CAMON LS52 Lawn Scarier

LS52-03/2022.A Page 1

Table of Contents

1.0 Introducon .............................................................................................................................2

1.1 Welcome ................................................................................................................................2

1.2 About This Manual ................................................................................................................2

2.0 What the Machine is Designed For............................................................................................3

2.1 Applicaons ...........................................................................................................................3

3.0 Specicaons............................................................................................................................4

4.0 Unpacking and Assembly ..........................................................................................................5

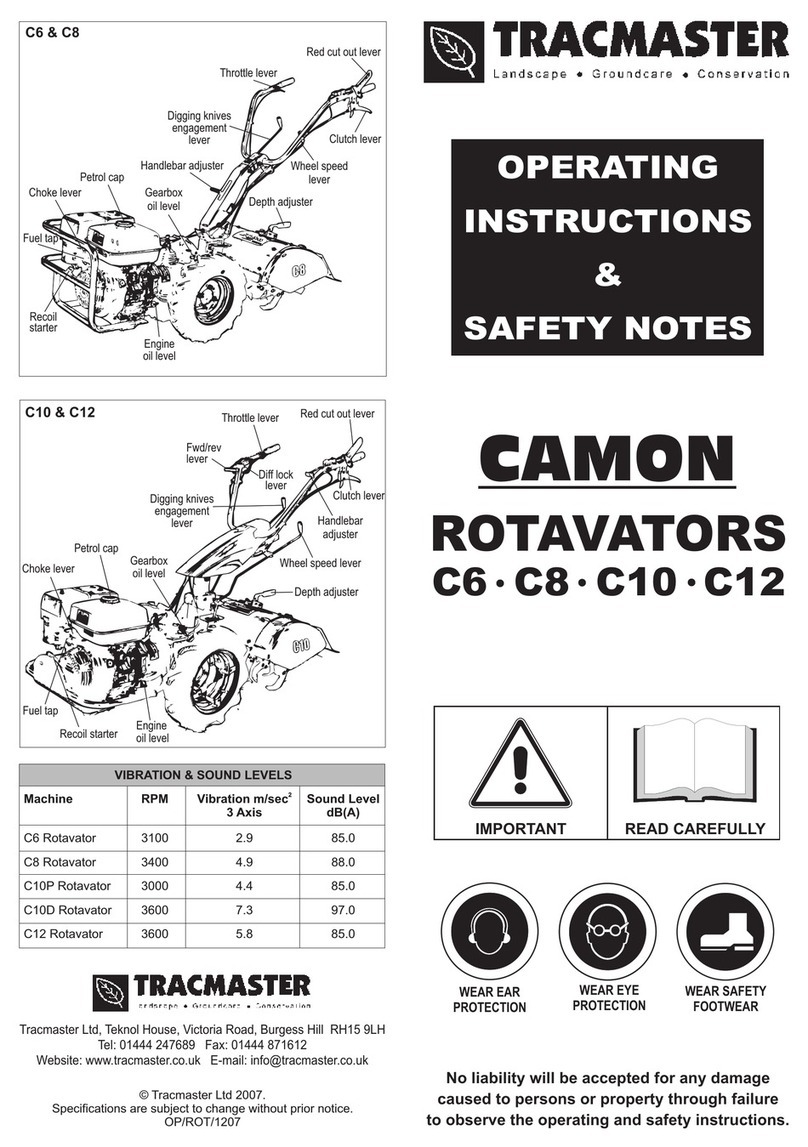

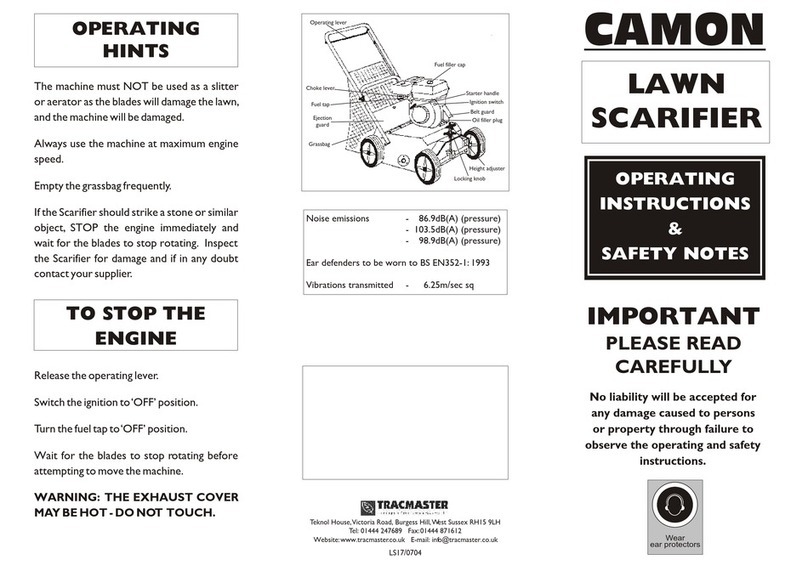

4.1 Major Components Diagram .................................................................................................5

4.2 Unpacking Instrucons ..........................................................................................................5

5.0 Safety Instrucons – Pre-Operaon ..........................................................................................6

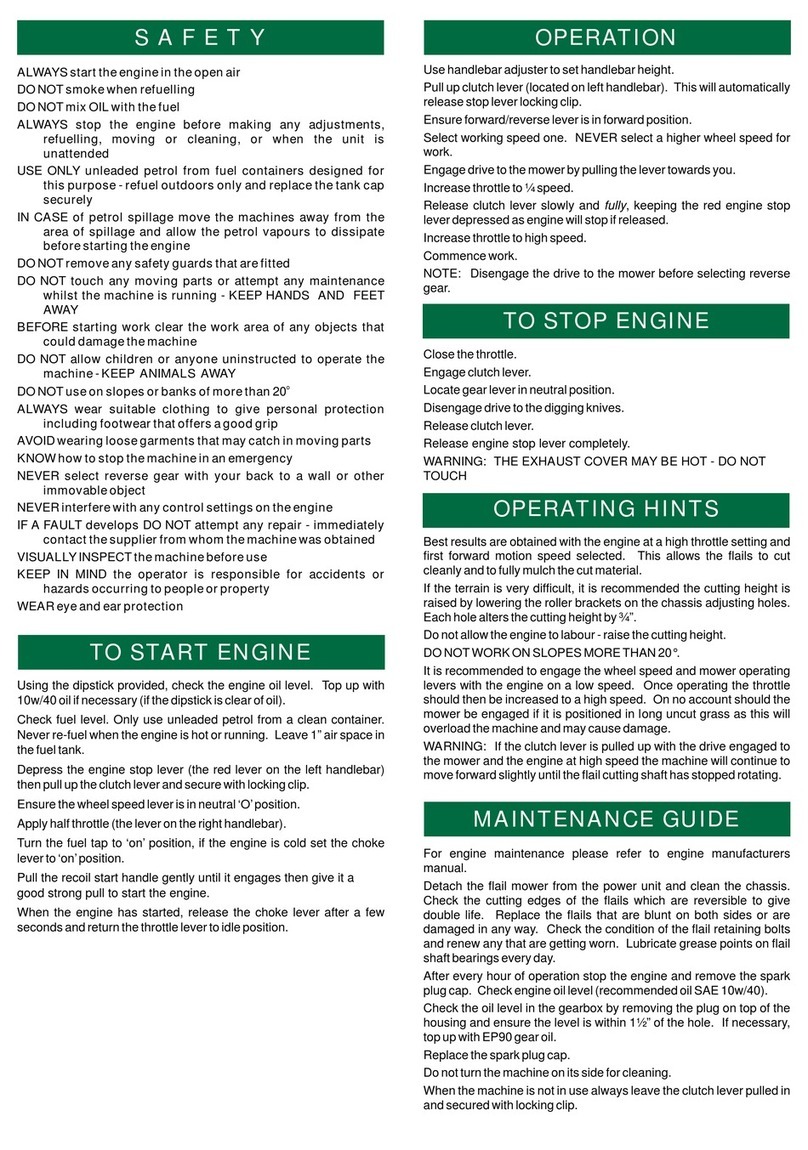

5.1 Basic Safety Instrucons ........................................................................................................6

5.2 Main Components and Operang Elements .........................................................................6

5.3 Engine and Drive ....................................................................................................................6

5.4 Operang Lever .....................................................................................................................6

5.5 Height Adjustment.................................................................................................................6

5.6 Collecon Bag ........................................................................................................................7

5.7 Rotor Sha .............................................................................................................................7

5.8 Commissioning ......................................................................................................................8

5.9 General Safety Instrucons ...................................................................................................8

5.10 Engine Specic Safety Instrucons ........................................................................................9

5.11 Machine Safety Scker Explanaons .....................................................................................9

6.0 Safety Instrucons Starng and Operang..............................................................................11

6.1 To Start the Engine ..............................................................................................................11

6.2 To Stop the Engine ...............................................................................................................12

6.3 Safety Equipment ................................................................................................................12

6.4 Operaon.............................................................................................................................12

6.5 Procedure for Unexpected Shut Down ................................................................................14

6.6 How to Clear Unwanted Debris from the Underside of the Machine .................................14

6.7 Residual Risks of the LS52 Lawn Scarier ............................................................................15

7.0 Maintenance ..........................................................................................................................16

7.1 Schedule ..............................................................................................................................16

7.2 Basic Maintenance ..............................................................................................................16

7.3 Advanced Maintenance .......................................................................................................16

7.3.1 Belt ............................................................................................................................16

7.3.2 Removing Cartridge/Rotor Assembly ........................................................................17

7.3.3 Fing Cartridge/Rotor Assembly ..............................................................................18

7.3.4 Blades ........................................................................................................................18

7.4 Engine ..................................................................................................................................21

7.4.1 Check Engine Oil Level ..............................................................................................21

7.4.2 Change Engine Oil .....................................................................................................22

7.4.3 Air Filter ....................................................................................................................22

7.4.4 Spark Plug .................................................................................................................22

7.5 Cleaning ...............................................................................................................................23

7.6 Troubleshoong ...................................................................................................................23

7.6.1 Machine ....................................................................................................................23

7.6.2 Engine ......................................................................................................................23

7.6.3 Lubricants ..................................................................................................................23

8.0 Transportaon, Storage and Handling.....................................................................................24

8.1 Transportaon .....................................................................................................................24

8.2 Storage.................................................................................................................................24

8.3 Handling ..............................................................................................................................24

9.0 Spare Parts .............................................................................................................................25

9.1 Parts Diagrams .....................................................................................................................25

10.0 Service Record ........................................................................................................................26

11.0 EC Declaraon of Conformity..................................................................................................27

12.0 Warranty Informaon.............................................................................................................28