Spartan Clean on the Go User manual

User Manual

Clean on the Go®Dispenser

WHAT’S IN THE BOX:

1. Dispenser with mounting bracket

2. Pick up tube - 4m (13ft) (1 roll for each product)

3. Discharge hose (2m [6.5ft] for 3.5, 4 and 8 GPM or “S” shaped discharge tube for 1 GPM spray bottle fill)

4. Hose hanger (bucket fill only)

5. Complete installation kit:

• Plastic clamps (2 pcs for each product)

• Metering tips (1 bag for each product)

• Foot filter and non-return valve assembly (1 piece for each product)

• Ceramic weight (1 piece for each product)

• Anchors (3 pcs)

• Screws (3 pcs)

• ¾” male GHT fitting

• Adhesive labels for product identification (1 chart for each product)

• 6ft water supply hose

Clean on the Go®

Low-Flow Dispenser

(Bottle fill)

Clean on the Go®

High-Flow Dispenser

(Bucket fill)

TECHNICAL FEATURES

Water supply connection Possible from right or left

Type of connection 3/4” Female GHT

Type of disconnection F-Gap (Flexible membrane)

A-Gap (Physical, visible gap)

Venturi ow rates 1 GPM (Gray) 3.5 – 4 GPM (Yellow)

Actuating systems Button

No. of product inlets 1 (models B1 and S1)

Maximum dimensions H = 22 cm (8 3/4”) W = 10 cm (3 7/8”) D = 12 cm (4 5/8”)

Working pressure Min 15 PSI (1 bar) Max 130 PSI (9 bars)

Ideal: 30 – 60 PSI (2 – 4 bars)

Temperature Max 160° F (70° C)

Notes Possibility of adding modules after installation

READ CAREFULLY BEFORE INSTALLING

• The correct procedures for dispenser installations are provided.

• Do not install where the dispenser is directly exposed to vapors or chemical fumes. Do not position

near sources of heat.

• Protect yourself: wear protective clothing and eye-wear when installing or maintaining the system,

take specific precautions as necessary.

• Follow the safety and handling instructions.

• Direct product discharge hose only into a specific container—not toward yourself or another person.

• Calibrate the dosing as per the product label instructions.

• This unit is supplied with an internal back-flow prevention device to avoid water supply contamination.

Local compliances standards may vary. Some jurisdictions may require a back-flow prevention device

at the system’s water inlet.

• The maximum operating pressure is 9 bars (130 PSI) and is intended as a maximum static pressure

applicable to the system. Care should be taken that the equipment cannot produce scenarios of

over-pressurization, which could cause damage to the structure of the system. The use of a pressure

reducer is always recommended and the installation of a tap on the water outlet of the system, which

can be closed when the system itself is not in use.

To prevent siphoning and to comply with ASME A112.1.2, install the dispenser so the end of the dis-

charge tube is a minimum of 10 cm (4”) above the flood level of the sink or other fixed container.

The dispenser should be installed approximately 1.5 m (5 ft) from the ground and near the chemical

containers for convenient use.

INSTALLATION OF A SINGLE UNIT

STEP 1 STEP 2 STEP 3

Use the mounting bracket as a

template to mark the mounting

hole pattern. Drill the holes for the

supplied 1/4” anchors and secure

the bracket with the three supplied

screws.

Attach the system to the mount-

ing bracket and slide it down...

...until the top tab clicks in place,

securing the system to the

mounting bracket.

STEP 4 STEP 5

Slide in the discharge hose (2 m / 6.5 ft or “S” tube)

over the barbed fitting, securing it into place.

Connect the water inlet supply hose and tighten

firmly with pliers.

STEP 1A STEP 2A STEP 3A

To install a multiple unit sys-

tem, start by installing the first

bracket on the wall as illustrat-

ed in Step 1. Then slide the

second bracket into the slot

from top to bottom on the left

side of bracket 1 until they are

properly aligned and secure.

Repeat step 1 for bracket two.

Unlock the left side of the first

system by pulling the rear clip

to its outward most position

as shown and remove the end

cap.

Unlock the right side of the

second system by pulling the

clip to its outward most position

and remove the water connec-

tion.

STEP 4A STEP 5A STEP 6A

Insert the unit connector

(#99097, sold separately) into

the first unit as illustrated.

Connect the second unit to the

first.

Apply the combined system

onto the bracket and complete

the installation as per step 3.

INSTALLATION OF A MULTIPLE UNIT

STEP 7 STEP 8 STEP 9

Select a suitable tip and insert

it completely into the barbed

tip seat as shown. To deter-

mine the correct tip, refer to the

tip chart.

Connect the product supply

tube or product pickup tube.

Cut the tubing to the required

length. Connect the foot valve

/ filter to the hose. Slide the

ceramic weight over the tube

and as far as possible over the

barbed fitting on the yellow foot

valve.

STEP 10 STEP 11

Tip calibration

1. Fill a graduated cylinder with

the concentrated product.

2. Using the chart in the manual,

select and insert the tip closest

to the desired dilution ratio.

3. Insert the pickup hose into the

graduated cylinder.

4. Put the outlet tube into an open

container and push the button

or lever in order to activate the

system. Draw up the product

until the pickup tube is com-

pletely filled.

5. Switch the system off and insert

the delivery hose in a 1 gallon (or 5 liter) container.

6. Mark the level of the product in the graduated container.

7. Switch the system on again until the 1 gallon (or 5 liter) con-

tainer is completely full.

8. Switch the system off and read the quantity of product in the

graduated container.

9. The difference in the product levels for points 6 and 8 indicates

the amount of product mixed per gallon (or liter).

Use a cable tie to secure the

tube on the barbed tip seat.

For a 4-product selector, repeat

the operations from step 7 to

11 for each product.

Water

Water

+

Chemical

tank

Chemical

graduated

tank

PRODUCT PICKUP TUBE AND TIP INSTALLATION

CERAMIC

WEIGHT

HYDRAULIC FEATURES: DILUTION RATIOS

Note: The following dilution ratios should be considered only as an initial reference. Variable factors such

as water flow/pressure, distance of product container to inlet fitting, and product viscosity often require

field adjustments.

Description

Part

code

Flow rate

(gpm)

Plumbing

standard

Dilution (oz/gal)

2 0.5 0.25

Clean on the Go®

Low-Flow (e-gap)

99093 1 e-gap Aqua

(0.46mm)

Mint Grn.

(0.41mm)

Clean on the Go®

Low-Flow (air-gap)

99094 1 air gap

Clean on the Go®

High-Flow (e-gap)

99095 3.5 e-gap Orange

(0.63mm)

Brown

(0.58mm)

Yellow

(0.51mm)

Purple

(0.36mm)

Pink

(0.25mm)

Burgundy

(0.21mm)

Clean on the Go®

High-Flow (air-gap)

99096 3.5 air gap

Accessories Dilution (oz/gal) Part code

Unit connector NA 99097

Rack NA 99073

Mating caps NA 914900

Low-Flow Mint Green tip (0.41mm) 2 99115

Low-Flow Aqua tip (0.46mm) 2 99112

High-Flow Orange tip (0.63mm) 2 99109

High-Flow Brown tip (0.58mm) 2 99110

High-Flow Yellow tip (0.51mm) 2 99111

High-Flow Purple tip (0.36mm) 0.5 99113

High-Flow Pink tip (0.25mm) 0.5 99116

High-Flow Burgundy tip (0.21mm) 0.25 99117

The dilution data given are determined under 40 PSI of pressure and 5.28 GPM flow rate. To set a desired

flow rate, a pressure regulator may be needed in cases where flow pressure is excessive. Where the mini-

mum and maximum flow properties are not available, consult a plumber to remedy the situation.

Flow volume needed from the pipe line to reach the optimal flow rate of the venturi:

• Gray venturi 1 GPM nominal flow rate: Needs at least 3.5 – 4 GPM from the pipe line

• Yellow venturi 3.5 – 4 GPM nominal flow rate: Needs at least 7 GPM from the pipe line

Based on water pressure and consistency, and to achieve desired dilution, multiple tip options are provided.

TROUBLESHOOTING

PROBLEM CAUSE SOLUTION

System does not

dispense solution

1. Water inlet strainer is clogged 1. Clean it or replace if necessary

2. Too much water pressure 2. Use a water pressure regulator in case of

more than 130 PSI (9 bars) water pressure

3. Insufficient water pressure 3. 15 PSI (1 bar) is the minimum required pres-

sure. If not available, consult a plumber.

4. The venturi is clogged 4. Soak venturi in hot water and inspect visual-

ly, gently removing debris. Replace assembly

if needed.

5. Activation valve is clogged by mineral 5. Soak the valve assembly in a solution of hot

water and limescale remover. Replace assem-

bly if needed.

Water ow won’t stop 1. Activation valve is clogged by minerals or

other waterborne debris

1. Soak the valve parts and valve seat in

limescale remover to clean. Replace them if

necessary.

Activation valve is

leaking

1. Valve cap not tight enough to seat 1. Firmly hand-tighten the valve cap until leak

stops.

2. Not properly positioned 2. Reposition the valve or change it if neces-

sary.

Connections and end cap

are leaking

1. Missing o-ring in the connection fitting and/

or end cap

1. Apply the o-ring or replace the entire part.

2. O-ring in the connections or end cap are

damaged

2. Replace the o-rings or replace the entire

end cap.

F-gap back-ow preventer

is leaking

1. Flexible membrane is damaged 1. Replace the back-flow preventer.

A-gap is spraying out

and/or leaking

1. Limescale film or dirt on the A-gap’s upper

nozzle

1. Soak in hot water and limescale remover to

remove buildup. Replace if necessary.

2. Venturi coated with limescale or dirt 2. Soak in hot water and limescale remover to

clean. Replace if necessary.

3. There is a buildup or clog in the discharge

hose

3. Clean the hose to eliminate restriction.

4. Discharge hose is above the dispenser 4. Make sure the discharge hose dispenses

below the dispenser, insuring no back pres-

sure.

Improper concentration

of chemical or no suction

1. Insufficient water pressure 1. 15 PSI (1 bar) is the minimum working pres-

sure. Check plumbing options.

2. Metering tip clogged 2. Replace tip.

3. Foot valve clogged 3. Soak in hot water. Hand-clean or change it.

4. Venturi or back-flow preventer clogged 4. Soak in hot water or limescale remover to

clean. Replace if necessary.

5. Air leak in chemical pickup tubing line 5. Check the entire line. Replace the tubing

and check the connections and cable tie.

6. Product is too thick 6. Change the pickup hose. Switch to a bigger

diameter (need 1/4 x 5/16” coupler).

7. Product container is too far from the system 7. The standard installation is positioning the

tank under the system (5 ft max).

8. Excess concentration 8. Tip is not the correct one or not fully seated.

Pressure variations can require adjustment

from chart recommendation.

System continues to draw

chemical after the valve

is closed

1. Chemical tank is positioned higher than the

dispenser, causing siphoning

1. Move chemical container below the dis-

penser discharge point.

Table of contents

Popular Dispenser manuals by other brands

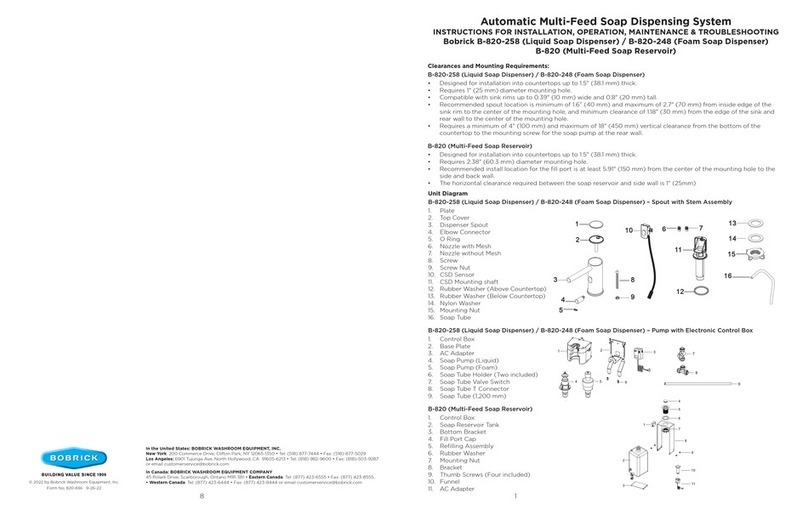

Bobrick

Bobrick B-820-258 Instructions for installation, operation and maintenance

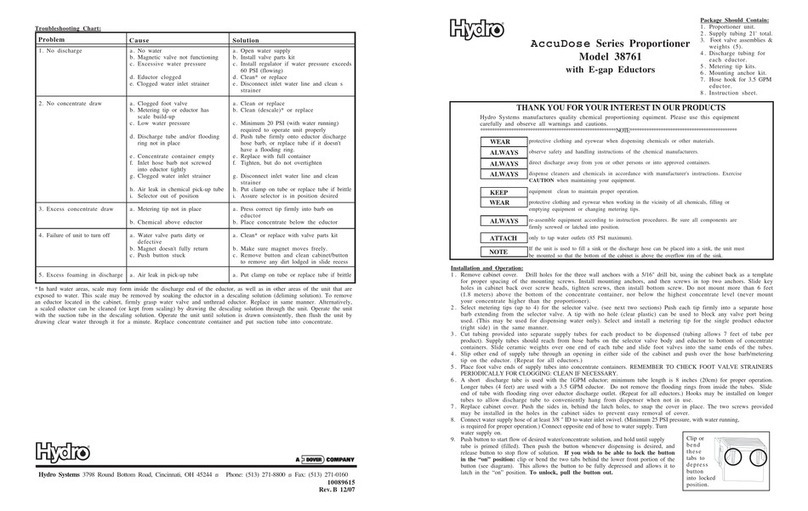

Dover

Dover Hydro AccuDose Series quick start guide

Cornelius

Cornelius QUEST CAFE Installation and operator's manual

Helvex

Helvex UMB-1102-AIB installation guide

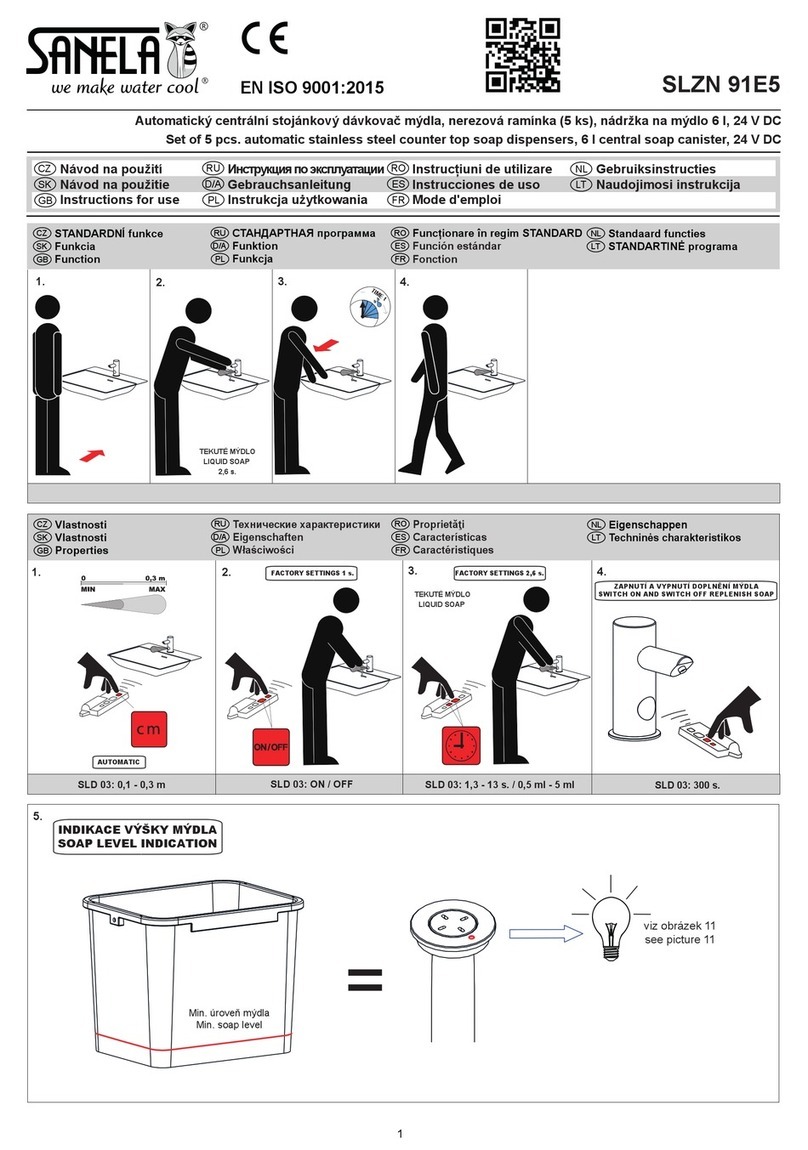

Sanela

Sanela SLZN 91E5 Instructions for use

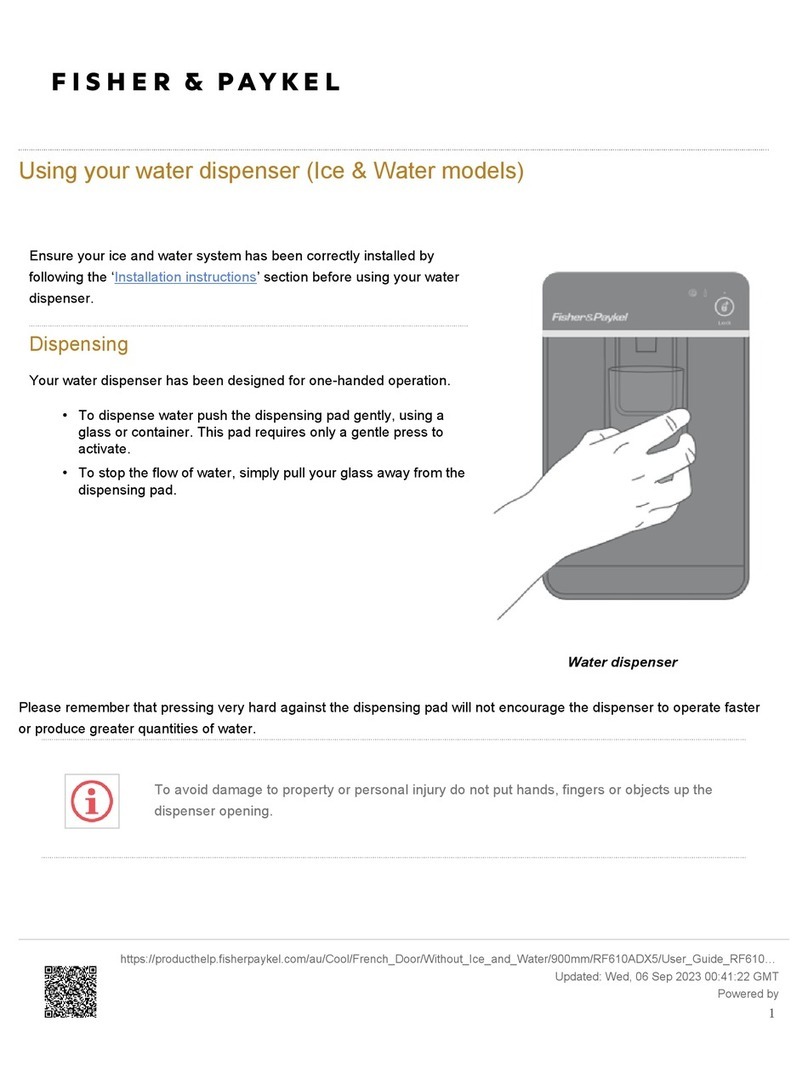

Fisher & Paykel

Fisher & Paykel RF610ADX5 manual