USB-Serial Conversion Cable

Windows is a registered trademark of Microsoft Corporation in the

United States and or other countries.

* Use a high-power port for the USB port.

Note: A driver must be installed on the computer. Refer to the

Instruction Manual included with the Cable for the installation

procedure.

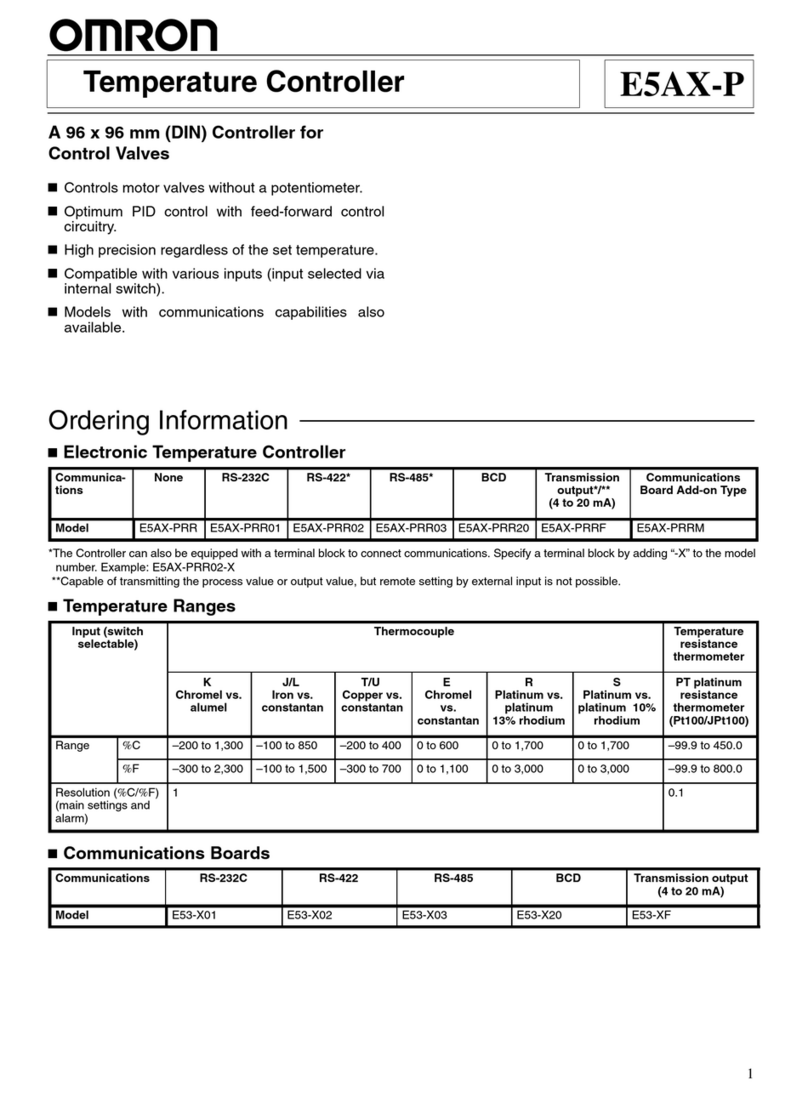

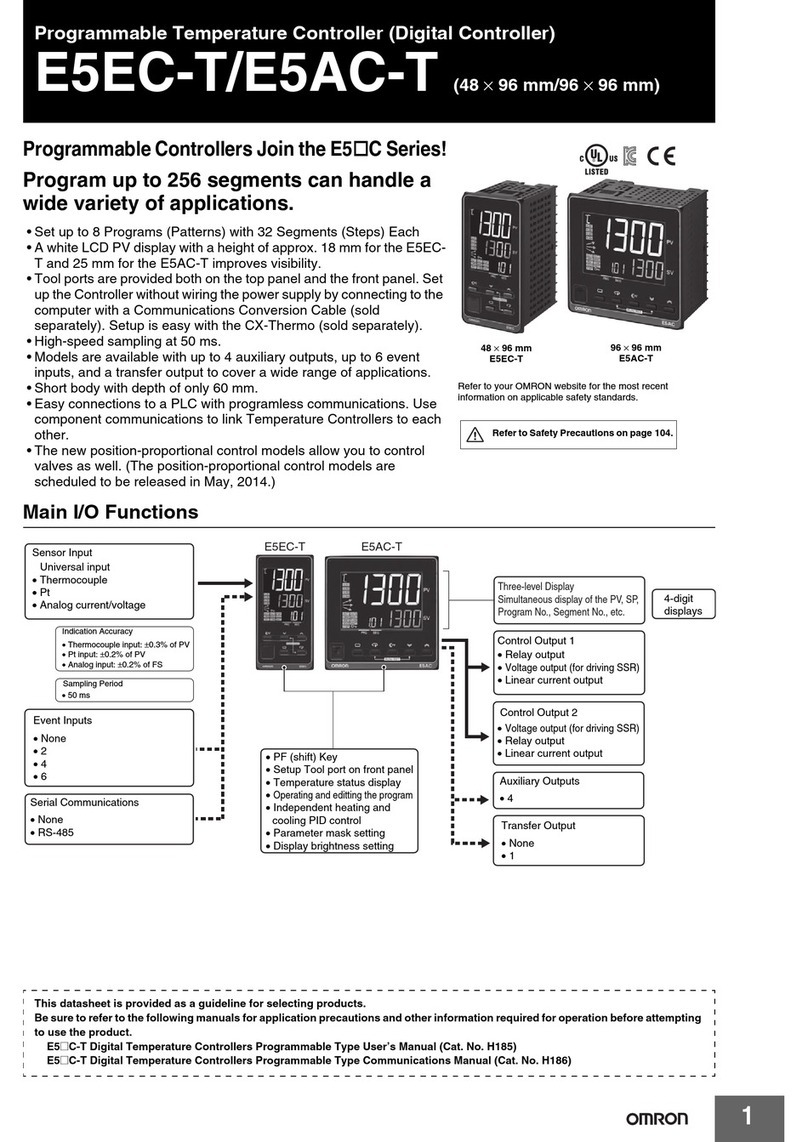

Communications Specifications

* The baud rate, data bit length, stop bit length, and vertical parity can

be individually set using the Communications Setting Level.

Communications Functions

MELSEC is a registered trademark of Mitsubishi Electric Corporation.

*1 Both the programless communications and the component

communications support the copying.

Current Transformer (Order Separately)

Ratings

Heater Burnout Alarms and SSR Failure

Alarms

*1 For heater burnout alarms, the heater current will be measured

when the control output is ON, and the output will turn ON if the

heater current is lower than the set value (i.e., heater burnout

detection current value).

*2 For SSR failure alarms, the heater current will be measured when

the control output is OFF, and the output will turn ON if the heater

current is higher than the set value (i.e., SSR failure detection

current value).

*3 The value is 30 ms for a control period of 0.1 s or 0.2 s.

*4 The value is 35 ms for a control period of 0.1 s or 0.2 s.

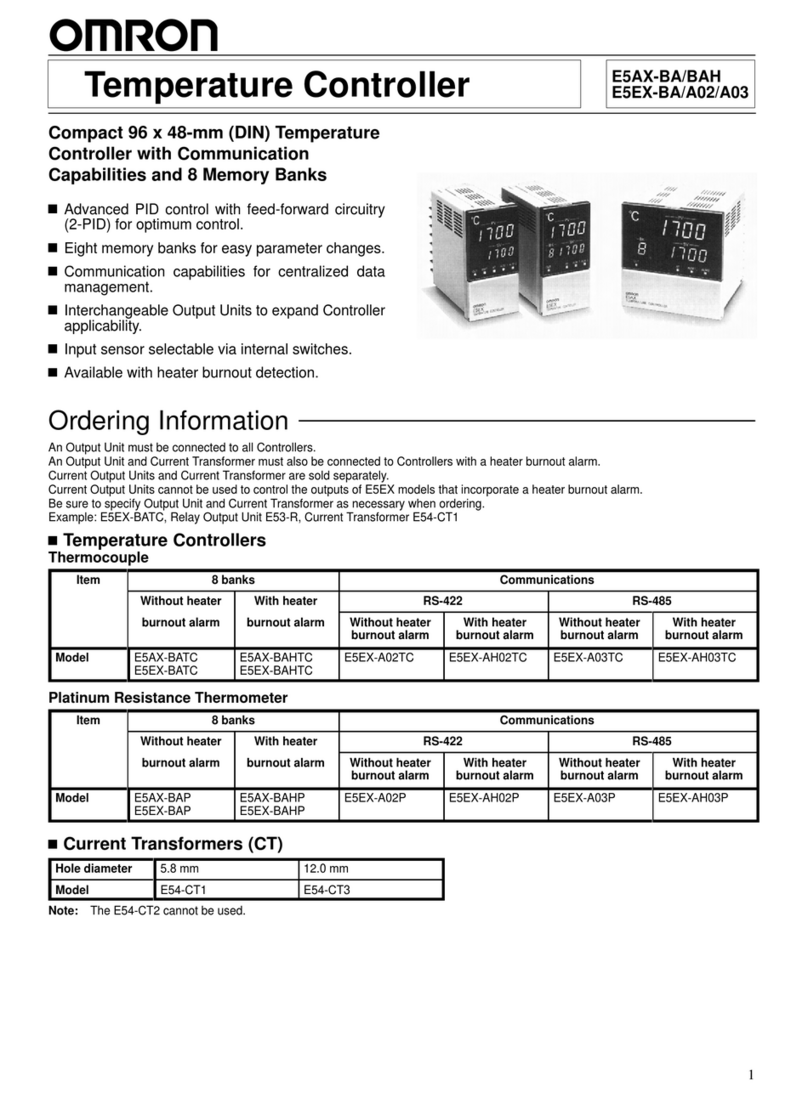

Electrical Life Expectancy Curve for

Relays (Reference Values)

Applicable OS Windows XP, Vista, or 7

Applicable software CX-Thermo version 4.61 or higher

Applicable models E5@C-T Series, E5@C Series, and E5CB Series

USB interface standard Conforms to USB Specification 2.0.

DTE speed 38400 bps

Connector

specifications

Computer: USB (type A plug)

Digital Temperature Controller:

Special serial connector

Power supply Bus power (Supplied from USB host controller.)*

Power supply voltage 5 VDC

Current consumption 450 mA max.

Output voltage

4.7±0.2 VDC

(Supplied from USB-Serial Conversion Cable to

the Digital Temperature Controller.)

Output current

250 mA max.

(Supplied from USB-Serial Conversion Cable to

the Digital Temperature Controller.)

Ambient operating

temperature 0 to 55°C (with no condensation or icing)

Ambient operating

humidity 10% to 80%

Storage temperature -20 to 60°C (with no condensation or icing)

Storage humidity 10% to 80%

Altitude 2,000 m max.

Weight Approx. 120 g

Transmission line

connection method RS-485: Multidrop

Communications

RS-485 (two-wire, half duplex)

Synchronization

method Start-stop synchronization

Protocol CompoWay/F, or Modbus

Baud rate* 9600, 19200, 38400, or 57600 bps

Transmission code ASCII

Data bit length* 7 or 8 bits

Stop bit length* 1 or 2 bits

Error detection

Vertical parity (none, even, odd)

Block check character (BCC) with

CompoWay/F or CRC-16 Modbus

Flow control None

Interface RS-485

Retry function None

Communications buffer 217 bytes

Communications

response wait time

0 to 99 ms

Default: 20 ms

Programless

communications*1

You can use the memory in the PLC to read and

write E5@C-T parameters, start and reset opera-

tion, etc. The E5@C-T automatically performs

communications with PLCs. No communications

programming is required.

Number of connected Temperature Controllers:

32 max.

Applicable PLCs

OMRON PLCs

CS Series, CJ Series, or

CP Series

Mitsubishi Electric PLCs

MELSEC Q Series, L Series

Component

Communications

When Digital Temperature Controllers are con-

nected, set points and RUN/STOP commands

can be sent from the Digital Temperature Control-

ler that is set as the master to the Digital Temper-

ature Controllers that are set as slaves.

Slope and offsets can be set for the set point.

Number of connected Digital Temperature Con-

trollers: 32 max. (including master)

Copying*1

When Digital Temperature Controllers are con-

nected, the parameters can be copied from the

Digital Temperature Controller that is set as the

master to the Digital Temperature Controllers that

are set as slaves.

Dielectric strength 1,000 VAC for 1 min

Vibration resistance 50 Hz, 98 m/s2

Weight

E54-CT1: Approx. 11.5 g,

E54-CT3: Approx. 50 g

Accessories

(E54-CT3 only)

Armatures (2)

Plugs (2)

CT input (for heater

current detection)

Models with detection for singlephase

heaters: One input

Models with detection for singlephase or

three-phase heaters: Two inputs

Maximum heater

current 50 A AC

Input current

indication accuracy ±5% FS ±1 digit max.

Heater burnout

alarm setting range

*1

0.1 to 49.9 A (in units of 0.1 A)

Minimum detection ON time: 100 ms *3

SSR failure alarm

setting range *2

0.1 to 49.9 A (in units of 0.1 A)

Minimum detection OFF time: 100 ms *4

500

300

100

50

30

10

5

3

1

0123456

Switching current (A)

E5CC-T

250 VAC, 30 VDC

(resistive load)

cosφ = 1

Life (× 104operations)

10

E5CC-T