SPARLING MainLine FM-104 Owner's manual

Issue Date: March 2002

TM

FM104/FM184/FT194

NOTE:

To insure all warranties expressed or implied are allowed, it is important

that the unit be installed and calibrated per this manual. Follow all instruc-

tions starting in SECTION 1.0 on page 1 concerning verifying equipment and

operation, installation instructions, notes and wiring instructions.

SPARLING INSTRUMENTS, INC.

4097 N. Temple City Blvd.

El Monte, CA 91731

Ph (626) 444-0571

Fx (626) 452-0723

Email: [email protected]

Internet: http://www.sparlinginstruments.com

Copyright© 2002 Sparling Instruments, Inc.

All rights reserved.

IDS104/184/194 Page i

TABLEOF

CONTENTS

Section1-Unpacking &Inspection .............1

1.1 Receiving & Inspection .................................. 1

1.2 Storage ........................................................... 1

1.3 Operation ....................................................... 1

1.4 Specifications ................................................. 2

Section 2 - Pre-Installation............................3

2.1 Process Fluid ............................................... 3

2.2 Handling Precautions................................... 3

Section 3 - Installation.....................................3

3.1 Site Selection Criteria ................................... 3

3.2 ounting Tubes/Saddles ............................. 4

3.3 ounting the eterhead .............................. 5

Section 4 - Flow Rates & Dimensions ........6

Section 5 - Preventative Maintenance

ofMeterhead .......................................................8

5.1 Annual Inspection of eterhead .................... 8

5.2 Disassembly & Repair ................................... 9

5.3 Reassembly .................................................. 9

Section 6 - Preventative Maintenance

ofTotalizer..........................................................10

6.1 Inspection of Totalizer .................................. 10

6.2 Extended Battery Life ................................... 10

6.3 Troubleshooting .......................................... 10

Section7-WiringDiagrams

Integral/Remote/4-20mA Output/

FT194Forward&Reverse Register 11

Section 8 - Programming of

ElectronicTotalizer.......................................... 13

8.1 Preliminary Calculations ............................... 13

8.2 Connect Programmer ................................. 14

8.3 Programming ode.................................... 15

8.4 Reset Totalizer ............................................. 16

8.5 Programming Analog Rate Output .............. 16

Figures

1.1 eter Operation ........................................... 1

3.1 Installation Considerations ........................... 3

3.2 Tube mounting ............................................. 4

3.3 Tube mounting .............................................. 4

3.4 Tube mounting .............................................. 4

3.5 Install Straightening Vanes ............................. 4

4.1 Dimensions ................................................... 6

5.1 Inspection Steps ........................................... 8

5.2 Disassembly & Repair ................................... 9

7.1 4-20mA & Scaled Pulse Output .................... 11

7.2 Remote ounting ........................................ 11

7.3 4-20mA Installation on Forward/Reverse Unit 12

8.1 Programming .............................................. 14

8.2 Total Scale ................................................... 15

8.3 Total Scale DP .............................................. 15

8.4 Total Disp DP ............................................... 15

8.5 Rate Scale ................................................... 15

8.6 Rate Scale DP .............................................. 15

8.7 Rate Disp DP ............................................... 15

8.8 Update ........................................................ 15

8.9 Smooth ....................................................... 15

8.10 Disp To ........................................................ 15

8.11 Reset Totalizer ............................................. 16

8.12 4mA ............................................................. 16

8.13 20mA ........................................................... 16

Tables

1. Flow & Dimensions ....................................... 7

2. Conversion of Gallons to Other

Engineering Units ......................................... 13

3. Rate eter Scaling Factors ......................... 14

4. Standard Registration for FT194 .................. 16

PagePage

1.0

Unpacking &

Inspection

1.1 Receiving & Inspection

Locate the packing slip shipped with your unit, this will list all the items sent with the shipment.

Compare packing slip to order acknowledgement you received previously and verify that all items

correspond.

If all items correspond, examine the shipping containers for unusual denting and/or damage. If

shipping containers are in good condition, begin unpacking. Do a general examination of each

part as it is removed from its packaging, checking for any obvious signs of physical damage.

If there is no apparent damage to the items you may begin the installation procedure in SECTION 3,

although we recommend that you familiarize yourself with SECTION 2: Application/Installation

Considerations prior to going to SECTION 3.

If any item shows damage due to shipment call the Customer Service Department immediately, at

(626) 444-0571 you will then be advised of the measures to take.

If you find items are missing from your shipment, contact the Sparling Customer Service Depart-

ment immediately, at (626) 444-0571. They will verify the order and trace any missing item for you.

1.2 Storage

This equipment should be stored in a clean, dry environment. Do not store outside in an

unprotected area. Observe the storage temperature requirements.

1.3

Operation

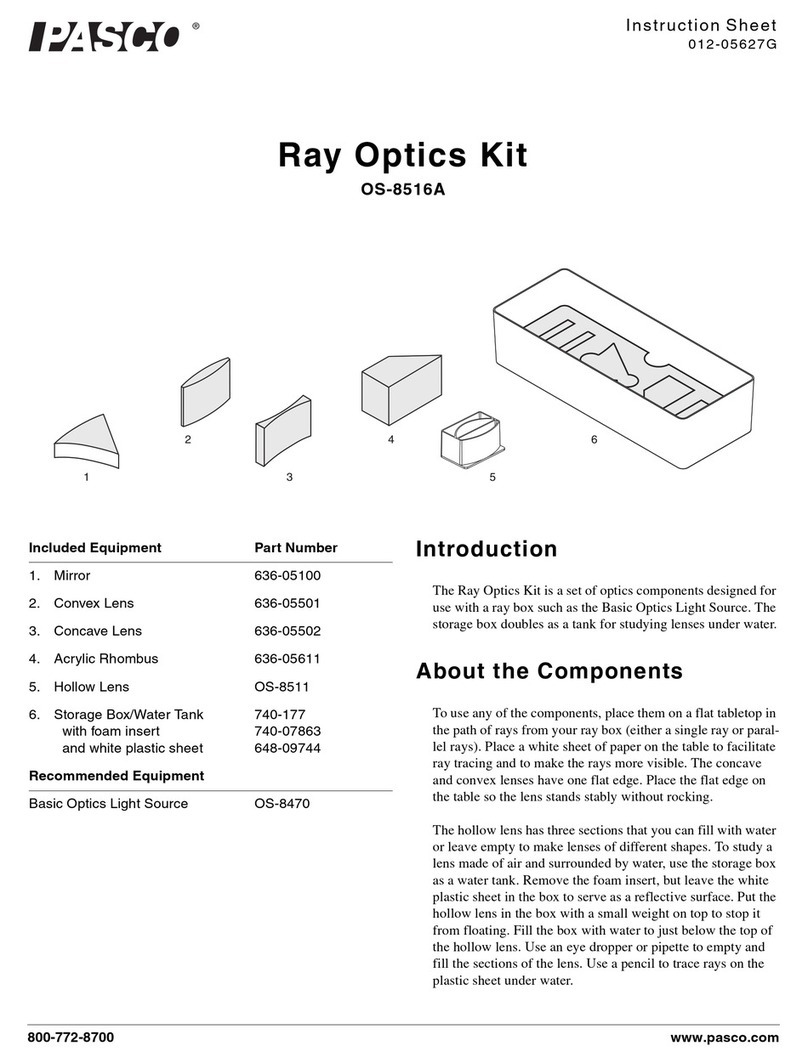

The odel's F 104 and F 184 feature the FT194 battery powered

electronic rate/totalizer which senses the rotation of the propeller

by means of a magnetic pickup sensor located in the gearbox. The

rate/totalizer and pickup are completely isolated from the flow

stream.

Utilizing the simple principle of the screw propeller, the Sparling

F 104/F 184 registers total flow, much as an odometer registers

auto mileage. The electronic rate/totalizer converts the revolutions

of the propeller to cubic feet, gallons or other standard engineering

volumetric units. The rotation of the propeller also affords a basis

for indicating and recording gallons per minute or other rates.

The LCD digital display is activated by a photoelectric cell. When

the cover of the bonnet is opened, the display is activated.

The display will go into "sleep mode" after a preprogrammed

time interval. Low light conditions may require the use of a

flashlight to activate and read the display.

IDS-104/184/194 Page 1

Figure 1.1

Meter Operation

1.4

Specifications

FM 104/184

Operating

Temperature 32°F to 100°F (higher temperature construction is available).

Storage Temperature -40°F to 175°F

Materials of

Construction Coverplate .............................................................................. Cast Iron (2" - 14")

Coverplate .................................................................................. Steel (16" - 72")

Propeller ......................................................................................... Polyethylene

Gearbox ................................................................................... Bronze (2" - 30")

Gearbox ............................................................................... Cast Iron (36" - 72")

echanical Parts........................................................................... Stainless Steel

Saddles ................................................................................ Cast Steel (6" - 14")

Saddles ..................................................................... Fabricated Steel (16" - 72")

eter Tubes / Coatings ........ Cast Iron / stainless steel metering section (2" - 3")

Fabricated Steel (4" - 36")

Wetted parts high build epoxy polyamide paint EPA approved for potable water

FT 194

Accuracy Rate: ±0.25% of full scale

Totalization: ±0.1% of rate (in addition to propeller meter accuracy)

Power 3.6V Lithium battery (8 year average life)

4-20mA and scaled pulse output with external 24 Vdc power source

Battery operating temperature: -55°F to 185°F

Operating Temperature -10°F to 158°F (-23°C to 70°C)

Storage Temperature -40°F to 158°F (-40°C to 70°C)

Display 5-digit rate indicator (0.35 inches high)

8-digit totalizer indicator (0.25 inches high)

LCD 2-line display with simultaneous rate and total, and low battery indication.

Construction Sturdy die cast aluminum bonnet

NE A-4X, NE A-6, & IP67 environmental ratings.

Optional Outputs 4-20mA, scaled pulse output and open collector output (100mA at 30 Vdc), contact

on time 100 milliseconds.

User selectable units of measure for every contact closure.

Scaling Totalizer Scaler - 0.0001 to 9999.0 / Rate Scaler - 0.0001 to 9999.0

Decimal point can be moved to five positions

Scaling Units Totalizer - Gallons, cubic feet, liters, cubic meters, acre feet

Rate - GP , CFS, GD, LPS, 3/Hr

Electrical Rating General Purpose

Page 2 MainLineTM

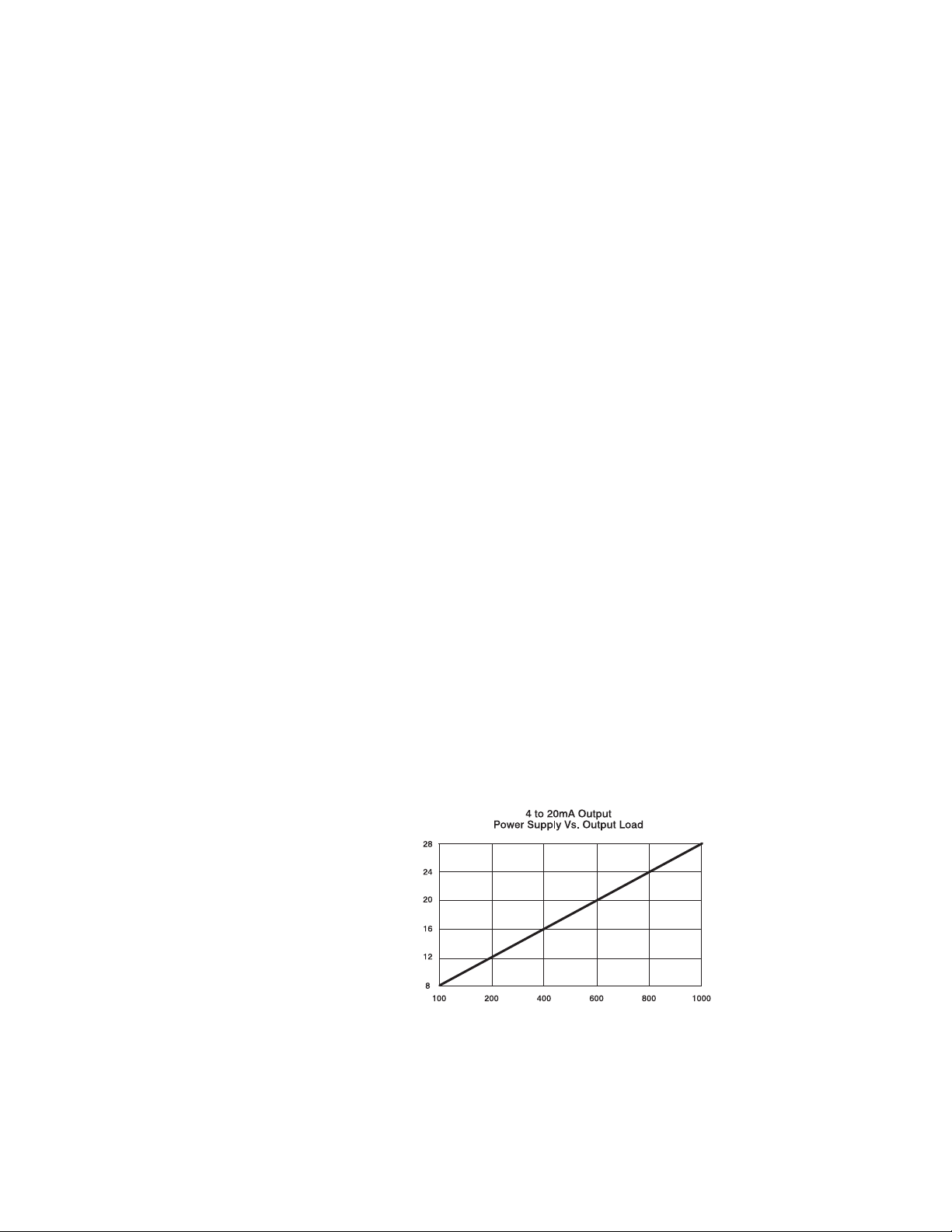

Power Supply Voltage (VDC

Output Load (Ohms

Figure 3.1

Installation Considerations

3.0

Installation

3.1 Site Selection Criteria

Choose a location that

assures a full pipe of water

flowing at or above the

minimum velocity for the

meter. There should not be

any enlargements, diffusers

or obstructions upstream

that would produce a jet or

spiraling flow into the meter.

Ten diameters of straight

pipe upstream and 1

diameter downstream are

recommended to avoid

errors caused by skewed

velocity profiles. See figure

3.1.

A jet caused by a partially

opened valve, a centrifugal

pump, or a pipe enlarge-

ment upstream from the

meter can cause inaccu-

rate registration.

Often such disturbances

can be avoided by locating

the meter on the suction

side of the pump. The

meter will register just as

efficiently on a vertical or

slanting pipe as on a

horizontal line. The straight-

ening vanes eliminate cork-screw effects in the flow profile of water. Flow conditioners may be required in

installations where less than optimum conditions exist. See Figure 3.1.

2.0

Pre-

Installation

2.1 Process Fluid

The F 104 and F 184 ainLine Electronic Propeller eters are designed to operate with relatively clean

process water. The percentage of solids should not exceed 0.5%. While the propeller shape is designed to shed

debris and the propeller material is durable and somewhat pliable, large solid objects in the flowing stream

could damage or become entangled in the propeller, causing inaccuracy or malfunction. These meterheads will

function despite the presence of small abrasive particles (such as sand) but the life of the propeller shaft

bearings may be reduced.

2.2 Handling Precautions

Although this device is ruggedly constructed, it is a precise measuring instrument and can be damaged

by rough handling or if dropped. If the meterhead is not shipped already installed into a flow tube, care

should be taken to avoid damaging the propeller during installation.

IDS 104/184/194 Page 3

Page 4 MainLineTM

3.0

Installation

cont'd.

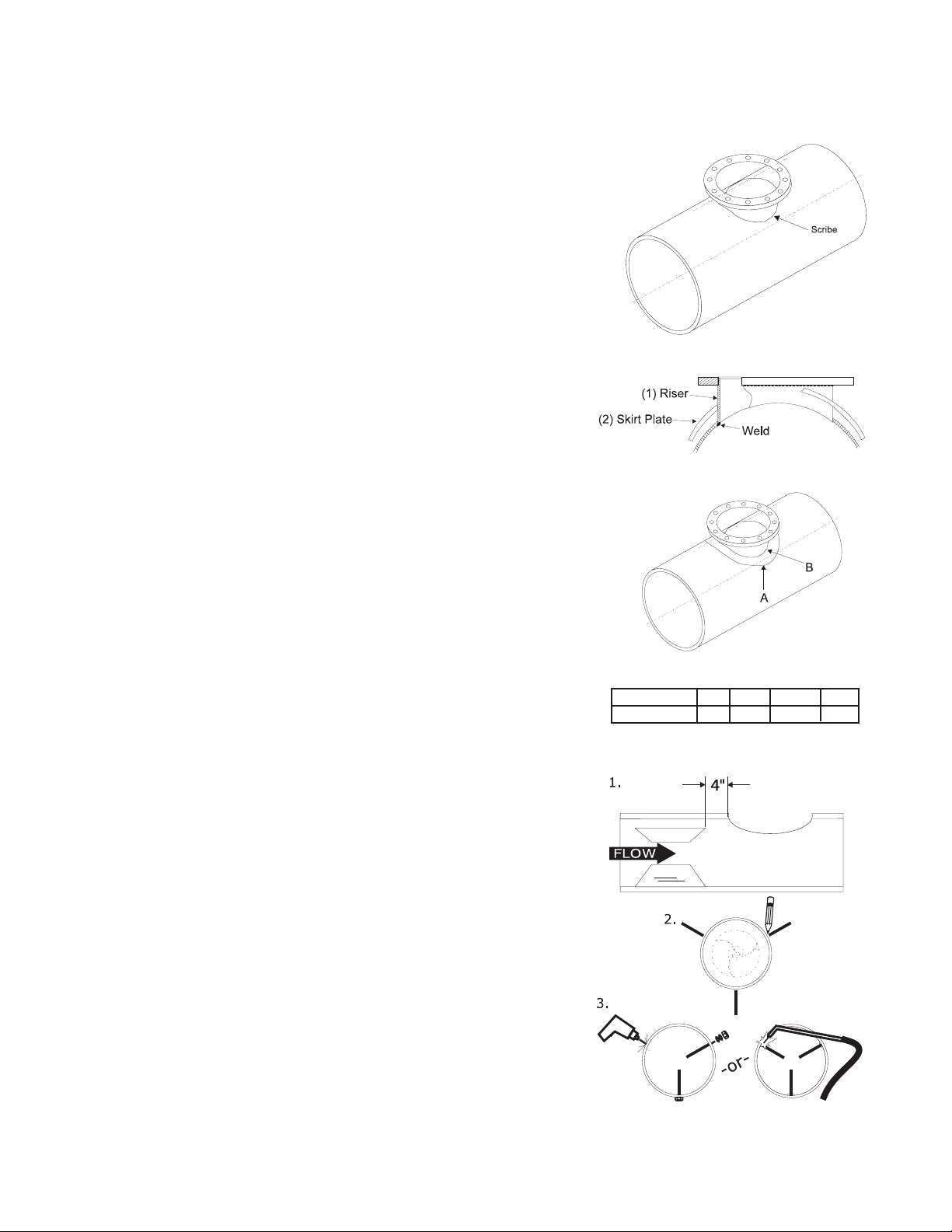

3.2 Mounting Tubes & Saddles

eterheads can be mounted into a round process line using 1)

a Sparling odel T1 In-Line Flow Tube or 2) a Sparling odel

S1 Welding Saddle.

3.2.1 eterhead with T1 In-Line Flow Tube (2" - 36")

a. Be sure to read Section 3.1 Site Selection Criteria

prior to installing your meter.

b. Install the meter tube in the line just as though it were

a short length of pipe.

c. The propeller must face the on-coming flow. Arrows

on the meter tube and cover plate will point in the

direction of the flow.

3.2.2 eterhead with S1 Welding Saddle (6" - 72")

a. For welding 6"-14" saddles to steel or wrought-iron

pipe, place the saddle on the pipe and scribe a

line INSIDE the saddle.

b. Cut or burn a full opening in the pipe so there will be

no projections of the pipe beyond the straight inside

edge of the saddle. Smooth the pipe around the

opening to make a good surface for the saddle.

c. Cast steel saddles (sizes 6" - 14") should be tacked

first, then welded in place, taking care not to over-

heat any part of the saddle.

d. Fabricated steel saddles (sizes 16" - 72"):

(i) Place riser on pipe (Fig. 3.2). Scribe around

outside of riser as shown. Cut hole.

(ii) Insert riser into the hole in skirt plate (Fig. 3.3), do

not weld at this point. Pull skirt plate up against

the flange of riser.

(iii)Insert riser into cut-out in pipe. ake sure

bottom edge of riser is flush with I.D. of the

pipe and holes in the flange are straddling the

center line of pipe. Weld riser to inside pipe as

shown.

(iv)Lower skirt plate down onto pipe. Position to

achieve conformity with O.D. of pipe. Weld in a

continuous bead at point "A" and "B".

e. If straightening vanes are required, go

to section 3.2.3. If not, skip to section 3.3

3.2.3 Install straightening vanes (if required)

as shown on Figure 3.5.

Three straightening vanes are required.

Vanes should be equally spaced radially and

parallel with the longitudinal axis of the pipe (1)

Figure 3.4

Figure 3.5

Install Straightening Vanes

Figure 3.2

a. b.

Figure 3.3

Size eter 6-14 16-30 36 & 42 48-72

Dimension "A" 4 8 12 15

3.0

Installation

cont'd.

Bolting Vanes

a. For easy vane installation, place each vane in its equivalent position on the outside of the pipe (2) and

mark the location for bolt holes.

b. Drill holes. Install vanes inside the pipe. Place lead washer and then steel washer on the bolt on

outside of pipe and tighten nuts securely (3a).

Welding Vanes

a. Space vanes equally at 120° radially and locate longitudinally as shown.

b. (3b) Secure vanes with a continuous bead weld around both ends and with intermittant staggered

bead welds along the vane.

Note: Installations with both forward and reverse

flows* may require additional vanes on the

downstream side of the meter. Install in the same

manner, 4" from the downstream saddle opening.

*Option requiring dual remote mounted totalizers.

3.3 Mounting the Meterhead

3.3.1 Tube mounted meters (2" - 36")

2"-4" - Not required - meterheads are shipped with meterhead mounted in place.

6"-36" - Follow directions per Section 3.3.2 following.

3.3.2 Saddle meters (6" - 72")

a. Place gasket on the face of the saddle

b. 6" - 8" eters

Hold meterhead with propeller facing UPSTREA .

Lower propeller into pipe and slide it upstream to position for capscrews and secure the

coverplate.

c. 10" - 72" eters

Hold meterhead over opening with propeller toward you and blades lengthwise with the

pipe.

Tilt coverplate toward you.

Lower until one blade lies horizontally on the end of the saddle.

Ease the propeller down through the saddle with a "rolling" motion.

Turn the headplate so that the propeller faces upstream.

The arrow on the plate points in the direction of the flow. Tighten cap screws evenly (6"-14" sizes)

Insert screws and install nuts (16" - 72" only) tighten them evenly, and meter is ready to operate.

IDS 104/184/194 Page 5

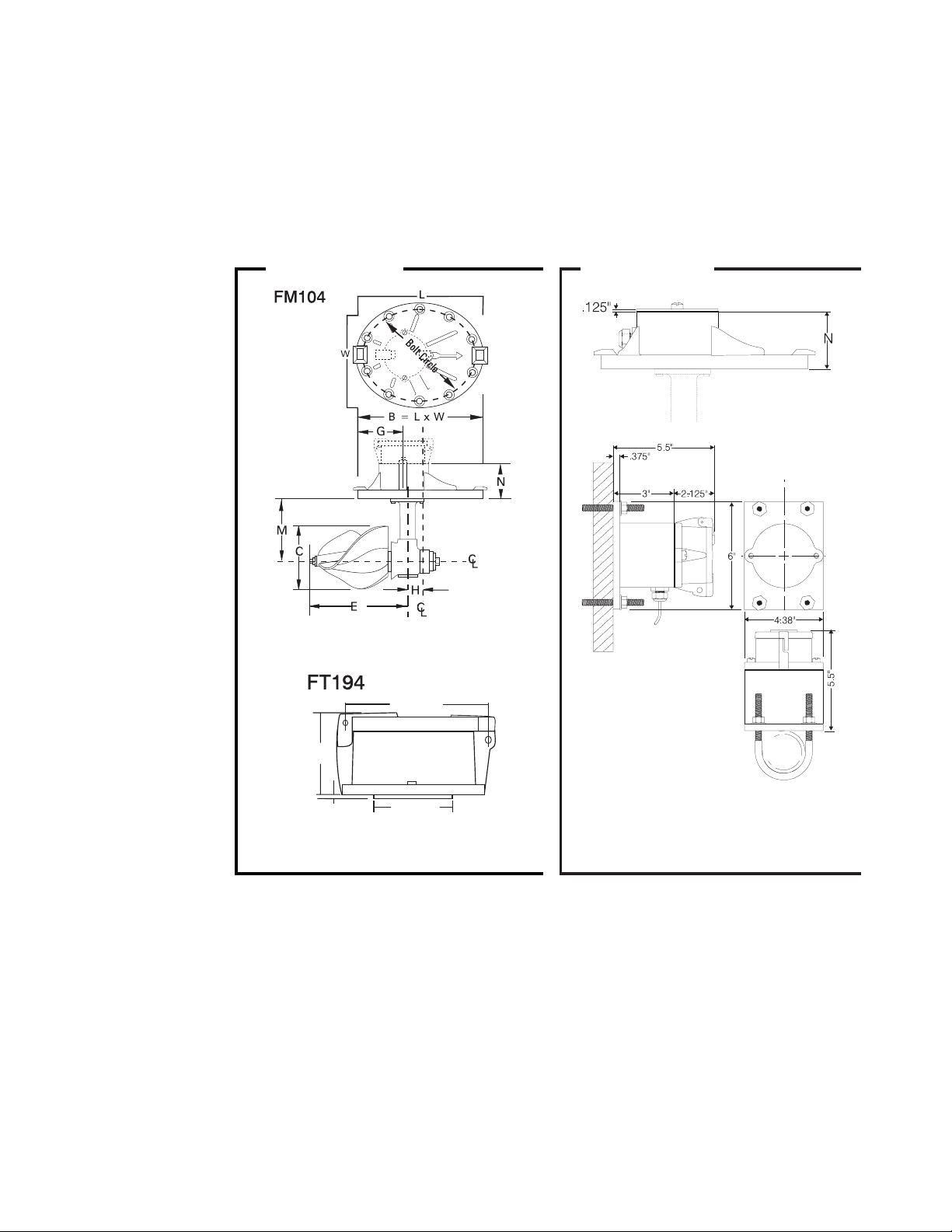

Page 6 MainLineTM

3.781"

2.125"

.125" 2.995"

Integral Mount

aximum flow ranges can be safely exceeded by 50% when used intermittently (10-15% of the time). Your Sparling

meter utilizes specially designed propellers and bearings matched to your flow range to insure long life.

For proper configuration of meter construction anticipated flow ranges, including minimum and

normal flow rates expected, should always be specified on application sheets acocmpanying your

order.

4.0

Flow Rates &

Dimensions

Remote Mount

Figure 4.1

Dimensions

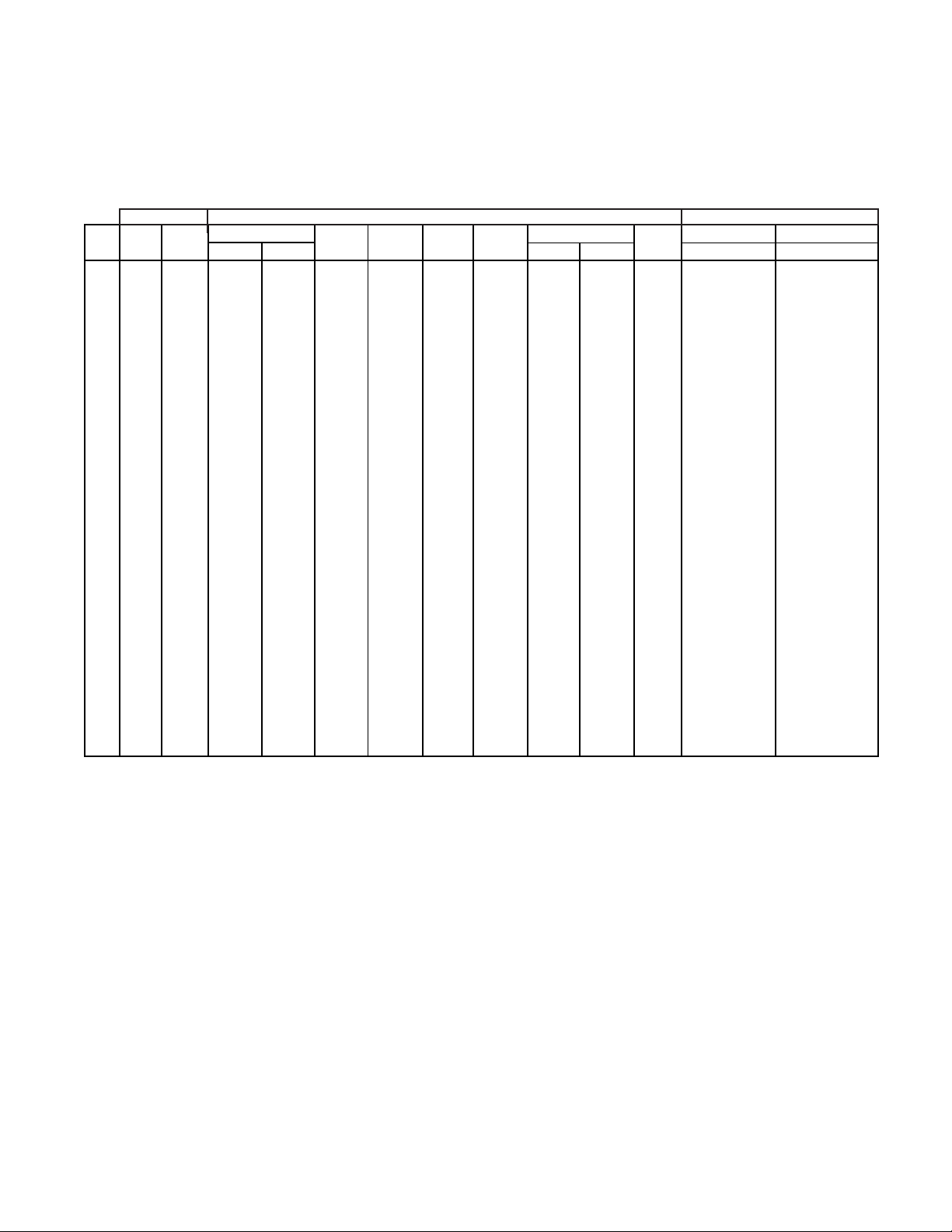

TABLE 1 - FLOW & DIMENSIONS

Weight (lbs) Dimensions (inches) Flow (gpm)

Fabr. Cast B Low Flow Std. Flow

Size Steel Iron L W CE GH

150 lbs 250 lbs Nin. ax. in. ax.

2 20 8.13 5.13 2.38 4.00 3.13 0.50 1.75 1.75 2.56 30 - 80 60 - 150

3 20 8.25 6.25 2.75 4.00 3.18 0.63 2.75 2.75 2.56 35 - 200 70 - 360

4 20 9.50 6.75 3.50 6.94 4.13 0.63 3.44 3.44 2.56 50 - 400 120 - 600

6 25 10.38 7.31 4.75 6.31 3.69 0.94 4.25 4.25 2.93 90 - 900 200 - 1600

8 29 11.00 10.63 7.00 6.31 5.81 -0.32 5.31 5.31 2.81 100 - 1200 240 - 2300

10 34 11.00 10.63 8.00 6.31 5.81 -0.32 6.31 6.31 2.81 125 - 1600 320 - 3000

12 36 11.00 10.63 10.00 6.31 5.81 -0.32 7.31 7.31 2.81 150 - 2200 400 - 4000

14 37 11.00 10.63 11.00 6.31 5.81 -0.32 8.00 8.00 2.81 250 - 3000 520 - 5000

16 210 23.50 23.50 13.00 12.00 8.20 4.25 12.25 12.25 2.88 350 - 3800 700 - 6800

18 210 23.50 23.50 16.00 12.00 8.20 4.25 13.25 13.50 2.88 450 - 4500 900 - 8100

20 215 23.50 23.50 16.00 12.00 8.20 4.25 14.25 14.50 2.88 550 - 5500 1100 - 9900

24 215 23.50 23.50 16.00 12.00 8.20 4.25 16.25 16.50 2.88 800 - 8500 1600 - 15000

30 220 23.50 23.50 16.00 12.00 8.20 4.25 19.25 19.50 2.88 1200 - 12000 3000 - 21600

36 825 32.00 32.00 25.25 18.75 9.20 6.50 23.00 24.00 3.13 1500 - 16000 3000 - 28800

42 835 32.00 32.00 25.25 18.75 9.20 6.50 26.00 27.00 3.13 2000 - 22000 4200 - 40000

48 1350 38.75 38.75 25.25 18.75 9.50 9.50 29.50 30.50 3.25 2500 - 28000 5400 - 50000

54 1360 38.75 38.75 25.25 18.75 9.50 9.50 32.50 33.50 3.25 3200 - 35000 6800 - 63000

60 1370 38.75 38.75 25.25 18.75 9.50 9.50 35.50 36.50 3.25 4000 - 42000 8400 - 76000

66 1380 38.75 38.75 25.25 18.75 9.50 9.50 38.50 39.50 3.25 4750 - 50000 10000 - 90000

72 1390 38.75 38.75 25.25 18.75 9.50 9.50 41.00 42.50 3.25 5500 - 60000 12000 -110000

"B" 16" - 72" for 150 psi only

IDS 104/184/194 Page 7

5.0

Meter

Maintenance

a.

b.

c.

d.

5.1 Preventative Maintenance — Annual Inspection of Meterhead

Preventative maintenance of the F 104 and F 184 is limited to annual inspection of the propeller shaft bear-

ings, propeller, straightening vanes and tube condition.

5.1.1 Remove Meterhead

Depressurize the line, remove the cap screws and slide the meterhead in the downstream direction.

Lift the downstream end of the coverplate and withdraw the meter from the line. It may be necessary

to maneuver the meter so that one blade tip can be lifted through the opening, allowing clearance for

the remaining blades.

5.1.2 Inspect vanes for damage and tubes and vanes for foreign matter

Examine the pipe for any foreign matter that may have accumulated. Look at the upstream ends of

the straightening vanes and remove accumulated matter. See if the vanes have been damaged -

straighten any bends.

5.1.3 Inspect Propeller & Bearings

a. See that the propeller blades are smooth and clean.

b. Spin the propeller with your fingers (a). The propeller

should spin freely without binding and crunching noises.

The register should advance properly.

c. Next, pull on the propeller (b). The propeller should

have a little freedom of movement (about 1/64") due to the

designed play in the bearings which allows grit to pass

through. If movement is over 1/64" but under 1/32" adjust

per 5.1.4 Adjust Bearings.

d. Finally, hold the propeller with your fingers and rock it

from side to side (c). There should be minimal movement

when rocking the propeller, about 1/64".

If you experience:

binding or crunching when spinning the propeller

the propeller has excessive play

it could signal excess bearing wear or failure. Go to Section

5.2 Disassembly and Repair

If the register does not advance properly, go to Section 5.2

Disassembly and Repair.

Check the gasket before replacing the meterhead. Replace it

if it is damaged. Finally, if everything checks out as it should,

return meter to line, bolt in place and repressurize the line.

5.1.4 Adjust Bearings

The front propeller shaft bearing is the key to the life of the meter. If it is kept in good condition the

other parts will last almost indefinitely.

Adjust the thrust screw (d) on the back of the propeller shaft plug to achieve 1/64" end play.

Screw the thrust screw until it comes in contact with the end of the propeller shaft, then back off

the thrust screw 1/4 turn and tighten the locknut and re-check the end play.

Spin the propeller to ensure that it spins freely and that the register advances properly. No further

maintenance is required and the meter may be reinstalled. If you found a problem, proceed to 5.2

Disassembly & Repair.

Figure 5.1

Inspection Steps

Page 8 MainLineTM

IDS 104/184/194 Page 9

5.0

Meter

Maintenance

5.2 Disassembly & Repair

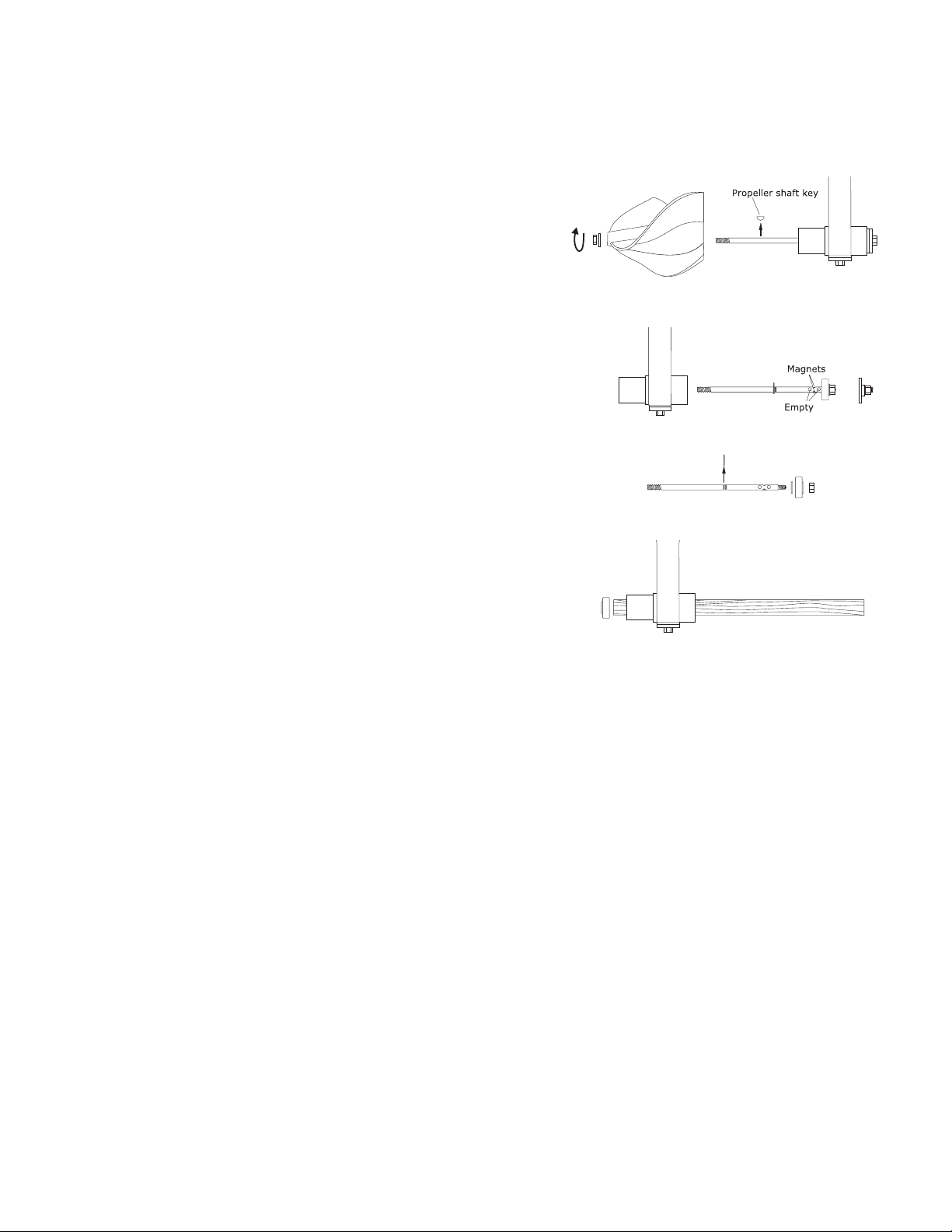

5.2.1 Grip the propeller and remove the propeller

nut. Slip the propeller off by tapping it lightly

and remove the propeller shaft key (a).

5.2.2 Remove the propeller shaft plug assembly

and drive the propeller shaft out the rear of

the gear box by tapping at the end of the

propeller shaft with a rubber mallet or a piece

of wood to protect the shaft (b). While remov-

ing you may have to rotate the shaft to avoid

damaging the bearing retaining ring - do not

force.

5.2.3 Grip the propeller shaft between the

magnets and the front bearing retaining ring.

Remove the rear bearing nut, rear bearing,

rear bearing washer and the front bearing

retaining ring (c). Inspect the propeller shaft

for straightness, carefully examining magnet

discs for cracks, looseness or missing discs.

If faulty, a new propeller shaft must be installed.

5.2.4 Using a wooden dowel, gently tap out the front

bearing from the gear box (d).

5.2.5 Check both bearings for wear and excessive

play. Replace worn out bearings.

5.3 Reassembly

5.3.1 Install the front bearing by pushing the bearing into the gearbox. DO NOT HA ER THE BEARING

INTO PLACE. Coat bearing with Lubriplate.

5.3.2 Install the rear bearing washer, rear bearing and the bearing retainer nut on the propeller shaft.

Tighten the nut snugly, but do not over-tighten. Coat bearing with Lubriplate.

5.3.3 Install the front bearing retainer on the propeller shaft. The retainer should be placed in the front slot

for ball bearings or in the rear slot for rubber bearings. Note: there is a rounded side and a sharp

side to the front bearing retaining ring. Be sure to put the rounded side toward the propeller.

5.3.4 Insert the propeller shaft assembly into the rear of the gearbox. Rotate the shaft if necessary to

avoid damaging the front bearing retaining ring. Reinstall the propeller shaft thrust plug assembly

and tighten firmly.

5.3.5 Install the propeller shaft key, the propeller, and the propeller washer and nut. Use the new propeller

nut furnished with the front bearing. Tighten the nut snugly.

5.3.6 Check the propeller shaft end play. Adjust the thrust screw on the back of the propeller shaft plug

to achieve 1/64" end play. Screw the thrust screw until it comes in contact with the end of the

propeller shaft, back of thrust screw 1/4 turn and tighten the lock nut and recheck the end play.

5.3.7 Spin the propeller and check for free movememt and that the register advances properly. Binding

bearings may be freed by alternate light taps to the rear of the gearbox and the front of the propeller shaft

to properly seat the bearings. Recheck propeller shaft end play.

a.

d.

b.

c.

Figure 5.2

Disassembly & Repair

Page 10 MainLineTM

6.0

Totalizer

Maintenance

6.1 Preventative Maintenance — Inspection of Totalizer

The ideal time to inspect the totalizer is when you are changing the battery.

6.1.1 Inspect Display - Remove Totalizer

Open meter cover and check for condensation on inside of glass. Spin propeller and make

sure that the register advances properly. Remove screws holding the totalizer on the meterhead.

6.1.2 Inspect battery contacts

Examine the battery contacts for signs of moisture intrusion. Examine the battery for any signs

of leakage.

6.1.3 Inspect Connectors

There are two connectors. One on each side of the battery bracket. Check each for moisture

intrusion.

6.1.4 Reinstall Totalizer

If everything checks out you can reseat the gasket and mount the totalizer back on the meterhead.

Tighten screws until firm, then tighten an additional 1/4 turn. Spin propeller and make sure that

the register advances properly.

If there are any signs of moisture intrusion into the Totalizer see Section 6.3.

6.2 Preventative Maintenance – Extended Battery Life

To extend battery life please do the following

6.2.1 Remove battery during storage or after disconnecting power to prolong life.

6.2.2 In low light conditions shine flashlight on display to activate.

6.2.3 Always close lid.

6.3 Troubleshooting

6.3.1 Moisture under glass

Replace totalizer

6.3.2 Rate and Totalizer do not indicate

Bad contact? Examine & clean.

Propeller Jammed? See Section 5.2 Disassembly & Repair

Damaged or missing magnets in propeller shaft? See Section 5.2 Disassembly & Repair

6.3.3 Contacts corroded

oisture intrusion? Totalizer was not replaced properly. Replace totalizer.

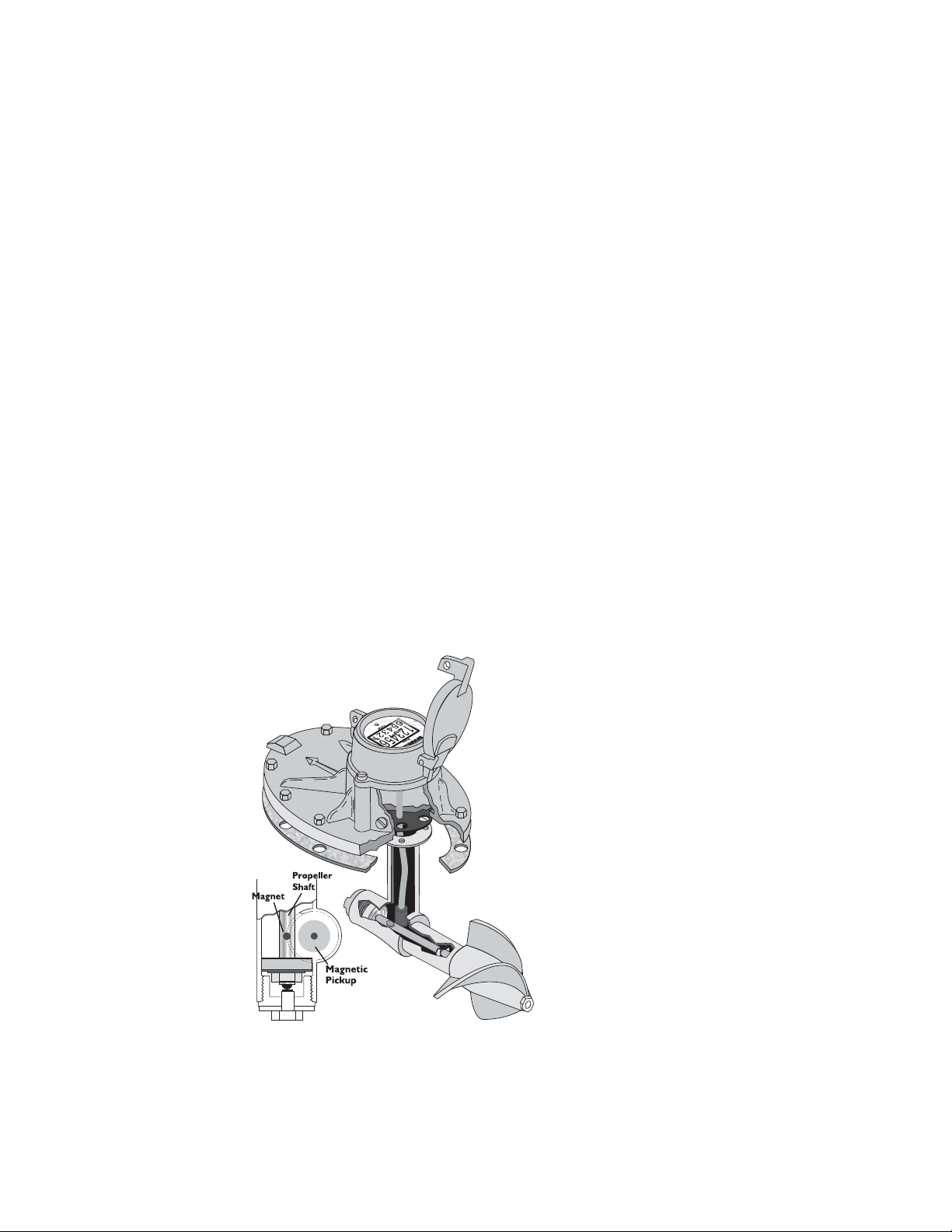

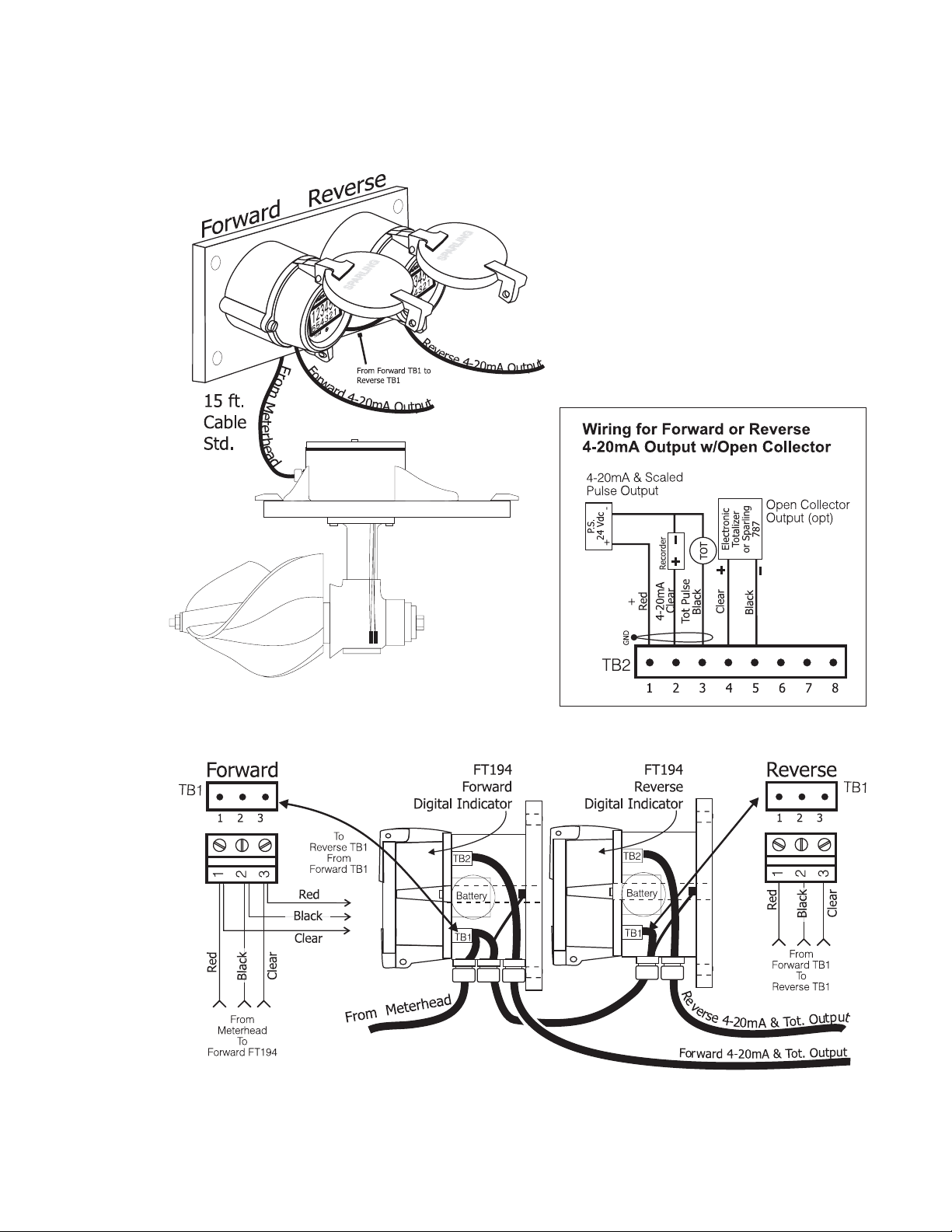

7.0

Wiring

Diagram

Remote/

4-20mA

Figure 7.2

Remote Mounting

and

4-20 mA & Scaled Pulse Output

IDS 104/184/194 Page 11

Wiring

Diagram

Integral/

4-20mA

Figure 7.1

Integral 4-20 mA & Scaled Pulse Output

7.0

Wiring

Diagram

FT194

Forward &

Reverse

Register

Figure 7.3

4-20 mA Installation on Forward/Reverse Unit

Page 12 MainLineTM

Your Sparling Propeller Meter has been fully programmed at the factory. No field programming is

required. Information on programming is included for the convenience of those customers who

require this function.

8.1 Preliminary Calculations

8.1.1 Calculation of Totalizer & Rate Scaling Factors

Before programming your meter you require

1) The Totalizer Scaling Factor and

2) The Rate Scaling Factor

These factors are not the same, but are both calculated using the meters' K (calibration) factor. The

meter K is located on the flowmeter calibration sheet shipped with your meter.

a. Calculate the Totalizer Scaling Factor

Totalizer Scaling Factor (in gallons = K x R

K = Propeller eter Calibration Factor = pulses/gallon

R = Registration (units/pulse - see table 4 - page 12)

i.e. 1 = 1 unit/pulse

10 = 10 units/pulse

100 = 100 units/pulse

Example: eter K = 2.236

Registration in Gallons = 10 Gallons/Pulse

Totalizer Scaling Factor (gallons) = 2.236 x 10 = 22.36

Totalizer Scaling Factor (any other engineering unit = K x R x E

K = Propeller eter Calibration Factor - pulses/gallon

R = Registration (units/pulse)

E = Engineering Unit Conversion Factor (from table below)

Example: eter K - 2.236

Registration (units/pulse) 100

Engineering Unit - Liters 0.2642 (from table below)

Scaling Factor (liters) = 2.236 x 100 x 0.2642 = 59.08

TABLE 2 CONVERSION OF GALLONS TO OTHER ENGINEERING UNITS

Desired Conversion

Engineering Unit Factor

Cubic Feet 7.48

Liters 0.2642

Cubic eters 264.2

Acre Feet 325,851

Imperial Gallons 1.2

8.0

Programming

of Electronic

Totalizer

IDS 104/184/194 Page 13

b. Calculate the Rate Scaling Factor

Rate Scaling Factor (GPM = K /60

K = Propeller eter Calibration Factor = pulses/gallon

E = 60 (GP ) = Desired Indication from Table 2 below

Example: eter K = 2.236

Desired Engineering Unit = GP (from Table 2) = 60

Scaling Factor (GP ) = 2.236 / 60 = 0.0373

Rate Scaling Factor (any other engineering unit = K / E

K = Propeller eter Calibration Factor - pulses/gallon

E = Engineering Unit Conversion Factor (from table below)

Example: eter K = 2.236

Engineering Unit Conversion Factor - 3/HR 13.626 (from table below)

Rate Scaling Factor ( 3/HR) = 2.236 / 13.626 = 0.1641

TABLE 3 RATE METER SCALING FACTORS

Desired Eng. Unit Scaling Factor

GP K

Gallons per inute Rate Indication 60

LPS K

Liters per Second Rate Indication 3.785

CFS K

Cubic Feet per Second Rate Indication 13.37

GD K

illion Gallons per Day Rate Indication 8.64

3/HR K

Cubic eters per Hour Rate Indication 13.626

8.2 ConnectProgrammer

Remove the totalizer mounting screws.

Lift the totalizer assembly out and remove the

three pin connector.

Plug in the eight pin connector from the

programmer into the totalizer socket. (If

there is already a connector plugged in,

disconnect it and plug in connector from

the programmer).

8.0

Programming

of Electronic

Totalizer

Figure 8.1

Programming

Page 14 MainLineTM

8.3 Programming Mode

8.3.1 Programming Totalizer

a. Press PG button on the programmer for 5 seconds. This acti-

vates the programming mode. The display will appear as shown in

Figure #8.2. The least significant digit will flash on and off.

b. Program in the Totalizer Scaling Factor you calculated per the

formulas in Section 8.1.1a The vertical arrow button increments

the active digit, scrolling from 0 to 9 and back to 0. The horizontal

arrow button selects the active digit. The active digit will flash.

c. Once the scaling factor is entered, press the PG button. The

display screen as shown in Figure #8.3 will appear. Using the

horizontal arrow button, move the decimal point to the calculated

position. If the leftmost decimal point is on when the horizontal

key is pressed, the decimal point will go out indicating no decimal

point.

f. Once the decimal point has been programmed, press the PG

button and the display per Figure #8.4 will appear. This allows

you to set the display decimal place, allowing you the degree of

resolution you require for your application. Using the horizontal

arrow button, move the decimal point to the desired position.

8.3.2 Programming Rate

a. Press PG button and screen as shown in Figure #8.5 will appear.

Program in the Rate Scaling Factor you calculated per the formulas

in Section 8.1.1b using the vertical arrow button to scroll the digit and

the horizontal arrow button to select the next active digit.

b. Press PG button and display screen as shown in Figure #8.6

will appear. Using the horizontal arrow button, move the decimal

point to the calculated position.

c. Press the PG button and the display per Figure #8.7 will appear.

This allows you to set the display decimal place, allowing you the

degree of resolution you require for your application. Using the

horizontal arrow button, move the decimal point to the desired

position.

d. Press PG button and display screen as shown in Figure #8.8 will

appear. Program Rate eter display update time. The range is 0.5 to

9.5 seconds. Normal setting is 0.5 seconds. CAUTION: inimum

update time is 0.5. Do not set to 0.0 or rate will not update.

e. Press PG button and display screen as shown in Figure #8.9 will

appear. Program Rate eter Smoothing. The range is 0% (no smooth-

ing) to 99% (1% of the new rate is used). Normal setting is 5%

f. Press PG button and display screen as shown in Figure #8.10

will appear. Program Rate eter Display Time Out - This sets the

"on time", the amount of time the display is active before going

into sleep mode. CAUTION: inimum "on time" should be

GREATER than 5 seconds. NOR AL setting is 300 seconds. If

you set "on time" to 0 the display will be perpetually blank and will

not activate. There is no time out when in programming modes.

8.0

Programming

of Electronic

Totalizer

cont'd. Figure 8.2

Figure 8.3

Figure 8.10

Figure 8.9

RATE

RATE

RATE

RATE

Figure 8.4

Figure 8.5

Figure 8.8

Figure 8.7

Figure 8.6

IDS 104/184/194 Page 15

8.0

Programming

of Electronic

Totalizer

cont'd.

Figure 8.11

Figure 8.13

Figure 8.12

8.4 Reset Totalizer - Figure 8.11

CAUTION

DO NOT PERFORM THIS STEP UNLESS YOU WANT TO

RESET YOUR TOTALIZER TO ZERO.

TO BYPASS THIS SCREEN AND LEAVE TOTALIZER

INTACT, PRESS PGM.

To reset totalizer, press the horizontal arrow button for a

few seconds until the totalizer resets to zero.

8.5 Programming Analog Rate Output (optional)

8.5.1 THESE OPTIONS WILL ONLY DISPLAY IF ANALOG OPTION

BOARD IS INSTALLED AND EXTERNAL 24 VDC POWER SUPPLY

IS CONNECTED.

a. Press PG Button and display screen as shown in Figure #8.12

will appear.

b. Program Analog Rate 4 mA value, which for standard analog

output is 0. The range is from 00000 to 99999

c. Using Vertical and Horizontal buttons program 00000.

The decimal point is the same as set in the rate meter screen.

This screen sets numbers only and does not change the deci-

mal. These options will only display IF Analog Option Board IS

installed AND external 24 Vdc power supply is connected.

d. Press PG button and display screen as shown in Figure #8.13

will appear.

e. Using Vertical and Horizontal arrows, program Analog Rate 20

mA value, which will be full scale and will be customer specified.

The screen sets the numbers only and does not change deci-

mal. THESE O TIONS WILL ONLY DIS LAY IF ANALOG O TION

BOARD IS INSTALLED AND EXTERNAL 24 VDC OWER SU -

LY IS CONNECTED.

TABLE 4 STANDARD R EGISTRATION FOR FT194

Nom. Cubic U.S. Imperial Acre Cubic

Size Feet Gallons Gallons Feet Meters Liters

21.0 10.0 10.0 0.00001 0.01 10.0

31.0 10.0 10.0 0.0001 0.1 100.0

410.0 100.0 100.0 0.0001 0.1 100.0

510.0 100.0 100.0 0.0001 0.1 100.0

610.0 100.0 100.0 0.001 1.0 100.0

810.0 100.0 100.0 0.001 1.0 1000.0

10 100.0 100.0 100.0 0.001 1.0 1000.0

12 100.0 1000.0 1000.0 0.001 1.0 1000.0

14 100.0 1000.0 1000.0 0.001 1.0 1000.0

16 - 30 100.0 1000.0 1000.0 0.01 10.0 10000.0

36 & 42 1000.0 10000.0 10000.0 0.01 10.0 10000.0

48 - 72 1000.0 10000.0 10000.0 0.1 100.0 100000.0

Page 16 MainLineTM

Other manuals for MainLine FM-104

1

This manual suits for next models

2

Table of contents

Other SPARLING Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Siemens

Siemens DELTA 5TC8 425 Operating and mounting instructions

Badger Meter

Badger Meter IOG Series Installation and operation manual

Agilent Technologies

Agilent Technologies PSA Series Installation note

RIDGID

RIDGID micro LM-100 manual

Metal Work

Metal Work FLUX 0 user manual

Axis

Axis S1148 installation guide