Transtech PQI 380 Service manual

1

Pavement Quality Indicator

Operator’s Handbook

2

Introduction 3

Measurement Technology 3

Application Summary 4

Safety 4

Disclaimer 4

Controls & Components 5

Contents 5

Gauge Features 6

External / Internal Controls 7

Power Save / Auto Shutdown 8

Setting Up the PQI 380 8

Installing / Charging the Batteries & Battery Care Tips 9

Battery Voltage 10

Starting the Software 10

Main Menu 11

Local Time and Change Date Format 11

Setup the GPS 13

Control Menu 14

Select Measurement Units 15

Data Logging 15

Mix Details 16

Editing Mix Details 16

Project Details 20

Editing Project Details 21

Reading Modes-Selection and Denition 22

Reading Mode Selection 22

Reading Mode Denition 22

Single Reading Mode 23

Average Reading Mode 24

Continuous Reading Mode 26

Segregation Reading Mode 26

Calibration 28

Core Calibration Method 28

Calculating the Offset 29

PQI 380 Offset Setup 29

Data Storage and Downloading Data 31

Downloading Data 32

Viewing, Printing or Deleteing a Project File 32

Maintenance & Troubleshooting 34

Factory Calibration 34

Calibration Reset 35

Factory Parameters 35

Maintenance 36

Troubleshooting 37

Standardization 38

Measurement Table / Core Comparison Calibration Worksheet 40

Warranty 43

Table of Contents

3

TransTech’s Pavement Quality Indicator model PQI 380 utilizes state of the art technology to achieve

accurate asphalt pavement density readings. It’s primary features are:

• No special license or radioactive materials required

• Lightweight and easy to use

• 12 hours of portable operation

• Measures density in common units (lb/ft3or kg/m³)

• Relative moisture detection and correction when necessary

•Storesinniterecords

•DatadownloadviaUSBashdrive(semicolondelimitedtextleformat)

Introduction

Measurement Technology

The PQI 380 uses impedance spectroscopy to measure the electrical response of asphalt from which

thedensityiscalculated.AsshownintheComsolsimulationbelow,theelectricaleldtransmits

through the material from the sensor plate of the PQI 380. The impedance is then measured and

usedinthecalculationofthedensityforthatspecicaggregate.

4

Application Summary

The PQI 380 is intended primarily for use on newly-laid asphalt pavements with lift thickness ranging

from 0.75 inches to 6 inches. The calibration of the PQI 380 to a density standard (core) is very

important for the reliability and consistency of the density measurements for each material.

Safety

Every effort has been made to make the PQI 380 convenient to use and inherently safe. The PQI 380

uses non-nuclear, low-voltage direct current to obtain measurements, therefore, there are no badges,

licensing,storageortransportconcerns.Likeanyinstrument,however,theusershouldexercisecare

and common sense in its use to prevent mishaps.

Warning

Do not use the unit on or near electrical wiring.

A potential shock hazard exists if contact is made with the exposed wiring.

Warning

Use care in handling the unit. Personal injury can occur through improper handling.

Take proper care to avoid accidentally dropping the unit.

Warning

Unauthorized disassembly of the unit will void the warranty.

Warning

Shipping the gauge with the batteries inside is not recommended.

Caution

Charging the gauge overnight or unattended is not recommended

Caution

Turn the unit off when not in use and during transport.

Caution

Be sure not to switch standardization plates with other gauges. Check the

Serial Numbers located on the gauge and on the plate to be sure they match.

Disclaimer: TransTech reserves the right to change or modify product design, construction,

specications,ormaterialswithoutpriornoticeandwithoutincurringanyobligationtomakesuch

changesandmodicationsonTransTechproductspreviouslyorsubsequentlysold.

5

Controls & Components - Contents

Fold open

compartment

contents

Charger

AC Cord

DC Cord

CD Manual

Handle

CD Manual

Slot for PQI 380 and

Standardization Plate

(To remain in case)

The PQI 380 is packaged and shipped with the following components. Contact TransTech Systems

customer service if any of the parts are missing.

• PQI 380 unit

• Standardization Plate

• Storage/shipping case

• Operators Quickstart Guide

• CD Manual

• PQI 380 handle

• 120/220V AC to 12V DC battery charger

• 12V DC Car Charger

• Battery Pack

6

Gauge Features

Handle

TouchScreen

Used to input and

interact with the gauge

Faceplate

Protective bezel

for touchscreen

GPS Module

(Accurate to 5+/- Meters)

On / Off Button

Powers gauge ON / OFF

Handle Extension

Connection for handle

extension

USB Port

Allows communication

betweenaashdrive

Charger Port

Allows connection to

the ac or dc charger

Infrared

Temperature

Sensor

Reports surface

temperature of the soil

Shroud with

10” Sensor Plate

Location where sensor

plate is located

Battery Door

battery cover plate

Gauge Shell

Body of the gauge

Reective Vinyl

Operation in dark areas

safety feature

Battery

7

External / Internal Controls

ExternalcontrolsonthePQI380consistof

anON/OFFswitchanda480x640VGA

touch screen display for navigating through

the user interface and entering alpha/

numeric data.

Besurenottodragyourngerfromone

buttontothenext.Armyetlighttouchis

all that is needed to navigate from screen

to screen.

Unique yet consistent icons are located on most screens for easy one touch navigation. When data

input is required of the operator the screen will display the above keyboard. Toggle from upper to

lower case letters using the Shift button. The upper case keyboard provides the option of a

minus key while the lower case keyboard provides the plus key. Once editing is completed simply

press Enter to save and return to the previous screen.

8

The Status Barislocatedatthebottomofthescreen(excludingthekeyboardscreens)andwill

continuously update the remaining voltage of the batteries while displaying the date, time and status

of the GPS and data logging features.

Thenumerickeypadasshowninthisexampleallowsforonlynumbersandadecimalpoint.

Press Accept to save your entry and in most cases return to the previous screen.

External / Internal Controls

ThePQI380hasabuiltinpowersavingmode.Iftherearenobuttonspressedafterapproximately

20 minutes the unit will go into a power saving mode. Pressing any key will wake the PQI 380 for

continued use. If the PQI 380 is left on for an hour without any buttons being pressed, it will shut itself

down, to conserve battery run time

Power Save / Auto Shut Down

PriortousingthePQI380forthersttimethegaugewillneedtobeconguredtomake

measurements and record data correctly.

The following steps must be completed before operating the PQI 380:

1. Installing and charging the batteries

2. Starting the software

3. Set the local time / set date

4. Set up the GPS

5. Select units of measurement

6. Select data logging

7.Denetheasphaltbeingtested(MixDetails)

8.Deneprojectdetails(forthedataloggingfeature)

9. Select measurement mode

Setting up the PQI 380

9

Installing Batteries

1. Turn the PQI 380 unit OFF

2. Connect the charger to the charger connector located on the back of the PQI 380

3. Plug the charger into a standard AC outlet

4.Theredindicatorlampwillturngreentoindicatethatthebatteriesarecharged(approx.4hrs)

5. Unplug charger from the power source before disconnecting the charger from the PQI 380

YouwillndaplateonthebackofthePQI380with4springloadedbolts.

1.Turneachboltapproximately2fullturnsuntilthespringreleases

2. Remove the plate from the gauge

3.Nextyouwillndawirewithaconnector,disconnectthebatteryfromthegauge

4. Then pull the nylon strap to slide the battery out of the compartment.

(Do not pull the battery by the connector wire, doing so could damage the battery)

Charging Batteries

Battery Care Tips

• Whenever uncertain about the battery charge level or condition, recharge it

• The battery will self-discharge and should NOT be left uncharged for more than 30 days

• An occasional complete discharge followed by a full recharge is recommended

• NEVER drop the battery as this can damage the internals

• DO NOTstoreinfreezerorexposetoextremeheat

• Battery should be fully charged before use

10

Starting the Software

Battery voltage can be viewed on the status bar located at the bottom of all screens. A fully charged

battery will display over 8 volts. The battery voltage will decrease as the PQI 380 is used. A low

batteryvoltageiconwillbedisplayedatapproximately6.5 volts.

Battery Voltage

Low Battery Indicator

The gauge will continue to operate until the battery can not supply enough voltage to complete a

measurement. Once this happens, the gauge will automatically shut down and will not restart until

charged. Depending on the condition of the batteries, once the voltage drops below 6 volts, the

gauge may be able to take about 12 to 15 additional readings. It is important to re-charge the

battery after each use.

Pressing the ON button will power on the PQI 380. After a few seconds the TransTech splash screen

willappearfollowedbytheMainMenuscreen.TheMainMenuscreenwilldisplayveoptions,

Start PQI380, Calculator, Contact TransTech, GPS Control and Update

Software.

11

Main Menu

Start button opens the

Control Menu screen

Calculator button opens the

built in calculator

Contact button displays

TransTech and distributor

contact information

GPS Control button opens

the GPS Settings screen

Update Software button opens

the software update screen

Local Time and Change Date Format

You may set the date and time in two locations. From the Main Menu, press Set Time & Date

located on the status bar or from the Control Menu press Date & Time.

12

Local Time and Change Date Format

To set the time, press the Set Time button. Press the appropriate numbers for the time in

24hourformat.Onceyouaresatisedwithyourentry,pressAccept to save and return to the

previous screen.

To set the date, press the Set Date button. The date will display in either the MM/DD/YY or

DD/MM/YY format which may be toggled from the button located on both screens. As you did with the

time, press the appropriate numbers for the date in the format chosen. Press Accept to save

and return to the previous screen. (Note: Date will be preset by the factory)

13

When the GPS is enabled the satellite icon on the status bar turns from red to green.

GPS formatting can also be toggled from the Universal Transverse Mercator (UTM) grid to

Latitude/Longitude (LAT-LON). Initially the display will read Sats 0 for both formats until connections

havebeenmade.Theaboveexamplesshowaconnectiontovesatellites(Sats5)inbothformats.

GPS locations will appear on the bottom left corner of all reading mode screens and will store with

each reading when data logging is enabled.

Setup the GPS

Setting up the GPS is nothing more than turning it on and waiting to connect to satellites. The GPS

feature can take up to 15 minutes to connect to satellites depending on your location. From the Main

Menu, press GPS Control. GPS status can be toggled ON or OFF.

14

Control Menu

From the Main Menu press Start PQI 380 to enter the Control Menu. From this menu, you will

ndtheiconslistedbelow.

Starts the

standardization process

Openstheproject

details screen

Opens the

diagnostics screen

Opens the time

and date screen

Opens the

mixdetailsscreen

Starts the

measurement process

Opens the datalogging

screen where you can toggle

datalogging on / off

Opens the modes screen

where you can choose a

measurement mode

Opens the units screen, where

you can toggle lbs/ft3to kg/m3,

F° to C°, in. to mm. or

%compaction to %voids

Opens the data management

screen, where you can delete,

downloadandprintjobles

15

From the Control Menu, press Units. Density, Temperature, Depth, Stone Size and

% Compaction can be toggled independently between system international (SI “metric”) and U.S.

customaryunits.Forexample,youcansetthedensitytolb/ft3while temperature is set to celsius,

depth is set to inches while stone size is set for millimeters.

Data Logging

From the Control Menu, press Data Logging. If you wish to save your data, you must enable

thedataloggingfeaturebytogglingthebuttontoON.Theoppydiskonthestatusbarwillturnfrom

red to green when data logging is enabled.

Data will not save for continuous or segregation reading modes.

Datastoredincludesallprojectandmixdetails,aswellasthecompaction,density,temperatureand

the date and time of each reading. If the GPS is on and it is connected to satellites, the location in the

format chosen as well as GPS date and GPS time for each reading will also be recorded.

Select Measurement Units

16

Mix Details

ThedensitydeterminedbythePQI380ishighlymaterialdependentsoitisextremelyimportantthat

themixinformationforeachmixdesignareinputaccuratelyintothegauge.

Note: Readings taken prior to accurately setting up the mix details section of the gauge will

result in incorrect density and compaction results.

ThePQI380isconguredtostore20uniquemixesthatareidentiedbyuserentereddescriptions.If

20mixeshavebeendenedinthePQI380anda21stmixisrequired,oneoftheoriginal20willneed

tobemodiedtoreectthemixdetailsofthenewmixdesign.Thedetailsofthenewmixwillneed

tobeinputbyeditingthedetailsofapreviouslydenedmix.Oncetheoldmixdetailsareoverwritten

with new information, the old information is gone and the new information is saved in the gauge.

Previouslystoreddataleswiththeoldmixinformationwillnotbeoverwritten.

ThedefaultmixesstoredinanewPQI380willhavegenericmixnames(i.e.Mix1,Mix2,etc),the

stonesizeswillallbesetto9.5mm(0.375in.)atadepthof5incheswithaMaximumTheoretical

Density (MTD) of 125lb/ft3. Readings taken prior to editing the default information on a mix that

does not resemble the default information will result in incorrect density and compaction.

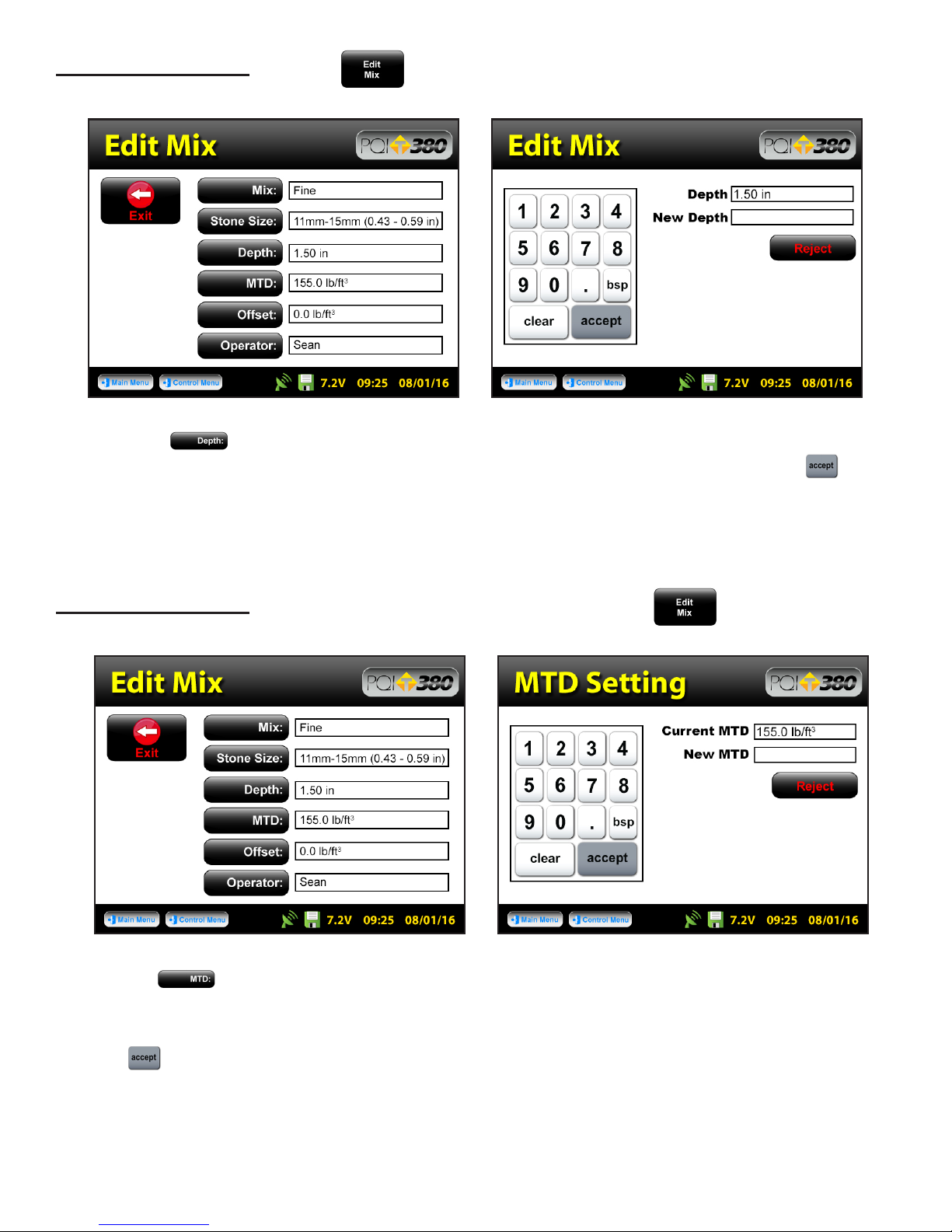

Editing Mix Details

From the Control Menu, press Mixtoenterthemixdetailsscreen.Themixhighlightedingreen

ontheleftisdisplayedindetailontheright.Toeditthedetailsofthismix,press

Edit Mix.

17

TherearesixblackbuttonslabeledMix,StoneSize,Depth,MTD,

Offset and Operator. By pressing one of these labeled buttons, you will enter the

keyboardscreenwhichwillallowyoutoeditandsaveinformationforthatmixvalue.

ForexamplepressMix,thekeyboardwillopenallowingyoutochangethemixname.Press

clear if you would like to start over with a new name. Press shift to toggle from lowercase

to uppercase letters. Once editing has been completed, press Enter.

Press Stone Size.Thereareveoptionsofaggregatesizeslistedinmillimeters(inches).If,

however,youdonotseeyourspecicstonesizelistedchoosethecloseststonesizeavailable.For

example,ifyourmixhasanaggregatesizeof20mm(0.79in),select16mm - 23mm (0.63 - 0.91).

Press Accept after you made your selection.

Editing Mix Details - Mix Name

Fine

Editing Mix Details - Stone Size

18

Press Depth. enter the depth of the asphalt mat on the numeric keypad in the units you

previously selected for the depth. Once the correct value has been entered, press Accept.

An out of range Warning will display for depths entered outside of the following range:

0.75in - 6.0in (19.05mm - 152.4mm)

Press MTD. enter the Maximum Theoretical Density (MTD)ofthemixonthenumeric

keypadintheunitsyoupreviouslyselected.TheMTDisprovidedfromtheasphaltmixdesignerand

is a key value in determining the percent compaction. Once the correct value has been entered, press

Accept.

An out of range Warning will display for an MTD entered outside of the following range:

100lb/ft3- 200lb/ft3(1601.8kg/m3 - 3203.7kg/m3)

Editing Mix Details - Depth

Editing Mix Details - Maximum Theoretical Density (MTD)

19

Theoffsetforthismaterialcanbeadjustedatalatertime.Measurements taken prior to adjusting

the offset will not include the offset. You will need to take a measurement to determine the offset.

The offset feature will be revisited later in the calibration section of this document.

Press Operator. Enter your name as the operator of the gauge, press Enter. The gauge

willreturntotheeditmixscreen.Verifyallmixinformationonthisscreen.Onceyouhaveveriedthe

resultsofthemix,pressExittosavethemix.

Editing Mix Details - Offset

Sean

Editing Mix Details - Operator

20

AfterpressingExitfromtheEditMixscreenthegaugewillreturntotheMix Details screen. Here you

mayusethegreenupordownarrowstoselectanewmixforeditingorchangeanexisting

mix.ThegreenhighlightedmixistheCURRENTMIXthatthegaugewillusewhentaking

readings.Priortoexitingthisscreen,besurethisisthemixyouwantandtheinformationtotheright

hasbeenveried. Press Control Menu on the status bar to return to the Control Menu. If

thegaugeisshutdown,thecurrentmixpriortoshutdownwillremainthecurrentmixwhenstarted

back up.

Project Details

ThePQI380isconguredtostore10uniqueprojectsthatareidentiedbyuserentereddescriptions.

If10projectshavebeendenedinthePQI380andan11thprojectisrequired,oneoftheoriginal10

willneedtobemodiedtoreectthenewproject.Thedetailsofthenewprojectwillneedtobeinput

byeditingthedetailsofapreviouslystoredproject.Oncetheoldprojectsareoverwrittenwithnew

information, the old information is gone and the new information is saved in the gauge. Previously

storeddataleswiththeoldmixinformationwillnotbeoverwritten.

Youmayrevisiteachprojectatanygiventimetocontinuetakingreadings.Datafromreadingstaken

withineachprojectwillstoreintheorderofwhichtheyweretaken.Ifmixdetailschangewithina

project(i.e.offset,stonesize,etc)orprojectdetailsareadded,dataforreadingstakenafterthe

changeswillcontinuetostoreonthesamedatleintheorderofwhichtheyweretaken.Onlyby

changingtheprojectnameitselfwillthedatabestoredonaseparatedatle.

ThedefaultprojectsstoredinanewPQI380willhavegenericprojectnames(i.e.Project1,Project2,

etc)alongwithgenericprojectdetails(i.e.MyStreet,MyRoad,Contact).TheProjectDetailsscreen

willresembletheMixDetailsscreensuchthatyouareabletoselectyourprojectusingtheup

anddownarrows.ThegreenhighlightedprojectistheCURRENT PROJECT.

ReadingstakenwillstoreonadatleusingtheCURRENT PROJECT NAME. If the gauge is

shutdown,thecurrentprojectpriortoshutdownwillremainthecurrentprojectwhenstartedbackup.

Editing Mix Details

Other manuals for PQI 380

1

Table of contents

Other Transtech Measuring Instrument manuals