1. Identify a suitable location (see ‘Where to

Install’ p3).

2. Ensure enough clearance to carry out

cleaning as the rods must be lifted out of the

unit to clean. See dimensions in column B in

the table below.

3. Mark and then cut out the correct length of

pipe section to be removed to accommodate

the BoilermagXT unit and isolation valves.

Ensure the cut is level and burr free.

(Isolation valves are not included in the

BoilermagXT pack.)

4. Install appropriate isolation valves to the

pipework and fit the valves to the two PN16

flanges (see below for flange dimensions).

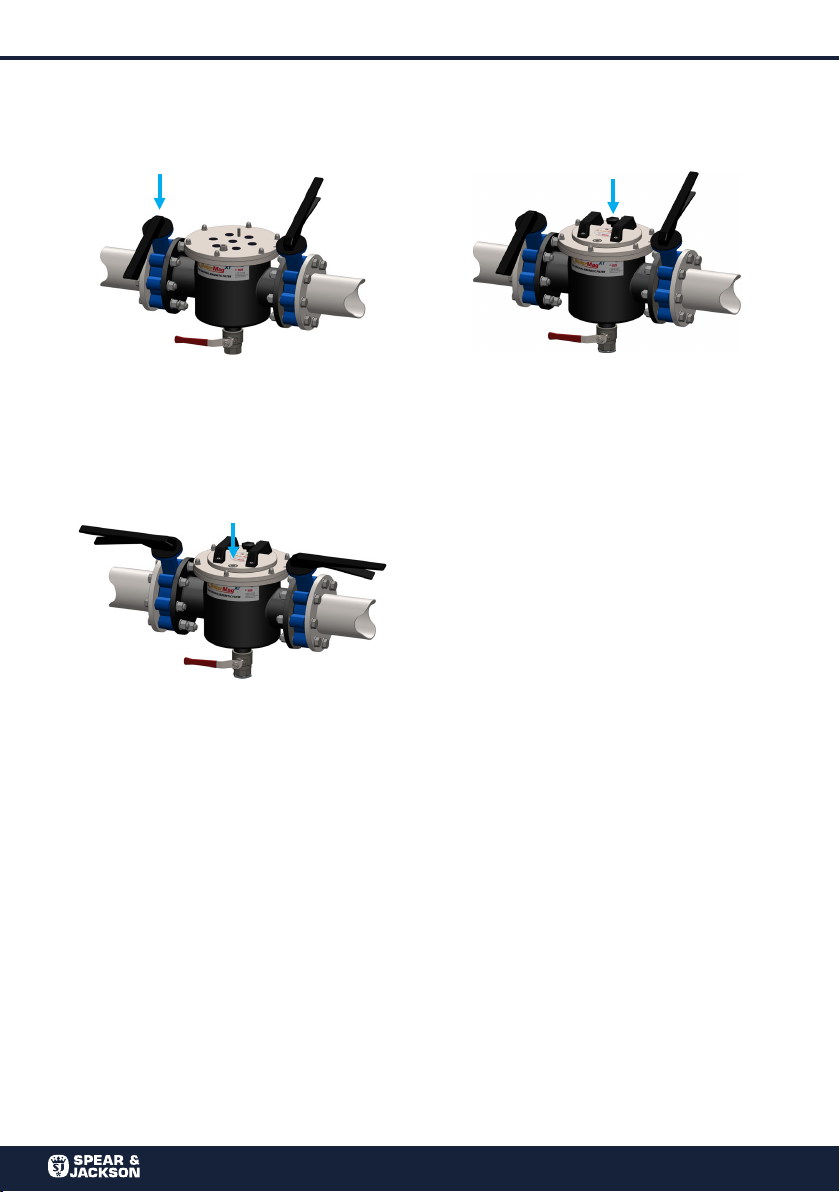

5. Position the BoilermagXT in place then align

and secure the fittings to connect the unit

to the valves.

6. Open the isolation valves and turn on the

heating system

7. Complete the BoilermagXT warranty card and

return to Spear & Jackson.

8. Run the heating system at normal operating

temperature and check installation integrity.

Flange details

Part No. Inlet / outlet ∅ABFlange spacing C

BMXT150/2/AAV 2" 305 260

BMXT200/3/AAV 3" 390 360

BMXT200/4/AAV 4" 390 360

BMXT300/6/AAV 6" 360 470

BMXT300/8/AAV 8" 400 525

BMXT400/10/AAV 10" 770 760

BMXT400/12/AAV 12" 820 760

B

A

C

2" PN16 4" PN16 6" PN163" PN16

10" PN16

Ø165

Ø125

Ø18

Ø220

Ø180

Ø18

Ø285

Ø240

Ø22

Ø340

Ø22

Ø295

Ø405

Ø355

Ø26

Ø200

Ø160

Ø18

Ø460

Ø410

Ø26

all dimensions in mm unless stated

Installing BoilermagXT

Installation details

www.boilermag.com