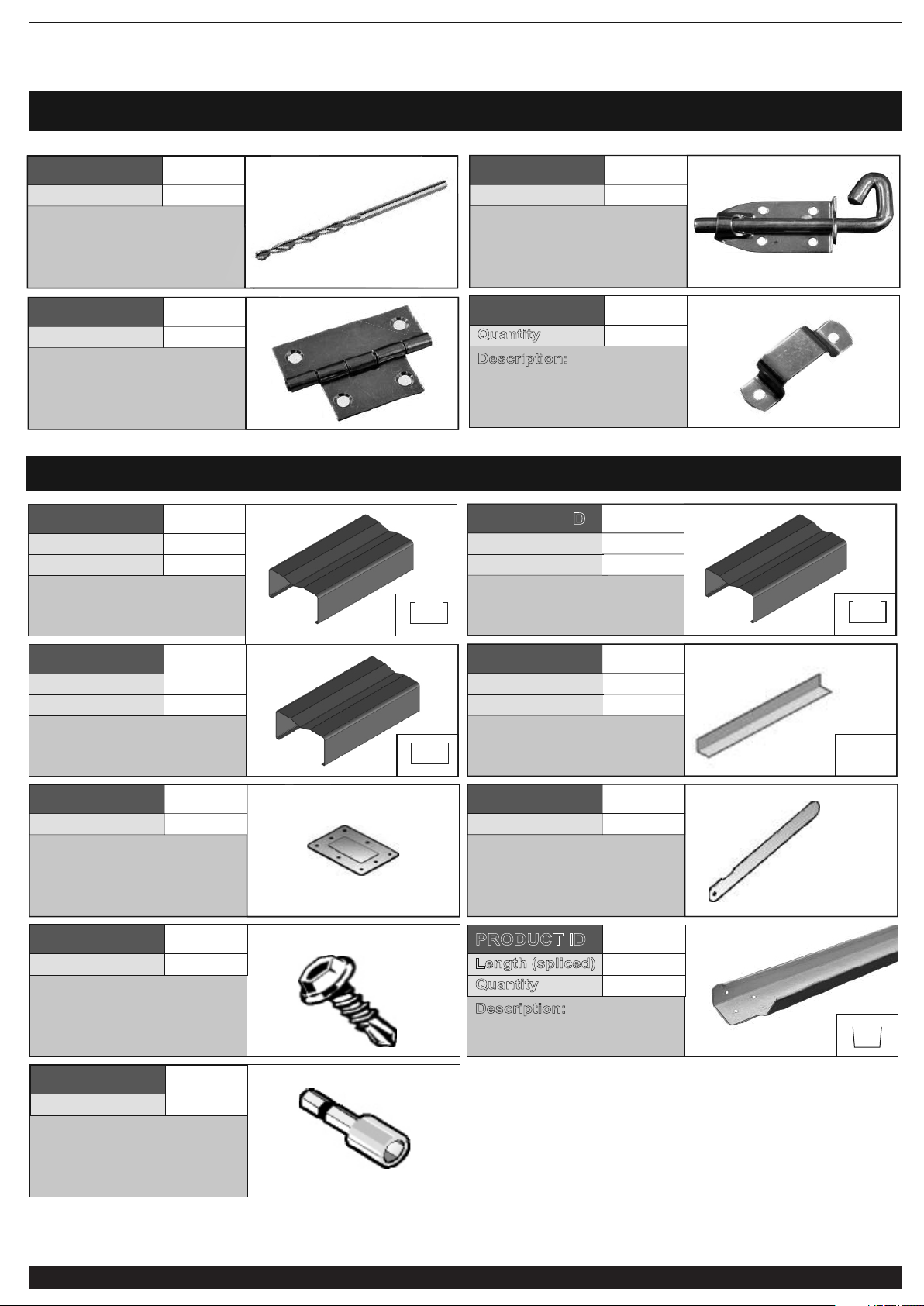

PARTS LIST

Description:

Door Panel (Partially Slit)

Length

Quantity 6

1738mm

PRODUCT ID F

Description:

Wall Panel

Length

Quantity 24

1800mm

PRODUCT ID C

Description:

Wall Corner Panels

Length

Quantity 3

1800mm

PRODUCT ID D

Description:

Roof Panels

Length

Quantity 34

1454mm

PRODUCT ID E

Description:

Gable Wall Panel

PRODUCT NUMBERS

8

Quantity (total)

B1 B2

Description:

Gable Wall Panel

PRODUCT NUMBERS

8

Quantity (total)

A2A1 A3

B3

A5A4 A6

B4 B5 B6

A8A7

B7 B8

Description:

Door Frame Top/Bottom

Length

Quantity 2

1008mm

PRODUCT ID H

Length

Quantity 6

1742mm

PRODUCT ID I

Description:

Door Frame Side

Description:

Door Boxing

Length

Quantity 6

1706mm

PRODUCT ID J

2

Description:

Door Bracing

Length

Quantity

1040mm

PRODUCT ID k

4

Description:

Door Seal

Length

Quantity 1

1706mm

PRODUCT ID L

PAGE 3

Description:

Door Panel Centre

Length

Quantity 1

1738mm

PRODUCT ID G

Description:

Door Frame Top/Bottom

Length

Quantity 4

674mm

PRODUCT ID h

2

Description:

Door Bracing

Length

Quantity

1280mm

PRODUCT ID K

2

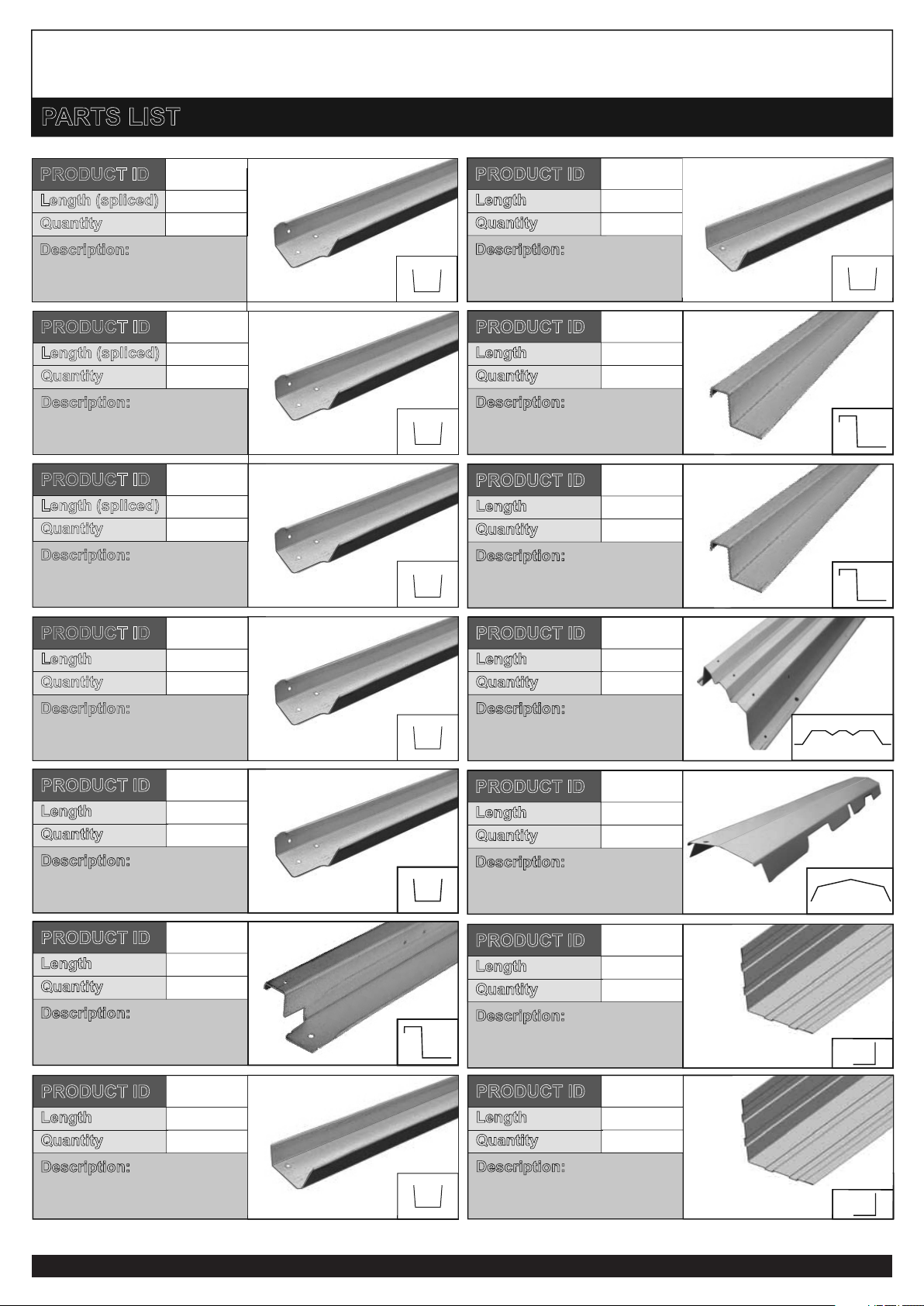

Description:

Side Channel Gable Top

Length

Quantity 2

1411mm

PRODUCT ID O

Description:

Side Channel Gable Bottom

Length (spliced)

Quantity 2 Sets

PRODUCT ID N

2921mm

=(1461 + 1460)

Description:

Top/Bottom Front/Rear

Channel

Length (spliced)

Quantity 4 Sets

3267mm

PRODUCT ID M

=(1460 + 1807)

PARTS LIST

PAGE 4

Description:

Door Jamb

Length

Quantity 4

1800mm

PRODUCT ID Q

Description:

Side Channel Gable Top

Length

Quantity 2

1415mm

PRODUCT ID P

2

Description:

Bottom Door Spacer

Length

Quantity

1367mm

PRODUCT ID R

1

Description:

Top/Bottom Front/Rear

Channel

Length (spliced)

Quantity 4 Sets

2921mm

PRODUCT ID m

=(1460 + 1461)

2

Description:

Bottom Door Spacer

Length

Quantity

1021mm

PRODUCT ID r

1

Description:

Top Door Spacer

Length

Quantity 1

1367mm

PRODUCT ID S

Description:

Ridge Cap

Length

Quantity 9

708mm

PRODUCT ID U

Description:

Ridge Beam

Length

Quantity 8

1710mm

PRODUCT ID T

Description:

Gutter Trim

Length

Quantity 4

2096mm

PRODUCT ID V

Description:

Top Door Spacer

Length

Quantity 1

1021mm

PRODUCT ID S1

Description:

Gutter Trim

Length

Quantity 2

1750mm

PRODUCT ID V1

Description:

Roof Angle Trim

Length

Quantity 2

1446mm

PRODUCT ID W

Description:

Roof Angle Trim

Length

Quantity 2

1443mm

PRODUCT ID W1

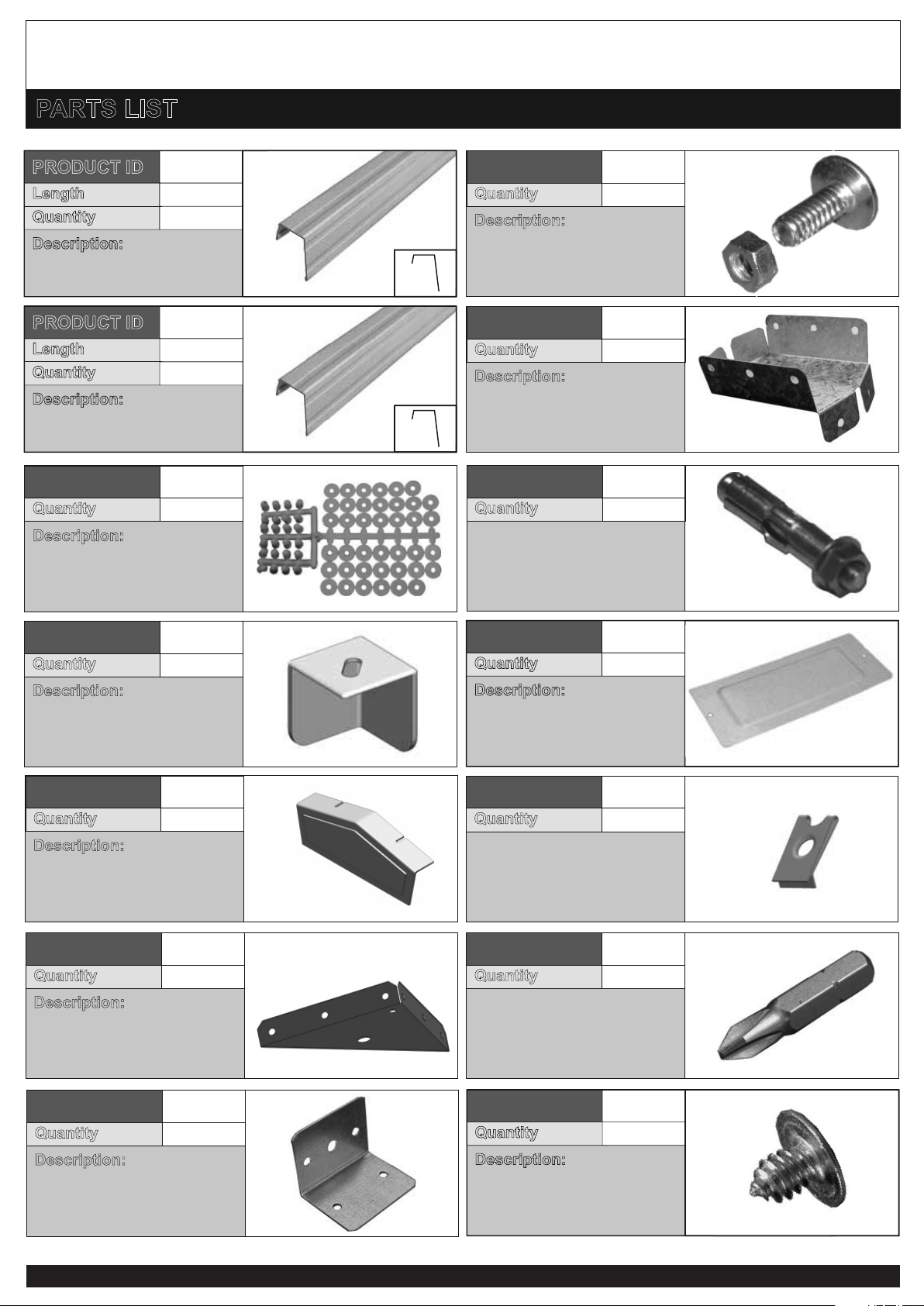

PARTS LIST

Clip Nut

Quantity 5

Description:

Nut & Bolt 3/16”

Quantity 16

Description:

Ridge Beam Bracket

Quantity 2

Masonry Anchor

Quantity 12

PAGE 5

Description:

Door Plate

Quantity 2

Description:

Plastic Washer and Screw

Cap Sheet

Quantity 3

Description:

Plastic Corner Cap

Quantity 4

Description:

Corner Bracket

Quantity 8

Description:

Plastic Ridge End Cap

Quantity 2

Description:

Quantity 12

55mm Bracket

Phillips Head Bit

Quantity 1

Description:

Self Tapping Screws - Silver

Quantity 600

PARTS LIST

PAGE 6

Description:

Hinges (offset)

Quantity 6

Quantity 1

Description:

2.5mm Drill Bit

Description:

Padbolt

Quantity 4

Description:

Keeper

Quantity 4

Description:

Portal Leg

Length (spliced)

Quantity 4

PRODUCT ID A

Description:

Roof Beam

Length (spliced)

Quantity 4

PRODUCT ID B

2

Description:

Top Gusset

Length

Quantity

1820mm

PRODUCT ID C

2

Description:

Corner Gusset

Length

Quantity 2

810mm

PRODUCT ID D

1728mm

1346mm

PORTAL FRAME - PARTS LIST

Description:

70x100 Plate

Quantity 4

Description:

Gable Gusset Strap

Quantity 2

Description:

Nut Runner

Quantity 1

Description:

Self Drilling Tek Screw

Quantity 126

(Portal)

Description:

Bracing channel

Length (spliced)

Quantity (2 x 1461 + x 1460) (2 )

2710mm

PRODUCT ID X

=(1461 + 1460)

PAGE 7

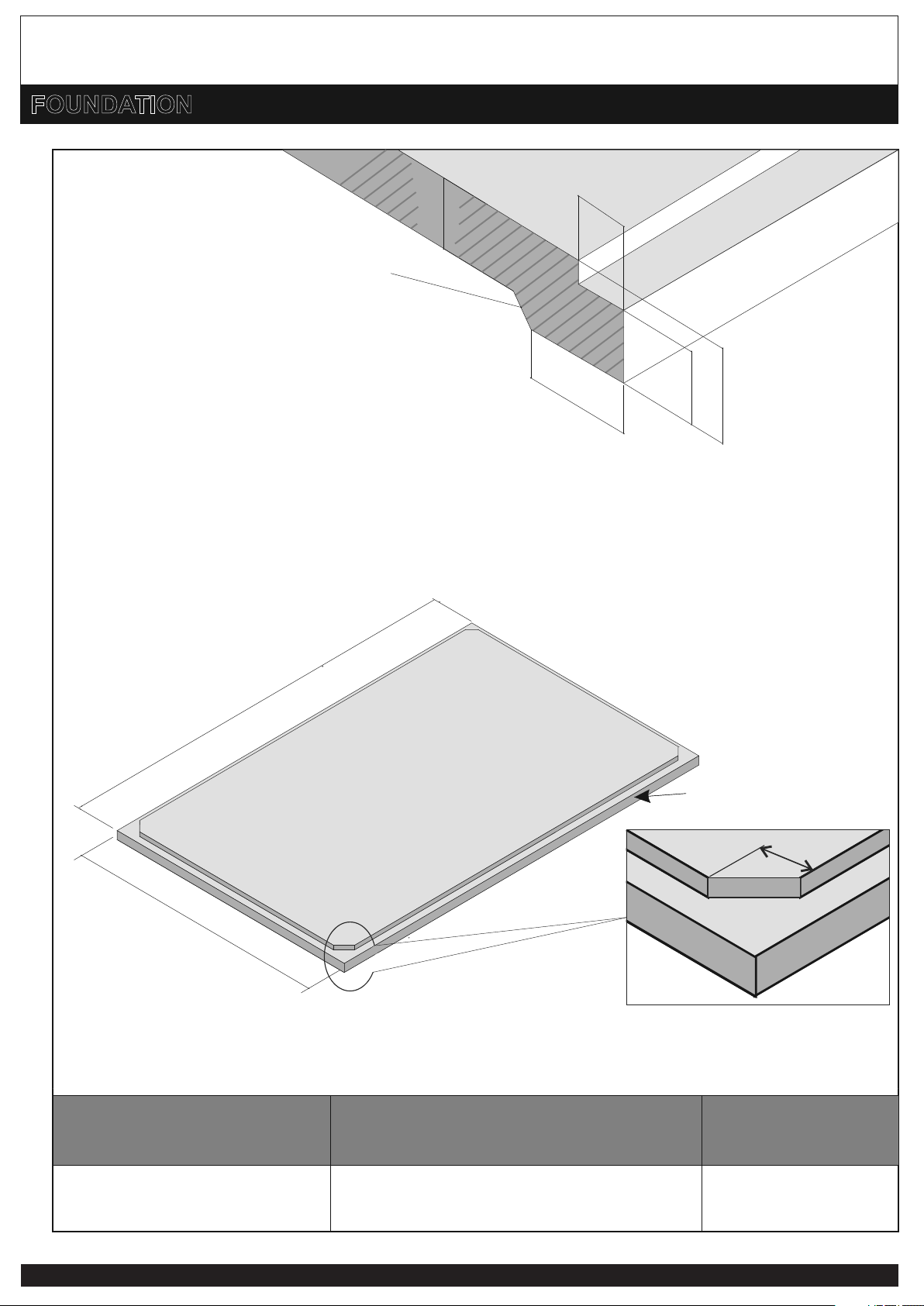

6015mm x 2900mm 12

WS 2010

Front side of shed

DEPTH

WIDTH

FOUNDATION

Recommended slab rebate detail

Although not required, it is strongly recommended that, to avoid water leakage around the base of your

shed, a rebate be cast into the slab. This will allow the shed to sit below the slab level and prevent water

from reaching the upper level of the slab.

130mm

150mm

75mm

150mm

75mm

Recommended

edge thickening

SHED CODE OUTER SLAB SIZE

width x depth

Slab Details

Your garden shed must be erected on a solid, level and square foundation. We strongly recommend you

pour a concrete slab 75mm thick, reinforced with SL62 mesh (minimum) using dimensions from the

table below.

*Masonry anchors are supplied*

ANCHORS

M8 x 40mm

125

If you planning a rebated slab make sure to cut the 4 corners at 125 x 45 as shown in detail

below. Also cut short the length of the portal leg by 20mm.

o

2

LEG

LEG

m

m

50

0

2

m

m

807

1

2750mm

3290mm

1

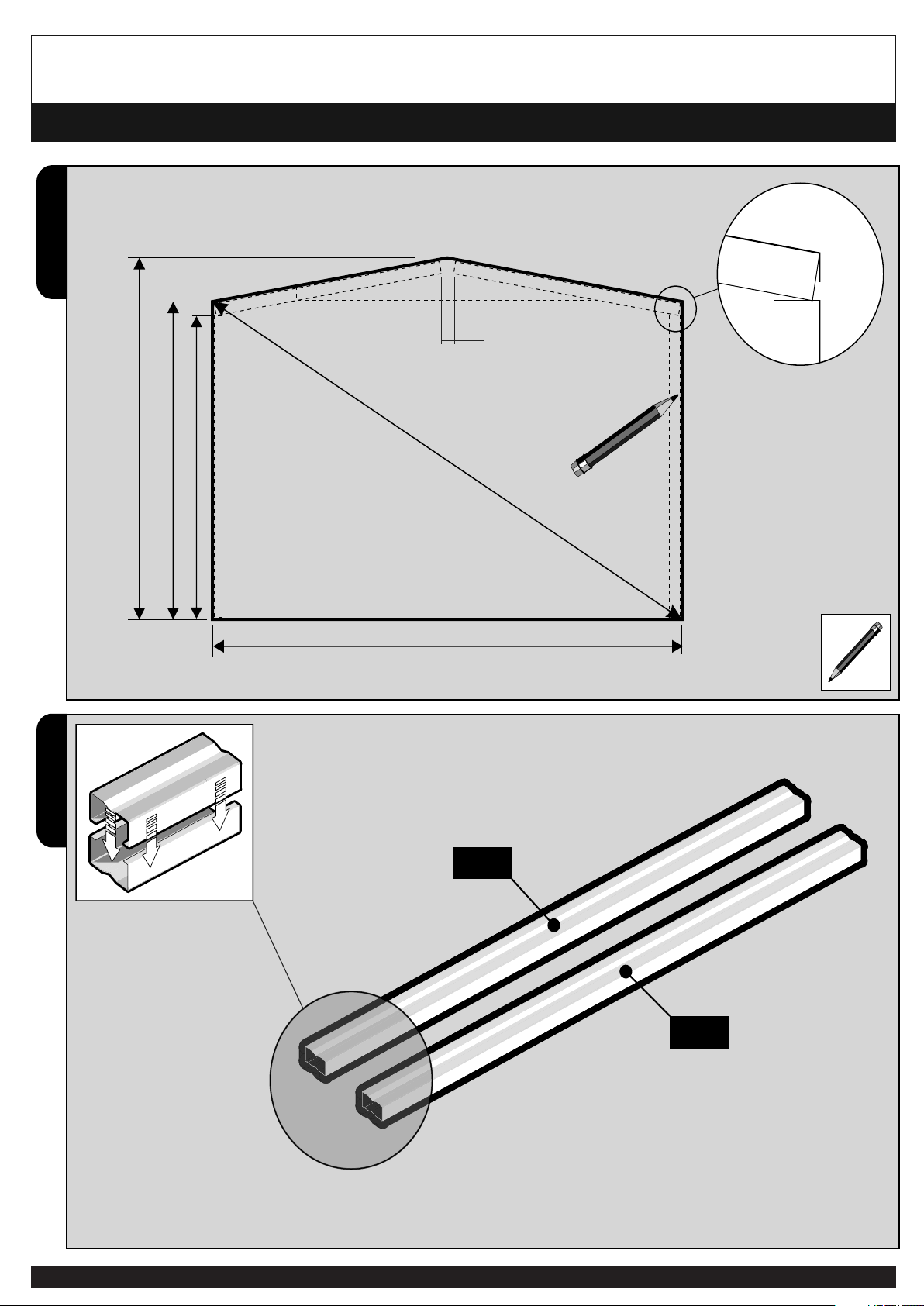

Mark out with pencil or chalk on the flat ground as shown

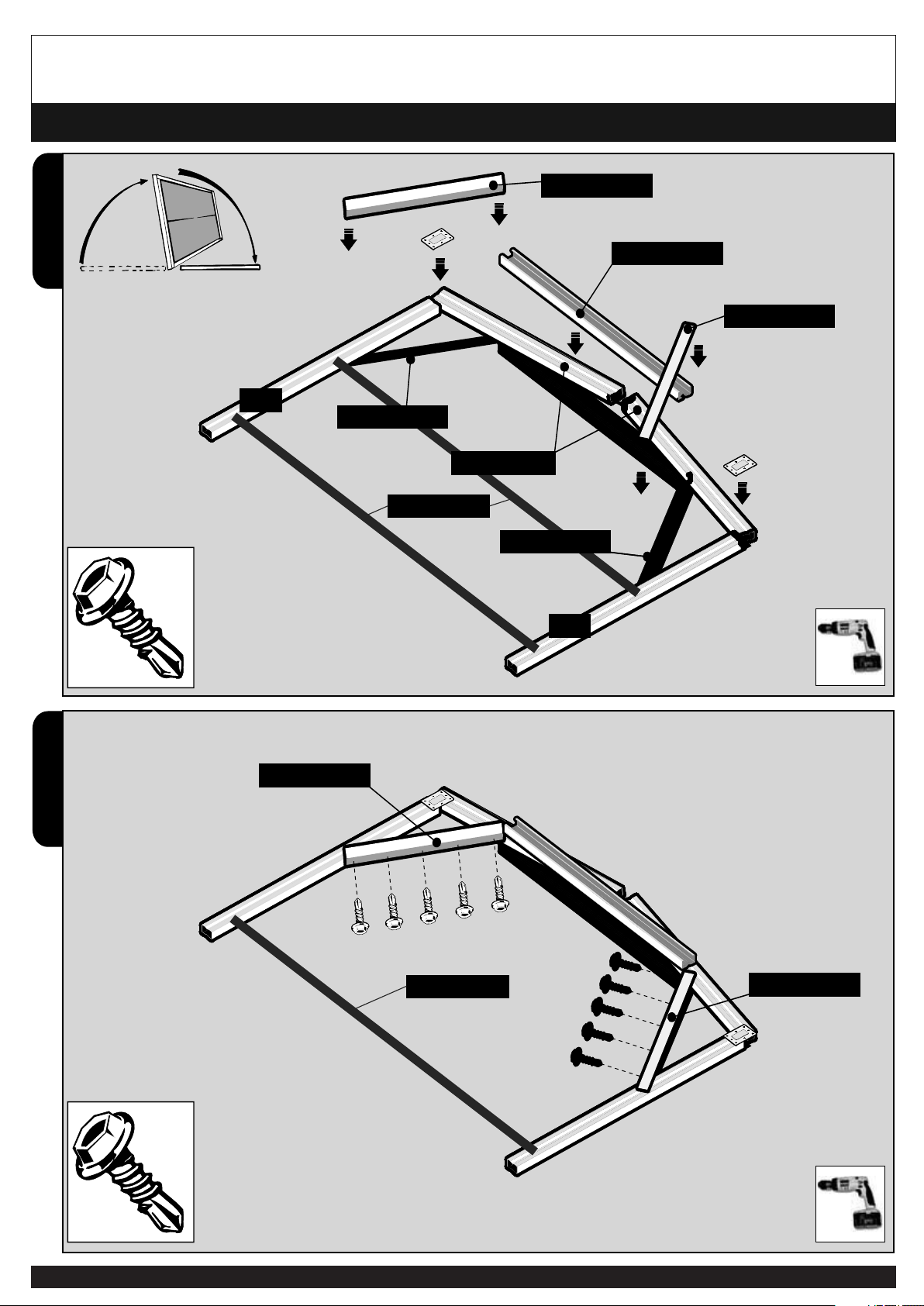

All four Portal Legs are required to be boxed as shown to make 2 legs

Roof beam sits

on top of leg

PORTAL FRAME ASSEMBLY

PAGE 8

All four Portal Legs are required to be boxed as shown to make 2 legs

54

m

m

725

1

Make sure to cut 20mm off, if you have a rebated slab.(L= 1708)

PORTAL FRAME ASSEMBLY

PAGE 9

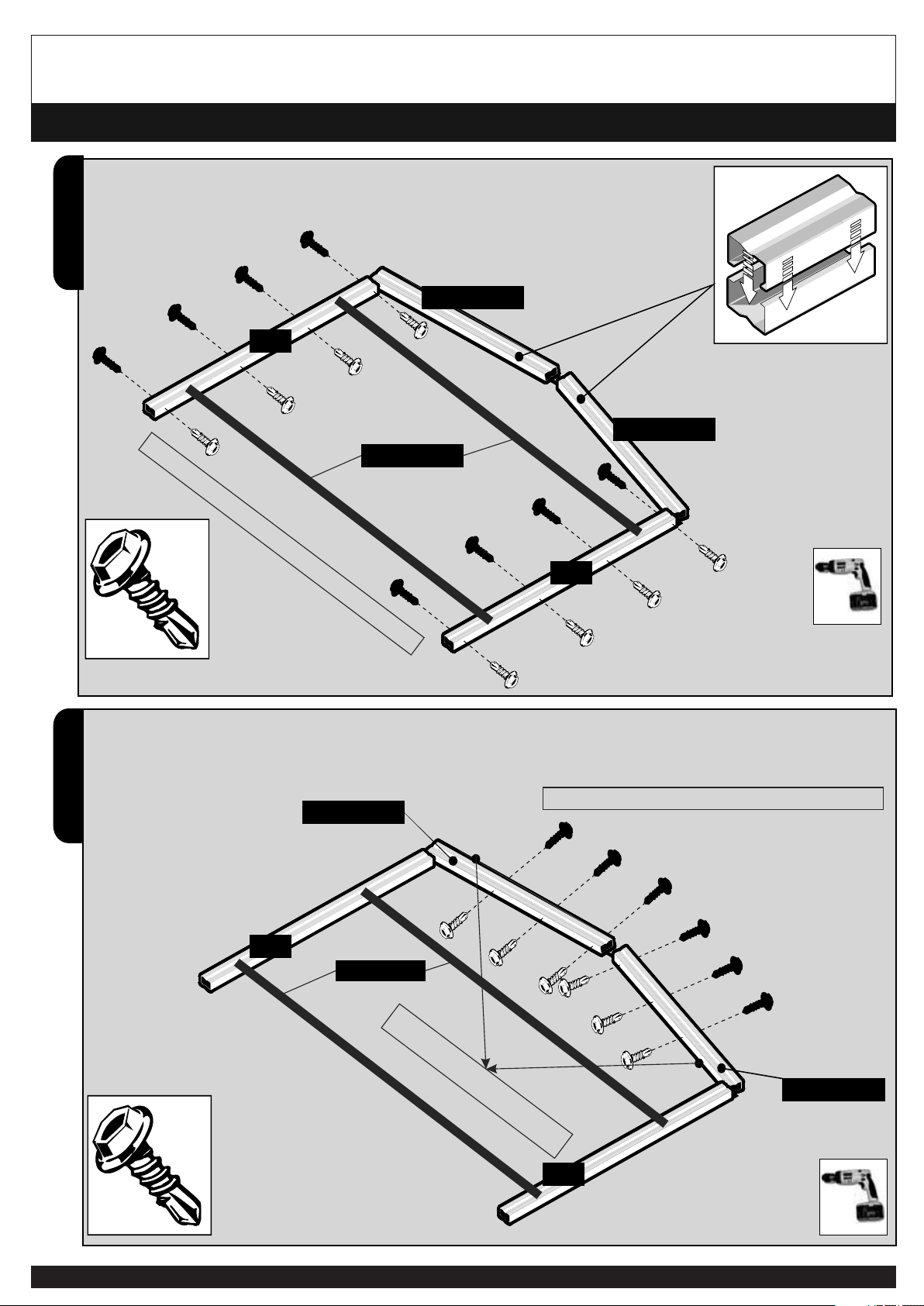

3

4

LEG

LEG

ROOF BEAM

ROOF BEAM

ROOF BEAM

ROOF BEAM

All four Roof Beams

are required to be

boxed as shown

Screw the boxed legs together using the Tek Screws (portal)

Screw the boxed roof beams together using the Tek Screws (portal)

Screws should be through the center of the beam

First screw should be minimum 200mm

away from the outer edge.

LEG

LEG

Screws should be through the center of the beam

Bracing “X”

Use bracing channel “X” to temporarily hold it in place.

Join the bracing channels to the length of 2710mm.

Bracing “X”

PORTAL FRAME ASSEMBLY

PAGE 10

5

6

=

=

LEGLEGLEG

ROOF BEAMROOF BEAM

ROOF BEAM

ROOF BEAM

TOP GUSSETTOP GUSSET

TOP GUSSET

ROOF BEAM

ROOF BEAM

LEG

LEG

Attach the Roof Beams to

the Legs using the

100x70 Plate

Assemble, lay beams out as shown and fix first side of portal

Bracing “X”

PORTAL FRAME ASSEMBLY

PAGE 11

7

ROOF BEAM

CNR GUSSET

CNR GUSSET

LEG

LEG

ROOF BEAM

CNR GUSSET

CNR GUSSET

LEG

LEG

ROOF BEAM

Bracing “X”

PORTAL FRAME ASSEMBLY

PAGE 12

9

8

CNR GUSSET

CNR GUSSET

CNR GUSSET

CNR GUSSET

CNR GUSSET

CNR GUSSET

TOP GUSSET

LEG

LEG

ROOF BEAM

Flip portal and repeat steps 5 - 7

Join both sides of the Corner Gussets using the Portal Tek Screws, then remove the top bracing “X”.

CNR GUSSET

CNR GUSSET

ROOF BEAM

Bracing “X”

Bracing “X”

PORTAL FRAME ASSEMBLY

PAGE 13

Make sure the portals stood up properly on the slab. Out of square portal fixing may create hassle

later while panel fixing.

“SEE DETAILS ON THE NEXT PAGE”

2x2 panel door

2835mm 3180mm

Stand up the portal frame and position as per the dimension given here.

“SEE DETAILS ON THE NEXT PAGE”

Make sure the distance 3180 from the 2x2 Panel Door side edge of the slab.

Portal frame sit 75mm inside the width of the slab over the edge the edge.

It is possible to inter change the position of this door (left or right).

3 Panel Door

75mm

PORTAL FRAME ASSEMBLY

PAGE 14

50mm

50mm

50mm

50mm

Place the 55mm Bracket as shown then

fix it to the portal leg. Make sure it is

square and flat to the slab.

Now Pre drill the Dia 8mm hole to a depth

of 50mm.

Insert and tighten the masonry anchor on

all 4 brackets.

75mm

Now can remove the bracing channel “X”.

PAGE 15

Notched ends are orientated to the

both edges of the rear panel

REAR WALL PANEL

Lay the wall panels out with the large rib

overlapping the small.

1

2

Screw the wall panels in the centre

of the rib as shown.

Overlap top and bottom channel by 130mm. Fit the top and bottom

channel to the wall panels. Ensure the holes in the channels are inline with

holes in the rib of the sheeting. Make sure the small flange on the

channel

positioned outside face of the sheeting.

Outside

Ensure that the small lip

of the channel is to the

outside of the shed.

Wall

Sheet

Channel

Large Rib Small Rib

“D” - Wall Corner Panel

Out side of shed

In side of Shed

Notched ends are orientated to the inside of the shed

130

15

m

m

m

m

130

Required to manipulate sheeting panel to align the channel holes

PAGE 16

REAR WALL - TOP & BOTTOM CHANNEL FIXING

1

2

1

2

Join M(1460) & M(1807) =3267

130mm

Overlap 130mm and join all the channel and

sheeting together

Join m(1461) & m(1460) =2921mm

130mm

Overlap 130mm and join all the channel and

sheeting together

Join M(3137) & m(2791) => 5930mm

Overlap 16mm so that the holes align properly.

Make sure to screw the channels through sheeting from outside.

m

m

m

m

m

3267-130 = 3137mm

130mm

Overlap

130mm

Overlap

2921-130 = 2791mm

5930 - 15 = 5915mm

15mm

Overlap

PAGE 17

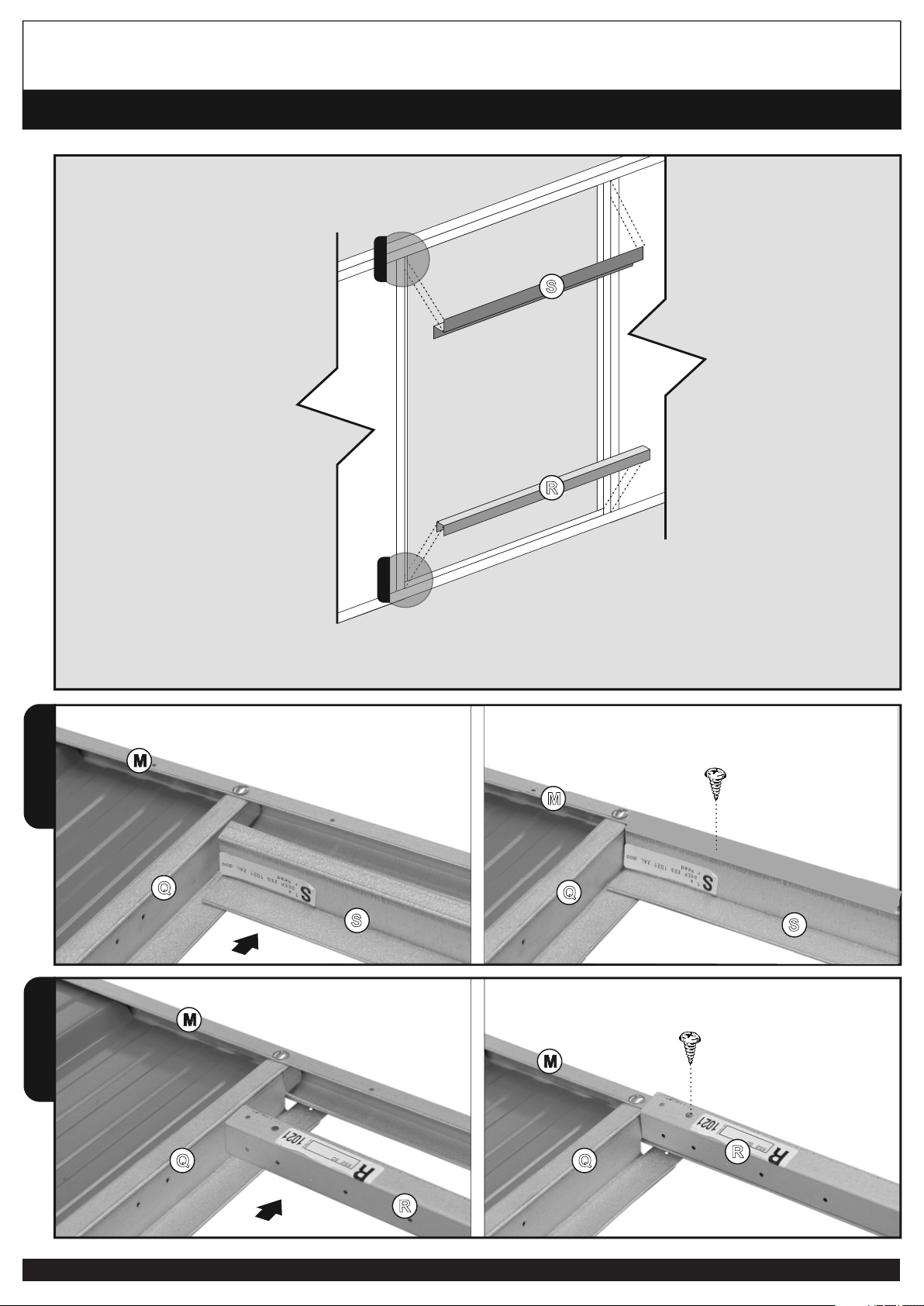

FRONT WALL PANEL

2

Top and bottom door jamb connection.

QQ

MM

1

M

M

Notched ends are orientated to the

outer edges of the panel

Overlap the top and bottom channels by 130mm similarly m&m. M&M

Fit the top and bottom channel and door jambs to the wall panels. Ensure

that the positioning of large rib on the sheets are as indicated in the picture.

Also ensure the channel is flush with the edge of the sheets.

It is possible to interchange the orientation of the doors. Make sure the

Outside

Ensure that the small lip

of the channel is to the

outside of the shed.

Wall

Sheet

Channel

Large Rib Small Rib

Large Lip overlaps Small

Lip when fastening sheet

to sheet

CCC

D

MM

Large Rib

MM

CCCC C

mM1

D

Large Rib

Large Rib

“D” - Wall Corner Panel “D” - Wall Corner Panel

130

130 15

4 Sheet Gap

3 Sheet Gap

Small Rib

m

m

m

Small Rib

Small Rib

channels also oriented as per the drawing here.

M

MM

Required to manipulate sheeting panel to align the channel holes

PAGE 18

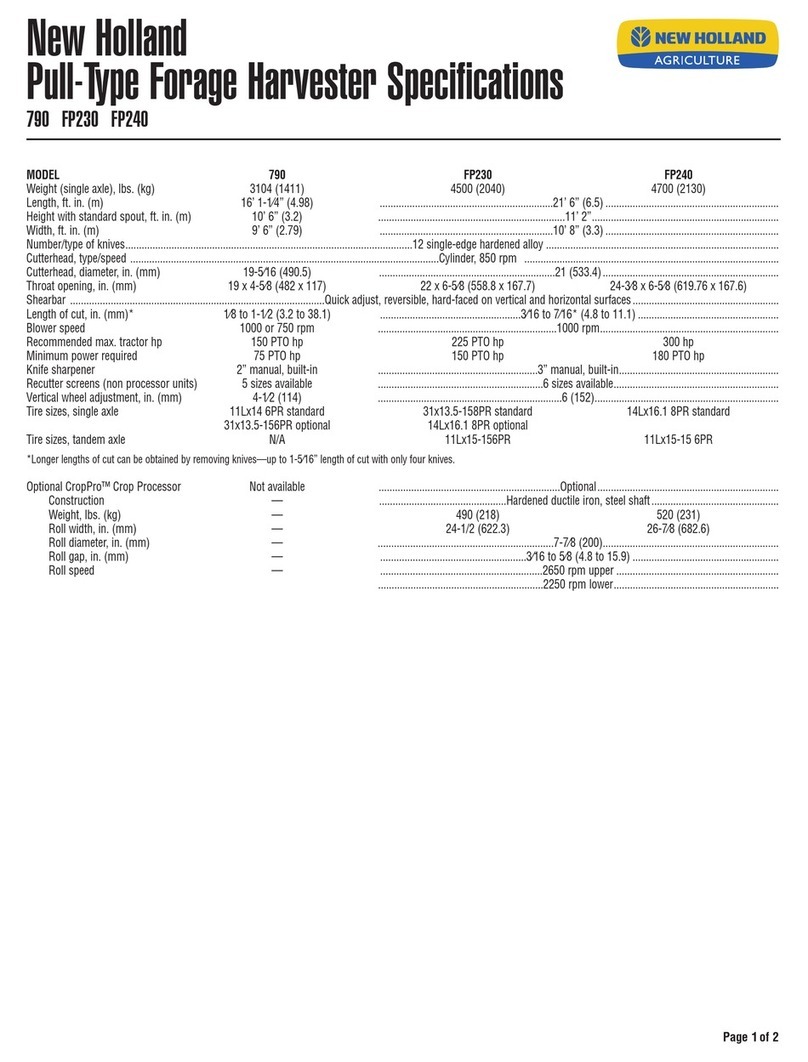

3

Fit the top door spacer and the bottom door spacer to the front wall panel as shown. Some pilot holes

may need to be drilled with the included 2.5mm drill bit

4

FRONT WALL PANEL- 2x2 PANEL DOOR

3

4

R

Q

S

S S

Q

M

M

R

R

Q Q

M

M

S

Q

M

PAGE 19

3

Fit the top door spacer and the bottom door spacer to the front wall panel as shown. Some pilot holes

may need to be drilled with the included 2.5mm drill bit

4

FRONT WALL PANEL- 3 PANEL DOOR

3

4

R1

Q

S1

S1 S

Q

M

M

R1

R1

Q Q

M

M

S1

Q

M

PAGE 20

FRONT WALL PANEL

Table of contents

Popular Lawn And Garden Equipment manuals by other brands

Everbloom

Everbloom Cornerstone R212421 installation guide

Krone

Krone Big Pack 890 Original operating instructions

Backyard Discovery

Backyard Discovery 14x10 BROCKTON PERGOLA Owner's manual & assembly instructions

New Holland

New Holland 790 Specifications

Miracle-Gro

Miracle-Gro Twelve Instruction guide

SGS

SGS SCT501 owner's manual

AquaCraft

AquaCraft 290100 instructions

Max

Max PASJ30(CE) Operating and maintenance manual

hillvert

hillvert HT-ELBERT170 user manual

Worksaver

Worksaver JDBS-412 Owner's/operator's manual

Tracmaster

Tracmaster Camon LS52 Original instruction manual

Husqvarna

Husqvarna 42" Collection System Operator and parts manual