Spencer Z4002 User manual

General Information pag. 2

Warnings pag. 2

Description of Product pag. 2

Operating Instructions pag. 3

Maintenance pag. 4

Accessories and replacement parts

pag. 4

INDEX

SP/06/130/IU

Spencer Italia S.r.l. Str. Cavi, 7 - 43044 Collecchio (PR) ITALY

tel. +39 0521 541111 fax +39 0521 541222 e-mail: info@spencer.it

www.spencer.it

Z4002

User's manual

Guarantee of Quality system for the production and the final control of the products certified by the

notifying body TUV Italy.

REV. 0 23/01/07

SIGNIFICATO COMMENTO

2

1.4 SERVICING REQUESTS

For any information regarding the use, maintenance and installation, please contact the Spencer Customer Care Service on 0039 0521 541111 -

Fax 0039 0521 541222 - e-mail: info@spencer.it or write to Spencer Italia Srl - Strada Cavi, 7 - 43044 Collecchio (Parma) ITALY.

1.5 DEMOLITION

Follow the current regulations.

1.6 LABELLING

The serial number as indicated below can be found on each appliance and must not be removed or covered. In order to facilitate assistance

please indicate or communicate the serial number (SN) or lot number (LOT) on the label.

2.3 PHYSICAL REQUIREMENTS OF THE OPERATOR

This device, during the loading / unloading procedure, requires not less then two operators which are strong, balanced and which have good

sense. The capacity of every operator must be considered before determining his role in the employment of the devcie.

2 WARNINGS

2.1 GENERAL WARNINGS

•Before carrying out any kind of operation on the product, the operator must carefully read the enclosed instructions, paying particular attention to the

correct safety precautions and to the procedures to be followed for installation and for correct use.

•In the case of any doubts as to the correct interpretation of the instructions, please contact Spencer Italia Srl, for any necessary clarifications.

•Regularly check the appliance. Carry out the prescribed maintenance in order to keep the appliance in good condition and to guarantee correct func-

tioning and a long life.

•In the case of any abnormalities or damage to the appliance, which could jeopardize the functioning, and the safety, the appliance must be immedia-

tely removed from service.

•Do not alter or modify in any way the appliance; any such interference could cause malfunctions and injury to the patient and/or rescuer.

•The appliance must not in any way be tampered with, in such cases all responsibility will be denied for any malfunctions or eventual injuries caused

by the appliance itself.

•Who modifies or has modified, prepares or has prepared appliances in such a way that they no longer serve the purpose for which they were inten-

ded, or no longer supply the intended service, must satisfy the valid conditions for the introduction onto the market.

•Ensure that all the necessary precautions are taken in order to avoid hazards that can arise as the result of contact with blood or body fluids.

•Handle with care.

2.2 SPECIFIC WARNINGS

•The product may only be used by trained personnel.

•Never exceed the maximum capacity as described in this User's Manual.

•Do not use if the weight has not been distributed correctly.

•Pay attention to possible obstacles on the way to drive.

•In case of anomalies or damages that may compromise the functionality and the safety of the device, take the device out of service immediately.

1 GENERAL INFORMATION

1.1 AIM AND CONTENTS

The aim of this manual is to supply all the information necessary so that the client, apart from attaining an adequate use of the appliance, will

also be capable of using the instrument in the most autonomous and secure way possible. This includes information regarding technical

aspects, functioning, maintenance, spare parts and safety.

1.2 CONSERVATION OF THE INSTRUCTION MANUAL

The instruction and maintenance manual must be kept with the product, inside the specially provided container and above all, away from any

substances or liquids which could compromise perfect legibility.

1.3 SYMBOLS USED

Thank-you for choosing a Spencer product

SYMBOL

See instructions for use.

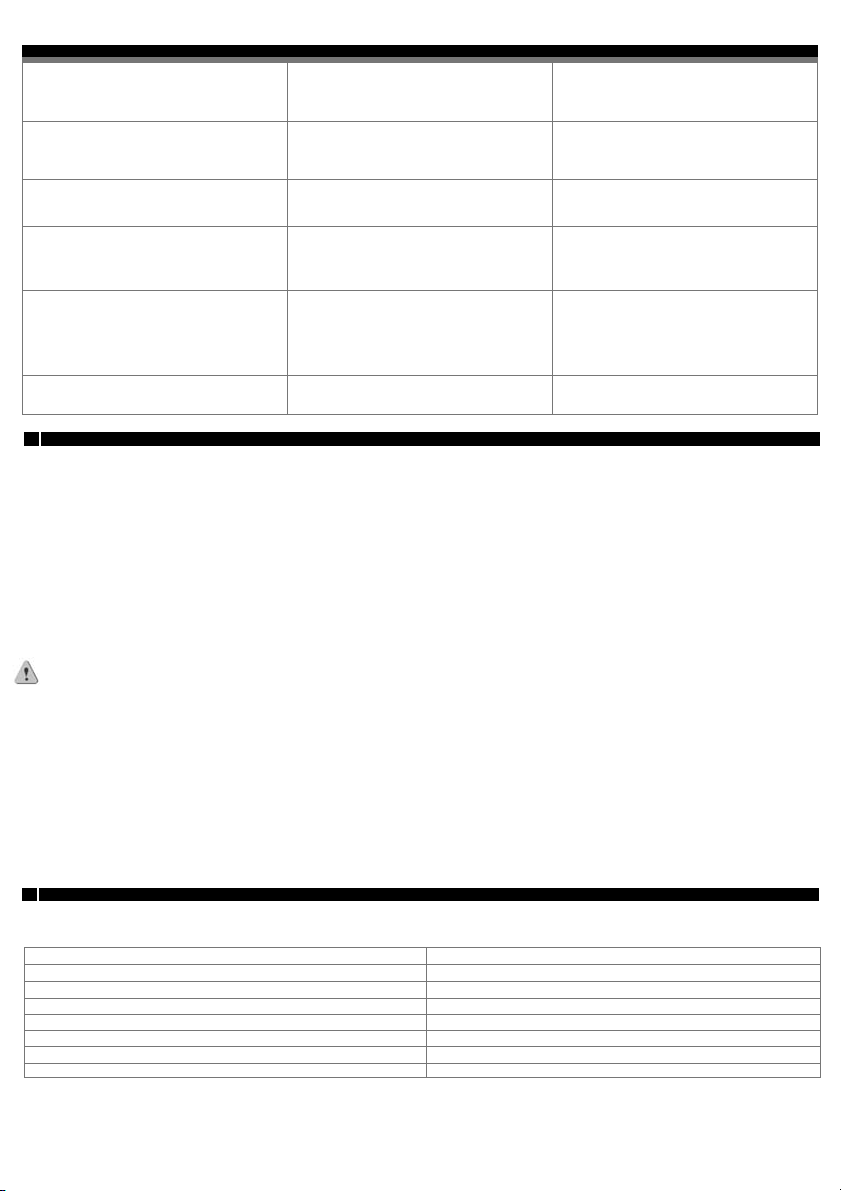

3 DESCRIPTION OF PRODUCT

3.2 MAIN COMPONENTS

1. n° 2 turning wheels Ø200 mm.

2. n° 2 turning wheels Ø200 mm with brakes. The braking system

blocks both the turning movement of the wheel and the turning of the

entire wheel unit.

3. n° 2 turning supports, made out of a rolling system, two handles and

a blocking lever, which allow quick and safe movement of the coffin

during loading, unloading and working.

4. n° 4 extensions, integrated in the frame, but removable in order to

obtain the minimum height (550mm)

5. n° 4 lever in order to ad just the intermediate heights

3.1 INTENDED USE

The Z4002 is a work bench which optimizes the movement and treatment of coffins, offering to the operator a correct ergonomic position in any situa-

tion.

2.4 CONTRAINDICATIONS AND SIDE EFFECTS

The appliance, if used as described in the manual, does not present any contraindications in use.

Fig.1

MEANING

3.4 ENVIRONMENTAL CONDITIONS

4.2 PREPARATION

On receiving the product: remove the packaging and display the material so that all is visible.

The appliance must be checked before every use so as to reveal any working abnormalities and/or damage caused by transport and/or storage.

4 OPERATING INSTRUCTIONS

4.1 TRANSPORT AND STORAGE

Before transporting the appliance, make sure that it is correctly packaged ensuring also that there are no risks of shocks or falls during the tran-

sport itself. Keep the original packaging for any eventual further transport. Damage to the appliance caused during transport and handling is not

covered by the guarantee. Repairs or replacement of the damaged parts are the responsibility of the Client. The appliance must be stored in a

dry place free from humidity.

During stockage, make sure not to place any heavy materials on top of the Z4002; the device should not be considered a support, if not for the

employment is has been designed for.

For both operation and stockage: from -20°C to +60°C

4.3 FUNCTIONING

Before every use, make sure to check the following points scrupulously:

•General functionality of the device

•Fixation of nuts and bolts

•Use of wheels and breaks

•Spring release

3.3 TECHNICAL DATA

Minimum heigth

Maximum height

Intermediate height

Lenght

Width

Weight

Capacitiy

550mm

850mm

795mm

1350mm

620mm

25 +/- 3%

250Kg

Wheels Ø200mm

Frame Material

Supporting Frame

Finish

Polyamide core

Polyurethane foam wrap

Sphere bearing in Stainless Steel

Stainless Steel AISI 304

tube Ø35x1,5mm Stainless A304

tube 25x15x1,5mm Stainless A304

Electro Shine Finish

4.3.1 Loading the coffin for working bench use of the device

In this phase at least two physically suitable operators are needed

1. Insert the brakes of the wheels of the Z4002

2. The operator has the possibility to replace the anti-vibrating rubber supports with the nails (to be find under the tube) by simply (un)screwing both

accessories; both allow the levelling of the bench, assuring stability and safety

3. Fold the roller supports in unloading position (inwards, in the direction of the space dedicated to the fork lift Fig. 2)

4. Load the coffin on top of the device, making sure to distribute the weight of the load in a balanced way

The central part of the device is dedicated to an easy positioning of the coffin by fork lift (Fig. 2). Two operators are needed anyway

4.3.2 Transport and unloading the coffin

In this phase at least two physically suitable operators are needed

1. Unblock the brakes

2. Activate the rotating supports, making sure the rolling system supports the bottom of the coffin with a rotation in outside direction

3. When close to the van, if previously inserted, unblock the rolling system with the apposite levers on both sides, in order to allow a natural rolling

of the coffin

4. Roll the coffin into the van, paying attention to its balance and the linear movement set up by the trolley's rolling system

4.3.3 Height management

In this phase no load may be placed on the device

4.3.3.1 In order to obtain an intermediate height, starting from the maximum height, turn the 4 upper knobs (Fig. 1 - n ° 5) in the direction indica-

ted by the arrows in order to unblock the system; move the upper structure downwards and block it with the same knobs, turning them in opposi-

te direction.

4.3.3.2 Obtaining the minimum height, starting from the maximum heigth:

1. Unblock the 4 upper knobs (Fig. 1 - n ° 5);

2. Remove the upper structure of the Z4002;

3. Unblock the 4 lower knobs of the extensions (Fig. 1 - n ° 4) by turning them in the direction indicated by the arrows;

4. Remove the 4 extensions;

5. Insert the upper structure on the lower structure without the removed extensions;

6. Fix the 4 knobs in the apposite holes by turning them.

3

Fig.2 Fig.3

5 MAINTENANCE

5.1 CLEANING

The metal parts are treated (Electro Shine Finish) also in order to increase the material resistance.

Wash the Z4002 with a clean cloth, using hygienic-sanitary liquids. Do not use aggressive substances of any type. Whenever necessary, dry

with a soft cloth. The use of high pressure cleaning increases the risk of corrosion.

5.2 MAINTENANCE

5.2.1 Ordinary maintenance

The person who carries out the precautionary maintenance of the appliance (user in person, manufacturer/supplier or a third party) has to gua-

rantee the following basic requirements:

•Technical knowledge of the appliance, of the periodic maintenance procedures as described in these instructions;

•Use of technical personnel in possession of specific qualifications and training in the maintenance operations of the appliance in question;

•Use of components/replacement parts/accessories that are either original or approved by the supplier, in such a way as to carry out every opera-

tion without causing alterations or modifications to the appliance;

•Possession of the checklist of operations carried out on the appliance;

All maintenance operations which do not include only lubrication of the moving parts, fixation of nuts and bolts, ordinary cleaning

and fixing the wheels, have to be performed by Spencer Italia or an authorized service centre.

5.2.2 Extraordinary Maintenance

The person who carries out the corrective extraoridinary maintenance of the appliance (user in person, manufacturer/supplier or a third party)

has to guarantee the following basic requirements:

•Adequate knowledge of the appliance, of its technical/construction features, of checks and final tests, of packaging, conservation and handling;

•Adequate knowledge of the technology used in the making of the appliance;

•Knowledge of the functions of the appliance, of any potential risks and of the probability of possible malfunctions or break-downs;

•To be in possession of all the instruments necessary for carrying out any kind of technical operation regarding servicing;

•To be in possession of original replacement parts or those authorized by the manufacturer;

•Specialized technical personnel trained by the manufacturer for the servicing of the appliance in question;

The device, if used as described in this User's Manual, has a life time of 5 years.

6 ACCESSORIES AND REPLACEMENT PARTS

6.1 ACCESSORIES

No accessories available.

6.2 SPARE PARTS

Copyright Spencer Italia S.r.l.

All rights reserved. No part of this document must be photocopied, reproduced or translated into another language without the written approval of

Spencer Italia S.r.l.

Warning

The information container in this document can be modified without warning and is not to be intended as a commitment on the part of Spencer Italia S.r.l.

With the right to modify. The Spencer products are exported to many countries in which the same identical regulations do not exist. It is for this reason that there can be many dif-

ferences between the description and the actual product delivered. Spencer works continuously perfecting all the models of the models sold. We therefore hope to have your

understanding if we reserve the right to modify the shape, equipping, lay-out or technical aspects that are herein described, at any given time. .

4

4.TROUBLESHOOTING

Blocked rolling support or difficult rolling

movement

Overload.

Use.

Insufficient lubrication.

1. Clean and lubricate the interested parts with

suitable products.

2. Take the device out of service and contact

the Service Centre.

Roll blocking system does not work pro-

perly

Use.

Insufficient lubrication.

1. Clean and lubricate the interested parts with

suitable products.

2. Take the device out of service and contact the

Service Centre.

Wheels turning difficultly Presence of dirt in the moving mechanism.

Overload.

Wheel's bearing damaged

1. Lighten the load.

2. Remove dirt.

3. Take the device out of service and contact

the Service Centre.

Wheel breaking system insufficient Use.

Presence of dirt in the moving mechanism.

1. Remove dirt from the mechanism.

2. Take the device out of service and contact the

Service Centre.

Knobs for intermediate heights blocked or

moving difficultly

Overload.

Use.

Insufficient lubrication.

1. Lighten the load.

2. Clean and lubricate the interested parts with

suitable products.

3. Take the device out of service and contact

the Service Centre.

PROBLEM CAUSE SOLUTION

General structural damage Improper use Take the device out of service and contact the

Service Centre.

Wheel grey Ø200mm

Chrome support for wheels Ø200mm

Chrome support for wheels Ø200mm with brake

Anti vibration rubber with screw M8x15

Black PVC handle Ø12

Protection tap M8 in black polyehtylene

Bearing Ø22mm for wheels Ø200mm

Blocking nail for coffin

ST42020A

ST41600A

ST41601A

ST10626B

ST10620B

ZC10103B

ST70636B

ZC10102B

Popular Outdoor Cart manuals by other brands

Carts Vermont

Carts Vermont 20 manual

Westward

Westward 2CZY4 Operating instructions and parts manual

Numatic

Numatic EcoMatic EM-5 Assembly

Bosch

Bosch XL-Cart Operating/safety instructions

Tennsco

Tennsco Modular Cart Top Component Assembly Assembly Instructions/Parts Manual

Clam

Clam POLAR TRAILER HD MAX manual