1

Thank you for choosing a JET digital torque wrench.

Before operating the torque wrench, please read

this manual completely, and keep it nearby for

future reference. This is a precision instrument and

must be treated and cared for as such. Rough

handling may affect performance and diminish life.

MAIN FEATURES

Digital torque value readout

12 led side lights and beeper indicate torque

when screen cannot be seen

+/-2 or +/-3% accuracy

CW and CCW operation

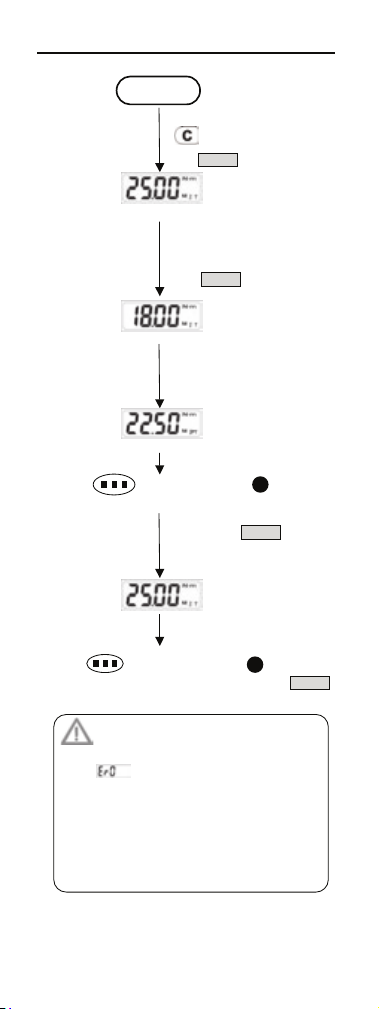

Peak hold and track mode

Measures in/lbs, ft/lbs, kg/cm, and nm units

9 presettable target torque values

50 data memory for recall and torque

auditing

Auto sleep after 5 minutes idle time

Compatible with rechargeable batteries

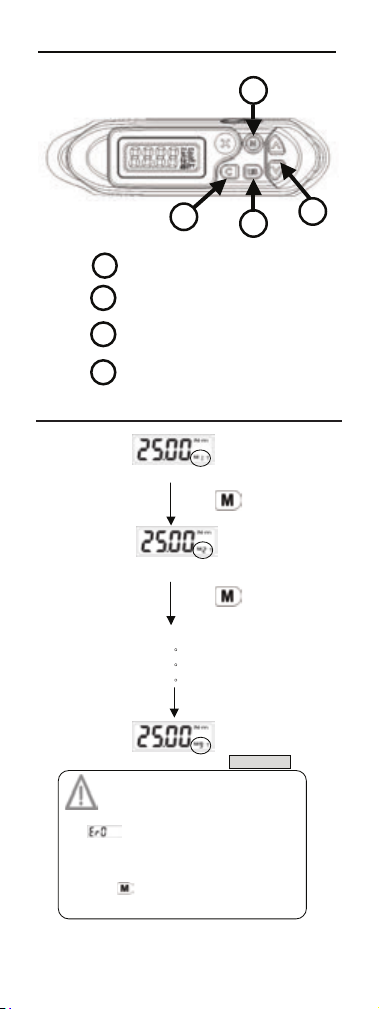

NAMES AND FUNCTIONS OF PARTS