SPETEC SuSi FMS Series Quick guide

Laminar flow systems

Translation of the original operating instructions

6.0 2020

Legal notice

Legal notice

SPETEC® GmbH

Am Kletthamer Feld 15

85435 Erding

Germany

Telephone: +49(0) 8122 95909-0

Fax: +49(0) 8122 95909-55

E-mail: [email protected]

Website: www.spetec.de

26.0 2020

Foreword

Foreword

Thank you for choosing to purchase a clean room system from Spetec. The clean room system is ideal for use in

industry and research.

The following pages provide instructions on proper and careful use of your clean room system as well as

information for servicing and maintenance.

6.0 2020 3

Table of contents

Table of contents

1 EC Declaration of Conformity............................................................................ 6

2 General information............................................................................................ 7

2.1 General information concerning these instructions................................................ 7

2.2 Explanation of symbols.......................................................................................... 7

2.3 Structure of safety information............................................................................... 8

2.4 On these operation instructions............................................................................. 8

2.5 Intended target groups........................................................................................... 9

2.6 Type plate............................................................................................................... 9

3 Technical data...................................................................................................... 10

3.1 Clean room systems............................................................................................... 10

3.2 Power consumption................................................................................................ 11

3.2.1 Laminar flow module.................................................................................. 11

3.2.2 Clean room stations and workstations....................................................... 11

3.3 Filter sizes............................................................................................................... 12

3.3.1 Laminar flow module.................................................................................. 12

3.3.2 Laminar flow boxes..................................................................................... 12

3.3.3 Clean room stations and workstations....................................................... 14

3.4 Dimensions............................................................................................................. 15

3.5 Internal dimensions of the frame of the laminar flow module................................. 16

4 Safety.................................................................................................................... 17

4.1 General safety information..................................................................................... 17

4.2 Safety equipment.................................................................................................... 18

4.3 Personal protective equipment............................................................................... 18

4.4 Foreseeable misuse............................................................................................... 19

4.5 Before use.............................................................................................................. 19

5 Description of the clean room system.............................................................. 20

5.1 Laminar flow module.............................................................................................. 20

5.2 Laminar flow box.................................................................................................... 21

5.2.1 Laminar flow box........................................................................................ 21

5.2.2 Exhaust flow box........................................................................................ 24

5.3 Protection box......................................................................................................... 25

5.4 Exhaust (protection) box........................................................................................ 25

5.5 Clean room stations and workstations................................................................... 26

6 Installing the clean room system...................................................................... 28

6.1 Installing the FMS series SuSi............................................................................... 29

6.2 Installing the FMS basic......................................................................................... 31

6.3 Installing the FBS-V series SuSi and EFBS-V series SuSi.................................... 33

46.0 2020

Table of contents

7 Commissioning.................................................................................................... 34

7.1 Connecting the cables............................................................................................ 34

7.2 Connectors.............................................................................................................. 35

8 Operation.............................................................................................................. 37

8.1 SuSi clean room systems....................................................................................... 37

8.2 Basic clean room systems..................................................................................... 39

8.3 EFBS, EFBS-V and EBS series clean room systems............................................ 40

9 Troubleshooting................................................................................................... 40

10 Maintenance......................................................................................................... 41

10.1 Care and service.................................................................................................... 41

10.2 Filter change........................................................................................................... 42

10.2.1 Changing the pre-filter................................................................................ 43

10.2.2 Changing the main filter on standalone devices........................................ 44

10.2.3 Changing the main filter on clean room cells and suspended laminar flow

modules....................................................................................................... 45

11 Cleaning................................................................................................................ 47

12 Disassembly and disposal................................................................................. 47

12.1 Disassembly............................................................................................................ 47

12.2 Disposal.................................................................................................................. 47

13 Spare parts list.................................................................................................... 48

14 Warranty conditions............................................................................................ 49

14.1 Warranty and liability.............................................................................................. 49

6.0 2020 5

EC Declaration of Conformity

1 EC Declaration of Conformity

In accordance with the Low Voltage Directive 2014/35/EU

and the Machinery Directive 2006/42/EC

and the Electromagnetic Compatibility Directive 2014/30/EU

We hereby declare that the following product, on the basis of its design and construction, in the configuration

placed on the market by us, satisfies the fundamental requirements of the aforementioned EU/EC directives.

Product

Product description

FMS 24 –112/2017

Laminar flow module

Standards applied:

Safety EN 292

EN 294

EN 60024-1

EN 954-1

EN 61310-1

Electromagnetic

Compatibility (EMC)

EN 55011:2009, Group 1, Class B

EN 61000-3-2:2006+A1:2009+A2:2009, Class A

EN 61000-6-2:2005

This Declaration of Conformity shall cease to be valid if the machine is converted or modified without our consent.

This declaration is made for and on behalf of the manufacturer.

Spetec GmbH

Am Kletthamer Feld 15

85435 Erding, Germany

Issued by: Karl Mairoth

Position in company: Product Manager

Erding,

Germany 26 March 2018

Place Date Signature

66.0 2020

General information

2 General information

2.1 General information concerning these instructions

Please read these instructions in full before commissioning the clean room system. They outline the way in which

it should be used and point out potential hazards.

2.2 Explanation of symbols

The clean room cell is not designed for

accessing the ceiling area.

When installing a clean room system or

carrying out a filter change, do no step under

suspended loads or parts.

6.0 2020 7

General information

2.3 Structure of safety information

The safety information in these instructions is presented in a standardised format with standardised symbols.

Observe the information provided. The hazard classes outlined are used according to the likelihood of occurrence

and the severity of the consequence.

Safety information

DANGER!

Imminent hazard with high risk

This could result in death or serious injury if the risk is not avoided.

WARNING!

Potential hazard with moderate risk

This could result in death or serious injury if the risk is not avoided.

CAUTION!

Hazard with low risk

This could result in minor or moderate injury or material damage if the risk is not avoided.

Information

NOTICE

Mandatory instructions.

User tips and other especially useful information.

2.4 On these operation instructions

Instructions

Steps that need to be carried out are presented as numbered lists. The sequence of the steps must be followed.

Example:

1. Step

2. Step

The results of an instruction are presented as follows:

Result 1

Result 2

Lists

Lists without a strict sequence are presented as bullet-point lists.

Example:

■Point 1

■Point 2

86.0 2020

General information

2.5 Intended target groups

The target groups for these operating instructions are operating and maintenance personnel, i.e. trained and

instructed technicians or trained production workers. These persons carry out work in accordance with the

authorisation granted by the operating company. These persons must have the expertise required to carry out

the work based on their professional training or comparable on-the-job training and be able to carry out the work

properly and with skill that takes into account safety and potential hazards. Their work shall be briefed, checked

and overseen by trained supervisory personnel/specialist personnel appointed by the operating company. Only

trained specialist personnel with appropriate personal protective equipment may enter the clean room cell to carry

out a filter change.

2.6 Type plate

Each product group has a type plate bearing the key data in accordance with the Machinery Directive

2006/42/EC.

In the event that a clean room system comprises multiple parts, a part number (Pn) and type plate must be affixed

for each clean room system.

In the event of individual solutions, the type plate is attached to the cable remote control.

6.0 2020 9

Technical data

3 Technical data

3.1 Clean room systems

Clean room systems

■FMS series SuSi

■FMS basic

■FBS series SuSi

■FBS-V series SuSi

■FMS series standard

■EBS series SuSi

■EFBS series SuSi

■EFBS-V series SuSi

Power supply 230 V AC

Frequency 50/60 Hz

Fuse Si: M 3.15 A

Temperature range +10°C to +50°C

Humidity 20% to 80% non-condensing

Clean room systems with acid-resistant fume cupboard

■EFBS series SuSi

■EFBS-V series SuSi

■EBS series SuSi

Power data for acid-resistant extraction

Brushless EC motor power supply 230 V AC

Frequency 50/60 Hz

Power consumption 20 W

Fuse Si: M 1.60 A

Extraction power max. 60 m3/h

Air vents, diameter 100 mm

Temperature range +10°C to +50°C

Humidity 20% to 80% non-condensing

10 6.0 2020

Technical data

Clean room workstations

■CleanBoy maxi

■CleanBoy mini

■CleanBoy basic

Power supply 230 V AC

Frequency 50/60 Hz

Fuse Si: M 3.15 A

Temperature range +10°C to +50°C

Humidity 20% to 80% non-condensing

3.2 Power consumption

3.2.1 Laminar flow module

FMS series SuSi

Size Average power consumption at 0.4 m/s

in W

Maximum power consumption in W

37 60 265

56 85 265

75 125 510

93 155 510

112 140 510

FMS series basic

Size Average power consumption at 0.4 m/s

in W

Maximum power consumption in W

75 115 285

3.2.2 Clean room stations and workstations

CleanBoy basic

Size Average power consumption at 0.4 m/s

in W

Maximum power consumption in W

75 115 285

6.0 2020 11

Technical data

3.3 Filter sizes

3.3.1 Laminar flow module

FMS series SuSi

Designation Filter dimensions in mm Weight in kg

Laminar flow module FMS 24* 610 x 400 20

Laminar flow module FMS 37 610 x 610 31

Laminar flow module FMS 56 915 x 610 37

Laminar flow module FMS 75 1220 x 610 52

Laminar flow module FMS 93 1525 x 610 58

Laminar flow module FMS 112 1830 x 610 64

* Special version

FMS series basic

Designation Filter dimensions in mm Weight in kg

Laminar flow module FMS 75 1220 x 610 30

3.3.2 Laminar flow boxes

FBS series SuSi

Designation Filter dimensions in mm Weight in kg

Laminar flow box FBS 37 610 x 610 77

Laminar flow box FBS 56 915 x 610 92

Laminar flow box FBS 75 1220 x 610 114

Laminar flow box FBS 93 1525 x 610 129

Laminar flow box FBS 112 1830 x 610 145

FMS series standard

Designation Filter dimensions in mm Weight in kg

Laminar flow box FBS 37 standard 610 x 610 57

Laminar flow box FBS 56 standard 915 x 610 67

Laminar flow box FBS 75 standard 1220 x 610 86

Laminar flow box FBS 93 standard 1525 x 610 96

Laminar flow box FBS 112 standard 1830 x 610 106

12 6.0 2020

Technical data

EFBS series SuSi

Designation Filter dimensions in mm Weight in kg

Laminar flow box EFBS 37 610 x 610 84

Laminar flow box EFBS 56 915 x 610 99

Laminar flow box EFBS 75 1220 x 610 121

Laminar flow box EFBS 93 1525 x 610 136

Laminar flow box EFBS 112 1830 x 610 152

EFBS-V series SuSi

Designation Filter dimensions in mm Weight in kg

Laminar flow box EFBS-V 37 610 x 610 71

Laminar flow box EFBS-V 56 915 x 610 81

Laminar flow box EFBS-V 75 1220 x 610 101

Laminar flow box EFBS-V 93 1525 x 610 115

Laminar flow box EFBS-V 112 1830 x 610 126

FBS-V series SuSi

Designation Filter dimensions in mm Weight in kg

Laminar flow box FBS-V 37 610 x 610 64

Laminar flow box FBS-V 56 915 x 610 74

Laminar flow box FBS-V 75 1220 x 610 94

Laminar flow box FBS-V 93 1525 x 610 108

Laminar flow box FBS-V 112 1830 x 610 119

6.0 2020 13

Technical data

3.3.3 Clean room stations and workstations

CleanBoy mini/maxi

Designation Filter dimensions in mm

CleanBoy 37 610 x 610

CleanBoy 56 915 x 610

CleanBoy 75 1220 x 610

CleanBoy 93 1525 x 610

CleanBoy 112 1830 x 610

CleanBoy mini/maxi basic

Designation Filter dimensions in mm

CleanBoy basic 75 1220 x 610

14 6.0 2020

Technical data

3.4 Dimensions

The dimensions apply for the following clean room systems:

■FBS series

■EFBS series

■PBS series

■EBS series

Size Dimensions in mm

37 645 x 735

56 950 x 1040

75 1255 x 1345

93 1560 x 1650

112 1865 x 1955

The dimensions apply for the following clean room systems:

■CleanBoy mini

■CleanBoy maxi

Size Width in mm

37 735

56 1040

75 1345

93 1650

112 1955

6.0 2020 15

Technical data

3.5 Internal dimensions of the frame of the laminar flow module

Internal dimensions of the frame from above

Designation Width in mm Length in mm

Laminar flow module FMS 37 645 645

Laminar flow module FMS 56 645 950

Laminar flow module FMS 75 645 1255

Laminar flow module FMS 93 645 1560

Laminar flow module FMS 112 645 1865

Internal dimensions of the frame from below

Designation Width in mm Length in mm

Laminar flow module FMS 37 680 685

Laminar flow module FMS 56 680 990

Laminar flow module FMS 75 680 1295

Laminar flow module FMS 93 680 1600

Laminar flow module FMS 112 680 1905

16 6.0 2020

Safety

4 Safety

4.1 General safety information

DANGER!

Danger of death due to electrical voltage to 230 V/50 Hz

This could result in death or serious injury.

■Do not touch live parts.

■Do not attach earths to mechanical connecting elements.

DANGER!

Danger of death due to residual voltages in capacitors on fan motors.

Contact with fan motors could result in death or serious injury.

■Do not touch metallic parts.

■Conversion work and maintenance may only be carried out with the clean room system switched off and

secured against reactivation.

WARNING!

Risk of injury due to voltages on the clean room system

This could result in serious injury or death.

■Remove the mains plug of the clean room system before opening the clean room system.

WARNING!

Risk of injury due to rotating parts

This could result in serious injury or death.

■Do not reach into mechanical moving parts.

■Conversion work and maintenance may only be carried out with the clean room system switched off and

secured against reactivation.

WARNING!

Risk of injury due to falling parts

This could result in serious injury or death.

■Do not stand under the main filter when carrying out a main filter change.

■A filter change must be carried out by two people.

■Do not stand under suspended loads when installing the clean room system.

6.0 2020 17

Safety

WARNING!

Risk of injury due to restoration of energy supply after an interruption

This could result in serious injury or death.

■Troubleshooting and maintenance may only be carried out with the clean room system switched off and

secured against reactivation.

4.2 Safety equipment

The clean room system does not have a mechanical emergency stop.

Safety equipment Function

Contact protection The pre-filter is protected by a grille to prevent objects from falling into the air

inlet.

4.3 Personal protective equipment

To prevent accidents, operating and maintenance personnel must wear personal protective equipment.

Protective work clothes

Protective work clothes are close-fitting clothes with low tear resistance, narrow sleeves

and no protruding parts. They are primarily designed to prevent the user from becoming

caught on moving machine parts. Do not wear rings, chains and other jewellery.

Safety goggles

Wear non-breakable safety goggles with side protection as compressed-air, splashed

water and flying chips can cause serious eye damage, including loss of sight.

Ear protection

Ear protection must be worn to prevent hearing damage. Ear protection must be worn if

exceptional operations cause noise emissions to exceed the legal limit of 70 dB(A).

Safety shoes

Safety shoes are designed to protect against heavy falling parts and slipping on slippery

ground.

18 6.0 2020

Safety

4.4 Foreseeable misuse

Disregard of the information provided or of the intended use can lead to (permanent) damage to the clean room

system. It can also lead to impaired operational safety.

The clean room system must not be operated under the following conditions:

■Outside of the national stipulations and rules.

■Outside of the values defined in the technical data.

■Where there is a risk of direct lightning strike or impact in the vicinity.

4.5 Before use

■Check that the supply voltage matches that on the type plate.

■Observe the legal stipulations for electrical commissioning.

■The clean room system may only be connected to a socket fitted with a protective conductor terminal.

■Do not reach into mechanical moving parts.

■Remove the mains plug before opening the casing.

■Remove the mains plug before changing the fuse. Use only the fuse types listed here.

■Conversions and attachments to the clean room system are permitted only with the consent of Spetec.

6.0 2020 19

Description of the clean room system

5 Description of the clean room system

Product series:

■Laminar flow module (FMS series)

■Laminar flow boxes (FBS, EFBS series)

■Protection box (PBS series)

■Exhaust (protection) box (EBS series)

■Clean room stations and workstations (CleanBoy)

The series of devices is modular in construction, which means that individual components are mutually compatible

and expandable.

5.1 Laminar flow module

The following versions of the laminar flow module are available:

■FMS series SuSi

■FMS series basic

The FMS series is a filter module equipped with pre-filters and a main filter of type H 14.

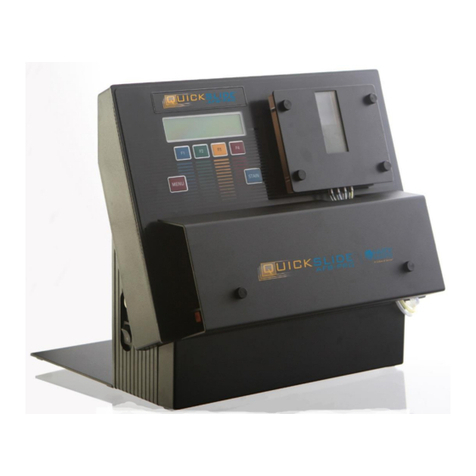

FMS series SuSi

The FMS series SuSi is a filter module with a display and can be converted into a laminar flow box.

20 6.0 2020

This manual suits for next models

39

Table of contents

Popular Laboratory Equipment manuals by other brands

Unit

Unit UTi85H+ user manual

Bio-Science

Bio-Science Ampulmatic-10 Purge Gas Injector Operation and maintenance manual

PerkinElmer

PerkinElmer OPTIMA 8000 Customer Hardware and Service Guide

Koehler

Koehler K3919 Series Operation and instruction manual

Thermo Scientific

Thermo Scientific 3962 operating manual

Leica

Leica TP1020 Instructions for use

Leica

Leica EM TXP operating manual

Hardy Diagnostics

Hardy Diagnostics QuickSlide AFB-PRO User's operation manual

MGI

MGI Complete Genomics DNBSEQ-G800RS user manual

BIO RAD

BIO RAD iCycler quick guide

Thermo Scientific

Thermo Scientific F6000 Installation and operation manual

Hach

Hach TitraLab AT1000 Series Basic user manual