Spartan WT913G User manual

WT913G

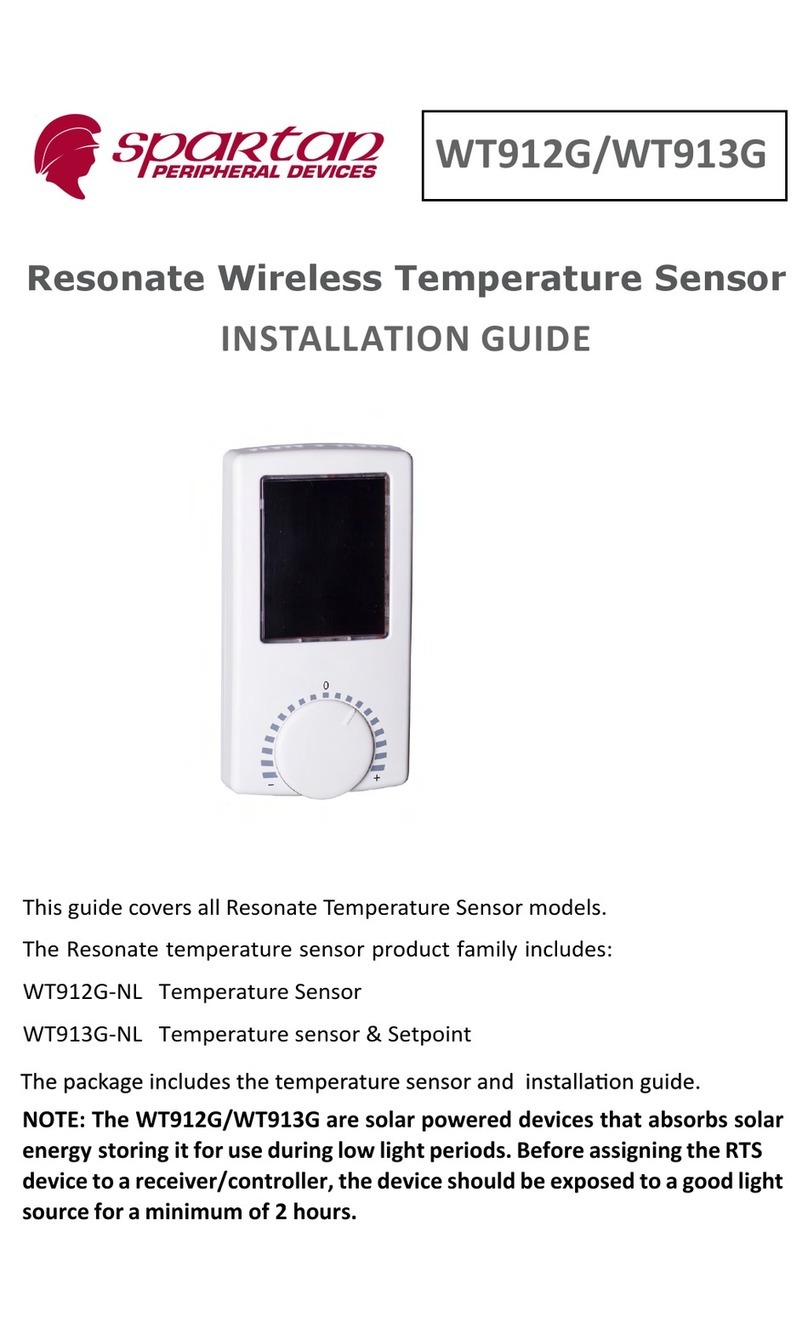

Resonate Wireless Temperature Sensor

This guide covers all Resonate Temperature Sensor models.

The Resonate temperature sensor product family includes:

WT913G-NL Temperature Sensor & Setpoint

NOTE: The WT913G is a solar powered device that absorbs solar energy storing

it for use during low light periods. Before assigning the RTS device to a receiver/

controller, the device should be exposed to a good light source for a minimum

of 2 hours.

INSTALLATION GUIDE

2

The temperature sensor

(also referred to as the sensor in this guide)

of 0-100% . The sensor is intended for indoor use only.

Some models have a temperature set point knob and/or a fan speed

adjust how the temperature control operates.

-

voke an occupancy event (for RTS-2HS models) or to go into test mode

ayllacipytsihcihwrevieceraotstimsnartrosneserutarepmetehT

device that is programmed to provide temperature control in the space

that the sensor is monitoring for closed loop temperature control. The

sensor and receiver must be within range, preferably in the same room

-

ing 50’ (15.2 m) range, greater care must be taken to insure proper re-

Even with a brief exposure to light the sensor will operate; however for

ehtniatnoctahtsmargeletsutatsstimsnartrosneserutarepmetehT

•A5-10-03: Temperature Sensor + Temperature Set Point Control

The valid ranges for each data element:

•Temperature: 0 - 40°C, (32° - 104°F)

•

•Humidity Sensor: 0 -100% RH

•Fan Speed Switch: Auto, OFF, Low (1) Med (2), High (3)

•

3

Temperature Sensing Operaon

Temperature and Humidity Monitoring - The temperature sensor will

record the temperature, temperature set point and humidity values*

every 10 seconds (sample period) when there is approximately 100 lux

(10 foot-candles) available. If there is less than 100 lux (10 fc), the sam-

ple period will increase to 100 seconds. Aer 24 hours at < 15 lux (1.5

fc) the sample period will increase to 200 seconds. *Assuming sucient

storage charge to operate.

Temperature Set Point - Users can adjust the temperature set point by

rotang the knob counterclockwise to lower the set point value; clock-

wise to increase the set point value.

The receiving temperature control equipment must scale the set point

range to values that are applicable for the applicaon.

Fan Speed Switch - Users can adjust the fan speed switch by sliding the

switch to a seng: Auto, OFF, Low (1) Med (2), High (3).

Occupancy Buon - (RTS-2HS models only) Users can override a room

occupancy state by pressing the occupancy buon on the lower right

edge of the sensor.

LED Operaon - LEDs are on the right side of the solar panel. The red

LED will ash when the Link or Occupancy buon is pressed. See Test

Operang Modes for further LED informaon.

Transming Values - The temperature sensor will transmit a telegram

when:

• 10 sample periods have been completed or

• when the fan switch or occupancy buon are used or

• when the temperature value dierence from the last transmied

value is greater than 0.3°C, (0.5°F) or

• the humidity value dierence from the last transmied value is

greater than 3%.

Installing the Temperature Sensor

The temperature sensor can be mounted on any surface; glass, stone,

concrete, wallboard, cubicle parons, etc. The sensor can be mounted

using screws (not supplied) through the removable back plate (2 key-

holes or using double sided tape or Velcro™ (not supplied).

The mounng locaon of the wireless transmier is important as this

will directly aect the receivers recepon of the telegrams. Before

4

1. The sensor has a removable back plate. Using your thumb, press

edge of the sensor body and pull the body

away from the back plate.

2. Mount the back plate to the wall surface in

plate that mate with standard electrical box

the sensor using double sided tape or Vel-

cro® (not supplied).

3. Once the back plate has been secured, align

the two top alignment tabs on the back plate with the temperature

clicks in place.

Linking the Temperature Sensor to a Receiver

This process requires the controller or receiver to be mounted and pow-

ered and within range of the temperature sensor to be linked.

The sensor is a solar powered device that absorbs energy through a so-

lar panel storing it for use during low light periods. Before assigning the

sensor to a receiver/controller, the device must be exposed to a good

1. Remove the sensor from the back plate by pressing in on the tab on

the lower edge and pulling away from the back plate.

2.

the receiver, if necessary refer to

3. Press the temperature sensors Link

4. -

ceiver.

5

Installing or Replacing the Baery

The baery is not required for normal operaon when the RTS

receives adequate natural or arcial light. The baery can be used

during installaon (start assist).

1. Remove the sensor from the back plate by pressing the key on

the lower edge of the sensor body and pull the body away from

the back plate.

2. To remove old baery: Using a small at head screwdriver or

pen as a lever, insert pointed end under the clear plasc baery

retaining clip’s edge and pop the clip o.

3. Install or replace the baery in the clip with a new CR2032 coin

cell baery insuring the posive side (+) will be facing up.

4. Align the two straight edges of the re-

taining clip with the baery holder and

press the clip in with your nger.

Test Operang Modes

Ensure the RTS is fully charged or insert a

baery before entering test modes. The

following tests can be selected when in test

mode.

Light Level Test: provides visual feedback of

the immediate energy produced by the solar panel.

1. To enter Light Level Test mode, press and hold the occupancy/

test buon for 6 seconds. The green LED will begin to blink.

2. Press the test buon again for 6 seconds to select Light Level

Test. The green LED will blink in accordance to the light level

it is detecng. This will change (2

second lag me) as you move the

sensor to areas with dierent light

levels. See following blink indicator

table.

Note:

Entering test mode secon:

If the red LED blinks (no green LED)

aer you have released the test

mode buon, place the sensor under

a lamp with at least 100 foot-candles

(1000 lux) for 1 hour before retrying.

6

LIGHT LEVEL TEST TABLE

The green LED will blink according to the energy produced by the solar cell

blinks lux foot candles me to fully charge discharge me

0,1 < 15 < 1.4 below operang level n/a

2 15-50 1.4 - 4.6 min operang level n/a

3 50-100 4.6 - 9.3 24 hours to full charge 100 hours

4 100-200 9.3 - 18.6 12 hours to full charge 150 hours

5 200-400 18.6 - 37.2 6 hours to full charge 200 hours

The me to fully charge is based on the storage capacitor charging from

a non-operaonal condion. Discharge me indicates how long a fully

charged sensor will operate in the dark. The test will repeat every 2 sec-

onds and run for a duraon of 100 seconds. You may quit the test at any

me by pressing the test buon for 6 seconds.

Range Conrmaon Test: provides visual feedback of the sensors signal

strength by a linked receiver with range conrmaon capability (only “F

series” controllers have range conrmaon ability). One and only one re-

ceiver can be linked to the sensor for proper operaon of the test. (disable

repeaters in range for proper test operaon).

1. To enter Range Conrmaon Test mode, press and hold the occupan-

cy/test buon for 6 seconds. The green led will begin to blink.

2. A quick press and release of the buon at this point will allow you to

select between light level test (green LED) and range conrmaon test

(amber). When the amber LED is blinking, go to step 3. (If the 3 LEDs

fail to blink during this test, insert a baery or place under a lamp with

at least 100 fc (1000 lux) for 1 hour before retrying.)

3. Press and hold the test buon again for 6 seconds to select Range

Conrmaon Test.

All three LED’s can blink in this test mode when the sensor transmits or

receives a Range Conrmaon Telegram. The sensor will display the signal

strength status for 5 seconds, see table below.

RANGE CONFIRMATION TEST TABLE

LED Signal Strength

Green > -70 dbm

Amber > -80 dbm

Red < -80 dbm

The test will repeat every 10 seconds and run for a duraon of 3 min-

utes. You may quit the test at any me by pressing the occupancy/test

buon for 6 seconds.

7

Installing Wireless Devices

Careful planning is needed when locang the receivers and transmit-

ters based on the construcon materials in the space and possibility of

tenant’s furniture disrupng the transmissions.

The temperature sensor should be installed in the space where the

receiver is mounted and connected to the temperature control equip-

ment however the signal will travel through material barriers.

Refer to the tables below for range consideraons with building

materials that reduce the radio signal power.

Material Aenuaon

Wood 0 - 10%

Plaster 0 - 10%

Glass 0 - 10%

Brick 5 - 35%

MDF 5 - 35%

Ferro concrete 10 - 90%

Metal 90 - 100%

Aluminum 90 - 100%

Material Radio Range-typical

Line of sight: 80’ (24m) corridors

Line of sight: 150’ (46m)open halls

Plasterboard: 80’ (24m) through 3 walls

Brick: 33’ (10m) through 1 wall

Ferro concrete: 33’ (10m) through 1 wall

Ceiling: not recommended

Wireless System Layout Hints

• Avoid locang transmiers and receivers on the same wall.

• Avoid locang transmiers and receivers where the telegrams

must penetrate walls at acute angles. This increases the mate-

rial the telegram must pass through reducing the signal power.

• Avoid large metal obstrucons as they create radio shadows.

Place receivers in alternate locaons to avoid the shadow or use

repeaters to go around the obstacle.

• (connued next page)

•Do not locate receivers close to other high frequency trans-

other source of interference including, ballasts, LED drivers,

computers, video equipment, Wi-Fi/LAN routers, GSM modems

interference.

Regulatory Statements

FCC Part 15.231 (315 and 902 MHz models only)

Contains FCC ID: SZV-STM300C or SZV-STM300U

The enclosed device complies with Part 15 of the FCC Rules.

(I.) this device may not cause harmful interference and

(ii.) this device must accept any interference received, including

IC RSS-210: (315MHz and 902 MHz models only)

ISO 9001: (only 315 MHz models that bear a MIC mark)

Law Compliance. This device is granted pursuant to the Japanese Radio Law

( )

電波法

電気通信事

業法

number will become invalid)

telephone: Toll Free: 1-888-554-4465, 1-450-424-6067 • fax: 1-450-424-6071

email: info@spartan-pd.com • website: www.spartan-pd.com

Table of contents

Other Spartan Temperature Controllers manuals

Popular Temperature Controllers manuals by other brands

Siemens

Siemens RDJ10RF/SET manual

AGPtek

AGPtek TA4 instruction manual

Warner

Warner KilnTroller II quick guide

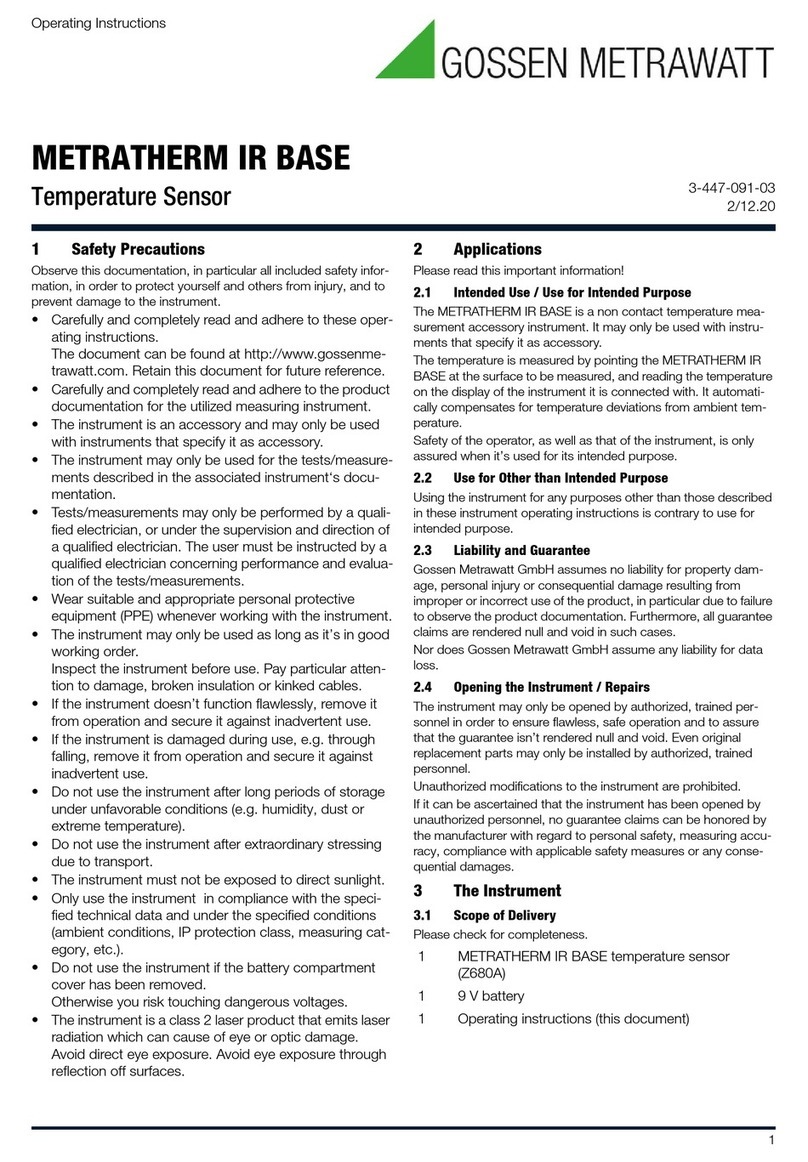

Gossen MetraWatt

Gossen MetraWatt METRATHERM IR BASE operating instructions

S+S Regeltechnik

S+S Regeltechnik HYGRASGARD ESFF Operating Instructions, Mounting & Installation

Eurotherm

Eurotherm 2108i Installing and operating instructions