Spectra Precision LL100N User manual

Laser Levels Online

Spectra RC601 Remote Control

REVISION 1.0

User Guide

© 2021 Laser Levels Online

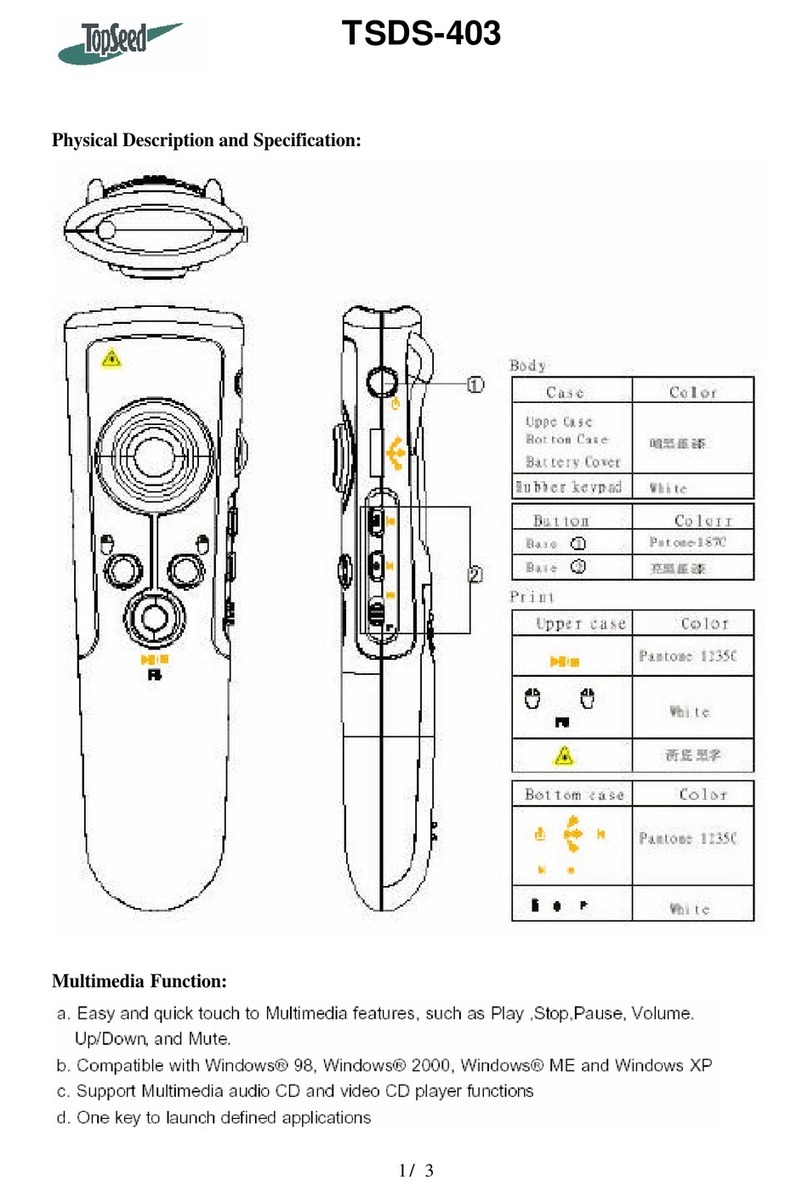

RC601UK REMOTE CONTROL

2

The Spectra RC601UK Infrared Remote Control enables the user to remotely (up to 30m), adjust

the following settings: Rotational speed, Scan angle & position, Manual Override (for single or

dual-axis grade/slope control). It cannot be used to turn the Laser ON or OFF (a feature not

available on any Spectra laser level system).

It is compatible with the Spectra LL100N, Spectra HV101 & Spectra LL300N only.

However, not all remote functions are available on all models of laser.

HV101 Scan Mode

(Stop Dot, 3°, 8°, 45°,

90° & 180° Line)

HV101 Rotational Speed Control.

Zero (Stop Dot), 50, 200, 600rpm

LL100N, HV101 & LL300N

Up / Down / Left & Right Arrows

(Grade / Slope Controls)

LL100N, HV101 & LL300N

Manual Override

(Disables Self Levelling!)

RC601UK REMOTE CONTROL

3

Power Supply & Battery Replacement

●The RC601UK is powered by 1 x 9v PP3 alkaline battery which will be pre-installed.

●When required, unscrew the rear battery compartment and t 1 x 9v PP3 alkaline

replacement battery, taking care to ensure correct polarity.

HV101

Rotational Speed Control

●Press the Rotational Speed Control button on the face of the laser or on the remote to cycle

through the 4 rotational speeds.

●The rotational speeds are Zero (Stop Dot), 50, 200, 600rpm.

●For Indoor work, we suggest using slower speeds, where the laser beam is easier to see by

eye; but for Outdoor Groundworks – run the HV101 at its maximum speed of 600rpm; which

gives the best working range when used with the supplied Laser Detector.

●The default rotational mode is 600rpm when the laser self levels after being turned on.

The following general guidance is only applicable to: Spectra HV101.

Scan Mode

●Press the Scan Mode button on the face of the laser or on the remote to cycle through the 6

scan modes. Each mode adjusts the angle of the beam.

●The scan modes allows the user to set a Stop Dot, 3°, 8°, 45°, 90° & 180° Line

●The scan mode is typically only used indoors and enables the user to see the beam better in

a specic position.

●The Detector cannot pickup the Laser beam when in scan mode.

●Pressing the Rotational Speed Control button once will turn o scan mode and return the

laser to rotating at 600rpm.

RC601UK REMOTE CONTROL

4

LL100N, HV101 & LL300N

The following general guidance is applicable to: Spectra LL100N, HV101 & LL300N.

Manual Override

●Press the Manual Override button on the remote once and the self levelling system will be

turned o. The Laser will continue to rotate but the laser will no longer be outputting a level

datum.

●This mode is typically enabled when the laser is being used to do Gradients and Slopes (See

Gradients & Slopes section on page 6 for further details).

●Pressing the Manual Override button once more will turn the self levelling system back on.

The Laser head will stop and adjust to a level datum and then begin rotating at 600rpm. The

laser is now running in self levelling mode once more.

Up / Down / Left & Right Arrows

●When the LL100N, HV101 or LL300N is in manual mode (Self levelling system has been

turned o), the Up / Down / Left & Right arrows are used to tilt the laser prism in either the X

or Y axis to set a progressive fall or gradient. (See Gradients & Slopes section on page 6 for

further details).

Grading

●The LL100N, HV101 & LL300N are all DUAL GRADE facility laser levels when using the Remote

Control. This means that they can be switched to “Manual” (to override the self levelling

system) allowing the user to set a grade (incline/slope) in the X axis only, Y axis only or both

together. The maximum settable slope is an approx. fall of 1m over 10m.

●For X & Y alignment, please see the case markings on the TOP of the laser head where sights

point in the direction of the axis being set.

RC601UK REMOTE CONTROL

5

LL100N, HV101 & LL300N

The following general guidance is applicable to: Spectra LL100N, HV101 & LL300N.

Setting Single Axis Slope

●This example sets a grade in the X axis.

●Press the ON/OFF button once and the Laser will power on and begin automatically self-

levelling.

●Press the Manual Override button on the remote once and the self levelling system will be

turned o & the red HI / MAN LED illuminates and begins ashing.

●Using the black Left & Right Arrow buttons on the remote, set the % slope (fall) required - as

measured on your sta.

●When complete, press the Manual Override button once more and this will turn the self

levelling system back on. The Laser head will stop and adjust to a level datum and then begin

rotating at 600rpm. The laser is now running in self levelling mode once more.

Setting Y Axis Slope

●This example sets a grade in the Y axis.

●Press the ON/OFF button once and the Laser will power on and begin automatically self-

levelling.

●Press the Manual Override button on the remote once and the self levelling system will be

turned o & the red HI / MAN LED illuminates and begins ashing.

●Using the yellow Up & Down Arrow buttons on either the face of the laser or on the remote,

set the % slope (fall) required - as measured on your sta.

●When complete, press the Manual Override button once more and this will turn the self

levelling system back on. The Laser head will stop and adjust to a level datum and then begin

rotating at 600rpm. The laser is now running in self levelling mode once more.

Setting Both X & Y Axis Slopes (Dual Grade)

●Proceed as above, but use all four Arrow buttons on the remote - as required.

HOW TO SET SLOPES (FALLS/GRADES)

6

Working Example

The following description in this guide, explains the general principles of setting a Slope (Fall/

Grade) when using a Spectra Rotary Laser Level with the Spectra RC601UK Remote Control.

Equipment

You will need the Laser Level, a surveying tripod, measuring sta (rod) with mm scale and a laser

detector/receiver. You will also need the remote control or if you have arrow keys on the laser

keypad those can be used instead. If your Laser Level does not have arrow keys on the Laser

keypad, you will also need a remote control as you cannot set a gradient and slope without

this.

Site Conditions

There are many dierent work site scenarios. As an example, we are assuming that you are

outside on a site with a clear eld of view and planning to set drainage falls.

All above ground and below ground drainage pipes should be laid to an adequate gradient. The

fall in a pipe is dened as the vertical height by which the pipe drops over a known distance. e.g.

a 2.5% gradient is a fall of 1m over 40m or 1:40. (1 in 40).

Typically, surface water or foul water drainage pipes are set between 1:40 to 1:80.

If a gradient is too steep i.e. steeper than 1 in 40, the liquid may run faster than the solids in a

foul water pipe thus leaving the solids stranded, which could then block the pipe. Conversely,

if a gradient is not steep enough (usually less than 1 in 110), then the pipe may still block, if the

solids slow down and become stranded.

Procedure

Place the Laser Level horizontally on the surveying tripod, switch it ON and allow it to auto (self)

level. Note the X-axis / Y-axis markings on the top cover of the laser.

Setting a 1:40 gradient: Position the measuring sta at 10m away from the tripod, held

vertically and move the laser detector (receiver) along the sta to nd the set level position,

usually by giving a continuous audible tone. By proportion, a 1m fall at 40m is only 250mm

at 10m, so carefully noting the set level dimension on the rear of the sta, move the detector

down by 250mm and clamp tight.

Using the remote control (from the sta location) or a colleague at the laser, press the Manual

Override button and have the axis to be adjusted facing the measuring sta.

Hold the “down arrow” button on the remote control or laser’s keypad, to slope the laser beam

down the measuring sta until it gives a continuous tone again, having found set level on the

detector. This has now set a 1:40 fall.

Return the laser detector to the original set level dimension on the sta.

Dig out ground & lower sta until the laser detector picks up the laser beam again.

HOW TO SET SLOPES (FALLS/GRADES)

7

Working Example (Continued)

Important note: All “grade facility” rotary lasers revert back to the auto (self) level condition if

switched O without retaining the gradient set. So its recommended to complete the ground-

works before switching the laser O.

Once this 1:40 fall is set, the User can use this inclined laser beam as a datum to set the depth of

either the crown of the drainage pipe or the Invert level, anywhere in range of the laser – along

that same axis.

Invert level of a pipe – is the level taken from the bottom of the inside of the pipe.

Crown of a pipe – is the Invert level plus the internal diameter of the pipe plus the pipe wall

thickness. It may be necessary to use this in calculations when level measurements are taken

from the crown of a pipe.

Manhole / Access Chambers:

A manhole or access chamber is required to gain access to a drainage system for un-blocking,

cleaning, rodding or inspection. (Land drainage systems excluded). They can be manufactured in

PVC, masonry or pre-cast concrete.

When setting appropriate drainage gradients it is important to allow for the depth down to

either the crown of the pipe (or the Invert level) from ground level, when using these manholes.

Dual Grading:

A rotary laser level with dual grading facility can be used for setting out driveways, car-parks or

areas with slopes (falls) in BOTH the X & Y axis.

The same procedure is adopted as above for drainage runs, except a second step in the process

is undertaken to set the laser to a fall in the other axis, to complete the dual grade setting-out.

Cut & Fill Machine control work:

If slopes of more than 10% (1:10) are required, which is outside the range of electronic

adjustment of the rotary laser’s prism; then simply switch the laser to Manual & t a “Laser

Grade Adapter” between the top face of the tripod & the base of the laser. Then set the required

slope. Search our website for more details.

Laser Levels Online

MAGNETIC MACHINE DETECTORS

Check Out Our Range Of Magnetic Detectors

Unit 35, Bridge Business Centre, Beresford Way, Dunston Road,

Chestereld, Derbyshire, S41 9FG, United Kingdom

Freephone: 08000 869 769 (Free from UK mobiles and landlines)

Put a Magnetic Detector / Receiver on your machine and extend the benets of any red beam

rotary laser. They are reliable, simple to attach, extremely robust and easy to use.

www.laser-level.co.uk/magnetic

Other manuals for LL100N

2

This manual suits for next models

4

Table of contents