Spartus D33 User manual

User’s manual

HAND GRINDER for tungsten electrodes

D33

WELDING EQUIPMENT SUITABLE FOR TODAY’S NEEDS

Thank you for purchasing our product!

You have made a right choice. Plasma welding and welding processes are

carried out in difficult conditions that expose welding equipment to extreme

tests of its strength. Only high quality equipment can ensure required reliability

and performance during realization of the above-mentioned processes. SPAR-

TUS® products are characterized by precisely such features: they are primarily

reliable and durable, but they are also versatile. We listen carefully to clients’

needs.Therefore, our offer covers such a wide assortment of products. Thank

you very much for your trust in our company. We would like to invite you to

familiarize yourself with the remaining products and offer at www.spartus.

info or directly at alocal distributor of SPARTUS® products.

Before using this product, read the instruction manual in its entirety, with understanding.

Keep the instructions for quick reference to it if necessary. Pay special attention to safety

instructions provided for your protection. In the event of any points of misunderstanding

instructions, contact your supplier or supervisor.

IMPORTANT!

TABLE OF CONTENTS

1. SAFETY RULES ............................................................................................................................................... 2

1.1 Intended use ................................................................................................................................................................. 2

1.2 Safety use ....................................................................................................................................................................... 2

1.3 Environmental conditions ....................................................................................................................................... 3

2. EC DECLARATION OF CONFORMITY ...................................................................................................... 3

3. GENERAL DESCRIPTION ............................................................................................................................. 4

4. TECHNICAL SPECIFICATIONS .................................................................................................................... 4

5. DEVICE STRUCTURE ..................................................................................................................................... 4

6. INSTALLATION AND USE ............................................................................................................................ 6

6.1 How to use SPARTUS® D33 hand grinder ........................................................................................................... 7

7. TROUBLESHOOTING .................................................................................................................................... 8

USER’S MANUAL EN

2

1. SAFETY RULES

Information in this manual on the safe use of the provided equipment does not release the

operator from following safety regulations in force on site.

In addition, the operator should have an information on the necessary safeguards as defined

in relevant national and international standards and regulations.

It is forbidden to use the equipment without previous reading of this manual.

This symbol is dedicated for tips not using of which may be dangerous to life or health. These tips

should be used while keeping special caution in these situations. These tips should be given to all

users of the device.

1.1 INTENDED USE

Hand grinder for tungsten electrodes SPARTUS® D33 is dedicated for sharpening of tungsten

electrode tip (non-consumable electrode), use for TIG welding procedure.

It is forbidden to grind tungsten electrodes with thorium without first connecting the extractor

and separating the dust with proper filtration. The dust generated as the result of the grinding

ofthorium electrodes is highly harmful to health and life of the operator..

It is forbidden to use the device for improper purposes!

1.2 SAFETY USE

Before each use check the condition of the device and additional accessories. It is forbidden

to use damaged or technically inoperable device. Used and damaged parts must be replaced

with original spare parts.

Breaking the safety rules may lead to the risk of losing health or life!

1.2.1 Eye and face protection

The wheel rotational speed reaches 1100 rpm. During the grinding, splinters and impurities

that can form in the eye may appear. High temperature can be produced due to strong friction

forces. The rotating wheel of the grinder can pose a risk to the operator’s hands and fingers.

In order to prevent hazards mentioned above and other risks that accompany the grinding

process, the following rules must be followed:

• it is absolutely forbidden to use the device when the protective cover is removed or damaged,

• it is forbidden to put hands or fingers inside the grinding chamber when the device is con-

nected to the electricity supply,

• sharpened electrode always should be secured by a clamp.

USER’S MANUAL

EN

3

1.2.2 Noise load

The device itself emits a low level of noise. However, during the sharpening of tungsten elec-

trode, the level of noise increases. Excessive noise can cause permanent damage to hearing.

In order to prevent threats mentioned above, following rules must be followed:

• use appropriate hearing protectors,

• people in the vicinity should be informed about the dangers of exposure to excessive noise.

People in the work zone must wear appropriate hearing protection.

1.2.3 Risk of electric shock

The unit is powered from single-phase network 230V +/- 10%. Like all device supplied with

electricity network, the grinder may cause risk of electric shock to the operator. Electrical

shock from the electricity network can result in permanent damage to health or loss of life.

In order to prevent threats mentioned above, following rules must be followed:

• it is forbidden to use when the power cord, plug or cover is damaged,

• do not touch electrical components of the device under voltage,

• take special care when using the device in small rooms or in areas with increased air humidity,

• avoid contact with water.

1.3 ENVIRONMENTAL CONDITIONS

Conditions during the operation, storage and transport

Ambient temperature during operation -10°C ÷ +40°C

Relative air humidity 50% in +40°C

90% in +20°C

Ambient air free from excessive amounts of dust, acids,

corrosive gases

Ambient temperature

during transportation and storage -20°C ÷ +55°C

2. EC DECLARATION OF CONFORMITY

Hand grinder SPARTUS® D33 is in conformity with the relevant Union harmonization

legislation:

LVD 2014/35/UE Low Voltage Directive

EMC 2014/30/UE Electromagnetic Compatibility Directive

harmonized standards:

EN 60745-1:2006 Hand-held motor-operated electric tools – Safety – Part 1: General

requirements.

Product is marked with CE sign .

This declaration applies only to the machine in the state in which it was on the market and

does not include components added by the end-user or subsequent actions carried out by it.

USER’S MANUAL EN

4

3. GENERAL DESCRIPTION

Hand grinder SPARTUS® D33 for tungsten electrodes enables precise and efficient sharpening

of the tungsten electrode tip according to the technological requirements.

The grinder enables sharpening of electrodes with diameters of 1.0 to 4.0mm at an angle 15°,

18°, 22.5° and 30°. The ergonomic shape ensures comfort of use.

The advantages of the device are above all high output, low noise and energy saving.

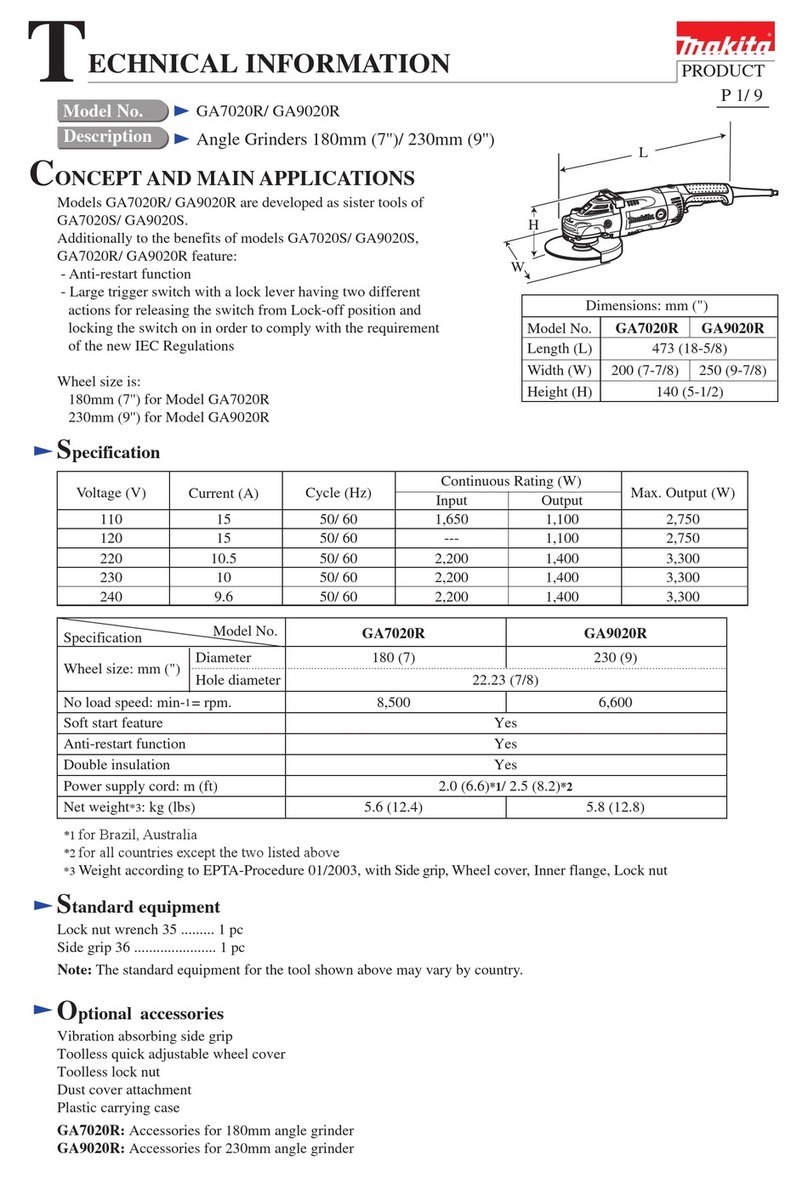

4. TECHNICAL SPECIFICATIONS

Input ~1 x 230V ± 10% 50 / 60 Hz

Electric motor power [W] 750

Grinding angle [°] 15, 18, 22.5, 30

Max. rotational speed [obr/min] 1100

Diameter of electrodes [mm] 1.0 – 4.0

Grinding wheel diameter [mm] φ33.5 x φ5 x 2.4(mm)

Min length of grinding electrodes [mm] 30

Dimensions [mm] 340 x 76 x 76

Grinder weight [kg] 1.6

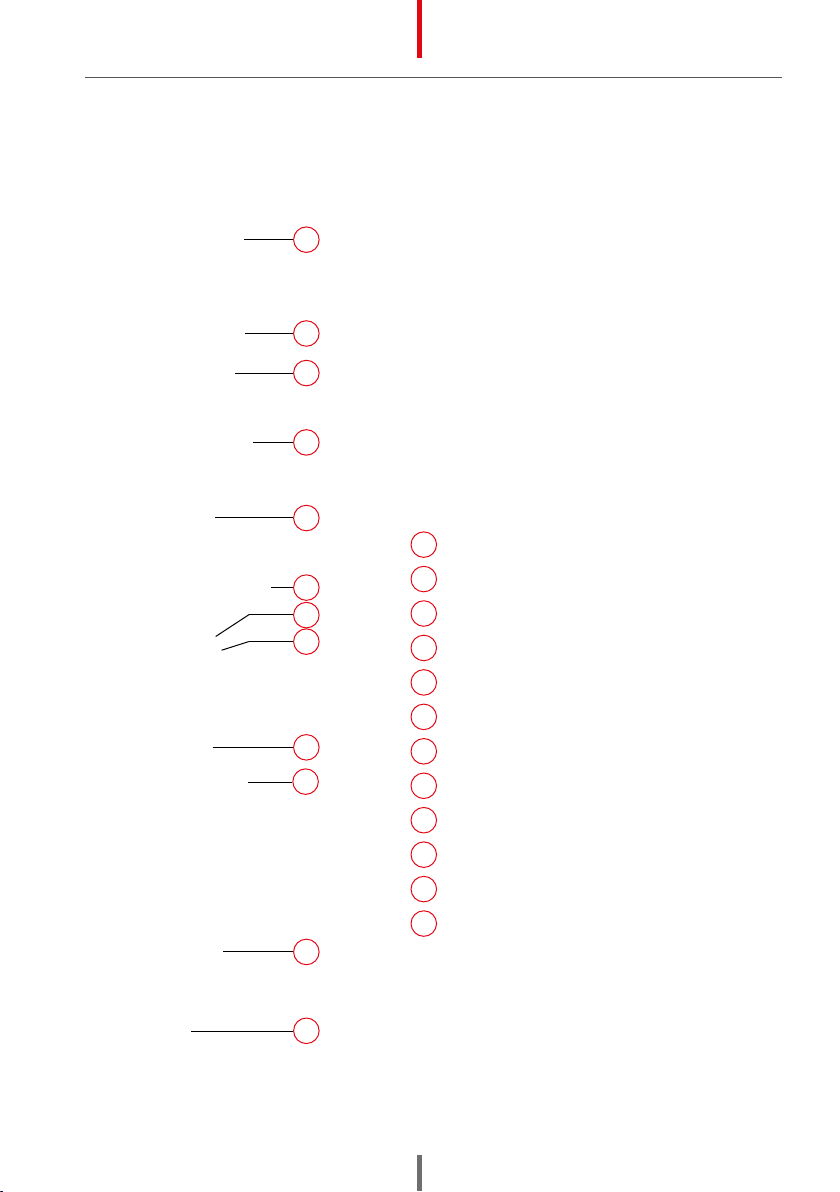

5. DEVICE CONSTRUCTION

Tip grinding station

15° / 18° / 22.5° / 30°

End face grinding station

1.0 / 1.6 / 2.0 / 2.4 / 3.2 / 4.0

Cutting station

1.0 / 1.6 / 2.0 / 2.4 / 3.2 / 4.0

USER’S MANUAL

EN

5

1

2

4

3

5

6

7

8

9

10

11

12

1SP147-99-201 Motor +housing

2SP147-99-209 Speed governor

3SP147-99-211 Switch

4SP147-99-212 Power cord

5SP147-99-208 Bearing

6SP147-99-207 Lining

7SP147-99-206 Front bearing bracket

8SP147-99-205 Cross-linked coupling

9SP147-99-204 Bearing coat

10 SP147-99-210 Grinding wheel

11 SP147-99-203 Angle plate

12 SP147-99-202 Dust cover

Hand grinder SPARTUS® D33

CODE: SP147-00-200

USER’S MANUAL EN

6

6. INSTALLATION AND USE

Situations and threats that may cause direct danger during use of the device.

Precautions to be taken by the operator in order to avoid hazards!

Health-impaired materials that electrodes are made of!

Tungsten electrodes can contain harmful materials. Follow the manufacturer’s instructions and

recommendations! In case of doubt concerning the composition of tungsten electrodes contact

the manufacturer / supplier of electrodes.

Activation with an electrode applied to the grinding wheel!

Launching and commissioning of the device with an electrode applied to the grinding wheel may

cause twist of the electrode and damage the grinding wheel, the equipment and personal injury!

During the launching, the electrode must not adhere to the surface of the grinding wheel. Check

the electrode position before switching on.

Open supply channel!

During the grinding procedure splinters and dust which can fall into the eye or be released into

the air can get through a supply channel.

Prior to switching on the device, place the electrode holder in the supply channel. Keep in mind

that the end of the grounded electrode should not touch the grinding wheel.

After turning off, wait until the grinding wheel has completely stopped before pulling out the

electrode holder from supply channel.

Too much clamping force between electrode and grinding wheel!

Using too much clamping force on grinding wheel can cause overheating and an annealing of

electrode. Annealed electrode may be unusable or damage the device.

Do not use too much clamping force between electrode and grinding wheel!

Rotate the electrode evenly over the grinding wheel during sharpening!

Before each use make sure that all components are properly installed and technically functional.

It is forbidden to use the device if it is technically inoperable!

The unit is powered from single-phase network 230V. RISK OF ELECTRIC SHOCK. Connect to

asingle-phase network with the parameters indicated in the technical documentation. Check

the status of plug and power supply lines. Replace the damaged power supply line or plug with

anew one!

USER’S MANUAL

EN

7

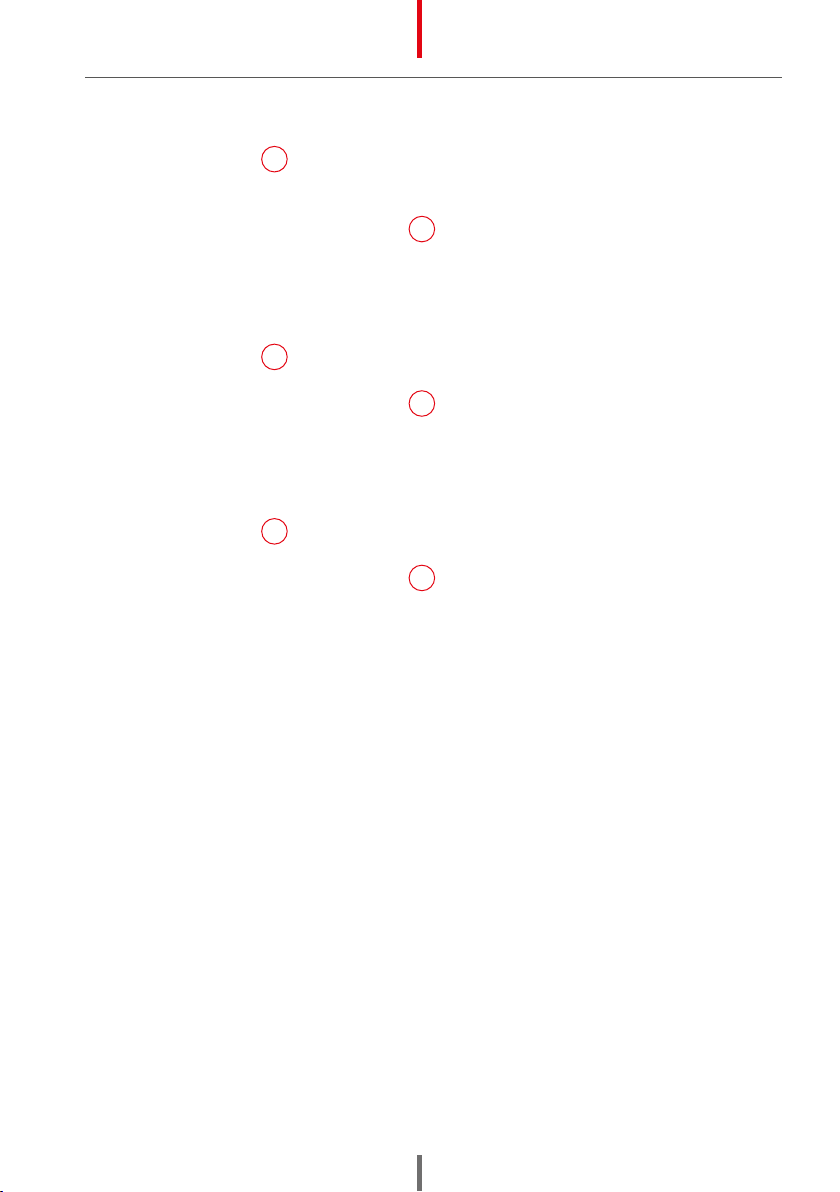

6.1 HOW TO USE SPARTUS® D33 HAND GRINDER

6.1.1 Tungsten electrode tip grinding method:

1. Check if the switch 3is in the„OFF”position.

2. Set the angle of electrode sharpening.

3. Put the electrode inside the tip grinding station.

4. Switch on the grinder using the switch 3.

5. Slowly and evenly rotate the electrode, thus sharpening end of the electrode.

6. Switch of the grinder.

7. Put off the electrode.

6.1.2 Grinding method of the end face of the tungsten electrode:

1. Check if the switch 3is in the„OFF”position.

3. Put the electrode inside the end face grinding station.

4. Switch on the grinder using the switch 3.

5. Observe the degree of grinding, when achieving the effect.

6. Switch of the grinder.

7. Put off the electrode.

6.1.3 Tungsten electrode cutting method:

1. Check if the switch 3is in the„OFF”position.

3. Put the electrode inside the cutting station.

4. Switch on the grinder using the switch 3.

5. Slowly and evenly rotate the electrode, until it is broken.

6. Switch of the grinder.

7. Put off the electrode.

6.1.4 Grinding speed adjustment:

According to grinding tungsten electrode of different diameters, choose the grinding speed to

achieve the best grinding quality.

6.1.5 Replacement method of grinding wheel:

1. Remove the protective cover by loosening the screw.

2. Unscrew the screws on the angle plate and remove it.

3. Remove the locking screw of the grinding wheel on the bearing coat. When removing it,

Hold a metal rod needs to be inserted into the hole on the circumference of the bearing

coat. Remove the old grinding disc and replace it to the new one.

4. The grinding wheel can be used on both sides.

USER’S MANUAL EN

8

7. TROUBLESHOOTING

The end of the tungsten electrode

after the grinding is overheated.

Too much clamping force between electrode

and grinding wheel.

Uneven grinding of the electrode. Incorrect tungsten electrode grinding technique.

The grinding wheel is worn out.

End of the electrode is not sharp enough

– the electrode is not sharpened. Too low grinding depth.

03.2023

Simple solutions and an attractive price – these are

the features of SPARTUS® Easy series devices. Our

equipment has been designed with ease of use and

ergonomics at work in mind.

A masterly combination of high quality production,

excellent parameters and ergonomics – these are fea-

tures of the SPARTUS® Master series of devices, which

were created with demanding welding jobs in mind.

Precision, functionality, excellent parameters and

resistance to high workloads – these are the features

of the SPARTUS® Pro industrial series of devices. This

series consists of specialised solutions which will

satisfy even the most demanding users.

Videopresentation of products

Subscribe to the channel SPARTUS.INFO

Table of contents