SPECS Globe Manual

Instruction and Operation Manual

Instruction and Operation Manual

Globe Valves

Doc.No.: SPECS-IOM-GV

Date: 08/2020

CONTENTS

1.

General

2.

Essential health & safety requirements of PED/Atex and solution

3.

Application scope and Technical Parameters

4.

Valve Structure

5.

Main Parts and Material

6.

Working Principle and Structure Description

7.

Valve Transportation

8.

Valve Storage

9.

Valve Installation

10.

Valve Operation and Maintenance

11.

Potential Failure and Troubleshooting

12.

Quality Warrant

13.

Servicing

Instruction and Operation Manual

- 1 -

1.

General

Thanks for your selection of SPECS's globe valve. As a type of pressure equipment, valve has

potential hazards of pressure and creation of explosive atmosphere resulting from leakage of

process fluid. For the safety purpose, user shall read this instruction to know what SPECS has

already taken into account in our design and manufacture, and what action shall be taken by user

according to essential health and safety requirements of European Directive 97/23/EC(PED) and

94/9/EC (Atex).

2.

Essential health & safety requirements of PED/Atex and solution

2.1 What

’

s

SPECS

design

idea

-Globe valve is designed as standard product, no consideration of each specific service

condition since its too wide.

-Globe valve is designed to BS1873, valve has adequate strength according to ASME B16.34

pressure-temperature rating. The globe valve was EC-type approved by

European Notified Body.

-Valve has different sealing materials in accordance with BS1873, which are

corrosion/wear resistance to certain type of fluid.

-Valve contains no light metal (such as Mg) and all parts are electricity conductive and

connected together to prevent ignite resource.

-Valve is designed with hand wheel, or gear operatoror electric actuator according to its size and

torque, and operation requirements.

2.2

What action user shall taken

2.2.1

General

2.2.1.1

In any occurrence, first ensure personnel safety.

2.2.1.2

Use the valves in accordance with ASME B16.34 pressure-temperature rating.

2.2.1.3

Make sure that the selected valve materials are corrosion/wear resistance to the service

fluid.

2.2.1.4

Where the service fluid is flammable/explosive, to limit the working temperature.

2.2.1.5

When performing Repair/maintenance operations, make sure that the valves are always

depressurized, vented and drained.

2.2.1.6

For actuator operated valves, make sure all supply lines (Electrical, hydraulic, Air) are

disconnected before starting any operation.

2.2.1.7

When performing Repair/maintenance operations, always use appropriate protection

e.g. protective clothing, (oxygen) masks, gloves, etc.

2.2.1.8

When performing Repair/maintenance operations, do not smoke, do not use any

Instruction and Operation Manual

-

2

-

portable no-Ex-proof electrical device in the area and do not use open fire without a valid work

permit.

2.2.1.9

Valve must periodically checked on:

-Tightness of bolted connection (body/bonnet, gland, flange connection).

-Corrosion/wear damages (crack, pitting, thickness of the valve).

-Make sure the valves are in fully open/fully closed position.

2.2.2

Specifics

Risk Preventive Action

Accidental contact with dangerous

service fluid*

Due to: Gasket or Packing Blow out

1. See 2.2.1 General

2. Immediately replace Gasket and packing

after a Blow-out (use approved/suitable

materials only

3. Use recommended torque as in Table 5 and

Table 6

Accidental contact with dangerous

service fluid* during disassembly or

maintenance operations

1. See 2.2.1 General

2. After removal from the production line, open

and close valve to guarantee depressurized

cavity.

3. Drain any remainder fluid or substances with

suitable devices before disassembly.

Structural yielding of valves body

with consequent risk of contact with

dangerous service medium*,

explosion or fire

1. See 2.2.1 General

2. Create precautions to avoid additional forces

on the valves

3. Avoid absolutely water hammer: install

precaution devices if necessary (e.g. brakes,

anti shock devices, etc.)

4. Avoid submitting excessive vibrations to the

valves.

5. Avoid quick Pressure and/or Temperature

deviations.

Accidental contact with High or Low

temperature parts

1. See 2.2.1 General

2. Predispose apposite insulation on the valve.

3. Alert by means of warning signs about risk of

burns.

4. For Cryogenic-/High Temperature service

use only valves equipped with Cryogenic-/High

Temp. Extension.

Fire or explosion in case of service

with flammable fluids 1. See 2.2.1 General

2. Install only Ex-proof electrical devices in the

area

3. While performing maintenance in the area,

shut down all electrical devices.

Explosion in case of oxygen service 1. See 2.2.1 General

2. Install only Ex-proof electrical devices in the

area

Instruction and Operation Manual

- 3 -

3. Install and use only valves completely

degreased.

4. Use valves only made with materials suitable

for oxygen service (see EN 1797-1)

Dangerous service fluid as there are: Toxic-, Corrosive-, Flammable-, High- or Low temperature etc. fluid

3.

Application Scope and Technical Parameters

3.1

Scope

The series valves are widely used in petroleum, chemical, power plant and allied industries for

normal operation of pipeline system by cut off or connect the pipeline.

3.2

Technical Parameters:

Design standard: BS1873, ASME B16.34

Flange dimension: ASME B16.5

Structure length: ASME B16.10

Nominal pipeline size: 50~300 mm (2~18")

Nominal pressure: 20~250 bars (150~1500LB)

Temperature range: see Table 3

Medium: see Table 3

Body material: ASTM material, see Table 1

Trim material: API 600 trim material, see Table 2

Valve testing: API598

Applicable ATEX:

Ⅱ

2

GD c

4.

Valve Structure

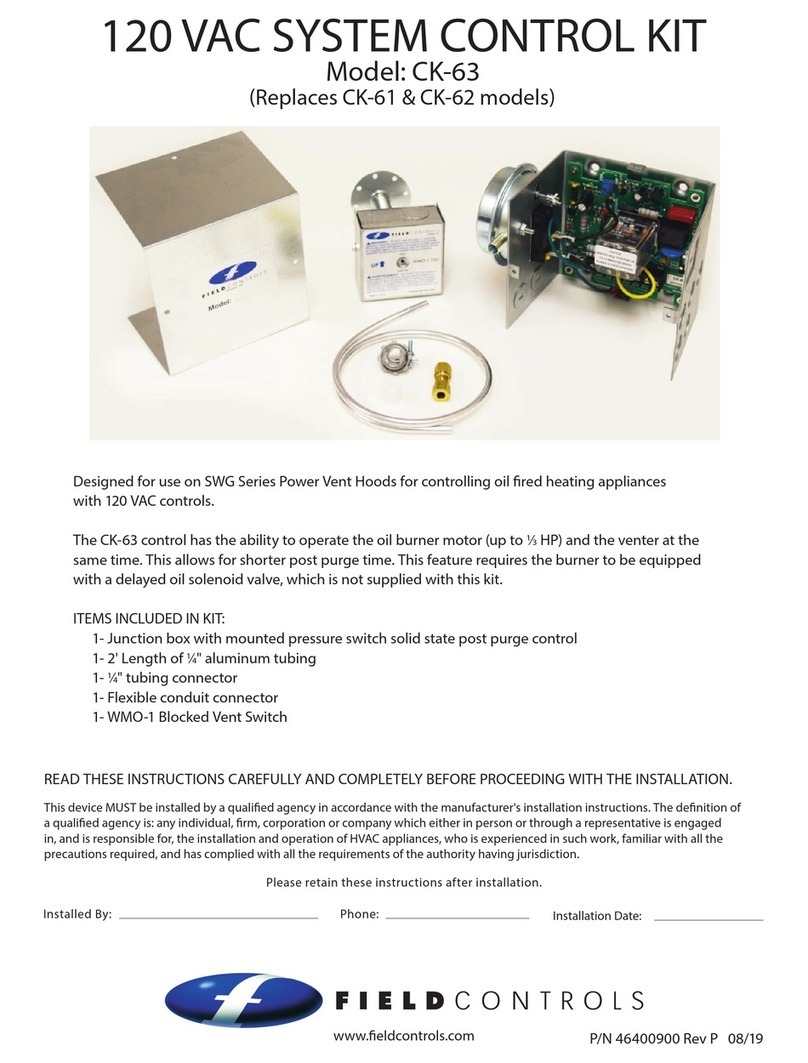

Please refer to Figure 1 and 2 for valve structure.

Instruction and Operation Manual

- 4 -

Fig.1 150LB/300LB

Fig.2 600LB/900LB/1500LB/2500LB GLOBE VALVE STRUTURE

-

Globe valve dimensions and weight refer to SPECS.

GLOBE VALVE STRUTURE

Instruction and Operation Manual

- 5 -

5.

Main Parts and Material

The user or the pipeline system designer mustselect valve body material and the class according

to the working temperature, working pressure, the type of fluid and standard temperature-

pressure rating as specified in ASME B16.34. The manufacturer takes only incoherence of user

selected material and valve class with the working condition.

Instruction and Operation Manual

Table 1 Valve main parts and material

ITEM PART NAME CARBON STEEL ALLOY STEEL STAINLESS STEEL

1

Body A216 WCB A352 LCB A352 LCC A217 WC6 A217 C5 A351 CF8 A351

CF8M A351 CF3 A351 CF3M A351

CF8C

2

Seat Ring A105 A350 LF2 A350 LF2 A182 F11 A182 F5 A182 F304 A182

F316 A182

F304L A182

F316L A182

F321

3

Disc A216WCB A352 LCB A352 LCC A217 WC6 A217 C5 A351 CF8 A351

CF8M A351 CF3 A351 CF3M A351

CF8C

4

Disc Thrust Plate A276 420 A276 304 A276 304 A276 420 A276 304 A276 316 A276 304L A276 316L A276 321

5

Disc Nut A276 410 A276 304 A276 304 A276 410 A276 304 A276 316 A276 304L A276 316L A276 321

6

Stem A182 F6 A182 F304 A182 F304 A182 F6 A182 F5 A182 F304 A182

F316 A182

F304L A182

F316L A182

F321

7

Bonnet Bolt Nuts A194 2H A194 4 A194 4 A194 4 A194 4 A194 8

8

Bonnet Bolts A193 B7 A320 L7 A320 L7 A193 B16 A193 B16 A193 B8

9

Gasket CL150-300 304+Graphite 304+Graphite 304+Graphite 304+Graphite 316+Graphite

CL600-2500

Ring Joint 304 304 304 304 316

10 Backseat Bushing A276 410 A276 304 A276 304 A276 410 A276 304 A276 316 A276 304L A276 316L A276 321

11 Stem Packing Braided Graphite &

Die formed Graphite Ring Braided Graphite &

Die formed Graphite Ring Braided Graphite &

Die formed Graphite Ring

12 Bonnet A216 WCB A352 LCB A352 LCC A217WC6 A217 C5 A351CF8 A351

CF8M A351 CF3 A351 CF3M A351

CF8C

13 Eye Bolt Pins Carbon Steel A276 410 Stainless Steel

14 Gland A276 410 A276 304 A276 304 A276 410 A276 304 A276 316 A276 304L A276 316L A276 321

15 Gland Flange A216 WCB A352 LCB A352 LCC A217 WC6 A217 C5 A351CF8 A351

CF8M A351 CF3 A351 CF3M A351

CF8C

16 Gland Eye Bolts A307 B A320 L7 A320 L7 A193 B16 A193 B16 A193 B8

17 Eye Bolt Nuts A194 2H A194 4 A194 4 A194 4 A194 4 A194 8 A194 8 A194 8 A194 8 A194 8

18 Yoke Bush A439 D-2 A439 D-2 A439 D-2

19 Screw Carbon Steel Carbon Steel Stainless Steel

20 Handwheel Ductile Iron Ductile Iron Ductile Iron

21 Handwheel Nut Carbon Steel Carbon Steel Stainless Steel

22 Washe

r

Carbon Steel Carbon Steel Stainless Steel

- 6 -

Instruction and Operation Manual

- 7 -

Table 2 Common used trim material

API600 Trim

No. Seat ring Disc sealing Stem Back seat

1

ER410 ER410 ASTM A182 F6a ASTM A182 F6a

2

304 304 ASTMA182 F304 ASTMA182F304

5

STL STL ASTM A182 F6a ASTM A182 F6a

8

STL ER410 ASTM A182 F6a ASTM A182 F6a

9

Monel Monel Monel Monel

10 316 316 ASTM A182 F316 ASTMA182F316

12 STL 316 ASTM A182 F316 ASTMA182F316

Table 3 body material suitable for fluid and temperature range

ASTM

A216-

WCB

ASTM

A352-

LCB

ASTM

A352-

LCC

ASTM

A217-

WC6

ASTM

A217-

WC9

ASTM

A351-

CF8

ASTM

A351-

CF8M

ASTM

A351-

CF3

ASTM

A351 -

CF3M

RECOMMEND

TEMPERATU

RE LIMITS

(℃)

-29~427

-46~ 343

-46~

343

-29~

593

-29~

593

-29~

537

-29~

537

-29~

427

-29~

454

APPLICATION

STEAM,

WATER,OI

L

VAPOUR,

GAS and

GENERAL

LOW

TEMPERATURE

SERVICE

STEAM,WATER,OI

L VAPOUR,GAS

HIGH

TEMPERATURE

SERVICE

STEAM,WATER,

OIL

VAPOUR,GAS

HIGH and LOW TEMPERATURE

SERVICE

CORROSION RESISTANCE

Note: where the process fluid is flammable/explosive, it must limit the working temperature of the

pipeline system.

6.

Working Principle and Structure Description

6.1

Working principle

The series is globe valves. When hand-wheel rotate clockwise, the disc descends and the valve

shuts off; when rotate counter clockwise, the disc ascends and the valve opens.

6.2

Structure description

6.2.1

Flange end or but welding end may be selected as to purchaser optimum.

6.2.2

Packing seal structure and flexible graphite combination packing is used for the series

valve.

6.2.3

Class 150LB to 300LB valves use a reinforced flexible graphite gasket and 600to 2500LB

Instruction and Operation Manual

- 8 -

valves use ring joint metal gasket.

6.2.4

Cone sealing is used for the valve and the seal material is selected to API 600 or to the

customer requirements.

6.2.5

F

or

big

v

alve

,

hand-wheel

i

s r

eplaced

b

y

gear opera

t

or

,

plea

s

e

s

ee

SPECS

’

s c

atalogue

..

7.

Valve Transportation

Valves are heavy and metal products, care shall be taken to avoid physical injury during

transportation. Cord and lift device and transportation tool shall be ready, valve package

inspected and broken package repaired. Packaging shall conform to specification

requirements, it is forbidden to rotate the hand-wheel when valve is packaged. Valve shall be in

full-close status. For mis-opened valve, the sealing surface shall be cleaned and valve re-closed

and ends of bore blocked. Actuator and valve shall be packaged

separately.

During transportation or lifting, cord shall be tied to the yoke, no tied to the hand-wheel or stem.

Valve shall be handled with care, no bump to other thing.

The paint, nameplate and flange sealing surface shall be protected during transportation,no drag

valve on the ground especially with the end sealing surface contacted the ground.Don't unpack

when the valve is not ready for installation at the construction field. The valve shall be placed at a

safety location against weather.

8.

Valve Storage

8.1

Valve shall be stored in air and dry room with bore blanked for protection.

8.2

Long-time-stored valve shall be re-inspected prior to use. Close attention shall be paid

against sealing damage when removal of dirties for the cleanness of sealing surface. Of

necessary, valve shall be pressure tested once more.

9.

Valve Installation

9.1

Carefully check valve identification against valve specifications before installation. Always

keep the fluid flow direction with the arrow identified on the body.

9.2

Check the inside of bore and the sealing surface before installation, any attached dirty

shall be removed with clean soft cloth.

9.3

Check the operational of actuator to prevent block before installation.

9.4

Valve operation device is recommended to be installed at location 1.2m from the ground

for convenient of operation. Where the center of valve and the hand-wheel is over 1.8m from the

ground, a platform shall be built for the frequently operated valve. For pipeline with

Instruction and Operation Manual

- 9 -

9.5

numbers of valves, valves shall be installed on the same platform as likely as possible for

convenient of operation.

For single valve installed at location over 1.8m and less operated, apparatus may be used such as

chain-wheel, extension bar, move platform and move ladder etc. Where valve is installed

underground, extension bar or ground-well shall be set. For safety reason, the ground-well shall be

covered.

9.6

For valve installed on horizontal pipeline, the stem is suitable at uprightness position; or,

the downward stem shall be inconvenience for operation and maintenance, as well the valve is

liable to corrosion. If the ground valve slant installed, operation and maintenance shall also be

inconvenience.

9.7

When valves are installed in pipeline side by side, enough space shall be considerate for

operation, maintenance and dismantle. The clearance of hand-wheels shall not less than100mm;

in case of narrow clearance, valves shall be installed interleaving.

9.8

For valve with flange end, user shall select proper bolt, gasket according to the working

temperature, working pressure and fluid, equally fasten the bolts and nuts. Bolt shall be with full

thread and 8UN serial thread shall be used for bolt over 1 inch in diameter.

9.9

For valve with butt-welding end, user shall perform welding and post welding heat

treatment using qualified WPS and welder in accordance with the requirements of ASME B31.3.

10.

Valve Operation and Maintenance

10.1

After installation and for the pressure test of the pipeline or the system, the disc must be

fully opened. It is not recommended to use the valve as adjustment of flow rate or emergent pressure

relief blow- off. SPECS is not responsible for damage, loss or expense arising out of

such usage.

10.2

Usually globe valves have no heat insulation structure, never touch the surface of valves to

prevent burn when the valve has a high/low surface temperature.

10.3

Dust, grease and medium residual trend to accumulate at the surfaces of body, and moving

parts such as stem, gearbox, the guide of yoke etc., wear and erode the valve, and even

generate friction heat that is dangerous in explosive atmosphere, and shall be cleaned frequently

according to the

working conditions.

10.4

After put into service, valve shall be checked and maintained periodically especially for the

situation of sealing surfaces and worn, the age of packing and the corrosion of body. In

Instruction and Operation Manual

- 10 -

case of such situation, valve shall be repaired or replaced. It is suggested that inspection and

maintenance of valve shall be perform every three months provided the fluid is water or oil,every

month or to local law provided the fluid is strong corrosive.

10.5

When performing Repair/maintenance operations, user shall use valve packing, gasket, bolt

and nut of the same size and material as the original one. Valve packing and gasket may be

ordered as spare parts for maintenance and replacement. It is forbidden to open the bonnet or

replace the bolt, nut or packing when the valve contains pressure. After

replacement of packing, gasket, bolt and nut, valve shall be closure test prior to reuse.

10.7

User may repair the valve-sealing surface providing a successful closure test is performed

and the sealing is ok.

10.8

Generally valve trim prefers replacement to reparation. It is better to use provided part as

replacement. If part produced by valve manufacturer is not available due to emergency,user

shall produce the part to SPECS's technical documentation. SPECS takes no responsibility

for loss caused out of part produced other than SPECS.

10.9

It is not recommended for reparation of valve pressure-containing part by user. If the

pressure-containing part is used for a long time and consequently defection occurs and affect

safety use, user shall replace the valve with a new one.

10.10

Welding repair on valve online is forbidden.

10.11

The online valve shall not be knocked, walked on or used as weight support.

11.

Potential Failure and Troubleshooting

Instruction and Operation Manual

- 11 -

Failure (risk) Cause Troubleshooting

Leakage of packing

1.

Gland flange nuts loose

2.

Rings of packing not

enough

3.

Packing aged or failure

4.

Stem sealing damaged

1.

Equally tighten eyebolt nuts

2.

Add packing

3.

Replace packing

4.

Stem shall be maintained

periodically by reparation or

replacement conjunction with

the maintenance of pipeline

Leakage between sealing

surfaces

1.

Dirties between sealing

surfaces

2.

Sealing surfaces damaged

1.

Clean sealing surface

2.

Repair the sealing surfaces

Operation failure

1.

Packing too tight

2.

Thread of stem nut over

worn

3.

Stem bent

4.

Foreigner existence between

stem and stem nut or gland

1.

Proper loose gland flange nuts

2.

Replace stem nut

3.

Rectify or replace stem

4.

Clean foreign matter

Leakage between bonnet

flanges

1.

Bonnet bolts loose

2.

Bonnet gasket failure

1.

Proper tighten bonnet nuts

2.

Replace bonnet gasket

Body and bonnet broken

and leaked

1.

Water hammer

2.

Fatigue

3.

Freezing broken

1.

Carefully operation to prevent

suddenly stopping pumping and

rapidly shutting.

2.

Replace valve that exceeds

guarantee period or is found with

early fatigue defection

3.

Drain away water in winter

12.

Quality Warrant

12.1 SPECS warrants its valves

the date of delivery to the original customer, against defects in material and workmanship under

proper and normal use and service and not caused of resulting from improper

Instruction and Operation Manual

- 12 -

application or usage, improper installations, improper maintenance and repairs, modifications or

alterations.

12.2 Purchaser shall give notice to SPECS upon finding of any defect or assuming defect, SPECS has

privilege to check the facts of the defect

12.3

SPECSsole obligation under this warranty shall be limited to the follows:

—repair of the material or,

—replacement of the parts and materials or,

—refund the purchase price or collect the defected products from the original purchaser.

12.4

SPECSisnotresponsible to claims caused from unexpected natural disaster such as

earthquake, typhoon of any kind arising out of the defect.

12.5

The scope and limitation of warranty can be changed through the agreement between

SPECSand purchaser.

13.

Servicing

13.1

Where contractually specified, SPECS may provide field installation and adjustment.

13.2

SPECS will trace the quality of sold valve and provide service to customer requirements..

Table of contents

Popular Control Unit manuals by other brands

Becker

Becker Beck-O-Tronic 6 Assembly and operating instructions

CAME

CAME R Series manual

NXP Semiconductors

NXP Semiconductors Freescale MC9S12C32 user guide

Standby

Standby MS350 manual

Paxton Access

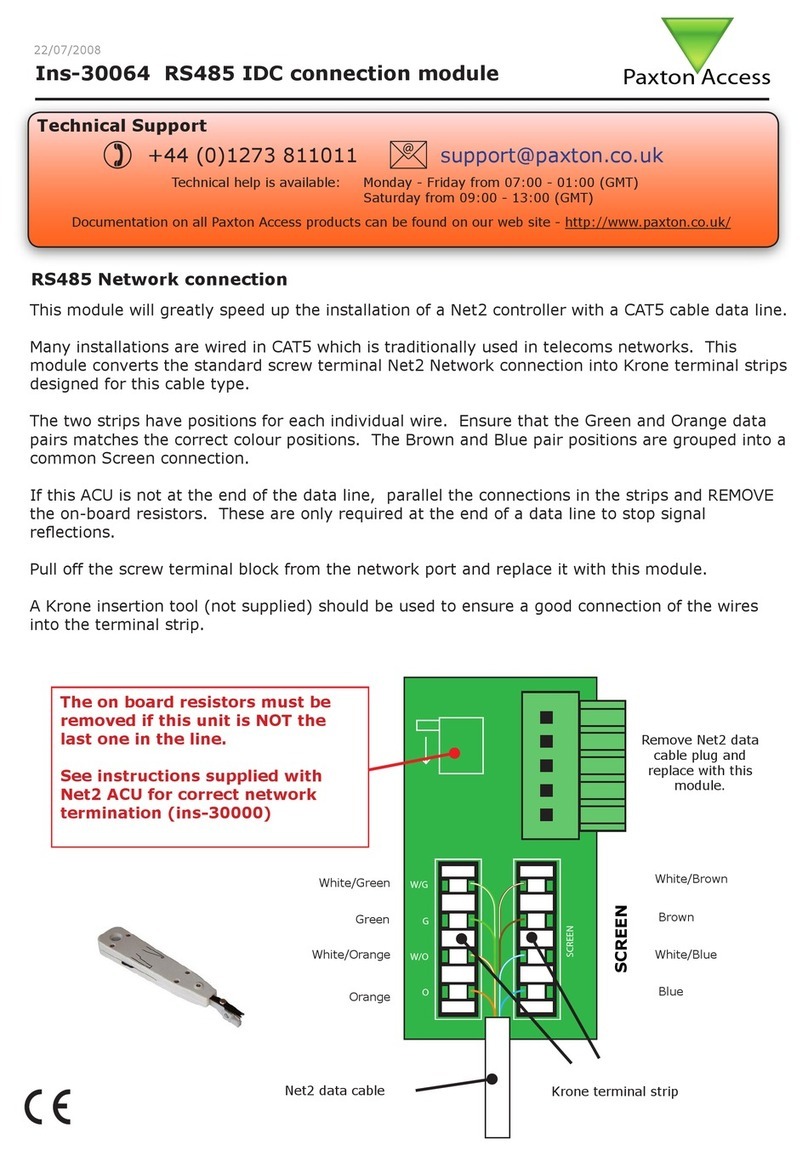

Paxton Access RS485 IDC connection module installation guide

Kohler

Kohler K-2976-KS Installation and care guide