7.1 Cooling:

Normally,

Cabinet temperature > temperature set-point (SEt value) + differenal (diF), compressor starts when minimum protecon me elapses.

Cabinet temperature < SEt value, compressor stops.

Note: The minimum protecon me equals to OdO (delay Output (from power) On) at power on for the first me and later dOF (delay

(aer power) OFF).

If cabinet temperature sensor is faulty, cooling outputs in duty cycle mode per Ont/O.

①Ont=0, O=0, the compressor is always off.

②Ont=0, O≠0, the compressor is always off.

③Ont≠0, O=0, the compressor is always on.

7.2 Defrost

1) dEt=0 (defrost endurance me is set to 0), defrost is disabled.

2) dEt≠0, neither during defrosng nor dripping:

① Evaporator sensor is enabled (H42=y), evaporator sensor temperature ≥ defrost stop temperature (dSt), defrost cannot start.

② H42=y, evaporator sensor temperature < dSt, or evaporator sensor is disabled (H42=n), defrost can start in any one of the following

condions:

a.If dPO=y (defrost (at) Power On is enabled), and dOH (defrost Offset Hour) elapses.

b.Defrost interval me (dit) elapses.

c.Press for 3 sec.

Note: dit and dOH is counted per dCt=1(fixed me interval), dCt=0(compressor operang hours) or dCt=2(compressor stop hours).

3) During defrosng, defrost stops in any one of the following condions:

① Evaporator sensor is enabled (H42=y), evaporator sensor temperature > dSt.

② dEt (defrost endurance me) elapses.

③ Press for 3 sec.

4) The controller enters dripping me aer defrost to drain the water generated during defrosng. Cooling is disabled during drainage

me (dt). It enters cooling cycle status aer drainage me elapses.

5) Display during defrosng

ddL=0 (Defrost display Lock): shows the temperature read by the cabinet probe.

ddL=1: locks the reading on the temperature value read by cabinet probe when defrosng starts, and unl the next me the Set-point

value is reached.

User Manual ECS-974neo Temperature Controller

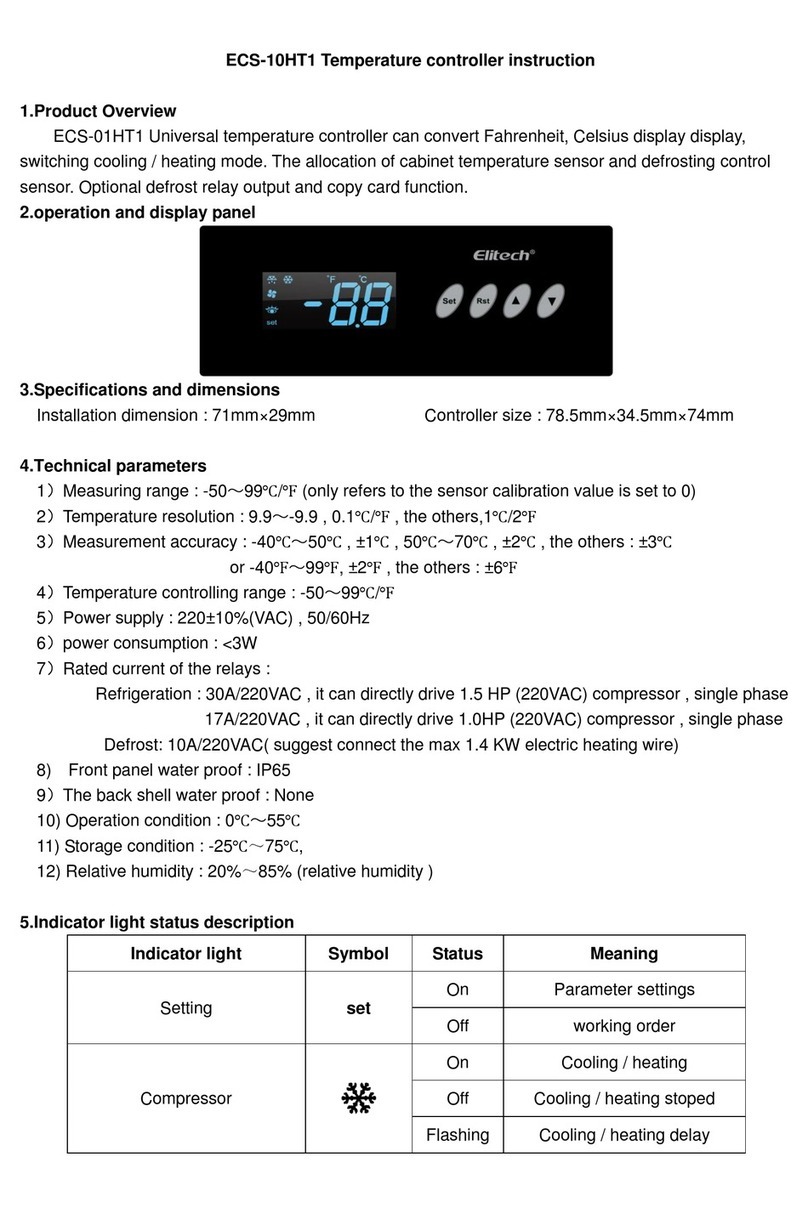

6. Keys’ function

7.Control output

6.1 Keys

Key Funcon Operaon LED

SET

Access user menu Press and release set LED on

Access administrator menu Press for 5 sec set LED on

Shi between menus and parameters Press set LED on

▲

Scrolls through the menu items & increases the values Press set LED on

Upload data to copy card Press for 3 sec Display “uP” if upload succeeded;

display “Er” if upload failed.

▼

Scrolls through the menu items & decreases the values Press set LED on

Download data from copy card Press for 3 sec Display“do” if download succeeded;

display “Er” if download failed.

Exit user menu Press set LED off

View the temperature read by evaporator probe Press Display defrost temperature

Force defrost to start/stop Press for 3 sec on or off

▲+▼ Reset to default (the second copy) Press for 10 sec Display “rSt” if it succeeded.

6.2 Operaon

1) Set temperature

a. Press and release the SET key to enter user menu, set LED lights and SEt is displayed.

b. Press the SET key to display SEt value.

c. Use ▲ and ▼ keys to change SEt value.

d. Press key or keep the controller inacve for 30 sec to save sengs and exit.

e. If the keys are locked, LOC is displayed and it is disabled to adjust SEt value.

2) Set password

a. Press the SET key for 5 sec, the controller displays PA1 (administrator menu password). (If you want to enter administrator menu, you

need to input correct password. When PA1≠0, and you enter administrator menu, the controller displays PA1 value. When PA1=0, you

will enter administrator menu directly).

b. Press the SET key to display 00, then press ▲ or ▼ to enter the password value.

c. Aer entering password value, press the SET key (to confirm the password), PA1 is displayed. The controller automacally verifies the

correctness of the password. When the password is verified (enter administrator menu), use ▲ or ▼ key to scroll through diF, HSE……

CA2, ddL; Otherwise, the controller will exit sengs.

d. Once set, PA1 value must be remembered. Otherwise, parameters cannot be changed. The value 125 is a universal password.

3) Set parameters (PA1 value is input correctly to access administrator menu sengs)

a. When a menu item is selected, press SET key to set its value.

b. Use ▲ or ▼ to change the value.

c. Press SET key to back for selecng another item.

d. Press key or keep the controller inacve for 30 sec to save sengs and exit.

4) Reset parameters

a.In measuring status, press ▲ and ▼ keys for 10 sec, rST is displayed and the controller resets to default.

b.When Elitech copy card CPK-4 is used to download parameters to the controller, it doubles parameters.

c.The first copy is used to control and the second is used to reset parameters.

d.If the second is changed, please connect CPK-4 again to download parameters.

5) Force to start/stop defrost: Press for 3 sec to shi between cooling, defrost and drip.

6) Copy card

Upload (copy parameters in the controller to the copy card)

a.Use keys to set parameters

b.Insert the copy card, press ▲ key unl “uP” is displayed.

c.Plug out the copy card aer 5 sec to power on the controller again.

Download (copy parameters in the copy card to the controller)

a.Insert the copy card, press ▼ key unl “do” is displayed.

b.Plug out the copy card aer 5 sec to power on the controller again.

Note: “Er” shows to indicate upload/download programming failure. Check whether the copy card is connected well.

“EP” shows to indicate the data in copy card disagrees with controller model, causing programming failure. Find a correct copy card to

upload or download parameters.

In this course, keep the power supply stable and copy card connected well. Please do not plug out the copy card before the operaon is

finished.