Sphenic Technologies Inc. SPDi Spark User manual

SPDi Plasma Ignition

Installation Manual

V o l k s w a g e n 1 . 8 T P a g e | 1/4

Engine: Volkswagen/ Audi 1.8 Turbo

Safety Instructions: (Please read and understand these safety instructions thoroughly prior to use)

1. This kit is designed to be installed on the Volkswagen 1.8T engine. SPDi kits are available for other engine types.

2. This kit should be installed by a knowledgeable, professional mechanic.

3. Prior to beginning installation, ensure that your vehicle is situated in a safe manner: a) place vehicle on a flat level

surface; b) turn the engine off and allow it to cool; c) remove the ignition key; d) automatic transmissions should be

placed in park, e) manual transmissions should be placed in gear or in neutral with the emergency brake engaged

4. It is recommended, but not essential, that the negative battery cable is disconnected during installation. Please consult

the vehicle owner's manual to determine if there are any issues related to the alarm system or vehicle computer systems

prior to disconnecting the battery.

5. SPDi should only be installed on engines in good operating condition. Engine defects should be corrected (repaired) prior

to SPDi installation. Check engine lights should be investigated and corrected.

6. Hazard: The SPDi module does not contain any user replaceable parts. Do not attempt to open, dismantle or modify the

SPDi module for any reason. An electrical shock risk exists even when the unit is not powered.

Notes:

1. Spark Plugs: It is highly recommended that new Spark Plugs are installed with SPDi.

2. Custom Tunes: Custom tuned engines will benefit from adjusting the air/fuel mixture and ignition timing to complement

SPDi technology.

3. Defects: If any defects are discovered with the SPDi system, immediately discontinue use and contact your SPDi dealer.

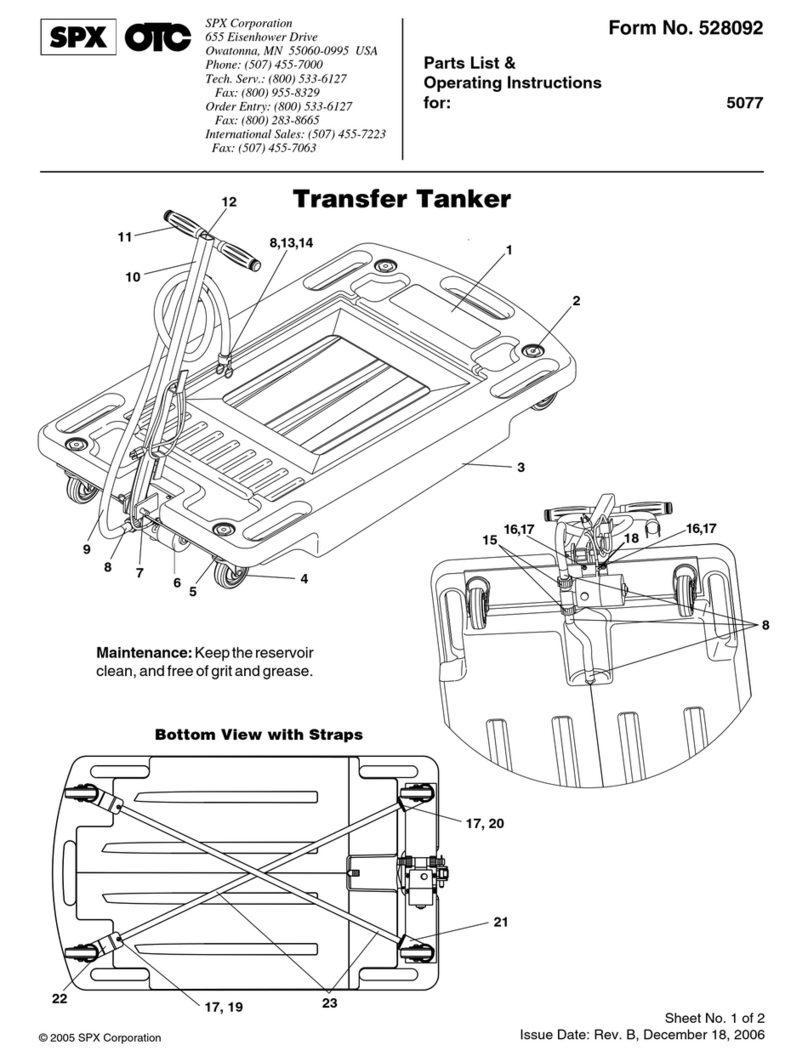

Parts Included:

1. SPDi Ignition Unit

2. SPDi Unit Mount

3. Power Relay

4. ECU Interface Harness

5. SPDi Ignition Coil x 4

6. Ignition Wire Harness

7. M4 Bolt 20mm & Nut x 2

8. Zip Ties x 4

9. M6 bolt 20mm x 10

10. M6 Nut x 2

11. M6 Washer x 2

12. Quick Splice

Connector x 5

Tools Required:

8 & 10mm socket

8 & 10mm wrench

Spark Plug Socket

Torque Wrench

Electric Drill

7/64” Drill Bit

Utility Knife

Pliers

SPDi Plasma Ignition

Installation Manual

V o l k s w a g e n 1 . 8 T P a g e | 2/4

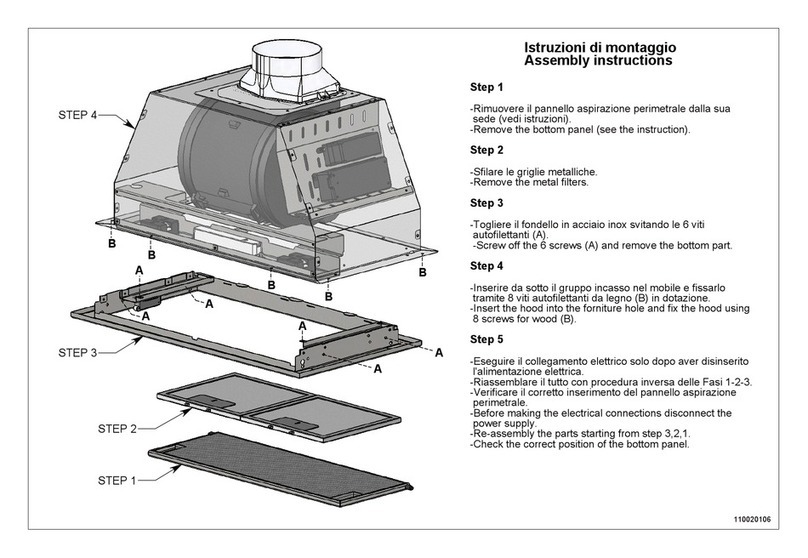

Installation Procedure:

1. Remove battery cover and disconnect negative(-

) battery terminal at the beginning of the

installation.

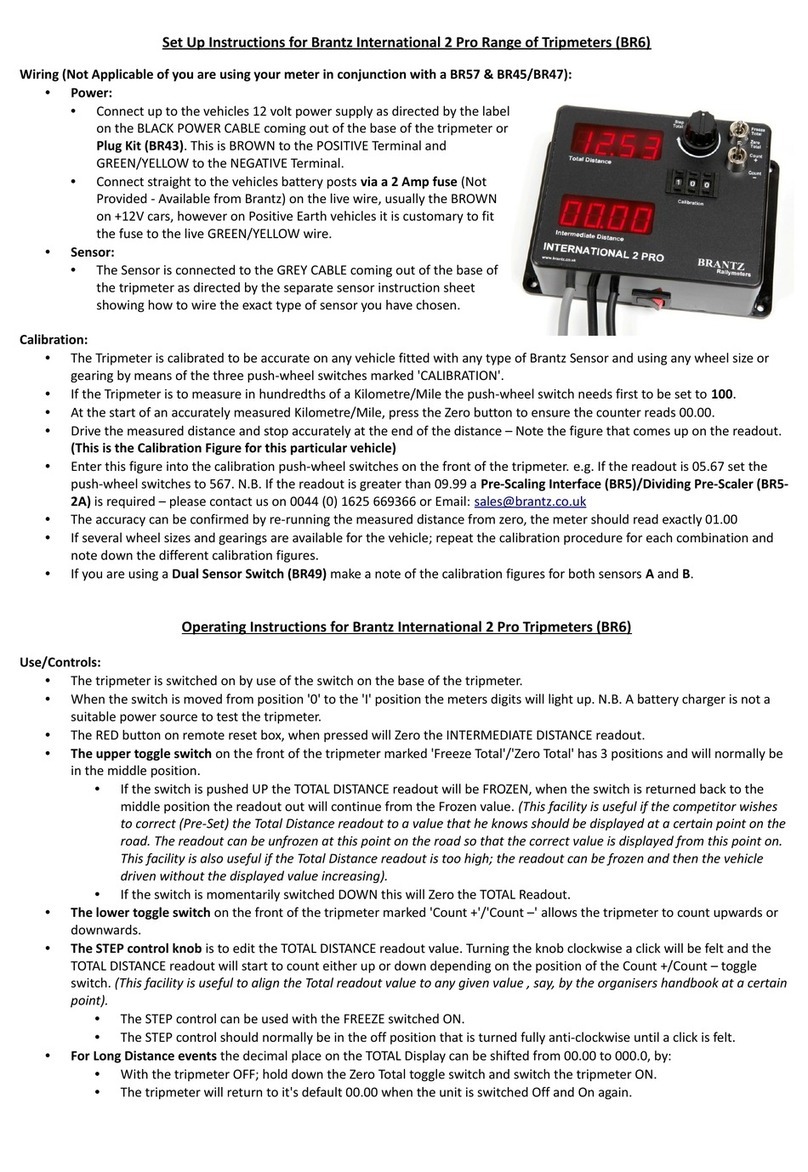

2. Remove the top engine cover [4 bolts] to expose

the ignition coils.

3. Disconnect and remove the stock ignition coils,

as illustrated below.

4. Remove the stock spark plugs and replace with new

plugs. [NGK PFR6Q recommended]

Gap to 0.023" [0.6mm] and reinstall. Torque the plugs

to stock specifications 22ft-lb [30N·m]

5. Install SPDi coils aligning the coil plug connector as

illustrated. Install the coil hold down bolts, if the stock

coils did not include these use the 8 Provided M6.

Torque to stock specifications 7ft-lb [10N·m]

6. Install the SPDi unit onto the mounting bracket with

the 2 x 4mm bolts and nuts provided, place the relay on

the bottom of the mounting bracket as illustrated.

SPDi Plasma Ignition

Installation Manual

V o l k s w a g e n 1 . 8 T P a g e | 3/4

7. Place the assembled unit as illustrated near the

driver's side of the hood latch, some small

modification of the body may be required to allow

the mount to sit flush. Once the bracket location is

determined, attach the provided paper sticker with

cross hairs, to mark the holes to be drilled. Confirm

this location has proper clearance for the wire

harness. Remove the mounting bracket and drill

17/64" [7mm] holes at the cross hair marked

locations.

8. Install the SPDi mounting bracket with the

provided 6mm bolts nuts and washers.

9. Place the ECU Interface Harness as illustrated. Do

not connect the harness to the SPDi unit yet. Connect

the relay plug to the relay under the SPDi mounting

bracket. Route the harness under the intake to the

valve cover. Route the power and ground to the battery

terminals. [Do not connect the battery connections]

10 A. Connect the SPDi ECU Interface Harness to the

stock ignition harness. [We recommend soldering the

connections for best performance and reliability] If

soldering is not possible, use the provided splice

connectors. [see 10 B for quick splice instructions]

Coil

ECU Harness

1999-2000

ECU Harness

2001-On

SPDi

Harness

1

Pin #3

Black/ Violet

Pin #3

Black/Blue

Blue

2

Pin #3

Black/Yellow

Pin #3

Black/Yellow

Orange

3

Pin #3

Black/Brown

Pin #3

Black/Brown

Purple

4

Pin #3

Black/Violet

Pin #3

Black/Violet

Yellow

1

Pin #1

Black/Violet

Pin #1

Black/Violet

Green

Connect Pin #1 on Cylinder 1 to SPDi ECU Interface

Harness Green Wire. This connection allows the stock

ignition to control the SPDi power relay.

Splice Into Stock Harness

At Least 1" Before Connector

SPDi Plasma Ignition

Installation Manual

V o l k s w a g e n 1 . 8 T P a g e | 4/4

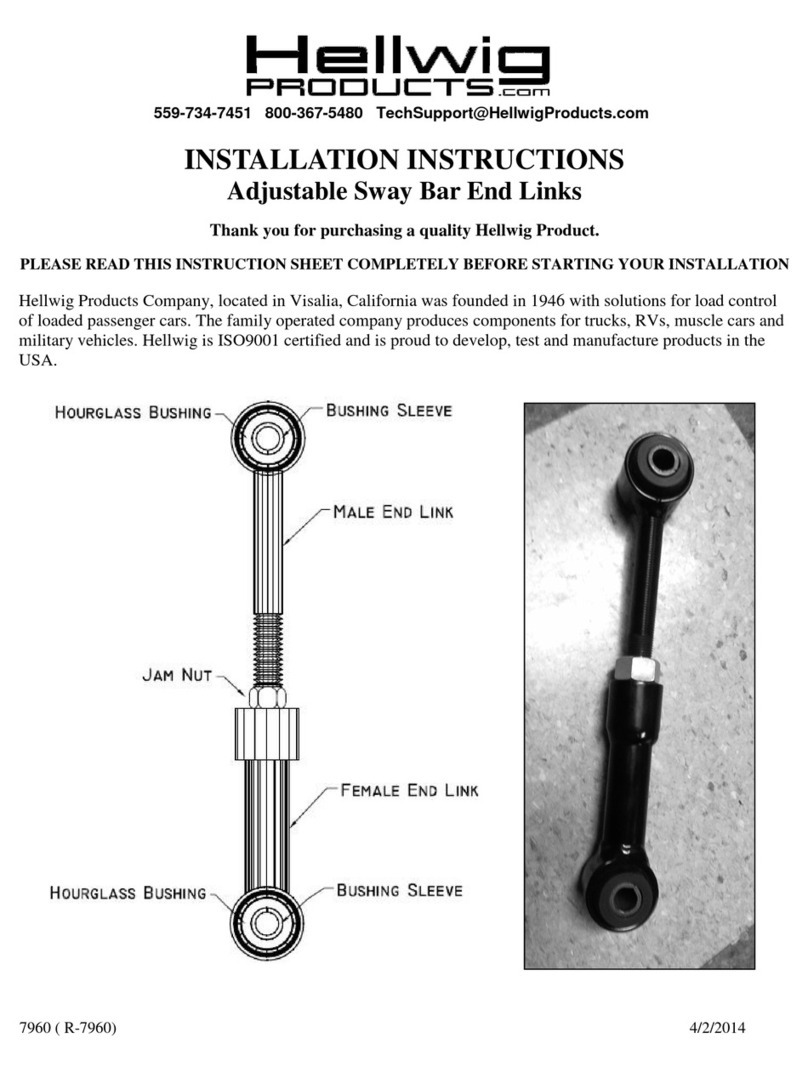

10 B. Quick Splice instructions (skip if soldering)

a) Place the stock ignition wire into the quick

splice connector.

b) Place the associated SPDi wire into the

quick splice connector.

c) Using pliers compress the metal splice

connector to make the connection.

d) Fold the protective cover until it clicks shut.

11.Place the Ignition Wire Harnesses as

illustrated. The Ignition Wire Harness is routed

behind the breather tube to the coils. Connect the

harness to the SPDi Unit. Connect to the coils

plugs.

12.Tuck the Ignition Wire Harness and the ECU

Interface Harness into the valve cover so all cables

are below coil height. Secure the harnesses with

the provided zip ties. The Engine cover may now

be reinstalled.

Notes:

a) Do not install SPDi without the relay

b) Do not install SPDi without the 10A inline

fuse.

c) Do not install a fuse larger than 10A.

Failure to install the relay or the 10A fuse could

result in damage to the SPDi unit.

13.Install the positive and negative SPDi power cables

to the battery terminals. The positive attachment can be

made at any location in the terminal box above the

battery. The negative cable can go direct to the

negative terminal of the battery. At this point reconnect

the negative battery terminal.

14.Connect the SPDi ECU Interface Harness to the

SPDi unit.

15. Installation is now complete. The SPDi system is

ready for use with the provided spark profile.

SPDi Spark is Programmable:

The SPDi control unit is programmable. It is possible to

upgrade the firmware and modify the spark profiles.

Changes to SPDi programming can be made by your

SPDi dealer. You may also program SPDi yourself with

the SPDi Programming Kit available at

www.spdispark.com.This kit includes a programming

cable and user interface software.

For Further Information Contact:

www.spdispark.com

sales@spdispark.com

support@spdispark.com

Sphenic Technologies Inc.

4 Industrial Road, Unit 1

Kemptville, Ontario, Canada

K0G 1J0