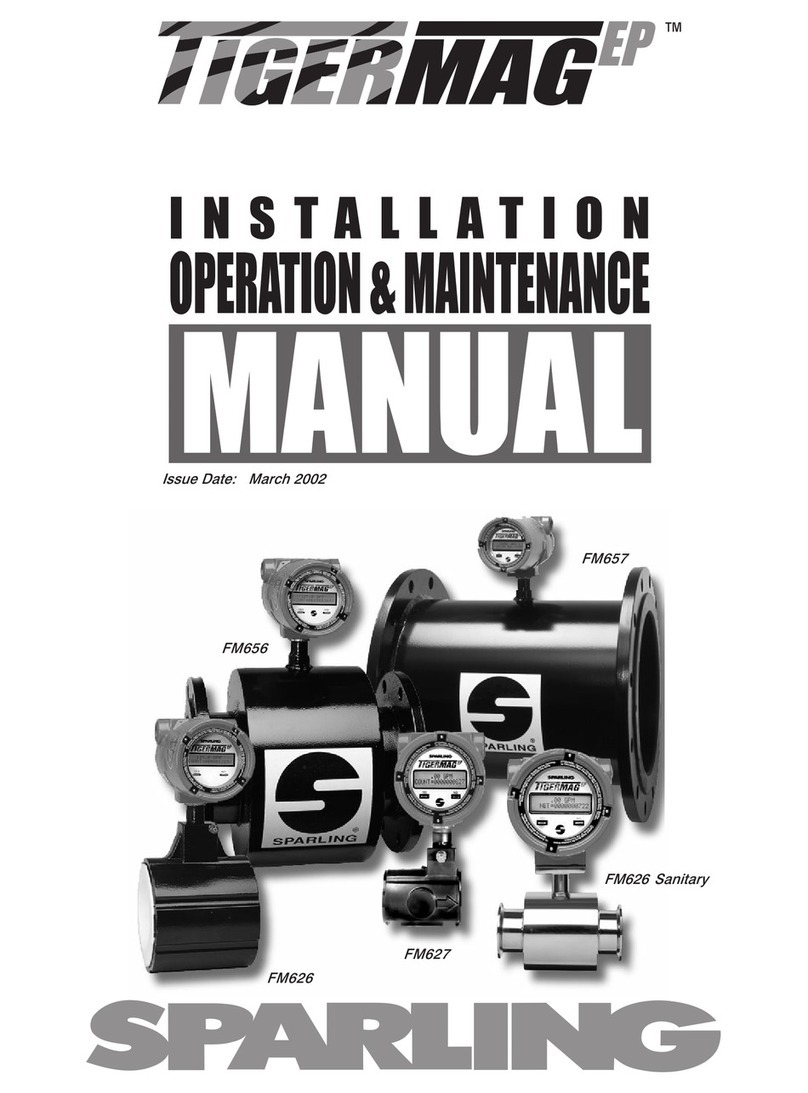

SPARLING TigermagEP FM656 Instruction manual

TM

Original Issue Date: March 2002

Revision 190101

FM657

FM656

FM626

Sanitary

FM626

FM627

TABLEOF

C

O

NTE

NTS

Page

SECTION

1 -

GENERAL

..............................

1

1.1

Measuring

System ........................................

1

1.2

Operating

Principal ........................................

1

1.3

Application

to

Magnetic

Flow

Measurement ................................................ 1

1.4

Interference ...................................................

2

1.5

SystemOperation .........................................

3

1.6

Construction ..................................................

4

1.7

Specifications ................................................

5

1.8

Interchangeability ...........................................

7

1.9

FlowRates,

Dimensions

&

Weight .................

7

SECTION

2 -

PRE-INSTALLATION

.....

10

2.1

Receiving

and

Inspection ............................

10

2.2

Storage .......................................................

10

2.3

Return

of

Equipment

....................................

10

SECTION

3 - INSTALLATION

...............

11

3.1

Application

Considerations ..........................

11

3.2

SiteSelection ...............................................

11

3.3

Rotating

the

TransmitterDisplay ..................

12

3.4

Removable

Electrodes ................................

13

3.5

Hot-Tap

Removable

Electrodes ..................

13

3.6

PipeConnections ........................................

15

3.7

Special Mounting Bolts & Gaskets ...........

16

3.8

Grounding ...................................................

20

3.9

ElectricalConnections .................................

21

3.10

Remote

Mounted

Transmitter ......................

24

3.11

Lightening

Protection ...................................

28

SECTION

4 -

START-UP

.........................

28

4.1

Start-Up

Procedure .....................................

28

SECTION

5 -

CALIBRATION

..................

28

5.1

Calibration ...................................................

28

SECTION

6 - MAINTENANCE

...............

29

SECTION

7 -

TROUBLESHOOTING

...

29

7.1

General

........................................................

29

7.2

Troubleshooting

Chart .................................

29

7.3

Electronics

SelfTest

.....................................

31

7.4

Electronics

Module

Replacement ................

31

7.5

SensorTesting ............................................

32

7.6

Coil

Continuity

Testing .................................

33

7.7

Coil

Insulation

Test

.......................................

33

Page

7.8

Electrode

Circuit

Insulation

Test ...................

33

SECTION

8 –

REPLACEMENT

PARTS

LIST ......................................................

34

APPENDIX 1-

PROGRAMMING

.........

35

1.1

General .....................................................

35

1.2

Entering

Data

.............................................

35

1.3

Batching

Modes

........................................

36

1.4

ShowMeter

Data

.......................................

36

1.5

Password

Entry

.........................................

36

1.6

RescaleRate .............................................

37

1.6.1

SelectRateUnits .......................................

37

1.6.2

SetFullScale .............................................

38

1.6.3

Select Rate as %of Full Scale ...................

38

1.7

RescaleTotal

.............................................

38

1.7.0

Lockout .....................................................

38

1.7.1

Alarms .......................................................

39

1.7.2

Count

Direction

..........................................

39

1.7.3

SelectTotal

Units

.......................................

39

1.7.4

SetRegistration .........................................

40

1.7.5

ResetTotalizer ..........................................

40

1.8

SetOutputs ...............................................

40

1.8.1

SelectPulseWidth.....................................

40

1.8.2

Backlight ...................................................

41

1.8.3

SetFlowDirection .....................................

41

1.8.4

Empty

Pipe

Detection

................................

41

1.8.5

Protocol ....................................................

41

1.9

Damping

Adjustments ..............................

42

1.9.1

Display

Damping

.......................................

42

1.9.2

Current

Damping

.......................................

42

1.9.3

Low Flow

Cutoff

........................................

42

2.0

Exit

Programming .....................................

42

2.1

Change

Password

.....................................

42

2.2

Change

Tag

...............................................

43

2.3

Diagnostics ...............................................

43

2.3.1

Check

HART

Transmission .......................

43

Check

Coil

Current .................................... 43

2.3.2

Check Current

Loop

.................................

44

2.3.3

Calibrate

4-20mA

Loop

.............................

44

2.3.4

SetFrequency ...........................................

44

2.3.5

Simulate75%

FS

.......................................

45

2.3.6

Simulator

Check ........................................

45

IDS-626/627/656/657

Page

i

TABLEOF

C

O

NTE

NTS

cont'd. APPENDIX 2 – Batch

Programming

Page Page

and

Operation

.............................

46

1.1

General .....................................................

46

1.2

Programming

............................................

46

1.2.0

Lockout .....................................................

46

1.3

Rescale

Total

.............................................

47

1.3.1

Batch

On/Off .............................................

47

1.3.2

Alarms .......................................................

47

1.3.3

Count

Direction

..........................................

47

1.3.4

Select

Total

Units

.......................................

48

1.3.5

User

Defined TotalizerUnits ......................

48

Conversion Factor ....................................

48

1.4.1

Descriptionof

Operating ...........................

49

APPENDIX3 -

Communication

......

50

1.1

RS232Sparling

Protocol

.............................

50

1.2

RS485 .........................................................

51

FIGURES

1.1

Measuring

Principal

.....................................

1

1.2

Block Diagram ............................................

3

1.3

Dimensions .................................................

8

3.1

Full

Pipe Required .....................................

11

3.2

Changing

the

Rotatable

Display ................

12

3.4

Hot Tap Electrode .....................................

13

3.5

Removing theElectrode ...........................

14

3.6

FM626

Gasket

Installation .........................

18

3.7

FM626 Sensor

Position

.............................

18

3.8

FM656

Gasket

Installation .........................

19

3.9

FM656 Sensor

Position

.............................

19

3.10

Grounding

.................................................

20

3.11

Conduit

Connections ................................

21

3.12

ElectricalConnections

I/O

PCB

.................

22

3.13

Installing

Diode

Across

Inductive

Loads .........................................

23

3.14

TigermagEP

Remote

Display ....................

24

FIGURES

cont'd.

3.15

TigermagEP

Remote

Conduit

Connections ..............................................

24

3.16

TigermagEP

Standard

Motherboard .............................................

25

3.17

Remote

Mounted

Transmitter ...................

27

4.1

Power Supply Voltage

Ratings

.................

28

7.1

AccesstoElectronics

................................

31

7.2

Removing theElectronics Module ............

31

7.3

Aligning

Electronics

Module

with

Card

Guides

.......................................

32

7.4

Replacing the E

2

PROMChip .....................

32

7.5

Coil

Resistance

Testing .............................

33

7.6

Coil

Insulation

Testing

................................

33

7.7

Electrode

Circuit

Insulation

Test ................

33

A1.1

TigermagEPDisplay .................................

35

A1.2

Main Program ...........................................

36

A1.3

Rescale RateFlow Chart ...........................

37

A1.4

RescaleTotalFlow Chart

...........................

38

A1.5

SetOutputs Flow Chart .............................

40

A1.6

Connecting

HART

Communicator .............

41

A1.7

SetDamping Flow Chart ...........................

42

A1.8

Change

Tag

...............................................

43

A1.9

Diagnostics

Flow

Chart .............................

43

A2.0

Simulate

Mode

..........................................

45

A2.1

Enclosurefor

TigermagEP

with

Batching .............................................

46

A2.2

RescaleRate

w/Batcher

Flowchart ..................................................

47

TABLES

1.

Nominal Flow Rates ......................................

7

2.

Weight ...........................................................

7

3.

Dimensions ...................................................

9

4.

Gasket

Material ...........................................

15

5.

Meter I.D. ....................................................

16

6.

Torque, Flange

&Bolt

Specifications ..............................................

17

Page ii TigermagEP™

1.3

Modbus

RTU

.. .........................................

52

1.2

1.0

Gener

al

1.1

Measuring

System

TheSparlingTigermagEPTM ModelFM-626,FM627,FM-656 andFM-657flowmetersare

obstructionless devices for monitoring the volumetric flow of conductive liquids infull closed

pipes.

Theflowmeterconsistsofasensor(waferorflanged)withanonmagnetic liner,sensing

electrodesand ameasuringtransmitter.

Operation is based on Faraday s Law of

Mag- netic Induction. An electrically

conductive liquid flowing through a magnetic

field induces avolt-

Operating

Principle age which is perpendicular to this field and to

the direction of the flow. This voltage is

proportional to theaverage flow velocity. See

Figure 1.1.

The mathematical formula describing

Faraday s lawreads:

E = B x L x V

E=Induced voltage

B=Magnetic field intensity (flux

density) L =Distance between the

electrodes

(pipe diameter)

V = Average flow velocity of

liquid

1.

3

Application

to

Magnetic

Flow

Measurement

Measuring

Principle

Figure 1.1

In a magnetic flowmeter the liquid acts as a moving conductor as it flows through the pipe. The

induced voltage (E) in the liquid is measured by two sensing electrodes mounted opposite

each other in the meter sensing head.

The length of the conductor is equal to the distance between sensing electrodes and also

the internal diameter (D) of the pipe. The flux density is proportional to the coil current (I),

times aconstant (k). The above formula can be restated asfollows:

E= I xk x D xV

flow

0

V

=

cross sectional

area

=

A

0

x

I

x

4

x

k

E

=

D

2

Note that if I is held constant, E is proportional to0or theinduced voltageis directly

proportional to the average flow rate (V).

IDS-626/627/656/657

Page

1

1.

4

Interference

1.4.1 ElectrochemicalInterference

The signal voltage is measured by two electrodes. Galvanic elements form on the surface

areas between the ion-conducting liquid and the metal electrodes. The polarization voltages

which result are dependent on temperature, pressure, and the chemical composition of the

electrodes and liquid. These are direct voltages which cannot be predicted and which can be

different at each electrode. The signal voltage must be separated from the interference

direct voltage. Proper grounding eliminates these unpredictable voltages from interfering

withthe signal voltage.

1.4.2 InductionInterference(Quadrature)

Electrode cables connect the electrodes with the meter electronics. Because these cables

must run within the magnetic field, a voltage is induced which is proportional to the rate of

change of the magnetic field strength. The meter design minimizes the length of conductor

within the magnetic field in order to keep thevalue of this interference as low as possible.

1.4.3 Other InterferenceVoltages

Pipes and the liquids within them are often used as a conductor for electrical grounding. This

creates a voltage potential between electrodes which can be high relative to the signal

voltage. Proper grounding of the flowmeter to the liquid is necessary to achieve correct meter

operation. Grounding rings should be installed if theflowing medium has a voltage potential,

if piping is nonconductive (plastic or lined) or if conductivity is below 20 micromhos/cm. See

Section 3.8 -Grounding.

Page 2 TigermagEP™

1.5

System

Operation

The Sparling TigermagEP™ uses the autozeroing, bipolar, pulsed-DC measuring

technique. The circuitry (Fig. 1.2) energizes the coil with 300 mA typical current at a

frequency ofupto 100 Hz. The signal generated at the electrodes is measured near the end of

each measuring cycle to eliminate the capacitive effects of coatings. The Hi-Z (1012 Ω) input

impedance eliminates the resistive effects of electrode coatings. The field current alternates

to a positive and negative state and the two measured signals are averaged to eliminate the

effect ofazero offset-this is the auto-zeroing feature.

1. MeasuringSensor

6. Sampleand Hold

11.Adjustable EmptyPipe

14.LCD Display with Hall-Effect

2. Electrode Cable PCB

3. Input Amplifier

7. Voltage to Frequency Converter

8. Nonvolatile E2PROM

Detection (in software)

12.Watchdog Timer

Switches

15. Optocouplers

4. Summing Point

9. Coil Current Multiplexer

13. Microcontroller

16.Frequency toCurrent

C t

5. Autozero Circuit

10.Built-in Simulator

17.Power Supply Section

Block Diagram

Figure 1.2

IDS-626/627/656/657

Page

3

1.6

Construction

1.6.1 Sensor

The FM626 is a wafer style meter. It is available with either a ceramic or optional Tefzel®

liner. The Tefzel® lineris rotamolded onto astainless steelsensor tube. Both liners arepress-

fit into acarbon steel housing. The FM627 is a wafer style meter. The flow sensor housing is

made of steel with a polyurethane liner. Sensor coils are completely encapsulated in

polyurethane. The FM656 flow sensor is a welded fabrication of 304 stainless steel, fitted

with two carbon steel flanges. The flow sensor contains a nonconductive liner of ceramic,

polyurethane, Tefzel®, hard rubber, soft rubber, or neoprene. The FM657 flow sensor

housing is made of steel with a polyurethane liner. Sensor coils are completely encapsulated

in polyurethane. All TigermagEP™ meters are rugged, waterproof assemblies capable of

handling awide range ofhighly corrosive and abrasive liquids.

Fused platinum electrodes, standard on ceramic meters from 0.1" to 2", require no O-

rings, eliminating the possibility of leaking. Platinum is suitable for nearly all conductive

liquids. The electrodes in all other liners are self-sealing.

All internal cavities of the FM-626 sensor housing are filled with a high temperature silicone

potting compound to prevent the possibility of moisture damage and to avoid the possibility

of collection of explosive gases.

▼WHENPROPERLY CONNECTEDWITHLIQUID-TIGHTCONDUIT, THEFM626ANDFM627

REMOTE FLOWSENSOR WILLWITHSTANDACCIDENTALSUBMERGENCE. (SEE FIG. 3.16 ON

PAGE25).

1.6.2 Integral Transmitter

The transmitter is mounted on the meter body and housed in a NEMA-4Xand NEMA-7 enclosure

thatis approvedbyCSAandFactoryMutual.Thepowerandsignalelectricalconnectionsaremadein

aseparate section of thehousing which is isolated from theelectronics.

1.6.3 Remote Transmitter

Thetransmitter ishoused in a NEMA-4X enclosure somedistance away from the meter

body. Remote mounting is recommended where pipe vibration is excessive or when

floodingis

possible.

Remote mounting tor the FM626 and FM656 is REQUIREDwhen high process

tempera- tures exist at high ambient temperatures (above 212° F/100° C). The FM627

andFM657should notbeinstalled where process temperatures will exceed 180° F.

The optional remote mounting kit includes interconnecting cable between the sensor

and transmitter enclosure. The standard interconnecting cable length is 15 feet.

Shorter or longer cables should be specified when ordered from the factory. The cable

maybeshortenedinthe field.

CAUTION

DO NOT MAKE CONNECTIONS WHILE

POWER IS APPLIED.

Disconnect Power Before Proceeding

Page 4 TigermagEP™

1.7

Specifications

Power Requirements See Nameplate

Fuses Slo-Blo (12-60 Vdc) ......................................................................... 2.0

amp Slo-Blo (77-265 Vac) .......................................................................

1.0 amp Spare fuse provided on connector PCB.

Wire Size Power ...................................................................... 16 AWG 14 AWG

Max Signal ............................................................................................... 18

AWG

Ground Cable Third wire ground of power cable

Accuracy 0.1" - 0.25"

(Frequency Output) 1.0% of flow rate (3-33 fps)

0.5" - 54.0"

0.5% of flow rate

(1-33 fps)

Reference Conditions 25° C, 6 fps full scale. Temperature effect, 0.025% Full Scale/°C.

Accuracy statement based on digital outputs

Repeatability Within ±0.1% full scale

Power Consumption Less than 20 W

utput Signals Simultaneous isolated analog and digital

(all referenced to the same isolated ground) Analog:

0 to 20 or 4-20 mAdc into 800 ohms max. Digital:

Scaled pulse and frequency

a. Scaled, 24 Vdc pulse with 12.5/25/50/100 ms on-time,

0-60 Hz max into 150 ohm impedance min.

b. Scaled frequency. 15 Vdc square wave, 50/50 duty cycle,

0-1000 Hz max into 1000 ohms min.

c. Fault, with open collector

d. All open collectors are rated (100mA at 30 Vdc)

e. RS232 Communication and digital outputs to zero when

Input Signal Positive zero return (PZR). Connect to remote dry contact to drive analog

an empty pipe condition can occur.

Minimum Conductivity 5 micromhos/cm

Flow Direction Open collector (rating: 100 mA at 30 Vdc). Active in reverse flow.

Fault Alarm Open collector. Active on self test failure, empty pipe and during

programming, low/no coil drive and failure of external totalizer to keep up

with the flow (registration too small). Relay option available

1.

Two Flow Alarms Open collector. Relay option available in remote mounting only.

1

1 Please note that Tigermag EP can only be configured with either two Flow Alarm Relays or the

Fault Alarm Relay

IDS-626/627/656/657 Page 5

1.7

Specifications

Cont'd.

Full Scale

Velocity Ranges0-3 to

0-33

fps (0-1to

0-10

mps)

Ambient Temp Limits

-20°

to

140°F (-30°

to 60 °C)

(Display

may

darken

above158 °F)

Process TempIntegral Mount

Hard rubber, Softrubber, Neoprene, Polyurethane .............-40

-180°F

Tefzel

®

,

Ceramic: ................................................................. -40

-

212°

F

Remote Mount (opt)

Hard rubber, Softrubber, Neoprene, Polyurethane ............ -40

-

180°

F

Tefzel

®

(to 300psi), Ceramic: .............................................. -40

-

266°

F

High Temp Coils (opt)

Tefzel

®

(to 100

psi):

............................................................. -40

-

300°

F

Ceramic: .............................................................................. -40

-

420°

F

Temperatures above 212°F (100°

C)

require mounting

the

electronics

in a

remote location (max. distance 15 feet at liquid

conductivity

of 5 micro-

mhos and min.

velocity

of 1 fps).

Storage Temp Limits

-20°

to

140°

F

(-30°

to

60°

C)

Construction

Metering Tube .......................................... Model 626

-

Steel, epoxy c

o

at

e

d

Model 656

-

0.5"-4" Steel, epoxy

coated

Model 656

-

6"

-

72"304 SSwelded, epoxy

coated

Model 627

-

1"

-

8" Cast Ductile Iron, epoxy c

o

at

e

d

Model 657

-

2"

-

48"Fabricated Steel, epoxy

coated

Fl

an

g

e

s

Carbon steel ANSI

compatible

Lining ................................... Model 626

-

Aluminum Oxide 99.5%

o

r

Tefzel

®

Model 656

-

Polyurethane, Aluminum Oxide 99.5

%

Tefzel

®

, Hard Rubber, Soft Rubber,

Neopr

ene

Model 627& 657

-

Polyuret

hane

Electrodes

..........................................................

316 SS.Others as

required

Integral Housing (XMTR) ................ Cast Aluminum, Hi-build

E

p

o

x

y

Coated

Remote Housing

(XM

TR

)

.............................................................

Fiberglass

Protection

rating

Integral ................................................................... NEMA-4X,

NEMA-7

Remote .................................................................................

NEMA-4X

Electrical

rating

Remote

Mount

General

Purpose

Integral

Mount

Hazardous

Locations

FMApproved* for Class

I, Division

1, GroupsB, C, D

Class

II

GroupsE, F, G

CE Approved (pending)

CSA

Approved* for Class1,

Division

2, GroupsA, B, C, D

*FM and

CSA applies

to

integrally mounted transmitters

up to

150

psi

onl

y.

Page 6 TigermagEP™

Nominal

Meter

Size

626

(

C

er

a

m

i

c/

T

efzel)

**

626 (Sanitary)

627 (Poly)

626, 656, 657 (others)

±

.5

%

1 fps

Min

3 fps

Max

33 fps

±

.5

%

1 fps

Min

3 fps

Max

33 fps

±

.5

%

1 fps

Min

3 fps

Max

33 fps

±

.5

%

1 fps

Min

3 fps

Max

33 fps

I

nches

mm

*

0.1

*0.25

*

0.5

1.0

1.5

2.0

2.5

3.0

4.0

6.0

8.0

10.0

12.0

14.0

16.0

18.0

20.0

24.0

30.0

36.0

42.0

48.0

54.0

60.0

66.0

72.0

2.5

12

25

40

50

65

80

100

150

200

250

300

350

400

450

500

600

750

900

1050

1200

1350

1500

1650

1800

0.04

.22

0.50

1.62

4

7

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

0.1

0.6

1.5

4

13

21

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

1.3

7.2

16

53

145

231

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

1.3

3.7

7.2

12

18

33

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

4

11

22

3

54

99

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

42

120

239

3

98

598

1088

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

1.6

N/A

7

N/A

20

35

88

147

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

4.8

N/A

21

N/A

60

105

264

441

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

53

N/A

231

N/A

660

1155

2910

4851

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

0.

2

5

9

N/A

20

35

85

145

23

333

409

545

667

879

1273

1909

2925

4040

5322

7144

8500

10300

12700

N/A

N/A

1.7

6

15

27

N/A

60

107

254

43

709

1000

1227

1636

2000

2636

3818

5727

8775

12120

15966

21433

25500

31000

38100

N

/

A

N

/

A

18

66

174

303

N/A

664

1182

2800

4800

7800

11000

13500

18000

22000

29000

42000

63000

96525

133320

175626

235800

280500

341000

419100

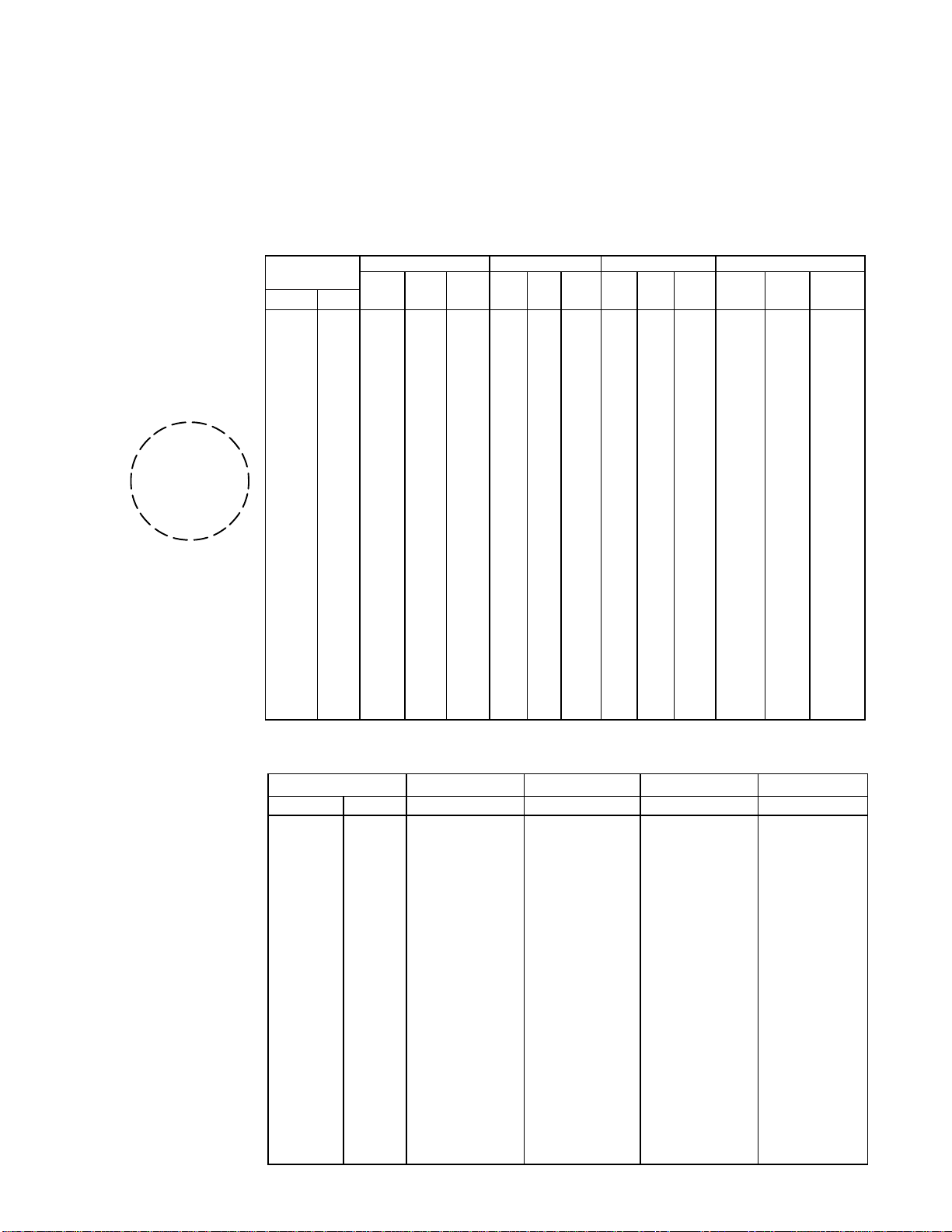

1.

8

Interchange-

ability

1.9

Flow

Rates,

Dimensions

&

W

eight

*On

m

e

t

e

r

s

smaller than 1"

accuracy is

±1% of

r

at

e*

T

h

e

T

igerma

gEP

™

transmitter

i

s

designed

t

o

be

used

w

ith

any

FM626,

FM627,

FM656

o

r

FM657

sensor.

Electronics

are

completely

interchangeable. M

eter

i

dentification

(tube

ID,

Serial

Number,

K

,

Offset,

etc.)

is

stored

on

an

E

2

PRO

M

chip

independent

of

transm

i

tter

electronics.

This

provides

universal

compatibility

between a

ll

Tigermag

EP

e

l

e

c

t

r

o

n

i

c

s

mo

d

u

l

e

s

,

eliminating the

need

f

or

reprogramming when

switching

modules. FM656 (0.5"-4"), FM627

(1"-4")

and FM657

(2"-4")

sizes have the same face-to-face

dimensions as FM626 wafer-style meters

(0.5"- 4"). See Figure

1.3

Table

1

-Nominal Flow Rates (Full Scale

G

P

M

)

0

**Ceramic linersare slightly

smaller

than Tefzel. Flowrates for

Tefzel

lined metersfrom .5" to 2"

ID's

are

slightlyhigherthan shown in

Table

1 (above).

Refer

to

PDS-626

for actual numbers.

T

ab

l

e

2

-

W

e

i

g

h

t

Nom

inalMeter Size

626

627

656 657

inches

mm

lbs kg

lbs kg

lbs kg

lbs kg

0.1

0.25

0.5

1.0

1.5

2.0

2.5

3.0

4.0

6.0

8.0

10.0

12.0

14.0

16.0

18.0

20.0

24.0

30.0

36.0

42.0

48.0

2.5

12

25

40

50

65

80

100

150

200

250

300

350

400

450

500

600

750

900

1050

1200

15 7

5 7

15 7

15 7

20 9

20 9

20 9

30 14

35 1

N/A N/A

N/A N/A

N/A N/A

N/A N/A

N/A N/A

N/A N/A

N/A N/A

N/A N/A

N/A N/A

N/A N/A

N/A N/A

N/AN/A

N/AN/A

N/A N/A

N/A N/A

N/AN/A

15 7

N/AN/A

20 9

N/AN/A

30 14

35 1

46 21

49 22

N/A N/A

N/A N/A

N/A N/A

N/A N/A

N/A N/A

N/A N/A

N/A N/A

N/A N/A

N/A N/A

N/AN/A

N/AN/A

N/A

N/A

N/A

N/A

18

8

20

9

26

12

30

14

N/A

N/A

48

22

55

25

75

34

105 77

155 8

235 117

365 140

460 182

555 209

625 250

860 336

1325

432

1800

648

2280

818

3500

977

N/A N/A

N/A N/A

N/A N/A

N/A N/A

N/AN/A

30

14

N/A

N/A

48

22

55

25

75

34

105 77

155 86

235 117

365 140

460 182

555 209

625 250

860 336

1325

432

1800

648

2280

818

3500

977

IDS-626/627/656/657

Page

7

Integral

626

626-S

627

656

657

Rem

ote

626

626-S

627

656

657

Dimensions

Figure

1.3

1.

9

Flow

Rates,

Dimensions

&

W

eight

cont'd.

Page 8 TigermagEP™

N

om

i

n

a

l

Meter

Size

Inches mm

Dimensions (

I

nches)

A

B

C

D

*All

626-S 627

626 626-S 627 656 657

626 626-S 627 656 657

626 626-S 627 656 657

0.1

0.25

0.5

1.0

1.5

2.0

2.5

3.0

4.0

6.0

8.0

10.0

12.0

14.0

16.0

18.0

20.0

24.0

30.0

36.0

42.0

48.0

54.0

60.0

66.0

72.0

2.5

12

25

40

50

65

80

100

150

200

250

300

350

400

450

500

600

750

900

1050

1200

1350

1500

1650

1800

4.00 N/A N/A

.00 N/A

N

/

A

4.00 N/A N/A

4.00 4.12 4.00

4.00 4.12 N/A

4.00 4.12 4.00

N/A 4.12

N

/A

6.00 8.00 6.00

6.00 8.00 6.00

13.38 N/A

8.00

13.38 N/A

8.00

18.15 N/A

N

/A

19.40 N/A

N

/A

21.38 N/A

N

/A

23.38 N/A

N

/A

27.25 N/A

N

/A

27.63 N/A

N

/

A

32.75 N/A

N

/A

43.50 N/A

N

/A

47.75 N/A

N

/A

51.75 N/A

N

/

A

51.75 N/A

N

/

A

53.50 N/A

N

/

A

65.50 N/A

N

/

A

65.50 N/A

N

/A

72.75 N/A

N

/

A

2.31 N/A N/A N/A N/A

2.31 N/A N/A N/A N/A

2.31 N/A N/A 3.50 N/A

2.92 2.375 2.92 4.25 N/A

3.62 3.50 N/A 5.00 N/A

4.12 3.50 4.25 6.00 6.00

N/A 4.00 N/A N/A N/A

5.70 4.50 5.40 7.50 7.50

6.60 6.625 6.60 9.00 9.00

N/A N/A 9.00 11.00 11.00

N/A N/A 10.70 13.50 13.50

N/A N/A N/A 16.00 16.00

N/A N/A N/A 19.00 19.00

N/A N/A N/A 21.00 21.00

N/A N/A N/A 23.50 23.50

N/A N/A N/A 25.00 25.00

N/A N/A N/A 27.50 27.50

N/A N/A N/A 32.00 32.00

N/A N/A N/A 38.75 38.75

N/A N/A N/A 46.00 46.00

N/A N/A N/A 53.00 53.00

N/A N/A N/A 59.50 59.50

N/A N/A N/A 66.25 N/A

N/A N/A N/A 73.00 N/A

N/A N/A N/A 80.00 N/A

N/A N/A N/A 86.50 N/A

8.75 N/A N/A N/A N/A

8.75 N/A N/A N/A N/A

8.75 N/A N/A 9.50 N/A

9.38 9.125 10.2 10.19 N/A

10.00 10.25 N/A 10.88

N

/

A

10.63 10.25 11.8 11.69

11.25

N/A 10.75 N/A N/A

N

/A

11.75 11.25 13.4 13.00

13.00

13.00 13.375 14.9 14.38

14.38

N/A N/A 17.3 17.00

16.25

N/A N/A 19.4 19.40

18.50

N/A N/A N/A 22.56

20.75

N/A N/A N/A 25.00

23.25

N/A N/A N/A 26.67

25.25

N/A N/A N/A 28.97

27.50

N/A N/A N/A 31.14

29.25

N/A N/A N/A 33.39

31.50

N/A N/A N/A 37.44

35.75

N/A N/A N/A 43.72

42.13

N/A N/A N/A 50.20

48.75

N/A N/A N/A 56.90

55.25

N/A N/A N/A 63.05

61.50

N/A N/A N/A 69.88 N/

A

N/A N/A N/A 76.75 N/

A

N/A N/A N/A 83.75 N/

A

N/A N/A N/A 90.00 N/A

8.50 N/A N/A N/A N/A

8.50 N/A N/A N/A N/A

8.50 N/A N/A 9.25 N/A

9.13 7.88 9.9 9.94 N/A

9.75 9.00 N/A 10.63 N/A

10.38 9.00 11.5 11.44

11.00

N/A 9.50 N/A N/A N/A

11.50 10.00 13.1 12.75

12.75

12.75 12.12 14.6 14.13

14.13

N/A N/A 17.0 16.75 16.00

N/A N/A 19.1 19.15 18.25

N/A N/A N/A 22.31 20.50

N/A N/A N/A 24.75 23.00

N/A N/A N/A 26.42 25.00

N/A N/A N/A 28.72 27.25

N/A N/A N/A 30.89 29.00

N/A N/A N/A 33.14 31.25

N/A N/A N/A 37.19 35.50

N/A N/A N/A 43.47 41.88

N/A N/A N/A 49.95 48.50

N/A N/A N/A 56.65 55.00

N/A N/A N/A 62.80 61.25

N/A N/A N/A 69.63 N/A

N/A N/A N/A 76.50 N/A

N/A N/A N/A 83.50 N/A

N/A N/A

N

A 89.75 N/A

1.

9

Flow

Rates,

Dimensions

&

W

eight

cont'd.

IDS-626/627/656/657

Page

9

Tab

l

e

3

-

Dim

ensions

4

Note 1:

Dimensions

and chart valuesfor 150 lb. flanges

(ANSI

template).

Note 2: Allow1/4" for 0.5 to 6" metersand 1/2" for 8" and largermetersfor grounding rings and gaskets.

Note 3:

"C"

&

"D"

Dimensions

±

0.125"

2.0Pre-Installation

2.1

Receivingand

Inspection

2.2

Storage

2.3

Returnof

Equipment

When the equipment is received, the outside of the package should be inspected for damage. If any

damage or shortage is found, notation to that effect should be made on the carrier s delivery receipt.

Visually inspect the sensor and transmitter for damage from rough handling or faulty packaging. If

concealed damage is discovered, notify the delivering carrier at once and request an inspection.

Confirm telephone conversations in writing. If inspection is not made, prepare an affidavit stating that

you notified the transportation company and that they failed to inspect. Save containers and

packaging material.

It is essential that the carrier be notified within 15 days from the date of delivery in order to be in a

position to present your claim. Make your claim promptly.

Unpacking and handling of TigermagEP™ Magnetic Flowmeters should be consistent with the

procedures used to handle field instruments.

This equipment should be stored in a clean, dry environment. Do not store outside in an unprotected

area. Observe the storage temperature requirements. Unpowered storage should not exceed two

years.

Obtain an RGA (Returned Goods Authorization) number from the factory prior to returning

any materials. The RGA number should be marked on the outside of the package. Failure to

obtain authorization will unnecessarily delay any work to be performed at the factory.

CAUTION

Page 10 TigermagEP™

When the meter is returned to our factory,

a statement MUST be attached indicating

the liquid that was flowing through the

meter, the concentration of the liquid, and

that the meter has been decontaminated

and flushed clean.

WE WILL OT HA DLE THE RETUR ED

EQUIPME T U LESS THIS STATEME T

ACCOMPA IES THE METER.

This procedure is in accordance with the

Toxic Control Act 7.

3.0

3

.

1

Application

Consider-

ations

3.2

Site

Selection

Installation

The TigermagEP

TM

can be

used

to

accurately measure the volumetric flow rate

of

liquids having

a

conductivity

of at

least

5micromhos/cm.

The presence of entrained air or gases in the process liquid will not prevent meter operation, but

will

producea

positive

(+)

error equal

to the%by

volume

gas entrainment.

▼FULLSCALE FLOW RATESSHOULD BE

SELECTED

ABOVE 3FEET PER SECOND (1

METER

PER SECOND) FOR BEST ACCURACY.

Select a pipe location which will always be full of liquid. The equipment should be located where

the

flowmeter will

be

accessible for adjustment. Provide

a

minimum

of

18"clearance

to

the

electronics

enclosure.

Themeter may

be

located in anyposition from vertical

to

horizontal. Flow may

be

in either

direction

through the meter. Vertical installation with the liquid flowing upwards, minimizes the possibility

of

slurryseparation and assures

a

full

pipecondition.

Full Pipe

Required

Figure 3.1

Horizontal installationrequires thatthesensing electrodes be positioned inthehorizontalplane.

See

Figure

3.7.

Provide at least three pipe diameters

of

straight piping approach between an upstream elbow

and

the midpoint

of

the meter. In small meters this can

be

achieved within the meter itself. More

straight

approach should

be

provided after valves

or

multiple elbows. Provide

at

least

10

diameters

after

expanders

or

laterals which are

of

smaller diameter than the line

size.

IDS-626/627/656/657

Page

11

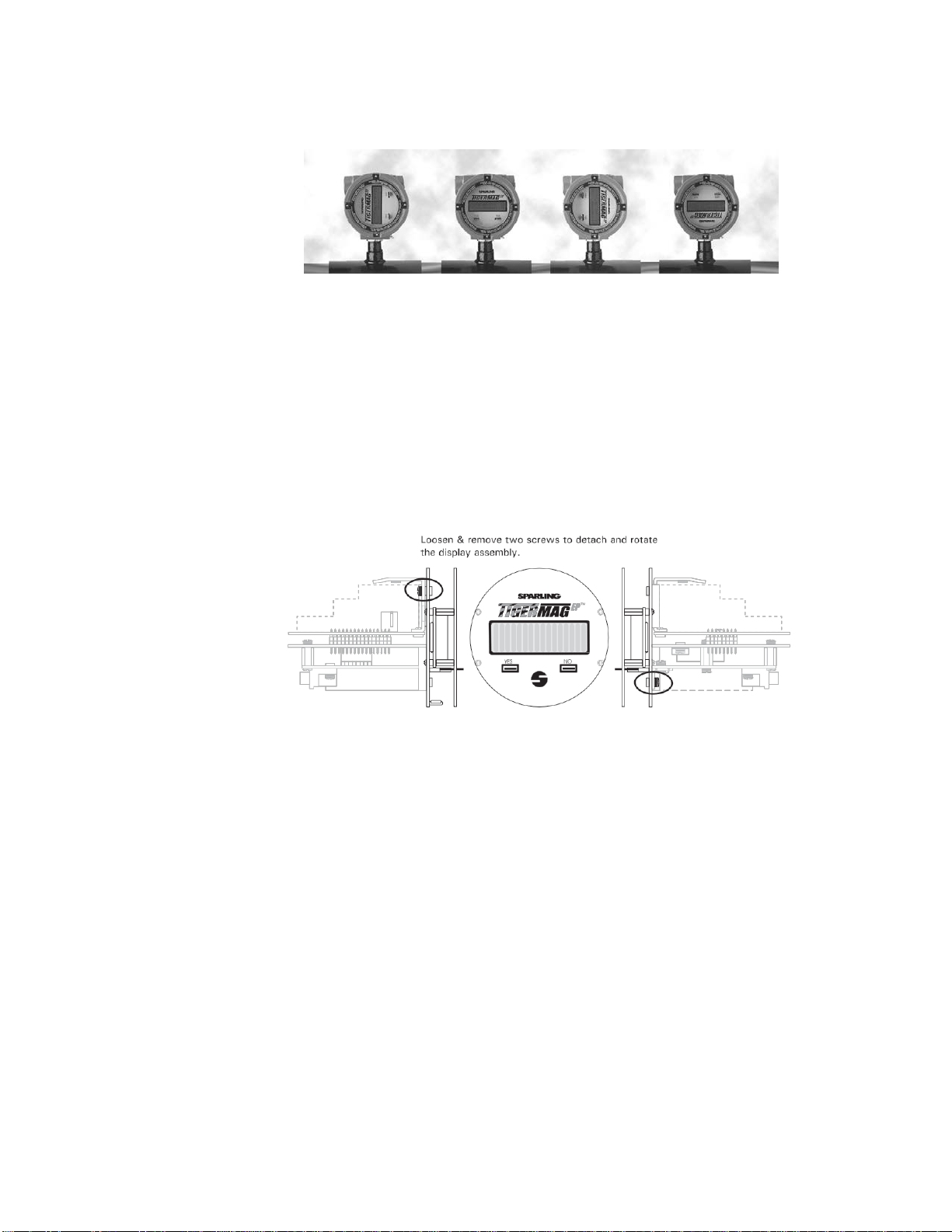

3.3

Rotating

the

T

r

ansmitter

Display

The Sparling TigermagEP's modular display

is

designed

to

allow

you to

rotate

the

display

in four

different orientations. The display assembly

can be

rotated,

at

90° intervals,

by

removing

the two

screws circled

in

Figure 3.2 below,

for

ease

of

reading

thedisplay.

The display features

long

lasting LCD numerals. The display may darken

if

ambient

temperatures

exceed its temperature rating

of

-4°

to+158°

F.Darkening usually occurs when the electronics

are

installed in direct sunlight. Toavoid this problem install

a

sun shield when the flowmeter

is

in

direct

sunlight.

The display assembly can be replaced in the field without replacing the entire electronics, by

following

the

same procedures

as

utilized

for

rotating

thedisplay.

Removing the Rotatable

Display

Figure 3.2

Page 12 TigermagEP™

3.4

Removable

Electrodes

(optional)

The line must be

depressurized

and drained in order to check and replace the removable

electrodes.

3.4.1 How the Design

W

orks

This design utilizes electrodes which are installed through accessible ports provided

on

the

sensor

body.

Electrodes are sealed using

two

o-rings. One o-ring

actsas a

primary seal while

the

other

is

a

backup seal. This redundant sealing approach provides positive

sealing.

To

withdraw

the

electrodes,

process line has to be

depressurized

and

drained. The

outercover

must be

removed

by

unscrewing

cap bolts using an

11/32

nut

driver

to

allow access

to the elec-

trode

cavity. Remove

cables from

electrodes

by

removing

nuts and lock

washers.

Usinga 3/4"

socket, unscrew

and

remove

the

electrode

assembly.

3.4.2 The Need for

Replacement

Sparling's flowmeter design utilizes High Impedance circuitry (Hi-Z) which

isnot

affected

bycoating

buildup

on the

electrodes. Replacement

of the

electrode

only

becomes necessary when

physical

damagedue to

erosion

or

corrosion

hasoccurred.

3.5

Hot

-

T

a

p

Removable

Electrodes

(optional)

Hot-Tap Removable

Electrode

Figure 3.4

Sparling's optional

hot-tap

removable electrode

design

allows

the

inspection

or

replacement

of

electrodes without

stopping the

flow

or

depressurizing

the

line. The electrode assembly

is sealed

with multipleo-rings to

maintain

isolation from the

pressurized

medium. During

removal

of the

electrode,

a

stainless steel

ball

valve

is closedto

keep

the

process fluid from leaking

out

while

the

electrodes are inspected

or

cleaned. The electrode housing, wired

as a backup

electrode,

func-

tions as a

redundant

electrodeassemblyproviding the flow signal to the

electronics.

In other

words,

even

when the

electrode

is

withdrawn,

the

flowmeter

keeps on providingimportantflow

information.

IDS-626/627/656/657

Page

13

3.5

Hot-Tap

Removable

Electrodes

(cont'd)

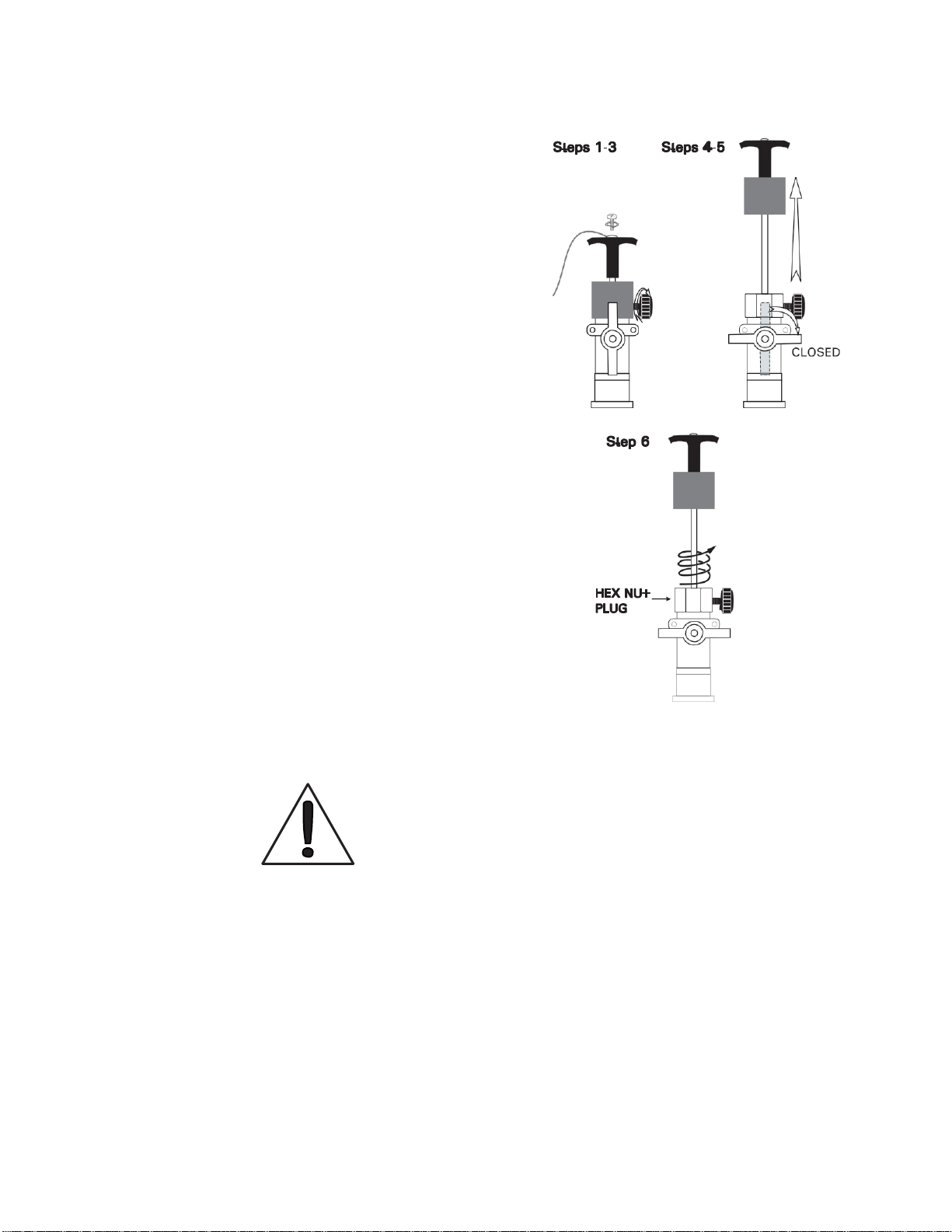

3.5.1 Electrode Removal

1. Use a cross recessed (phillips) screwdriver

to remove the screw and lock washer from

the handle.

2. Gently remove the electrode cable (orange

wire) and place aside.

3. Secure cable then loosen the side knob.

4. Using the handle on the electrode head, pull

electrode straight to the point that the valve

can be closed.

5. Close the ball valve clockwise.

6. Unscrew the hex plug from the valve coun-

terclockwise and remove the electrode

assembly.

3.5.2 Electrode Installation

1. Install hex plug clockwise. Seal tight into closed

valve assembly.

2. Open ball valve counterclockwise.

3. Push electrode assembly in, aligning the slot

in the cover with the screw, until firmly seated.

4. Tighten the side knob.

5. Place electrode cables on handle.

6. Install the lock washer and screw, tighten.

7. Replace gasket, cover, cover screws and

tighten securely.

Removing the Electrode

Figure 3.5

CAUTION

3.5.3 When to Replace

Sparling's flowmeter design utilizes High Impedance circuitry (Hi-Z) which is not affected by coating

buildup on the electrodes. Replacement of the electrode only becomes necessary when physical

damage due to erosion or corrosion has occurred.

Page 14 TigermagEP™

●Avoid Scratching or damaging the withdrawn

electrodes

●Ball valve must be closed before the hex-head

electrode assembly is unscrewed and removed.

●Electrode hes-head assembly must be replaced

and secured tightly before opening the ball valve

and reinserting the electrode

LINER

MA

T

E

R

I

AL

GASKET

M

ATERIAL

Ceramic

Teflon

®

Tefzel

®

Teflon

®

Coated

Asbestos

Hard or

Soft

Rubber

Asbestos

Neoprene

Rubber

Neoprene

Asbestos

Neoprene

Rubber

Polyurethane

Asbestos

Neoprene

Rubber

F

M

627

Polyurethane

Armstrong

Syntheseal

3.6

Pipe

Connections

MODELS

FM626

&

FM627

FLANGELESS

(WAFER)

SENSOR

The

flangeless

sensor is installed between two process pipe flanges. The sensor contains a

nonconductive polyurethane, ceramic or Tefzel

®

liner. The integrity

of

this linermust

bemaintained

for

the flowmeter

to

function.

CARE SHOULD

BE

TAKEN DURING INSTALLATION

TO

INSURE

THAT THIS LINER

IS

NOT DAMAGED

. Depending upon meter size, four (4) or eight (8)

steel

bolts

are required for installation of the FM626 & FM627. These bolts are used to install the

meter

between

existing flanges. See Table

4.

Gaskets

are

required between

the

meter

and the

pipe

flanges

and

betweengrounding rings and the mating

surfaces.

Install the two bolts

at

the

bottomof

the meter. Place the meter temporarily between the flanges

to

confirm correct positioning. Themeter should rest directly

on the

bolts. Remove

themeter.

▼REINSTALL THE METER TAKING CARE TO KEEP THE GASKET

CENTERED.

INSTALL ALL BOLTS AND TURN FINGER TIGHT. COMPLETE

INSTALLATION WITH TORQUE WRENCH. IT IS IMPORTANT THAT THE BOLTS BE TIGHTENED

ALTERNATELY

SOTHAT

EXCESSIVE FORCE

IS NOT

APPLIED

TO A

CONCENTRATED

POINT. SEE

F

IGURE

3.6. DO

NOT

EXCEED

THE

TORQUE

LIMITS

IN

T

ABLE

6.

MODELS

FM656 & FM657

FLANGED

SENSORS

The flanged sensor is installed between two process pipe flanges. The sensing head tube interior

is

covered with an electrically nonconductive liner which overlaps the flange seal surfaces.

The

integrity

of this liner must be maintained for the flowmeter

to function

CARE SHOULD BE TAKEN

DURING

INSTALLATION TO INSURE THAT THIS LINER

IS

NOT DAMAGED. FLANGE

GASKETS

MUST BE USED.

Gasket material should be selected which is compatible with the piping and

proc

ess

conditions.

Table

4

contains typical satisfactory gasket materials. Do

not

use spiral

wound

metal

gaskets

as

they may cause liner

damage.

T

ab

l

e

4

-

G

as

k

e

t

M

at

e

r

i

al

▼

THE

GASKETS

, METER

FLANGES

, AND

MATING PIPE FLANGES SHOULD BE DUSTED

WITH GASKET TALC PRIOR TO INSTALLA-

TION TO PREVENT DAMAGE TO THE LINER

SHOULD IT BE

NECESSARY

TO

REMOVE

THE

METER FROM THE LINE. DO NOT USE

GRAPHI

TE

T

O DUST THE

GASKET. A

CONDUCTIVE

FILM

WI

LL COAT

T

HE

M

ETER

I

N

TERI

OR

A

ND CAUSE A

MALFUNCTION.

DO

NOT EXCEED THE TORQUE

LIMITS IN

T

ABLE

6.

IDS-626/627/656/657

Page

15

3.7

Special

Mounting

Bolts

&

Gaskets

Sparling provides

carbon steel

mounting hardware

with

wafer

meter

sizes 0.1"to

4",On flanged

meters,

special mounting bolts are providedfor meter sizes

0.5", 1.5"

and 3" only.

Gaskets

are

provided

for

ceramic sensors

only.

Optional 304SS mounting

bolts

for these sizes are available

at

extra

cost.

Tab

l

e

5

- Meter

I.D.

Nominal

I.D

.

Actual

I.D

.

Ceramic

O

th

e

r

i

n

in

mm

i

n

mm

0.10

0.25

0.50

1.0

1.5

2.0

2.5

3.0

4.0

6.0

8.0

10.0

12.0

14.0

16.0

18.0

20.0

24.0

30.0

36.0

42.0

48.0

54.0

60.0

66.0

72.0

0.125

0.302

0.452

0.812

1.34

1.69

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

3.17

7.67

11.48

20.62

34.04

42.93

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N

/

A

N

/

A

0.48

0.91

1.47

1.94

2.24

2.87

3.83

6.00

7.75

10.00

12.00

13.00

15.00

17.00

19.00

22.90

29.00

34.60

40.60

46.60

52.50

58.50

64.50

70.25

N

/

A

N

/

A

12.24

23.09

37.34

49.20

56.90

72.85

97.18

152.40

196.85

254.00

304.80

330.20

381.00

431.80

482.60

581.66

736.60

878.84

1031.24

1183.64

1333.50

1485.90

1638.30

1790.70

Page 16 TigermagEP™

This manual suits for next models

4

Table of contents

Other SPARLING Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Bender

Bender LINETRAXX RCM420 installation manual

NUCLEONIX SYSTEMS PRIVATE LIMITED

NUCLEONIX SYSTEMS PRIVATE LIMITED GR612 instruction manual

Bruker BioSpin

Bruker BioSpin minispec mq60 user manual

Eyedro

Eyedro EYEDRO-HOME Product guide

Newtons4th

Newtons4th SFRA45 Quick Measurement Guide

Vaisala

Vaisala GMP252 user guide