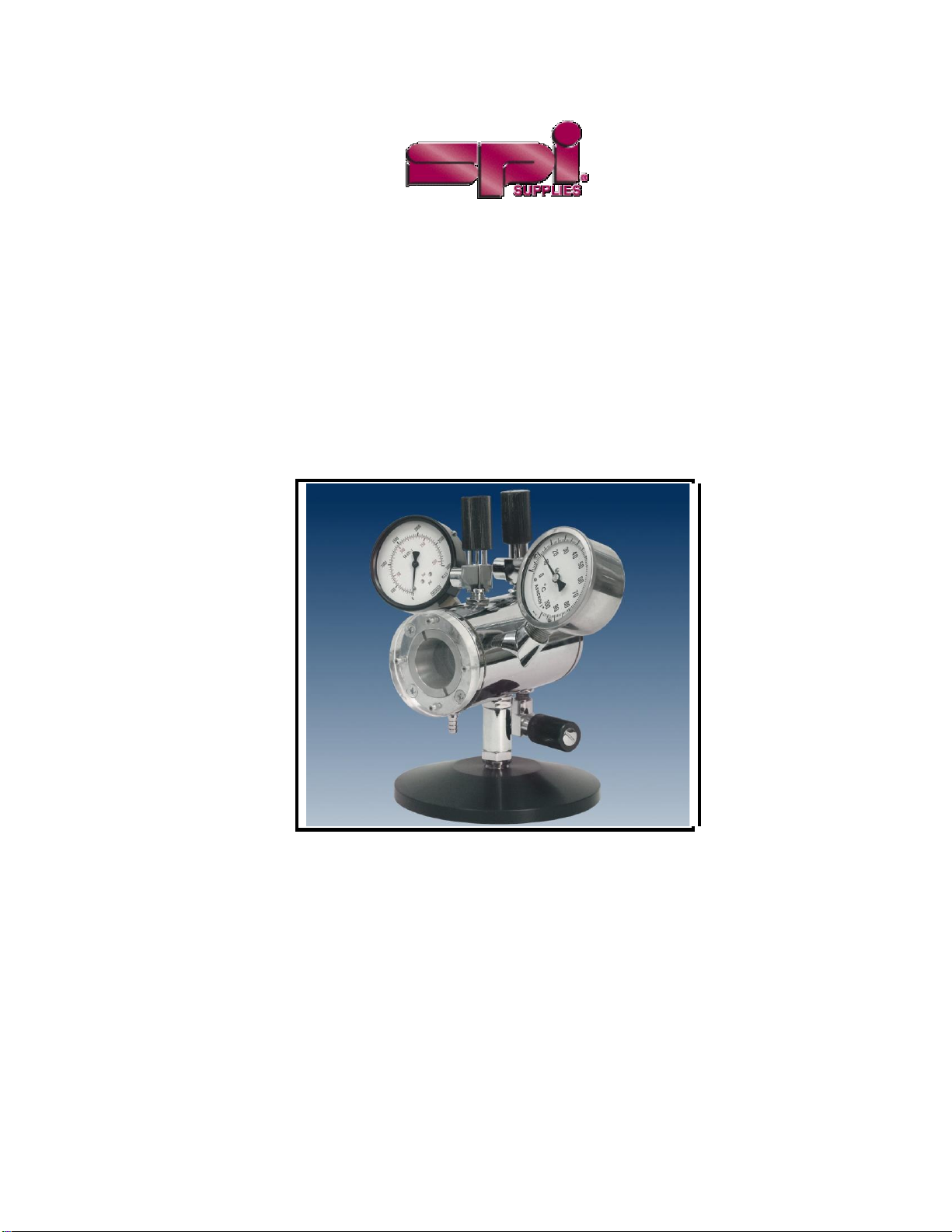

SPI Supplies 8 SPI-DRY Critical Point Dryer

2 HEALTH AND SAFETY

Safety is very important when using any instrumentation and all users of our equipment should read

this section.

This section of the Manual applies to all specimen preparation equipment supplied by SPI Supplies,

not just the particular instrument for which the manual refers.

Included in this section are details on warning notations and good working practices.

2.1 Safety Policy

This section contains important information relating to all health and safety aspects of the equipment.

As such it should be read, and understood, by all personnel using the instrument whether as an

operator or in a service capacity.

SPI Supplies is committed to providing a safe working environment for its employees and those that

use its equipment.

SPI Supplies regularly reviews its operations to make environmental, health and safety improvements

in line with applicable legislation.

The equipment has been designed as a free-standing bench mounted instrument. SPI Supplies cannot

be held responsible for any damage, injury or consequential loss arising from the use of its equipment

for any other purposes, or any unauthorized modifications made to the equipment.

All service work carried out on the equipment should only be undertaken by suitably qualified

personnel. SPI Supplies is not liable for any damage, injury or consequential loss resulting from

servicing by unqualified personnel. SPI Supplies will also not be liable for damage, injury or

consequential loss resulting from incorrect operation of the instrument or modification of the instrument.

2.2 Conformity

This instrument is supplied in a form that complies with the protection requirements of the EC

Electromagnetic Compatibility Directive 89/336/EEC and the essential health and safety requirements

of the low voltage directive 72/23/EEC both as amended by 92/31/EEC. Any modifications to the

equipment, including electronics or cable layout may affect the compliance with these directives.

2.3 Servicing

2.3.1 Disclaimer

All service work on the equipment should be carried out by qualified personnel. SPI Supplies cannot

be liable for damage, injury or consequential loss resulting from servicing from unqualified personnel.

SPI Supplies will also not be liable for damage, injury or consequential loss resulting from incorrect

operation of the instrument or modification of the instrument.

2.3.2 Operators and Service Engineers

A normal operator of the equipment will not be trained in or qualified for service work on the equipment

and may cause a hazard to himself/herself or others if such work is attempted. Operators should

therefore restrict themselves to the normal operation of the equipment and not remove covers from the

electronic equipment or dismantling of the instruments.

Service Engineers who are suitably trained to assess and isolate electrical, mechanical and vacuum

hazards should be the only personnel who access the equipment.

2.4 Hazard Signals and Signs

2.4.1 Hazard Signal Words

The standard three hazard signal words are defined as follows:

DANGER - imminently hazardous situation or unsafe practice that, if not avoided, will result

in death or severe injury.

WARNING - potentially hazardous situation or unsafe practice that, if not avoided, could

result in death or severe injury.