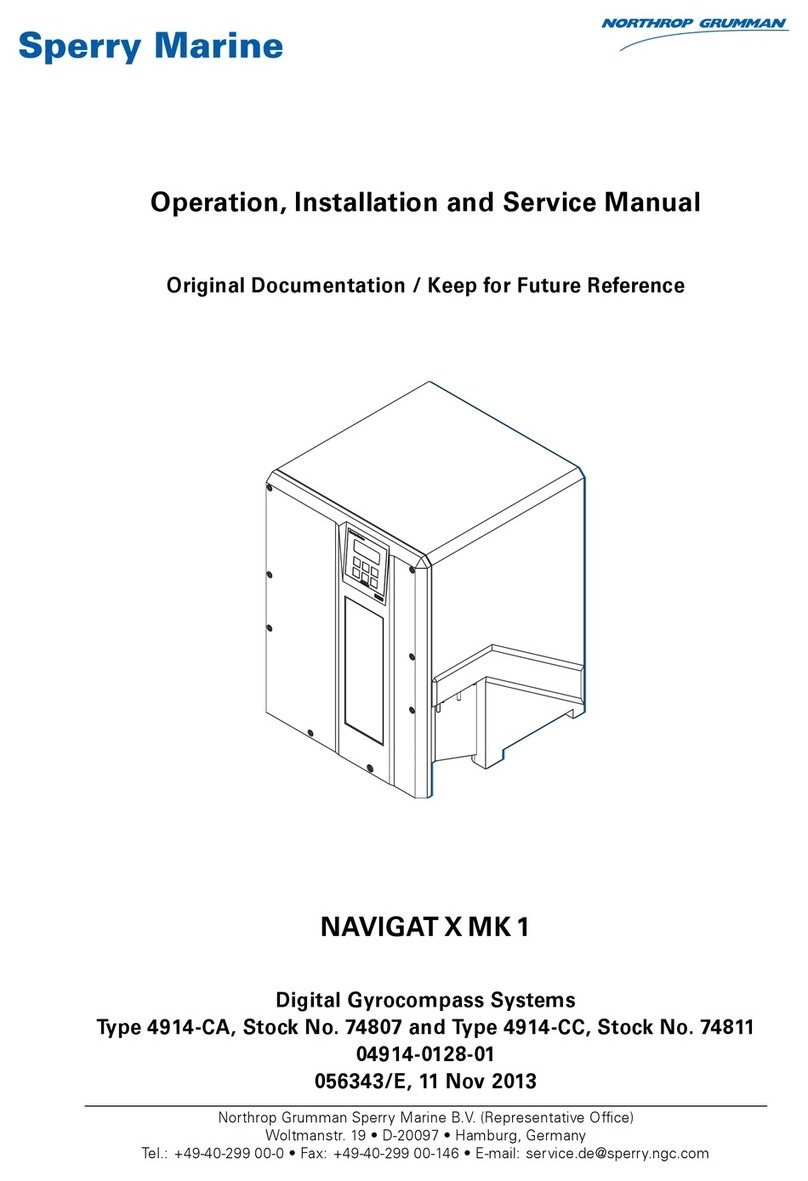

SperryMarine NAVIGAT 100 Manual

Northrop Grumman Sperry Marine B.V. (Representative Office)

Woltmanstr. 19 • D-20097 • Hamburg, Germany

Tel.: +49-40-299 00-0 • Fax: +49-40-299 00-146 • E-mail: service.eu@sperry.ngc.com

Operation, Installation and Service Manual

Original Documentation / Keep for Future Reference

NAVIGAT 100

Digital Gyrocompass Systems

Type 5026-AA, Stock No. 073518

05026-0128-01

056373/D, 19 Feb 2019

056373/D NAVIGAT 100

Copyright © 2019 Northrop Grumman Sperry Marine B.V.

This document and the information herein is and remains the intellectual property of Northrop

Grumman Sperry Marine B.V. [NGSM BV] and its associate companies and may not be copied,

reproduced or translated without the express permission of NGSM BV. A limited license is grant-

ed for the user to reproduce this documentation for his own internal use, but not for distribution

to third parties. Reproduction of this document for resale or commercial gain is expressly pro-

hibited.

Specifications were correct at time of press but may be varied in accordance with NGSM BV’s

policy of continuous product development.

Any technical content should be verified with NGSM BV.

For third-party copyright content in relation to the document present, see the third-party copy-

right information chapter in this manual.

Sperry Marine, with major engineering and support offices in New Malden, England, and

Hamburg, Germany, is part of the Northrop Grumman Navigation & Maritime Systems Division

N&MSD.

Revision Record

Rev. Date Remarks

D 19 Feb 2019 Updated release: applicable from NG 100 software version 1.205

C1 29 Mar 2018 Corrected release: amendments in chapter System Installation

C 30 Jan 2018 Updated release: applicable from NG 100 software version 1.110

B1 15 Jun 2017 Updated release: applicable from NG 100 software version 1.012; north

speed error correction amended; CompassNet installation kit added

B 25 Jan 2017 Updated release: certificate information amended, software update

procedure added

A2 05 Aug 2016 Updated release: minor amendments

A1 11 May 2016 Updated release: Certificates added, appended forms added; minor

amendments

A 20 Apr 2016 Initial release.

NAVIGAT 100 056373/D

iii

Contents

Safety Instructions

Safety Notice Conventions........................................................................ vii

General Safety Information for the Operator ......................................... viii

General Safety Information for Service Personnel................................. xiv

Chapter 1: Introduction

1.1 System Description................................................................................... 1-1

Intended Use ...............................................................................................1-1

Not Intended Use.........................................................................................1-1

1.2 System Overview and Main Components .............................................. 1-2

Door Label and type label.............................................................................1-3

NAVIGAT 100 Main Components .................................................................1-4

1.3 Design and Main Features........................................................................ 1-7

1.4 Operating Principle ................................................................................... 1-9

Heading Error Latitude Correlation............................................................. 1-10

1.5 Example System Configurations ........................................................... 1-12

Standalone Gyrocompass/TMC System ....................................................1-12

Rate-of-Turn Indicators ...............................................................................1-12

DIP-Switch Settings ...................................................................................1-13

1.6 Technical Data.......................................................................................... 1-14

Dimensions and Weight.............................................................................1-14

Power Supply .............................................................................................1-14

Operational Characteristics ........................................................................1-14

Accuracies..................................................................................................1-15

Environmental Requirements.....................................................................1-16

Inputs / Outputs .........................................................................................1-17

1.7 Third-Party Copyright ............................................................................. 1-18

1.8 Declaration of Conformity ...................................................................... 1-19

Chapter 2: Operation

2.1 Operating Conditions ............................................................................... 2-1

2.2 Display and Operating Keys ..................................................................... 2-3

Control and Display Unit (CDU) ................................................................... 2-3

Menu Timeout Function .............................................................................. 2-4

2.3 External Control Devices .......................................................................... 2-4

2.4 Power-up .................................................................................................... 2-5

NAVIGAT 100 Restart .................................................................................. 2-7

2.5 Selecting the Active Heading Source...................................................... 2-8

2.6 Adjusting the Display Brightness ............................................................ 2-9

2.7 Adjusting the Display Contrast.............................................................. 2-10

2.8 NAVIGAT 100 CDU Initialisation ............................................................ 2-10

056373/D NAVIGAT 100

iv

2.9 Optional Functions.................................................................................. 2-11

Muting Alarms Remotely ...........................................................................2-11

2.10 Operating Menu ...................................................................................... 2-12

Entering and Quitting the Menu Display ................................................... 2-12

Navigating the Menu ................................................................................. 2-13

Choice / Selection of Parameter Settings.................................................. 2-14

Editing Parameter Values .......................................................................... 2-16

Caption for Parameter Settings ................................................................. 2-16

2.11 Displaying Secondary Info...................................................................... 2-17

Secondary Info - North Speed Error Correction......................................... 2-19

2.12 Manual Settings Menu ........................................................................... 2-20

Manual Settings – Overview ..................................................................... 2-21

Manual Settings – Parameters .................................................................. 2-22

2.13 Monitoring ............................................................................................... 2-25

Monitoring – Overview .............................................................................. 2-25

Monitoring – Parameters........................................................................... 2-26

2.14 Info / Service............................................................................................ 2-28

Info / Service – Overview .......................................................................... 2-29

Info / Service – Parameters ....................................................................... 2-30

Chapter 3: Alerts and Errors

3.1 Alert Indication .......................................................................................... 3-2

Audible Alert Indication ............................................................................... 3-2

Visual Alert Indication .................................................................................. 3-3

3.2 Alert Handling............................................................................................ 3-4

Alarm Displays............................................................................................. 3-4

Warning Displays......................................................................................... 3-8

3.3 Alerts / check........................................................................................... 3-11

Chapter 4: Scheduled Maintenance

4.1 Maintenance of the NAVIGAT 100............................................................ 4-1

Cleaning of Compass Housing .................................................................... 4-1

Cleaning of Air Inlet Grill.............................................................................. 4-1

4.2 Gyrosphere Maintenance ......................................................................... 4-2

18-Month Maintenance ............................................................................... 4-2

Five-Year Maintenance ................................................................................ 4-3

Chapter 5: Preventive Maintenance

5.1 Protecting the Gyrosphere from Low Temperatures.............................. 5-1

Gyrosphere Damage through Shut Down ................................................... 5-2

5.2 Removing the Gyrosphere Container from the Compass Housing ...... 5-3

5.3 Installing the Gyrosphere Container in the Compass Housing............. 5-7

NAVIGAT 100 056373/D

v

Chapter 6: System Installation

6.1 Installation Recommendations................................................................ 6-1

Place of Installation ..................................................................................... 6-1

Ventilation / Temperature ............................................................................ 6-1

Electromagnetic Interference...................................................................... 6-1

Vibration ...................................................................................................... 6-2

6.2 Mechanical Installation ............................................................................ 6-3

Gyrosphere Container Mod 10/4 Preliminaries ........................................... 6-4

Installing the Compass Housing ................................................................. 6-4

6.3 Electrical Installation ................................................................................ 6-5

Power Supply .............................................................................................. 6-5

Wiring Up the System................................................................................. 6-6

6.4 Gyrosphere Installation ............................................................................ 6-7

6.5 DIP-Switch Settings .................................................................................. 6-8

6.6 Initial System Configuration .................................................................... 6-9

Configuration of the System ....................................................................... 6-9

Finalizing the Installation ............................................................................6-11

6.7 Alignment Error Correction .................................................................... 6-12

Performing Alignment Error Correction......................................................6-13

6.8 Magnetic Compass Calibration.............................................................. 6-14

Calibration Procedure Overview.................................................................6-14

6.9 Installation Check Procedures................................................................ 6-17

Environmental Conditions Check Procedure ..............................................6-17

Mechanical Installation Check Procedure ..................................................6-17

Electrical Installation Check Procedure ..................................................... 6-18

System Configuration Check Procedure ................................................... 6-18

Chapter 7: System Configuration

7.1 Service Setup 600 ..................................................................................... 7-1

Setup Access Code..................................................................................... 7-1

Service-Setup 600 – Overview .................................................................... 7-2

Service Setup 600 – Parameters................................................................. 7-7

7.2 Service Setup 610.................................................................................... 7-25

Setup Access Code................................................................................... 7-25

Service-Setup 610 – Overview .................................................................. 7-26

Service Setup 610 – Parameters ............................................................... 7-27

7.3 Service Setup 106.................................................................................... 7-31

Setup Access Code................................................................................... 7-31

Service-Setup 106 – Overview .................................................................. 7-32

Service Setup 106 – Parameters ............................................................... 7-33

7.4 Service Setup 998 ................................................................................... 7-36

Setup Access Code................................................................................... 7-36

Service-Setup 998 – Overview .................................................................. 7-37

056373/D NAVIGAT 100

vi

Chapter 8: Troubleshooting

8.1 Troubleshooting Instructions ................................................................... 8-1

8.2 Location of Parts on the NAVIGAT 100 Mainboard ................................ 8-2

Terminal Boards........................................................................................... 8-3

Connectors .................................................................................................. 8-4

Diagnostic LEDs.......................................................................................... 8-4

Chapter 9: Corrective Maintenance

9.1 NAVIGAT 100 Software Update................................................................ 9-2

Software Update Procedure ........................................................................ 9-4

Chapter 10: NAVIGAT 100 Spare Parts

10.1 Illustrated Parts List (IPL) Overview ...................................................... 10-1

Abbreviations

Appendix

A Setup and Configuration Tables

B Drawings

NAVIGAT 100 056373/D

Safety Instructions vii

Safety Instructions

Safety Notice Conventions

The following safety notice conventions are followed throughout this

manual:

DANGER

A Danger notice begins with the named type of

danger and contains an operating or mainte-

nance procedure, practice, condition, statement,

etc., which, if not strictly observed, will result in

injury or death of personnel.

WARNING

A Warning notice begins with the named type of

warning and contains an operating or mainte-

nance procedure, practice, condition, statement,

etc., which, if not strictly observed, could result

in injury or death of personnel.

CAUTION

A Caution notice begins with the named type of

caution and contains an operating or mainte-

nance procedure, practice, condition, statement,

etc., which, if not strictly observed, could result

in damage to, or destruction of equipment.

Note

A Note contains an essential operating or main-

tenance procedure, condition or statement,

which is considered important enough to be

highlighted.

Special safety symbols may be used in this

manual to indicate:

Risk of electrical shock.

Used in conjunction with a Danger or Warning

notice.

Electrical components sensitive to electrostatic

discharge.

Used in conjunction with a Caution notice.

056373/D NAVIGAT 100

viii Safety Instructions

General Safety Information for the Operator

WARNING

Risk of misusage

Before using the NAVIGAT 100, operators must be appropriately trained

and familiar with all operating procedures and safety instructions con-

tained in this manual. The manual is to be completely read before the

first usage of the NAVIGAT 100.

Keep this manual during the entire service life of the product and always

have it readily available in a nearby location for reference.

WARNING

Risk of deviation

Never rely on one heading source alone to navigate a vessel.

Always confirm the plausibility of the NAVIGAT 100 heading and the

speed and position input data against all available aids to navigation.

WARNING

Limited heading data accuracy during alignment

After a power-up from cold, the NAVIGAT 100 requires an alignment

time of three hours before reliable heading data are available.

Power up the system at least three hours before leaving harbour.

Power down the system during long docking periods only.

Make sure that the NAVIGAT 100 has settled before using its heading as

the reference for heading control systems, RADAR, ECDIS, etc.

A magnetic compass heading source should be selected as reference

only in case of failure of the gyrocompass(es).

WARNING

Limited heading data accuracy during settling time

After a reset of the gyrosphere, the NAVIGAT 100 requires a settling time

of up to ten minutes before reliable heading data are available.

Do not reset the gyrosphere when navigating.

Make sure that the NAVIGAT 100 has settled before using its heading as

the reference for heading control systems, RADAR, ECDIS, etc.

A magnetic compass heading source should be selected as reference

only in case of failure of the gyrocompass(es).

WARNING

Risk of deviation

In case the magnetic compass is selected as active heading source and

magnetic compass heading messages HDG or HDM are selected as

NMEA input, this messages always transfer uncorrected / not true head-

ing.

Navigating with the magnetic sensor as active heading source may

therefore cause deviation.

Always have in mind, that the gyrocompass is providing true heading

and is the more reliable active heading source.

A magnetic compass heading source should be selected as active head-

ing source only in case of failure of the gyrocompass(es).

NAVIGAT 100 056373/D

Safety Instructions ix

WARNING

Risk of Deviation

A manually entered speed value as GPS input mode may badly influence

the north speed error correction functionality of the system and cause

deviation.

Do not enter manual speed values as GPS input without good reason

and select automatic speed data input by GPS again as early as possible.

Always have in mind, that automatic speed data input by GPS is the

preferable option for long time stable operation of the system.

WARNING

Risk of Deviation

An inactivated north speed error correction will influence the function-

ality of the NAVIGAT 100 and cause deviation.

Never inactivate the north speed error correction without good reason

and activate the north speed error correction again as early as possible.

Always have in mind, that an active north speed error correction is the

required option for reliable heading functionality and long time stable

operation of the CompassNet system.

WARNING

Risk of Deviation

Loss of or invalid speed and/or position input data will flaw the north

speed error correction of the NAVIGAT 100 and cause deviation.

Always have in mind, that the north speed error correction needs valid

speed and position input for reliable heading functionality and long time

stable operation of the CompassNet system.

Note

In case of loss or invalid speed and/or position input data, the north

speed error correction value cannot be calculated anymore, „OFF“ and

dashes replacing the value indication are shown at the North speed error

correction secondary info page and a corresponding „NO GYRO CORR

(HDG MANAGER“ warning will be raised.

WARNING

Risk of Injury

Unprotected contact with loose (unpacked) supporting fluid is consid-

ered to be harmful to personnel. Never allow unprotected contact of

loose (unpacked) supporting fluid to eye or skin.

Always use safety gloves and safety glasses as personal protective

equipment (PPE) when handling with loose (unpacked) supporting fluid.

Note

Loose (unpacked) supporting fluid is considered to be harmful to the

environment and must always be treated and disposed of as black water.

Never treat used supporting fluid as grey water and pour overboard or

flush down a drain.

Always treat used supporting fluid as black water and dispose of by e.g.

flushing down a toilet.

Always follow the environmental regulations for black water treatment

with loose (unpacked) supporting fluid.

056373/D NAVIGAT 100

xSafety Instructions

CAUTION

Risk of unstable/unreliable heading in polar waters

When operating the vessel in polar waters, the heading information of

the gyrocompass may become unstable/unreliable resulting in possible

deviation. For safe steering in polar waters, the heading information of

the gyrocompass may therefore NOT be used for navigation and heading

information of a GNSS (Global Navigation Satellite System) compass be

preferred instead.

CAUTION

Risk of damage to the gyrosphere through shut-down

A shut down of the NAVIGAT 100 system, while the vessel is navigating,

will damage the gyrosphere, as the gyrosphere is only self protected

against physical damage, as long as the system is running.

NEVER shut down the NAVIGAT 100, while the vessel is navigating.

A shut down of the NAVIGAT 100 system for good reason is only possible

when the ship is NOT navigating.

Note

Sperry Marine requires to NOT shut down the NAVIGAT 100 system as

long as the vessel is navigating, even when operating in polar waters

with possible unstable/unreliable heading.

CAUTION

Risk of damage/destruction through low temperatures

The supporting fluid in the gyrosphere container will start freezing at

temperatures below 0° C.

The NAVIGAT 100 must no longer be operated when the ambient tem-

perature at the gyrocompass’ location falls below - 10° C while the com-

pass is in operation or when the ambient temperature falls below 0° C

while the gyrocompass is not in operation.

Always make sure, that the ambient temperature is higher than 0° C

respective 10° C. If this is not possible, the gyrosphere container with

gyrosphere must be removed from the NAVIGAT 100 and transported to

a place with sufficient ambient temperature.

Make sure to remove the gyrosphere from the gyrosphere container if no

place with sufficient ambient temperature is available to eliminate dam-

age from freezing supporting fluid. The removal is to be executed in a

service work procedure by authorized service personnel only.

CAUTION

Risk of damage through unauthorized service

Scheduled maintenance or service work on the gyrosphere is to be car-

ried out by authorized service personnel only.

CAUTION

Risk of damage through unauthorized service

Only authorized service personnel is allowed to remove the gyrosphere

from the gyrosphere container.

Always keep to the mandatory safety requirements and the correct ser-

vice work procedure to remove the gyrosphere from the gyrosphere con-

tainer.

NAVIGAT 100 056373/D

Safety Instructions xi

CAUTION

Risk of mercury contamination

The gyrosphere type 3 and the gyrosphere container mod. 10/3 and

mod. 10/4 are designed for mercury free operation. Any usage of mer-

cury will severely contaminate the gyrosphere type 3 / gyrosphere con-

tainer mod. 10/3.

Never use mercury with the gyrosphere type 3 and the gyrosphere con-

tainer mod. 10/3.

In case of usage of mercury by mistake, the contaminated equipment

must not be used and all safety instructions of the Sperry Marine Mer-

cury Handling Procedure 026150-0000-000 must be followed accordingly.

CAUTION

Risk of defective gyrosphere caused by “GYRO FAILURE”

Should a “GYRO FAILURE” alarm occur during power-up, the compass

is not working properly.

De-energize the system and visually check the connections to the gyro-

sphere, the follow-up step motor and the shaft encoder.

If the failure reoccurs when the compass is powered-up again, the instal-

lation has not been carried out correctly or the gyrosphere is defective

and must be replaced.

CAUTION

Risk of damage through aggressive cleaning agents

Do not clean the compass with organic solvents, acetone or any other

substance which could damage or discolour plastic.

Only use water and soap or a mild detergent to clean the compass.

CAUTION

Risk of damage through overheating

A polluted or clogged air inlet grill located at the back side of the compass

housing will decrease the functionality of the cooling fan and cause over-

heating of the gyrocompass.

Always maintain the required distances around the compass housing to

enable sufficient air supply and full cooling fan functionality.

Make sure to regularly clean the air inlet grill from dust and dirt and check

the cooling fan functionality to avoid overheating.

CAUTION

Risk of damage through rotating masses

After power-down of the compass system, the gyroscopes need at least

45 minutes to stop rotating. Opening the container or draining off the

supporting fluid during rotating will damage the gyrosphere.

Wait at least 45 minutes after power-down of the compass system and

make sure, that the gyroscopes have stopped rotating before opening the

container or draining off the supporting fluid.

CAUTION

Risk of damage through misusage

Scheduled maintenance or service work on the gyrosphere is to be car-

ried out by authorized service personnel only.

CAUTION

Risk of damage through unauthorized service

Any service and installation work on the gyrosphere is to be carried out

by authorized service personnel only.

Never undertake service or installation work if unskilled for the certain

procedure.

056373/D NAVIGAT 100

xii Safety Instructions

CAUTION

Risk of damage through unauthorized service

Only authorized service personnel is allowed to remove the gyrosphere

from the gyrosphere container.

Always keep to the mandatory safety requirements and the correct ser-

vice work procedure to remove the gyrosphere from the gyrosphere con-

tainer.

CAUTION

Risk of damage through unauthorized service

Only authorized service personnel is allowed to remove gyrocompass

system components from the compass housing.

Always keep to the mandatory safety requirements and the correct ser-

vice work procedures to remove gyrocompass system components from

the compass housing.

CAUTION

Risk of damage to the gyrosphere

The gyrosphere is always to be transported in its carrying box in the orig-

inal transport container.

Do not throw or drop the transport container.

The transport container is to be transported in an upright position only.

CAUTION

Risk of damage to the gyrosphere

Carry the carrying box containing the gyrosphere by hand only and han-

dle it with extreme care.

Remove the gyrosphere from the carrying box only if required for imme-

diate installation.

CAUTION

Risk of data loss through shutdown of the compass / power-off condition

After a shutdown of the compasses main and backup power supplies it

cannot be guaranteed that all menu settings remain stored unchanged.

Always check that the alignment error correction value is noted correctly

in the setup tables, before switching-off the power supplies, see “Setup

and Configuration Tables” on page A-1 Appendix.

Always make sure to separately note the alignment error correction

value before switching-down the compass for maintenance or repair pur-

poses.

Note

A visual inspection of cables and connectors of the gyrocompass should

be carried out regularly to detect any signs of damage or deterioration.

Note

In case a „Speed Invalid“ alarm is triggered while the vessel is not in

motion or moving very slowly (e.g. when manoeuvring in harbour), this

is often caused by fast currents of fairway water increasing the - 5.0 kn

minimum speed default value.

In this case, the minimum speed value must be adjusted accordingly.

Note

The access code for the setup menu to reset the gyrosphere operation

time counter is disclosed to authorized service personnel only and is not

described in this manual.

NAVIGAT 100 056373/D

Safety Instructions xiii

Note

The NAVIGAT 100 provides a serial bidirectional interface for a central

alert management system (CAM) according to specified standards ISO

16328 and IEC 61924-2.

Note

All alerts of the NAVIGAT 100 gyrocompass system are category B alerts

according to IEC 61924-2.

Note

For installation and service procedures of the gyrosphere and gyro-

sphere container, the following separate Installation, Maintenance and

Service Procedures, delivered with the gyrosphere, are applicable:

- 5026-0125-01, for gyrosphere type 3, gyrosphere container mod. 10/3.

- 5000-0125-03, for gyrosphere type 3, gyrosphere container mod. 10/4.

Note

Sperry Marine Service:

In case of service refer to www.sperrymarine.com/offices for a list of

all Sperry Marine Offices and Service Agents worldwide.

056373/D NAVIGAT 100

xiv Safety Instructions

General Safety Information for Service Personnel

DANGER

Life danger through electrical shock

When the NAVIGAT 100 compass is energized, the gyrosphere operating

voltage of 100 VAC @ 333 Hz is present on the NAVIGAT 100 mainboard,

the gyrosphere supply lines, and across the gyrosphere contacts.

Make sure that the main and backup power supplies of the compass are

always switched off and safeguarded against accidental switching-on

before undertaking any removal or installation procedures of the gyro-

sphere container.

DANGER

Life danger through electrical shock

When the compass is energized (main and/or backup supply present),

the gyrosphere operating voltage of 100 VAC @ 333 Hz is present on the

NAVIGAT 100 mainboard, the gyrosphere supply lines and across the

gyrosphere contacts.

Always make sure the compass' main and backup power supplies are

always switched off and safeguarded against accidental switching-on

when undertaking any service procedures of the gyrosphere,

DANGER

Life danger through electrical shock

When the compass is energized (main and/or backup supply present),

the gyrosphere operating voltage of 100 VAC @ 333 Hz is present on the

NAVIGAT 100 mainboard, the gyrosphere supply lines and across the

gyrosphere contacts.

Always make sure the compass' main and backup power supplies are

switched off and safeguarded against accidental switching-on when

wiring up the system.

DANGER

Life danger through electrical shock

When the compass is energized, the gyrosphere operating voltage of

100 VAC @ 333 Hz is present on the NAVIGAT 100 mainboard, the gyro-

sphere supply lines and across the gyrosphere contacts.

Be extremely careful when operating the compass while the housing is

open. Do not touch the NAVIGAT 100 mainboard, the connecting cables

to the gyrosphere container or any other conductive components on the

container or in the compass housing.

Always exclude any contact to energized components.

WARNING

Risk of deviation

During software update no reliable heading data are available from the

NAVIGAT 100 gyrocompass.

Do not apply software update procedures while the ship is navigating.

Always make sure to undertake software update procedures only while

the ship is not navigating, e.g. when in harbour downtime.

Note

The NAVIGAT 100 software update procedure is to be performed while

the gyrocompass is operating. It is not required to power down before

and to power up the system after the software update procedure.

NAVIGAT 100 056373/D

Safety Instructions xv

WARNING

Risk of Injury

Unprotected contact with loose (unpacked) supporting fluid is consid-

ered to be harmful to personnel. Never allow unprotected contact of

loose (unpacked) supporting fluid to eye or skin.

Always use safety gloves and safety glasses as personal protective

equipment (PPE) when handling with loose (unpacked) supporting fluid.

Note

Loose (unpacked) supporting fluid is considered to be harmful to the

environment and must always be treated and disposed of as black water.

Never treat used supporting fluid as grey water and pour overboard or

flush down a drain.

Always treat used supporting fluid as black water and dispose of by e.g.

flushing down a toilet.

Always follow the environmental regulations for black water treatment

with loose (unpacked) supporting fluid.

CAUTION

Risk of data loss through shutdown of the compass / power-off condition

After a shutdown of the compasses main and backup power supplies it

cannot be guaranteed that all menu settings remain stored unchanged.

Always check that the alignment error correction value is noted correctly

in the setup tables, before switching-off the power supplies, see “Setup

and Configuration Tables” on page A-1 Appendix.

Always make sure to separately note the alignment error correction

value before switching-down the compass for maintenance or repair pur-

poses.

CAUTION

Risk of damage/destruction after power-down

After power-down of the gyrocompass system, it may take up to

45 minutes for the gyroscopes to stop rotating and the gyrosphere is

therefore extremely sensible against any movement. Should the gyro-

sphere touch the wall of the container, the momentum of the rotating

gyroscopes will make it topple and damage the centre pin.

Avoid any movement of the gyrocompass system during power-down

time. Always be extremely careful in case the gyrosphere container must

be handled during power-down time.

CAUTION

Risk of damage/destruction through transport/wrong storing

When the container with the gyrosphere installed is temporarily stored

away, pack it into its original transport box or another suitable outer

package.

Always make sure that:

- the container is stored in an upright position,

- the temperature at the storage location cannot fall below 0°C,

- the container is not moved, tilted or subjected to shock.

056373/D NAVIGAT 100

xvi Safety Instructions

CAUTION

Risk of damage/restricted freedom of roll and pitch

An overhanging gyrosphere supply and pick off cable may restrict the

freedom of roll and pitch of the gyrosphere container.

The gyrosphere container can only use its full freedom of roll and pitch

when the gyrosphere supply and pick off cable is pushed deeply into the

bellows and the cable length minimized.

Always make sure to deeply push the gyrosphere supply and pick off

cable into the bellows to minimize the cable length when installing the

gyrosphere container. Never allow overhanging of the gyrosphere sup-

ply and pick off cable when installing the gyrosphere container.

CAUTION

Risk of damage to the gyrosphere

The gyrosphere is always to be transported in its carrying box in the orig-

inal transport container.

Do not throw or drop the transport container.

The transport container is to be transported in an upright position only.

CAUTION

Risk of damage to the gyrosphere

Carry the carrying box containing the gyrosphere by hand only and han-

dle it with extreme care.

Remove the gyroshpere from the carrying box only if required for imme-

diate installation.

CAUTION

Risk of EMC exceeding

Sperry Marine requires to install the main power and a backup power

supply for the NAVIGAT 100 through the strip-wound core inside the

compass housing to meet EMC values.

Never install the power supplies of the NAVIGAT 100 without using the

strip-wound core.

CAUTION

Risk of malfunction through wrong wiring

Wrong wiring, especially as running wires from one side of the compass

housing to the other or across the NAVIGAT 100 mainboard will cause

malfunction.

Always use the cable inlets on both sides of the compass housing for

accurate wiring and keep all wires running inside the housing as short as

possible.

Always avoid to run wires from one side of the compass housing across

to the other.

CAUTION

Risk of earth faults

Wrong wiring of the cable shields makes the cables act as antennas

resulting in earth faults.

Always make sure to correctly draw back the cable shields and fasten the

cables to avoid earth faults.

NAVIGAT 100 056373/D

Safety Instructions xvii

CAUTION

Risk of mercury contamination

The gyrosphere type 3 and the gyrosphere container mod. 10/3 and

mod. 10/4 are designed for mercury free operation. Any usage of mer-

cury will severely contaminate the gyrosphere type 3 / gyrosphere con-

tainer mod. 10/3.

Never use mercury with the gyrosphere type 3 and the gyrosphere con-

tainer mod. 10/3.

In case of usage of mercury by mistake, the contaminated equipment

must not be used and all safety instructions of the Sperry Marine Mer-

cury Handling Procedure 026150-0000-000 must be followed accordingly.

CAUTION

Risk of defective gyrosphere caused by “GYRO FAILURE”

Should a “GYRO FAILURE” alarm occur during power-up, the compass

is not working properly.

De-energize the system and visually check the connections to the gyro-

sphere, the follow-up step motor and the shaft encoder.

If the failure reoccurs when the compass is powered-up again, the instal-

lation has not been carried out correctly or the gyrosphere is defective

and must be replaced.

CAUTION

Risk of inaccurate alignment error correction

The compass must have been in continuous operation for at least 4 hours

before the alignment error can be determined accurately.

If bearing repeaters are used to determine the true heading, these must

be properly aligned to the vessel's fore-and-aft axis.

CAUTION

Risk of inaccurate magnetic compass calibration

The magnetic compass heading calibration corrects deviations due to the

combined effects of the magnetic environment, the particular sensor

being used and the receiving circuitry on the NAVIGAT 100 mainboard.

Therefore, a new calibration must always be carried out when:

- the steering magnetic compass is exchanged or newly adjusted,

- the magnetic compass heading sensor is exchanged and,

- when the NAVIGAT 100 mainboard is exchanged, in case a fluxgate sen-

sor is used.

Never use a true heading source, e.g. a gyrocompass, as the calibration

reference.

Never attempt to correct residual deviations of a properly adjusted mag-

netic compass by means of the calibration table.

CAUTION

Risk of inaccurate magnetic compass calibration

The magnetic compass used as the calibration reference must be prop-

erly installed and adjusted.

The procedure should be carried out in calm seas only.

CAUTION

Risk of inoperable device state

Updating a device’s firmware is a risky operation, as SUSI writes directly

to the device’s flash memory.

Under adverse circumstances, a failed update attempt may leave the

device in an inoperable state.

Always maintain a stable power supply during the update process.

Never interrupt an update in progress.

056373/D NAVIGAT 100

xviii Safety Instructions

CAUTION

Risk of damage of electrostatic-discharge-sensitive components

The NAVIGAT 100 contains electrostatic sensitive components.

Electrostatic discharge may permanently damage components.

When servicing the NAVIGAT 100, take considerable precautions to pre-

vent electrostatic discharge. Avoid touching any of the electronic cir-

cuitry.

CAUTION

Risk of loss of parameter settings through software exchange

It cannot be guaranteed that parameter settings in the Manual Settings,

Monitoring and Service Setup menus and the entries made in the Mag-

netic Compass Calibration table are left intact when the software is

exchanged.

Before exchanging the system software, record all parameter settings to

be able to re-enter them manually, if required.

Note

The NAVIGAT 100 provides a serial bidirectional interface for a central

alert management system (CAM) according to specified standards ISO

16328 and IEC 61924-2.

Note

All alerts of the NAVIGAT 100 gyrocompass system are category B alerts

according to IEC 61924-2.

Note

For installation and service procedures of the gyrosphere and gyro-

sphere container, the following separate Installation, Maintenance and

Service Procedures, delivered with the gyrosphere, are applicable:

- 5026-0125-01, for gyrosphere type 3, gyrosphere container mod. 10/3.

- 5000-0125-03, for gyrosphere type 3, gyrosphere container mod. 10/4.

NAVIGAT 100 056373/D

System Description 1-1

Chapter 1: Introduction

1.1 System Description

Intended Use

The NAVIGAT 100 is a digital gyrocompass standalone system for the

maritime navigation of vessels and must be operated only from appro-

priately trained and educated personnel familiar with all mandatory

safety and operating procedures.

The NAVIGAT 100 provides North-speed error corrected true heading

data as well as rate of turn (ROT) data for the navigation of maritime

vessels.

The NAVIGAT 100 is not designed to operate in a dual gyrocompass con-

figuration or as part of the Sperry Marine CompassNet (CN) Heading

Management System (HMS).

Not Intended Use

The NAVIGAT 100 and/or the provided true heading and ROT data of the

NAVIGAT 100 are not allowed to be used for the navigation of inland

water vessels and river boats.

Although the NAVIGAT 100 is a highly accurate system for providing

true heading and ROT data, operators must not rely on it solely as the

only heading source. The plausibility of the NAVIGAT 100 heading and

ROT data and the speed and position input data (as secondary data)

must always be confirmed against all other available aids to navigation.

Since the NAVIGAT 100 system can additionally be used for displaying

secondary navigation data (speed and position input data) generated

from other connected devices, the operator must not take displayed sec-

ondary data for granted and is obliged to confirm the validity of second-

ary data independently.

When navigating in polar waters (according to E190E IMO Guidelines

definition), the heading information of the gyrocompass may become

unstable/unreliable, due to physical principles, resulting in possible

deviation. For safe steering of the vessel in polar waters, the heading

information of the gyrocompass may therefore not be used and heading

information of a GNSS (Global Navigation Satellite System) compass be

preferred instead.

056373/D NAVIGAT 100

1-2 System Overview and Main Components

1.2 System Overview and Main Components

Figure 1-1:

NAVIGAT 100 housing

Figure 1-2:

Control and display unit

(CDU)

MENU

MUTE

DIM - DIM +

ENTER

ACK

Table of contents

Other SperryMarine Marine GPS System manuals