SPC Belgravia Classic Instruction manual

Belgravia Classic

Installation, Operation & Maintenance Manual

IOM 69 Issue 4

2IOM 69 Issue 4 – Belgravia Classic Fan Convectors

Contents Page

1|General 3

1.1 |Description 3

1.2 |Receipt and Preparation 3

2|Installation 4

2.1 |Removal of Access Panel 4

2.2 |Transit Protection 4

2.3 |Removing Motor Plate 5

2.4 |Change of Handing 6

2.5 |Mounting 6

2.5.1 |Wall Mounting 6

2.5.2 |Ceiling Mounting 7

2.5.3 |Tall Units 8

2.6 |Wiring 9

2.7 |Electric Motor Protection 9

2.8 |Pipe connections 9

3|Electrical Data 10

3.1 |Control Wiring 10

3.2 |Motor Wiring 10

3.3 |Common Control Options 11

3.4 |Thermostatic Operation 11

3.5 |Switch Operation 11

4|Maintenance 12

4.1 |General 12

4.2 |Filter 12

4.3 |Coil 12

4.4 |Fan Set 12

4.5 |Fusing 12

4.6 |Spares 12

5|Fault Finding 13

5.1 |No Fan Operation 13

5.2 |No Heating 13

6|Waste Electrical and Electronic Equipment (WEEE) Directive 13

6.1 |WEEE Marking 13

6.2 |Information for Customers 13

3IOM 69 Issue 4 – Belgravia Classic Fan Convectors

1. General

1.1 Description

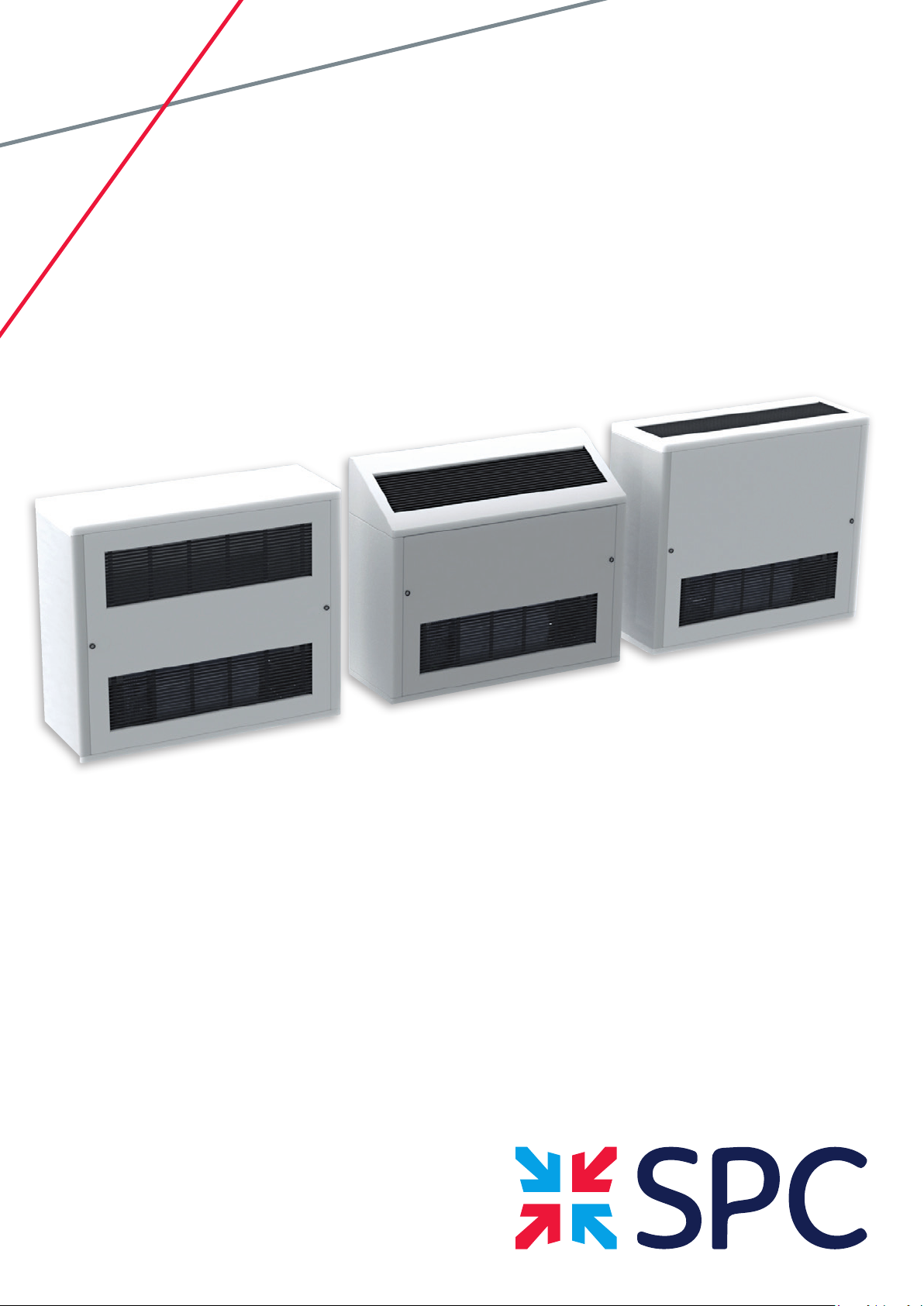

This manual covers the ‘Classic’ and ‘Natural’

models of the Belgravia Fan Convector range.

‘Classic’ units are the cabinet type intended for

either vertical or horizontal mounting. ‘Natural’

models are free convection units for vertical

mounting. Controls can be contained within the

casing to give a clean outline.

The units can be supplied with internal grilles

for visible surface mounting types or with

plenum and/or spigot connections for concealed

mounting in ceiling or wall space, when short duct

connections may be required to serve the heated

space via optional loose grille assemblies.

The ‘Natural’ unit possesses no motor plate as it

relies upon buoyancy driven airow through the

casing. The following sections relating to the motor

plate and its associated controls do not apply to

this type of unit.

1.2 Receipt and Preparation

The units are wrapped and display the SPC

works order number, model reference, site

reference (where appropriate), handing and site

details. Installation, operation and maintenance

instructions, together with wiring and any special

instructions are supplied with the unit.

On receipt, check that all details are correct to the

Customer Schedules prior to opening packaging.

Damage should be reported to the Carrier and to

SPC Oce immediately.

It is recommended that packaging is kept in

place and the units stored in a safe area until the

necessary services are completed, in order to

avoid the possibility of damage on site.

This document and wiring diagram supplied

should be kept with the unit until electrical

installation is complete.

4IOM 69 Issue 4 – Belgravia Classic Fan Convectors

2. Installation

2.1 Removal of Access Panel

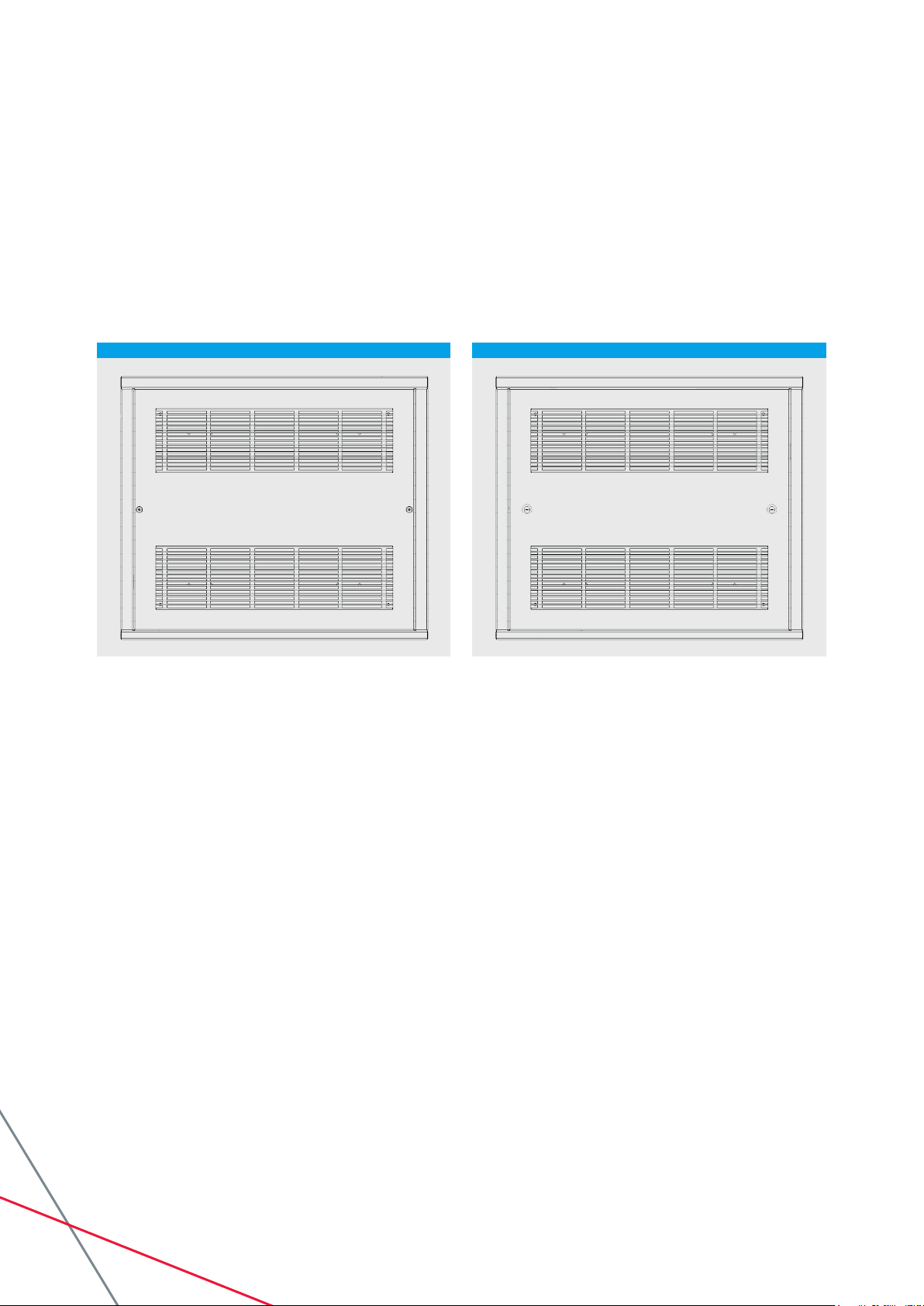

1. Tamperproof xings (TAP) are the default method of xing the access panel to the unit. This type of

xing requires unscrewing using an Allen key (provided). If security xings are used then the screw

head will include a pin and a special security Allen key is required for removal.

2. Lock xings may be provided (LAP) and are released using the quarter turn keys supplied.

2.2 Transit Protection

If despatched with a Polystyrene block tted

between side wall & void bracket, this should be

removed before installation.

THIS DRAWING IS THE PROPERTY OF SPC AND IS PROVIDED FOR

INFORMATION ONLY. IT IS NOT TO BE DISCLOSED TO ANY THIRD PARTY

WITHOUT THE WRITTEN PERMISSION OF SPC.

MATERIAL

FINISH

SCALE

TOLERANCE

TITLE

DRAWING No

ISSUE

ISS

ECN

CHANGE

DATE

DRN

CHKD

A3

01

--

ORIGINAL

19/05/2017

PSW

01

SKXXXXXXXX

XXXXXXXXXXXXXXXXXXXXXXXXXXX

XXXXX

NTS

SHEET 1

OF 1

DO NOT SCALE

ALL DIMENSIONS IN

MILLIMETRES UNLESS

OTHERWISE STATED

Main Tel:

+44 (0) 116 2490044

Main Fax:

+44 (0) 116 2490033

Website:

www.spc-hvac.co.uk

Address:

SPC House, Evington

Valley Road Leicester,

LE5 5LU, UK

EXT SALES

INT SALES

SUPPLIER

ACCOUNTS

PRODUCTION

STORES

ISSUED

TO

THIS DRAWING IS THE PROPERTY OF SPC AND IS PROVIDED FOR

INFORMATION ONLY. IT IS NOT TO BE DISCLOSED TO ANY THIRD PARTY

WITHOUT THE WRITTEN PERMISSION OF SPC.

MATERIAL

FINISH

SCALE

TOLERANCE

TITLE

DRAWING No

ISSUE

ISS

ECN

CHANGE

DATE

DRN

CHKD

A3

01

--

ORIGINAL

19/05/2017

PSW

01

SKXXXXXXXX

XXXXXXXXXXXXXXXXXXXXXXXXXXX

XXXXX

NTS

SHEET 1

OF 1

DO NOT SCALE

ALL DIMENSIONS IN

MILLIMETRES UNLESS

OTHERWISE STATED

Main Tel:

+44 (0) 116 2490044

Main Fax:

+44 (0) 116 2490033

Website:

www.spc-hvac.co.uk

Address:

SPC House, Evington

Valley Road Leicester,

LE5 5LU, UK

EXT SALES

INT SALES

SUPPLIER ACCOUNTS

PRODUCTION

STORES

ISSUED

TO

Position of TAP xings Position of LAP xings

5IOM 69 Issue 4 – Belgravia Classic Fan Convectors

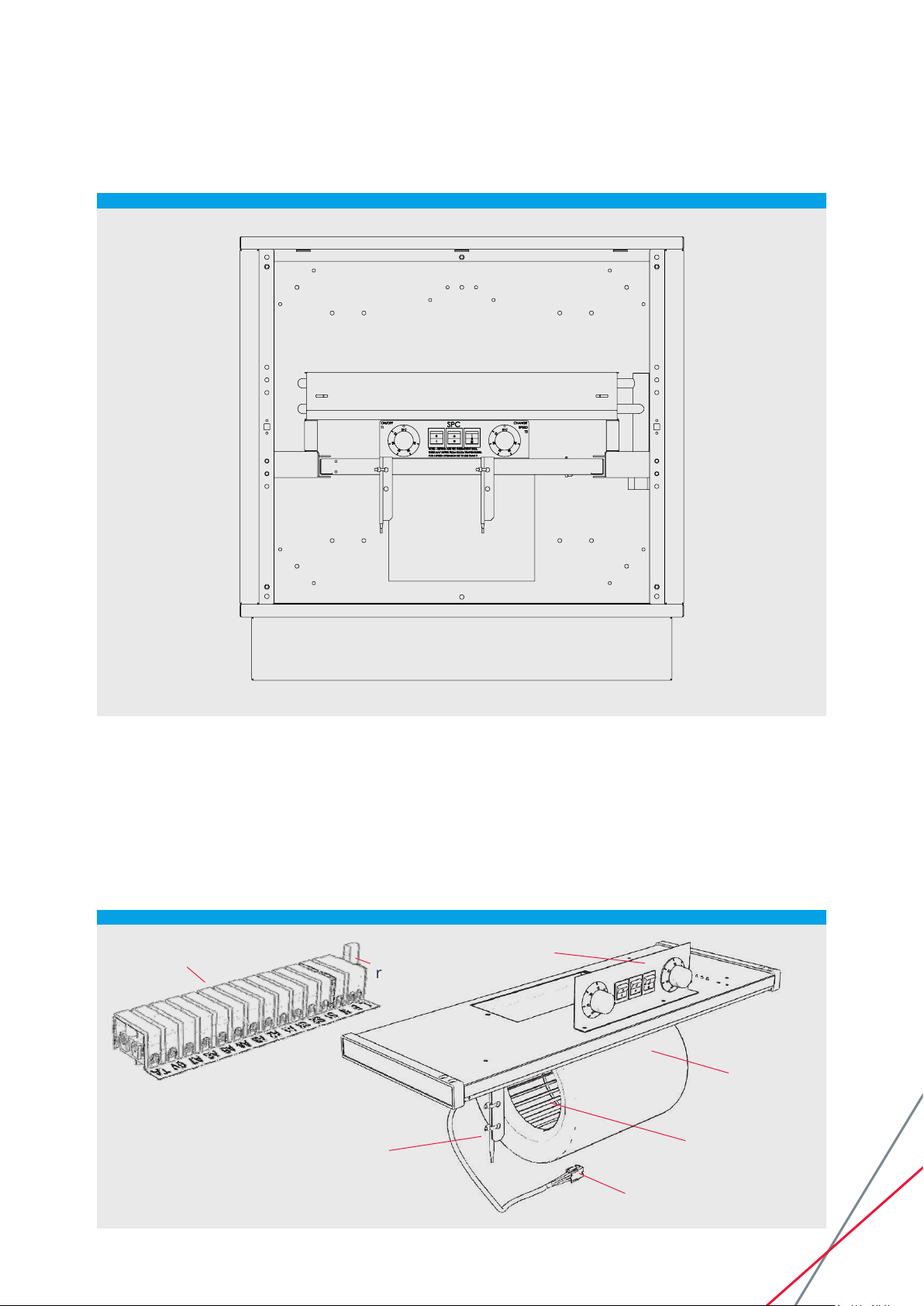

2.3 Removing Motor Plate

IMPORTANT: isolate unit electrically at mains controls.

• Remove front access panel.

• Disconnect plug/socket connections from motor

plate.

• Slide out motor plate, taking care not to damage

fan impellers in any way during this procedure, or

in the replacement.

• On ceiling mounted applications, the motor plate

is retained by bolts through the motor plate &

mounting bracket.

• Ensure motor plate is adequately supported

before releasing the bolts.

Optional

controls

Lift to

remove fuse

EC Motor

Fan Impeller

Split connector for

mainsying lead

Thermostat phial

SPC unit

wiring

PAGE 5 - IMAGE 1

6IOM 69 Issue 4 – Belgravia Classic Fan Convectors

2.4 Change of Handing

Units will have been supplied with pipework

connections on RHS unless specied otherwise. It

is possible to change the handing of the coil heat

exchanger on site by simply reversing its position

inside the unit.

After removing the front panel the coil is easily

removed by releasing two screws holding it in

position on its two support brackets.

The ow and return pipes pass through holes in

the fan plate brackets and if reversing the coil then

the knock-outs in the non-connection side will

need to be removed. The holes now in the side

from which the connections have moved should

be taped over.

After reversing the coil the screws should be

reattached to the brackets to hold it securely in

place.

2.5 Mounting

2.5.1 Wall Mounting

Vertical units can be low level oor mounted or

high level wall mounted.

Low level units are often supplied with a plinth to

hide pipework and lift the unit from the oor. If

they are supplied with a loose plinth then the fan

convector base screws into the plinth via 6-o M5

threaded inserts.

A series of reinforced 6mm dia holes are tted in

the backplate of the unit as shown in the diagrams

below. The wall should be marked out and drilled

with suitable anchors prior to securing through the

backplate.

THIS DRAWING IS THE PROPERTY OF SPC AND IS PROVIDED FOR

INFORMATION ONLY. IT IS NOT TO BE DISCLOSED TO ANY THIRD PARTY

WITHOUT THE WRITTEN PERMISSION OF SPC.

MATERIAL

FINISH

SCALE

TOLERANCE

TITLE

DRAWING No

ISSUE

ISS

ECN

CHANGE

DATE

DRN

CHKD

A3

01

--

ORIGINAL

19/05/2017

PSW

01

SKXXXXXXXX

XXXXXXXXXXXXXXXXXXXXXXXXXXX

XXXXX

NTS

SHEET 1

OF 1

DO NOT SCALE

ALL DIMENSIONS IN

MILLIMETRES UNLESS

OTHERWISE STATED

Main Tel:

+44 (0) 116 2490044

Main Fax:

+44 (0) 116 2490033

Website:

www.spc-hvac.co.uk

Address:

SPC House, Evington

Valley Road Leicester,

LE5 5LU, UK

EXT SALES

INT SALES

SUPPLIER ACCOUNTS

PRODUCTION

STORES

ISSUED

TO

7IOM 69 Issue 4 – Belgravia Classic Fan Convectors

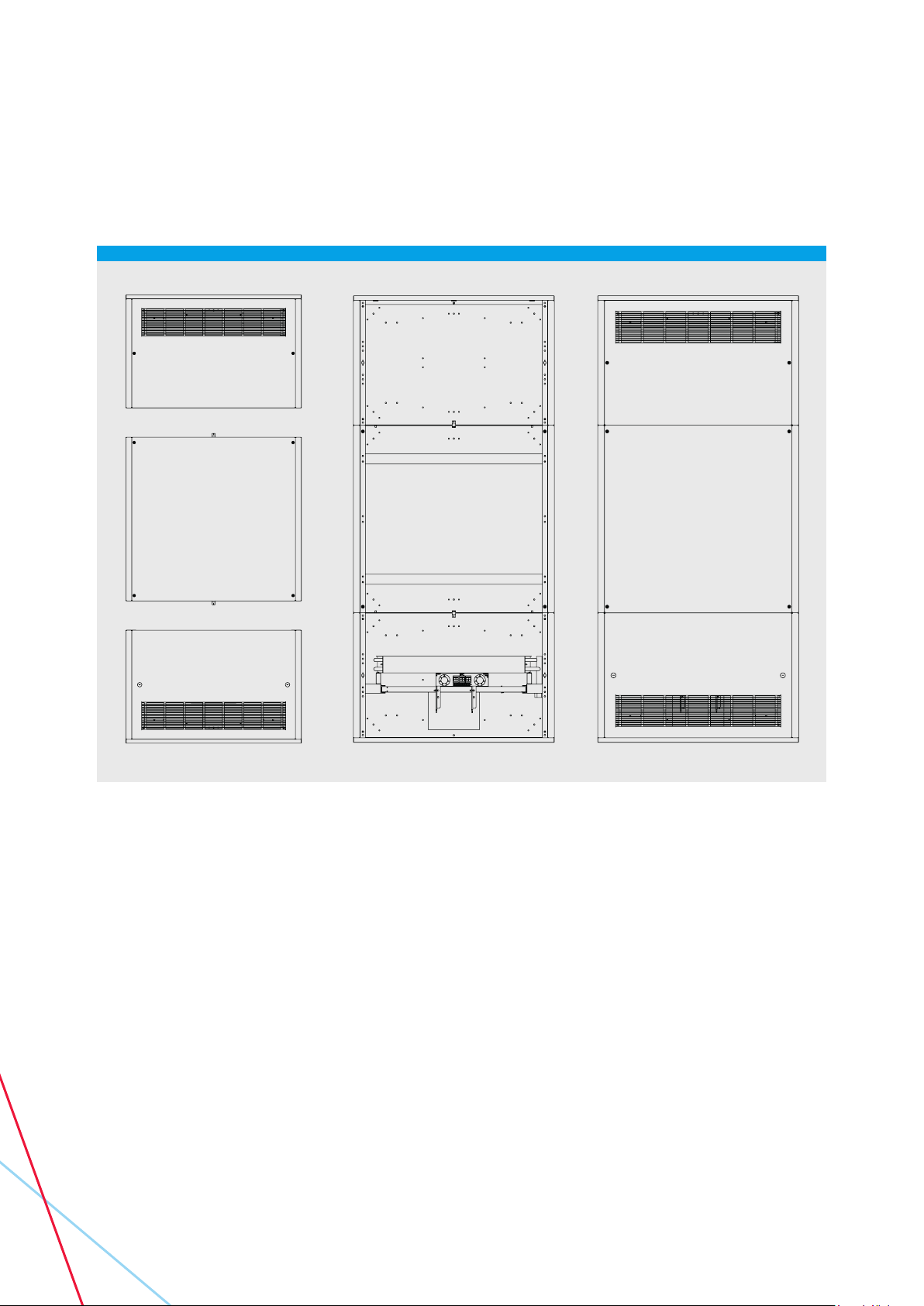

2.5.2 Ceiling mounting

Horizontal units may be bolted directly to the

ceiling/sot via the reinforced 6mm dia holes in

the top plate of the unit. These hole positions are

shown on the sketches below.

Unit Size DIM ‘A’

40 700

60 900

90 1200

150 1500

Unit Size DIM ‘A’

40 700

60 900

90 1200

150 1500

Unit Size DIM ‘A’

40 700

60 900

90 1200

150 1500

Standard unit mounting positions

Double sloping unit mounting positions

Single sloping unit mounting positions

DIM 'A'

600

90

80

6mm HOLES x 6

C

L

C

L

DIM 'A

725

90

80 440

6mm HOLES x 6

C

L

850

DIM 'A'

205

90

6mm HOLES x 6

C

L

C

L

PAGE 7

KEEP THE TABLES

DIM 'A'

600

90

80

6mm HOLES x 6

C

L

C

L

DIM 'A

725

90

80 440

6mm HOLES x 6

C

L

850

DIM 'A'

205

90

6mm HOLES x 6

C

L

C

L

PAGE 7

KEEP THE TABLES

DIM 'A'

600

90

80

6mm HOLES x 6

C

L

C

L

DIM 'A

725

90

80 440

6mm HOLES x 6

C

L

850

DIM 'A'

205

90

6mm HOLES x 6

C

L

C

L

PAGE 7

KEEP THE TABLES

8IOM 69 Issue 4 – Belgravia Classic Fan Convectors

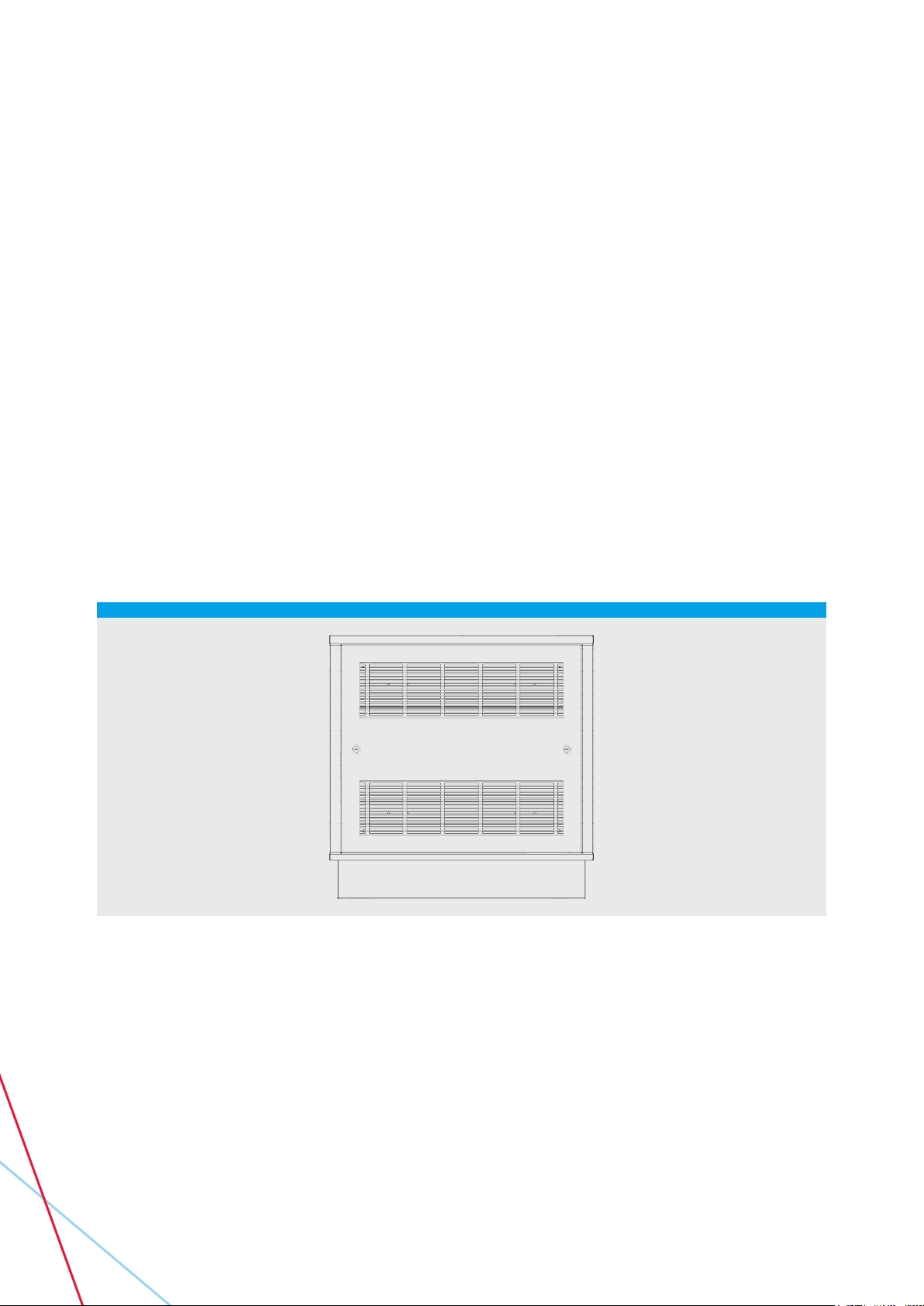

2.5.3 Tall units

Tallboy type units for vertical mounting are

supplied in three sections to assist with transport

and movement on site. All three sections should

be screwed together using the screws/nuts/

washers supplied. The assembly should be

undertaken either in the nished position or as

close to it as is practical.

PAGE 8

9IOM 69 Issue 4 – Belgravia Classic Fan Convectors

2.6 Wiring

All electrical work should be carried out in

accordance with current I.E.E. regulations.

See the wiring diagram supplied with the unit for

connection details.

All motors are tted with internal self-resetting

thermal overload protection (see note below) and

are equipped with a motor plate mounted

Anti-surge fuse (see spares list). All units are

supplied with a 2 metre length of 3 core cable as a

ying lead. This is normally coiled within the unit.

The customer should drill and gland to suit the

installation. The supply should be wired through

a suitable means of isolation such as a fused spur

box or similar. Recommended fuse is not more

than 3A (for standalone unit).

2.7 Electric Motor Protection

On ceiling mounted and reverse airow

applications where the fan motor is switched o

for long periods, with hot water still circulating

through the heat exchanger in excess of 82ºC

(180ºF), it is recommended that a system be

employed which automatically closes the hot water

supply valve to prevent damage to the electric

motor due to overheating.

2.8 Pipe connections

Standard units are supplied with ow and return

pipe connections sized at ¾” BSPP female. For

the standard 2 row coil heat exchanger the ow

and return pipes are interchangeable. If the fan

convector is equipped with a 3 row coil which

has ½” BSPP female connections then this will be

an enhanced output coil for use against low hot

water temperatures or owrates. For this type of

coil the connection coming from the leaving air

face should be made the ow and the connection

closest to the fan outlet, on the entering air face,

should be made the return connection. This

ensures that the optimum heat transfer capacity

can be achieved from the coil.

If a modulating valve is tted as a part of an LST

unit then the nal pipe connections will be in

15mm copper and the ow and return pipes

should comply with any arrows stamped on the

valve body.

10 IOM 69 Issue 4 – Belgravia Classic Fan Convectors

3. Electrical Data

Unit Speed Airow (L/S) EC Power Draw

(W) EC SFP (W/L/S)

Bel 40

L

N

H

89

112

140

11

16

27

0.12

0.14

0.19

Bel 60

L

N

H

108

184

223

15

53

84

0.14

0.29

0.38

Bel 90

L

N

H

120

231

317

18

34

73

0.15

0.15

0.23

Bel 150

L

N

H

180

289

329

22

58

80

0.12

0.20

0.24

3.1 Control Wiring

The wiring for internal control options is sited on

the motor plate. Wiring from the motor plate to

casing control options is via split connector break

plugs. Customer wiring should be made to the

Customer Connection Box for other than the

ying lead. Wiring to other than this point may

result in voiding of the warranty.

A wiring diagram showing customer connections

is included with each unit.

For wiring other than that specied on the

Customer’s order, the SPC Technical Department

should be contacted.

3.2 Motor Wiring

The motors are Electronically Controlled. They

have a 230v AC supply but are controlled via a

10v DC signal. A circuit board on the motor plate

has three potentiometers tted which give the

low/normal/high speed.

If only one speeds is specied this will be normal

unless otherwise stated.

11IOM 69 Issue 4 – Belgravia Classic Fan Convectors

3.3 Common Control Options

Reference** Function

Thermostat T-1 On - o

T-2 Change speed

LTC Low water temperature fan cutout

ALTC Adjustable low water temperature fan cutout (remote)

Switches RS-1 On - o

RS-2 Summer - winter

RS-3 Change speed (3 speeds)

**Additional References: Motor plate mounted = B, Case mounted = C, Remote = R

3.4 Thermostatic Operation

The T1 and T2 Thermostats both have graduated

scales to cover their range of operation. Since

the thermostatic bulb is frequently unit mounted

it may be oset by various amounts from the

measured room temperature.

Set the knob at mid-range and adjust to suit

comfort conditions within the room.

The range corresponds to a sensed temperature

range of 10°C to 30°C.

T1 and T2 are adjustable and determine the

comfort room temperature range. Set T2 for the

low and T1 for the high point. Example: T2 16°C

and T1 20°C.

The LTC is not adjustable (45°C) and provides

a fan cut-o for the situation when the water

temperature is not suciently high to provide

warm blown air from the fan convector. The LTC

is mounted at the non-void end of the unit, and

is screwed to a copper disc which is brazed onto

a return bend of the coil.

3.5 Switch Operation

The RS1 switches do not in themselves isolate

the unit.

The RS2 Summer-Winter switch provides an

override for the LTC and T1 (where tted),

enabling the fan to operate in the summer, for air

re-circulation.

The RS3 Change Speed Switch delivers one of

three voltage tappings to the motor. Where used

in a remote application care should be taken

when wiring into the customer connection box to

ensure correct sequencing

12 IOM 69 Issue 4 – Belgravia Classic Fan Convectors

4. Maintenance

4.1 General

WARNING! Electrically isolate the unit prior to work commencing

4.2 Filter

The AF3 air lter is motor plate mounted as

standard. The lter is held in place between 2

brackets and is removed by sliding it out. The

AF1 lter, where specied, is tted underneath

the heat exchanger and can be slid in and out

of two short side rails. The AF2 inlet air lter can

be specied as either internal or external and is

tted on the air inlet grille.

Filters should be gently tapped to remove most

of the accumulated dust and either vacuumed

clean or washed in lukewarm water with

detergent. Rinse in clean water and allow to dry

naturally before replacement.

If an inlet plenum is tted, the lter is removed

by dismounting the access panel to gain access.

4.3 Coil

Remove access panel and clean the coil with

a brush or by vacuuming, taking care not to

damage the coil surfaces.

4.4 Fan Set

The motor has sealed for life sleeve bearings,

which under normal circumstances require no

user maintenance. The motor deck is accessed

by means of the access panel and is readily

removed if required. Occasional vacuuming or

cleaning of the motor plate is recommended.

4.5 Fusing

Fan motor- Anti-surge 20mm x 5mm 2A to

BS4265/IEC127

(see wiring diagram).

4.6 Spares

• Fuses - as above

• Filters - quote model number (BEL 40/60 etc.)

or unit width. Units manufactured pre 1995 will

require dierent lters to later units

• Controls - as specication

• Motor - quote model number on motor plate

Quote motor plate mounted (AF3) or

coil mounted (AF1) or grille mounted

(AF2).

Quote wiring diagram number or

marked number if possible.

13IOM 69 Issue 4 – Belgravia Classic Fan Convectors

5. Fault Finding

5.1 No Fan Operation

Check fuse on motor plate.

Check power supply to unit.

Check loose wiring and breaker plugs or

damage to wiring.

Check switches

Check impellers run freely.

5.2 No Heating

Check thermostat operation (change set point

to maximum) where tted.

Check integrity of wiring.

Check coil vented.

Check hot water to unit.

Check thermostat bulb in airstream.

Check LTC contact on pipe-work or return bend.

6. WEEE Directive

(Waste Electrical and Electronic Equipment)

6.1 WEEE Marking

All products that are subject to the WEEE

Directive supplied by SPC from 2007 are

compliant with the WEEE marking requirements.

Such products are marked with the “crossed out

wheelie bin” WEEE symbol shown here.

SPC WEEE Certicate No: WEE/KF0742YR

6.2 Information for Customers

According to the timelines and requirements of

European Union member state WEEE legislation,

the following customer information is provided

for all SPC supplied products subject to the

WEEE directive.

This symbol on the product or on its packaging

indicates that the product must not be disposed

of with normal household waste.

Instead, it is your responsibility to dispose of

your waste equipment by arranging to return

it to a designated collection point for the

recycling of waste electrical and electronic

equipment. By separating and recycling your

waste equipment at the time of disposal you will

help to conserve natural resources and ensure

that the equipment is recycled in a manner that

protects human health and the environment. For

more information about how to recycle your SPC

supplied waste equipment for recycling, please

contact our customer services department

on +44 (0)1162490044 or

customerservice@spc-hvac.co.uk.

SPC House

Evington Valley Road

Leicester

LE5 5LU

T: 0116 249 0044

E: spc@spc-hvac.co.uk

spc-hvac.co.uk

IOM 69 Issue 4 – Belgravia Classic Fan Convectors

Table of contents

Popular Heater manuals by other brands

Comfort Glow

Comfort Glow CEH625 owner's manual

Gabarron

Gabarron Elnur ECOMBI HHR Series installation instructions

KING

KING PCKF Series Important instructions

Twin-Star International

Twin-Star International Duraflame 9HM9273 manual

THERMOCOAX

THERMOCOAX isopad IGB-G Series operating instructions

MILL

MILL CO1200WIFI3 Assembly and instruction manual