Aluminum Body Mounts Page 5

3.0 GETTING STARTED / INSTALLATION

Back to Table to Contents

3.1 LEVELING AND SUPPORT

The vehicle should be on a level surface before you start. Leave the vehicle on the ground

and remove all body mount bolts and lower bushing halves. Some bolts may be rusty, you may

need to apply penetrating fluid to remove them.

3.2 RADIATOR SUPPORT

Once the bolts are out there

should be enough room to slip

the top mount in the frame. With

the top mount in place, install

the interlocking lower mount.

Coat the threads of two 1/2 X 3”

bolts with anti-seize and loosely

thread into the body.

3.3SIDE

LOCATIONS

When there is enough room,

remove the old mounts and

slip the upper mounts in place. Coat the threads of your 7/16 X 3” bolts with anti-seize and

loosely thread through the lower bushings and into the body with a flat washer and lock washer

as shown in the diagram on page

Repeat for remaining bushing locations on that side.

3.4REPEAT

Repeat steps on the other side of the car.

4.0 FINISHING

Back to Table to Contents

4.1 TORQUE

As rubber mounts tend to compress and distort over time and all floor pans are slightly different,

ensure that the hood and fenders line up properly with the body, and that all bushings fully

contact the floor before torquing. Use additional shims (not included) to adjust as necessary.

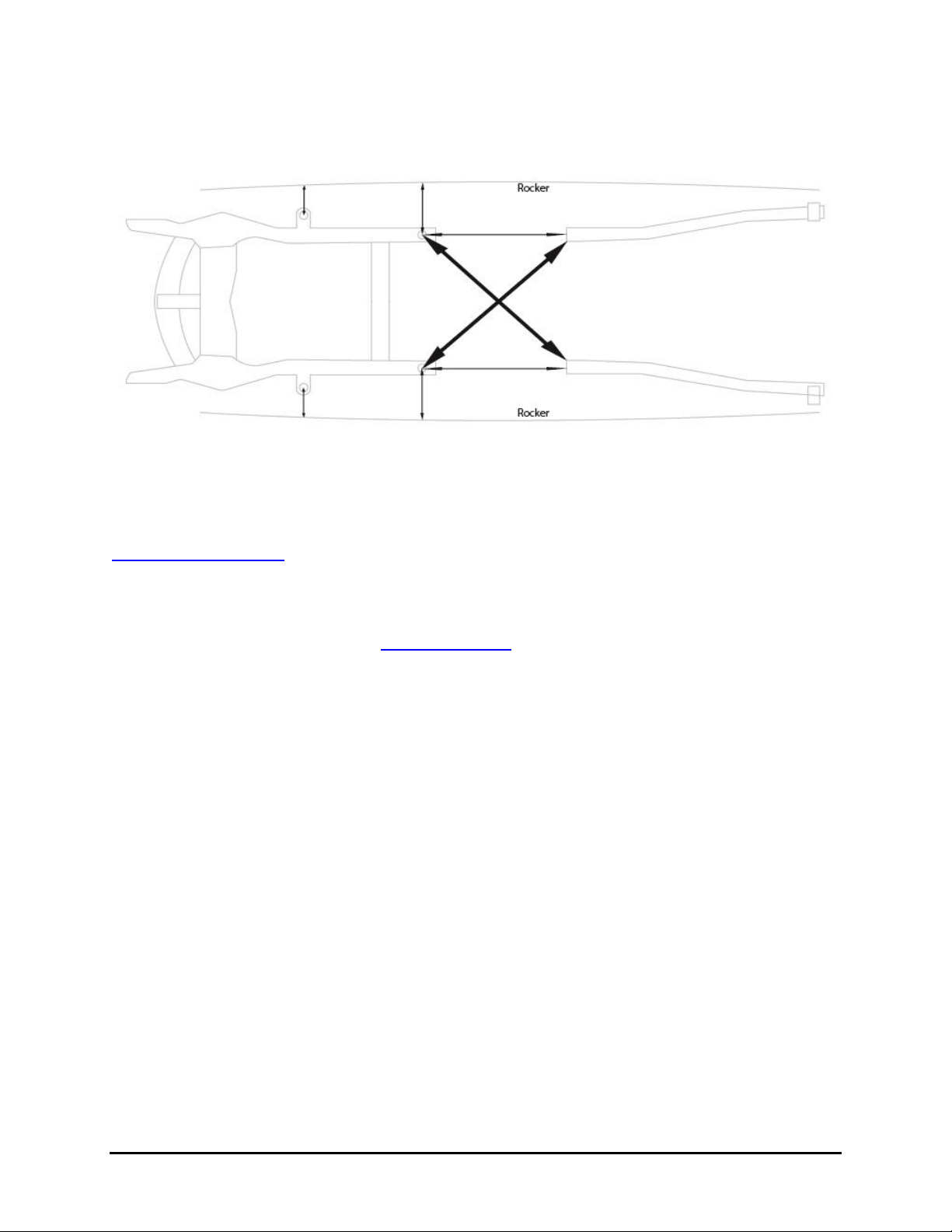

Cross measure the frame to ensure it is straight and square to the body. When the frame is

squared in, torque all bolts to 140 ft lbs.

NOTE: Recheck torque after approximately 100 miles of driving.