6 Transport and storage

• For delivery of used products: Comply with all legal requirements for the

handling of hazardous substances and the transport of dangerous goods. For

returns to Festo è 2 Safety.

• Store the product in a cool, dry, UV-protected and corrosion-protected envir-

onment. Ensure that storage times are kept to a minimum.

7 Assembly and installation

Requirements

NOTICE!

Avoid mechanical stresses on the valve. Do not use the actuator as a lever.

– The piping is unpressurized, and no medium flows in it.

– The line ends are mounted.

– Connecting cables and fittings are clean.

– An additional 3/2-way valve is built into the supply cable of the operating

medium.

Recommendation: For gentle operation, install a flow control valve (1.5 mm) in the

supply cable of the operating medium.

Cleaning the valve

• Remove all transport packaging. The material used in the packaging has been

specifically chosen for its recyclability (exception: oil-impregnated paper =

residual waste).

Traces of residual grease may be evident on the product due to the production

process used.

• Clean the valve immediately before installation.

Connect lines

1. Bring the valve into its mounting position.

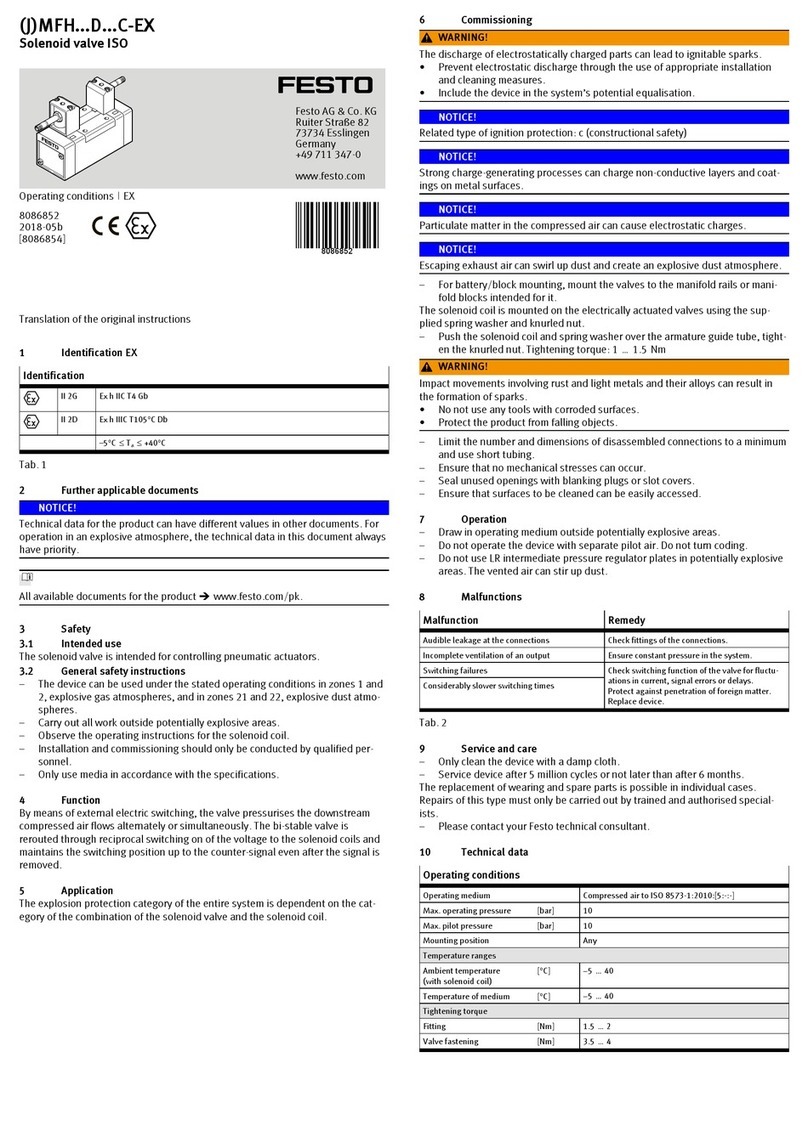

– Observe the flow direction. The permitted direction of flow is marked by

an arrow on the valve housing è Fig.1, 4.

2. Connect the piping on the valve housing.

– Tightening torque è Tab. 2 Tightening torque pipe connection.

3. Connect the operating medium line.

– Tightening torque: max. 26 Nm

Connection size ["] ½ ¾ 1 1¼1½2

Max. tightening torque pipe

connection

[Nm] 105 200 350 450 540 620

Tab. 2 Tightening torque pipe connection

8 Commissioning

Requirements

– The valve is fully mounted and connected.

Checking operating conditions

1. Check operating conditions and limit values è 14 Technical data.

2. Check connection points for tightness.

3. Check compatibility of the devices in the system for maximum pressure (con-

sider pressure peaks). If necessary, adjust the application parameters.

Commissioning the valve

1. Supply medium.

2. Slowly apply operating pressure to the valve. The operating pressure required

for reliable switching of the valve depends on the medium pressure

è 14.2 Technical data, pneumatic.

ÄThe valve opens.

9 Operation

WARNING!

Risk of injury from touching hot surfaces.

Valve housing and actuator can become hot at high temperature of medium.

Severe burns are possible.

• Do not touch the angle seat valve during operation or immediately afterward.

• Comply with operating conditions.

• Comply with maintenance conditions è 10 Maintenance.

After longer idle times:

• Actuate the valve several times and check for correct function.

10 Maintenance

WARNING!

Risk of injury from touching hot surfaces.

Valve housing and actuator can become hot at high temperature of medium.

Severe burns are possible.

• Allow the angle seat valve to cool off before working on it.

• Check product regularly from the outside for leakage and function.

• Check function of the product regularly.

• Clean product regularly with commercial cleaning agents.

11 Malfunctions

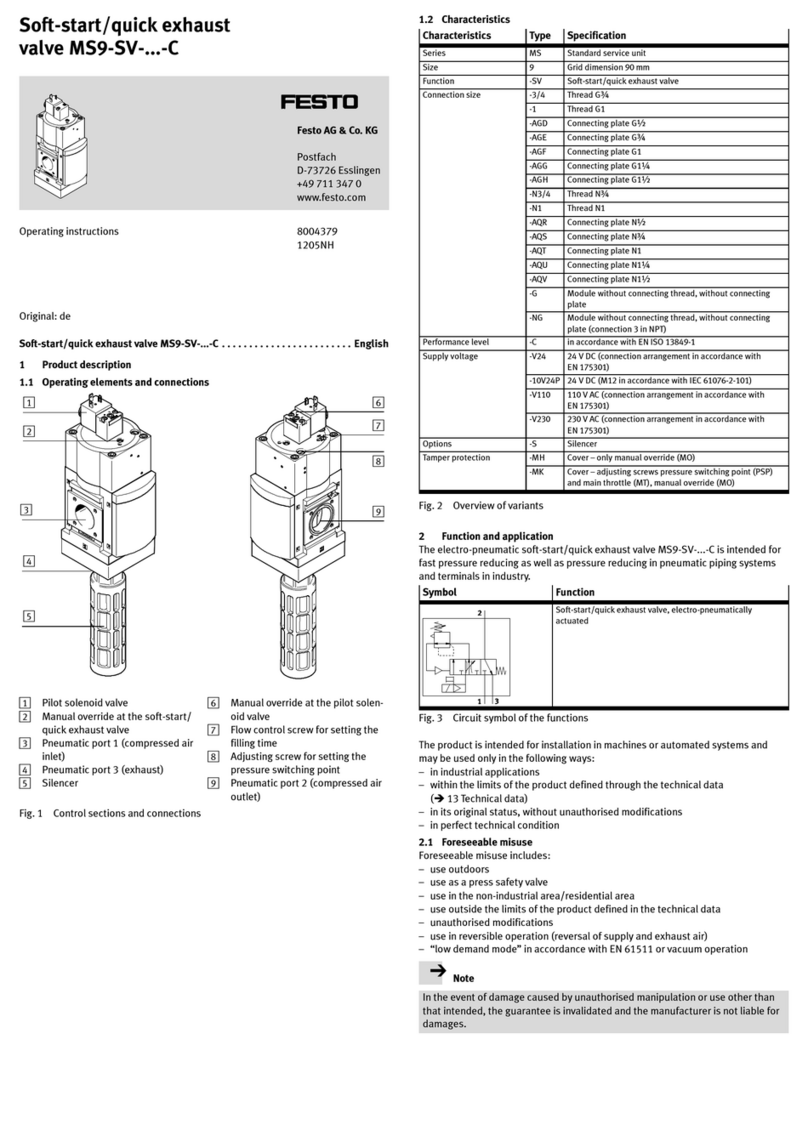

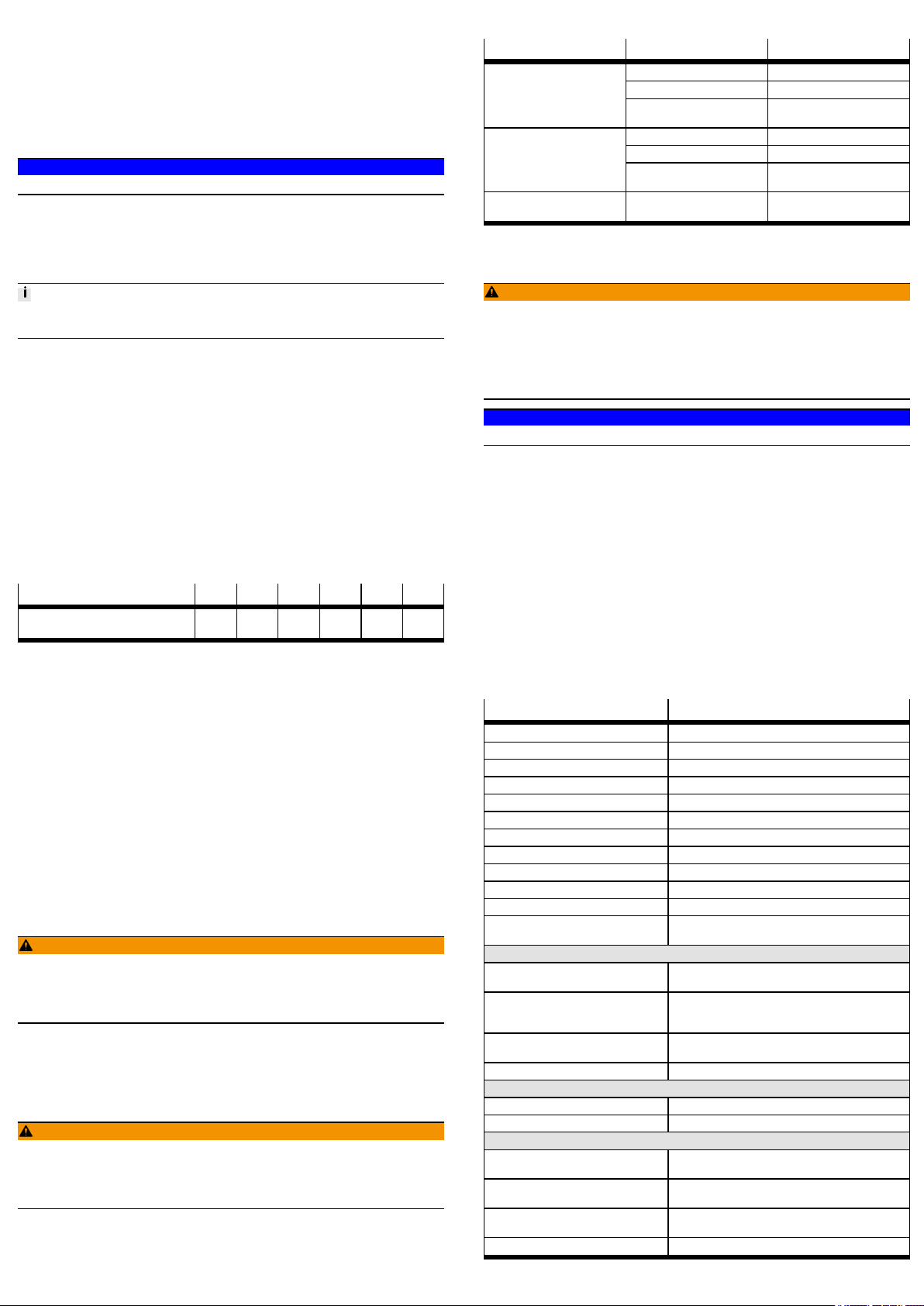

Fault description Cause Remedy

The valve is faulty. Replace the valve.

The flow direction is incorrect Replace the valve.

The valve does not close.

Operating pressure is still

present or is too high

Check operating pressure and

adjust it, if necessary.

The valve is faulty. Replace the valve.

Medium pressure is too high. Adjust medium pressure.

The valve does not open.

Operating pressure is too low. Check operating pressure and

adjust it, if necessary.

Medium leaks from a leakage

hole.

The valve is faulty. Replace the valve.

Tab. 3

12 Disassembly

WARNING!

Risk of injury from combustion and chemical burns.

The media in the piping system and the valve can be hot and under pressure.

Traces of medium can remain in the product and can escape when open or dis-

mantled.

• Allow the valve and piping to cool and depressurize them.

• Wear specified protective equipment.

NOTICE!

The disassembly of the actuator and valve body is not permitted.

1. Depressurise the piping and the connecting cable of the operating medium.

Allow the valve and piping to cool.

2. Empty the piping and valve completely.

– Make sure no one is located in front of the outlet opening.

– Catch discharging media in a suitable container.

3. Disconnect the connecting cable of the operating medium from the valve.

4. Disconnect the piping connections and remove the valve.

13 Disposal

– Dispose of the product in an environmentally friendly manner. In doing so,

take the remaining media into account (use of problematic materials if applic-

able)

– Observe the local regulations for environmentally friendly disposal.

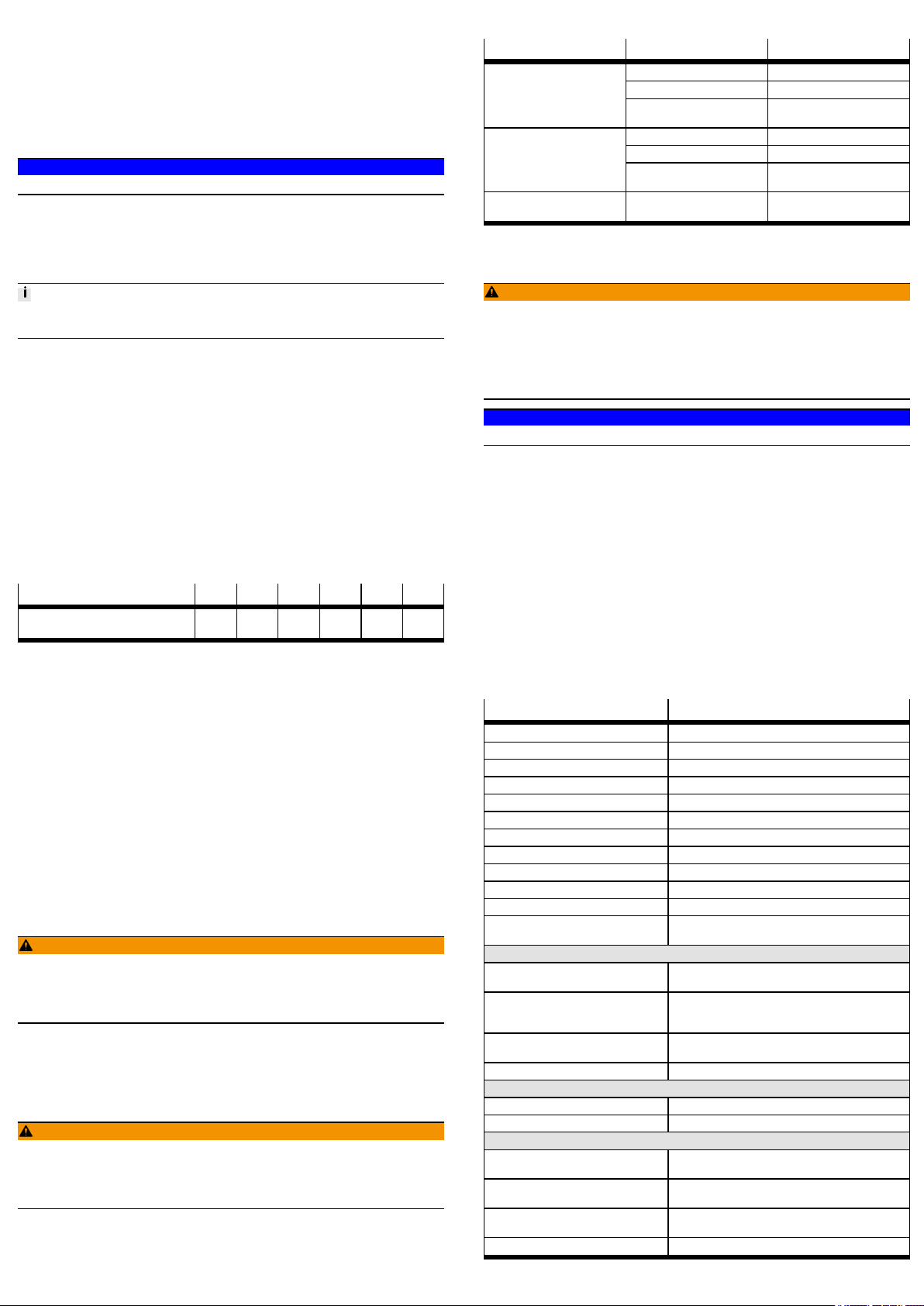

14 Technical data

14.1 Technical data, general

Type VZXF-L-M22C-M

Design Piston actuator with poppet valve

Actuation type Pneumatic

Sealing principle Soft

Mounting position Any

Type of mounting In-line installation

Valve function 2/2-way, closed, monostable

Flow direction Non-reversible

Exhaust function Without flow control option

Reset method Mechanical spring

Type of control Externally controlled

Product weight èwww.festo.com/catalogue

CE marking In accordance with declaration of conformity

èwww.festo.com/sp

Medium

Medium VZXF-...-A Compressed air grade of filtration 200 ìm, inert gases,

vapour1)

Medium VZXF-...-B Compressed air grade of filtration 200 ìm, inert gases,

water, neutral liquid media, petroleum, petroleum

based hydraulic fluid, vapour1)

Medium pressure [bar] –0,9…40, in accordance with information on product

labelling

Viscosity [mm2/s] £ 600

Operating medium

Operating medium Compressed air to ISO8573-1:2010 [7:4:4]

Operating pressure [bar] 6…10 è 14.2 Technical data, pneumatic

Temperature

Temperature of medium

(NBR, FKM)

[°C] –10…+80

Temperature of medium

(PTFE)

[°C] –40…+200

Perm. min./max. temp (TS)

(NBR, FKM)

[°C] –10…+80

Ambient temperature [°C] –10…+60