Spicer DSSM0100 User manual

Spicer®Driveshafts

Service Manual

DSSM0100

December 2010

Spicer®Life Series

i

Table of Contents

Inspection Procedures

Inspection Warnings and Cautions . . . . . . . . . . . . .. . . . .1

Universal Joints . . . .. . . . . . .. . . . . . .. . . . . . . . . . . . . . .4

Slip Member Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Tubing Inspection . . . . . . . . . . . ... . .. . ... . .. . . . . . . .7

Center Bearings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Lubrication

Warnings and Cautions . .. . . . . ... . . . . . . . . . . . . . . . . .8

Recommended Lubricants for Relubable Universal Joints and

Slip Members . .. . . . . . . . . .. . . . . . .. . ... . .. . . . . . . .9

Grease Compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Universal Joints . . . . . . . .. . . . . . . . . .. . . . . . . . . . . . . .10

Slip Joint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Center Bearings . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . .13

Removal

Warnings and Cautions . .. . . . . ... . . . . . . . . . . . . . . . .14

Driveshaft Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Grease Zerk Removal and Installation . . . . . . . . . . . . . . .16

Slip Member Boot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Center Bearing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Installation

Warnings and Cautions . .. . . . . ... . . . . . . . . . . . . . . . .21

Universal Joint - Snap-Ring Style. . . . . . . . . . . .. . .. . . .22

Universal Joint - Spring Tab Style . . . . . . . . . . .. . .. . . .24

Center Bearing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Slip Member and Boot . . .. . . . . . . . . . . . . . . . . . . . . . . .26

Driveshaft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Glossary

Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Appendix . . . . . .. . .. . . . . . . . . . . . . .. . . . . . .. . .. . . .32

For additional service information, go to www.dana.com or

call 1-877-777-5360.

ii

General Information

General Information

General Information

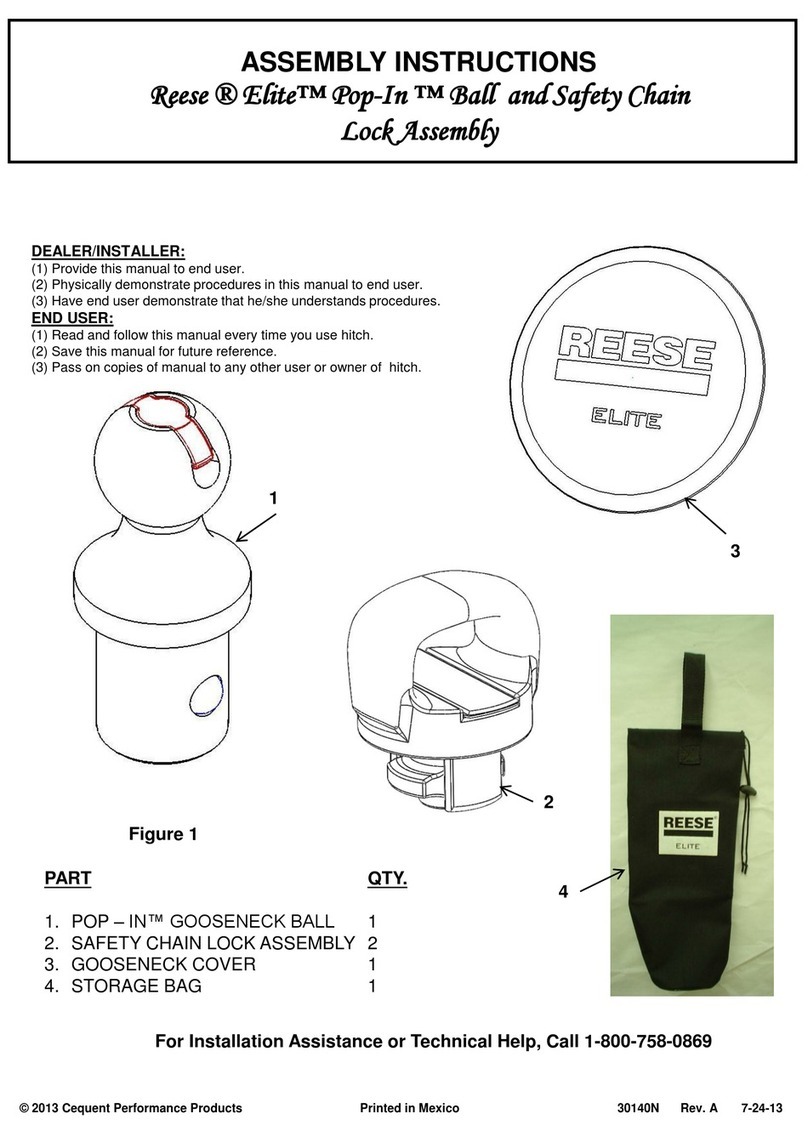

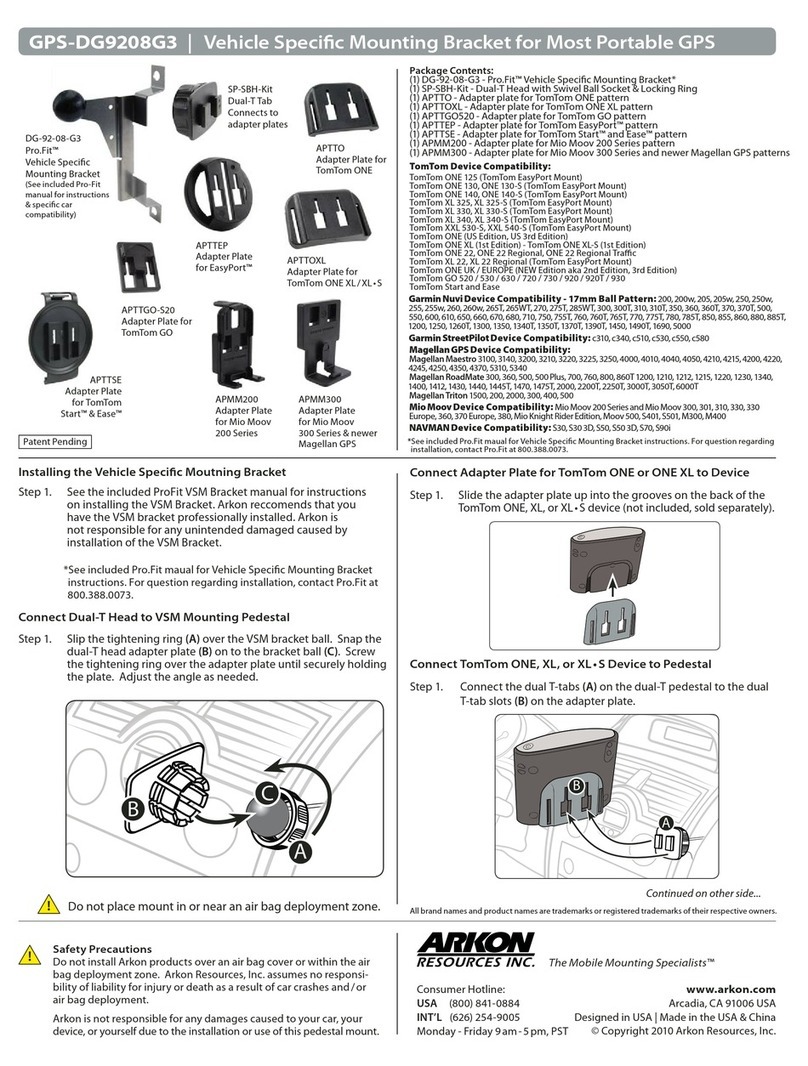

Spicer Life Series™ Features and Benefits

Note: Spicer Life Series™ driveshafts are found on vehicles

throughout the world. Therefore, this manual includes

worldwide terminology.

This manual encompasses inspection, lubrication, removal

and installation procedures for Spicer Life Series™ 55, 70, 90,

100, 140, 170 and 250 driveshaft assemblies.

Important Features of a Spicer Life

Series™ Driveshaft

Spicer offers a complete range of driveshaft solutions to meet

the full spectrum of needs in medium and heavy duty applica-

tions. The Spicer Life Series™ driveshafts have been designed

and developed to stand up to the wear and tear of heavy haul-

ing tasks. They are the first driveshafts in the industry to be

compatible with advancing powertrain specifications for

higher engine torque and lower axle ratios. No one does more

than Spicer in meeting the needs of the marketplace.

Spicer Life Series™ driveshafts offer:

• Longer life

• Lower lifetime management

• Increased strength for higher engine torque and

lower axle ratios

• Smaller driveshaft rotating diameter

A driveshaft that transmits high torque loads must be durable

and strong. Spicer uses forged steel and high strength cast

yokes to provide the necessary rigidity to maintain bearing

alignment under torque loads. Spicer Life Series Quick Dis-

connect™ end yokes reduce the time to remove or install the

driveshaft, equating up to a 75% labor savings for service.

Applications requiring flange connections, S.A.E., DIN and

cross-serrated T-Flanges are available. A new cold-formed,

bearing retainer provides structural rigidity and reduces bear-

ing movement which may result from overloading.

Spicer Life Series™ award winning* universal joint kits are

specifically designed to give extended driveshaft life. Flat-

ended needle bearings are used to withstand oscillating loads

while the driveshaft is rotating and to eliminate skewing in the

bearing cup. Thrust washers significantly reduce end galling

on trunnion ends and lower universal joint operating tempera-

ture. Synthetic rubber seals and plastic seal guards provide

lubricant retention and help prevent the entry of foreign mate-

rial, significantly increasing universal joint life. The centrally

located grease zerk (nipple) fitting increases the strength of

the journal cross and allows more torque carrying capacity.

High-strength steel tubing is used to provide maximum

torque carrying capacity at minimum practical weight.

Increased tube diameter allows a higher critical speed and

longer one-piece driveshafts. This increased stiffness also

improves noise, vibration and harshness. New slip member

booting or alternative seal can offers better protection against

environmental contaminants, increases component life, and is

lubricated for the life of the product.

The new integral tube sleeve and yoke shaft design, found on

heavy duty Spicer Life Series™ designs, along with larger

diameter involute splines, creates greater strength and tor-

sional stiffness with less weight. This new design leads to

improved balance and less slip effort, resulting in reduced

noise and vibration for the entire driveshaft system. Spicer

Glidecote®, found in all slip member assemblies, reduces

friction, thereby lowering thrust loads under high torque. This

nylon coating also prevents spline wear and extends life.

1

Warnings and Cautions

Spicer Life Series™ Inspection Warnings and Cautions

Before You Get Started

1. ALWAYS wear safety glasses when performing

maintenance or service. Failure to wear safety

glasses can result in personal injury and/or partial or

complete vision loss.

2. NEVER go under a vehicle while the engine is run-

ning. Be sure the vehicle's engine is off, and keys are

removed from ignition.

3. NEVER go under or work on a vehicle that is not on a

level or flat surface.

4. NEVER work on a driveshaft without blocking the

vehicle's wheels and releasing all parking brakes.

See warning below.

5. NEVER lift a vehicle without the appropriate weight-

rated, vehicle-support equipment.

6. NEVER REMOVE a driveshaft from the vehicle with-

out keeping the vehicle's transmission in neutral.

See above warning.

7. CAUTION – Spicer Life Series™ driveshaft assem-

blies can weigh in excess of 100 pounds (46 kilo-

grams). Be sure to use proper lifting techniques

when handling Spicer Life Series™ driveshafts. More

than one person may be needed when handling

driveshaft assemblies.

8. ALWAYS use support straps to prevent the drive-

shaft from falling, causing injury and/or damage dur-

ing the loosening or removal of any driveshaft

hardware.

9. NEVER heat components or use sledgehammers or

floor jacks to remove the driveshaft from vehicle.

Note: For driveshaft applications that have pillow blocks,

dampers, parking brakes or retarders, refer to these

component manufacturers' or the original equipment

vehicle manufacturers' service manuals for proper pro-

cedures.

Driveline

WARNING: Failure to replace damaged driveline components

can cause driveline failure, which can result in separation of

the driveline from the vehicle. A separated driveline can result

in property damage, serious personal injury, or death.

WARNING: Reassembly of a driveline out of original phase

can cause vibration and failure of the drivline and attaching

components.

WARNING: Driveshaft assemblies can weigh in excess of 100

pounds(46 kilograms). Be sure to use proper lifting tech-

niques when handling driveshafts. More than one person

may be needed when handling driveshaft assemblies.

WARNING: Never heat components, never use sledge ham-

mers, and never use floor jacks to disassemble driveshafts.

This can result in damaged, weekened, or bent components.

End Fitting

WARNING: A loose end-fitting can result in driveline failure,

which can in turn lead to separation of the driveline from the

vehicle. A separated driveline can lead to property damage,

serious personal injury, or death.

Universal Joint

WARNING: Excessive looseness across the end of universal

joint bearing cup assemblies can cause imbalance or vibration

in the driveshaft assembly. Imbalance or vibration can cause

component wear, which can result in separation of the driv-

line.

WARNING: DO NOT reuse bolts or use inferior grade bolts.

Reuse of bolts and/or use of inferior bolts can cause driveline

failure, which can result in separation of the drivline from the

vehicle.

WARNING: Failure to torque bolts to specification can cause

driveline failure, which can result in separation of the driveline

from the vehicle.

CAUTION: Use a journal locator to avoid nicking journal cross

trunnions or damaging oil seal slingers.

CAUTION: If a bearing assembly or journal cross is worn or

damaged, the universal joint assembly must be replaced.

CAUTION: Be sure the snap rings are properly seated in the

snap ring grooves.

WARNING

WARNING

WARNING

2

Warnings and Cautions

Warnings and Cautions

Slip Member

WARNING: Excessive radial looseness in the slip member

assembly can cause imbalance or vibration in the driveshaft.

Imbalance or vibration can cause components to wear, which

in turn can result in separation of the driveline from the vehi-

cle. A separated driveline can cause property damage, seri-

ous personal injury or death.

Yoke (Includes Slip Yoke, Yoke Shaft, and

Tube Yoke)

WARNING: A loose or damaged slip yoke seal allows contam-

inants to invade the slip member assembly. Invasion of con-

taminants into the slip member assembly can degrade the

grease, and damage slip member components, which can

result in driveline separation.

WARNING: DO NOT deform yoke cross holes by removing

excessive metal. Raised metal or deformed yoke cross holes

can be a cause of cross and bearing failure, which can result

in separation of driveline from the vehicle.

WARNING: Yoke shaft assemblies can weigh in excess of 50

pounds (23 kilograms). Be sure to use proper lifting tech-

niques when handling yoke shafts.

Tubing

WARNING: Bent or dented tubing can cause imbalance or

vibration in the driveshaft assembly. Imbalance or vibration

can cause component wear, which can result in separation of

the driveline from the vehicle.

CAUTION: Do not bend or dent the tube when handling or

servicing driveshaft.

Midship Nut

WARNING: DO NOT reuse the midship nut. Reuse of the

midship nut can cause driveline failure, which can result in

separation of the driveline from the vehicle.

WARNING: DO NOT touch or disturb the micro-encapsulated

adhesive found on the midship nut threads. Doing so may ini-

tiate the curing process and impair the installation of the nut.

Premature curing of the micro-encapsulated adhesive will

result in improper installation of the midship nut. Improper

instsallation of this nut can cause driveline failure, which can

result in separation of the driveline from the vehicle.

WARNING: Failure to torque the midship nut to required

specifications can cause driveline failure, which can result in

separation of the driveline from the vehicle.

WARNING: A loose midship nut can result in driveline failure,

which can result in separation of the driveline from the vehi-

cle.

Center Bearing

WARNING: Loose center bearing bracket bolts can result in

driveline failure, which can result in separation of the driveline

from the vehicle.

WARNING: Damaged center bearings or center bearing com-

ponents can cause imbalance or vibration in the driveshaft

assembly. Imbalance or vibration can cause component

wear, which can result in separation of the driveline from the

vehicle.

Foreign Material

WARNING: Build-up of foreign material, excessive paint, or

undercoating on a driveshaft can cause imabalnce or vibration

in the driveshft assembly. Imbalance or vibration can cause

component wear, which can result in separation of the drive-

line from the vehicle.

WARNING: A contaminated slip member can result in separa-

tion from the vehicle. A separated driveline can result in prop-

erty damage, serious personal injury or death.

Hardware

WARNING: Loose, missing, or damaged bearing retainers or

stamped straps, retaining bolts, nuts, end fitting tangs, snap

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

3

Warnings and Cautions

rings, or rotating bearing cups can result in driveline failure.

A separated driveline can lead to property damage, serious

personal injury, or death.

WARNING: DO NOT reuse bolts, straps, nuts, or damaged

bearing retainers or inferior grade bolts. Reuse of bolts,

straps, nuts, or damaged bearing reatiners, or use of inferior

grade bolts can cause driveline failure.

CAUTION: If loosening or removing bolts, always install a

new strap and bolts and torque bolts to specification.

Lubrication

WARNING: A missing, loose, or fractured grease zerk (nip-

ple) fitting or plug eliminates the ability to lubricate the univer-

sal joint. Improper or inadequate lubrication can cause

driveline failure, which can result in separation of the driveline

from the vehicle.

WARNING: Improper lubrication techniques can cause drive-

line failure, which can result in separation of the driveline

from the vehicle.

WARNING: A missing, loose, damaged, or fractured plug or

grease zerk (nipple) fitting can allow contaminants to invade

the universal joint. Invasion of contaminants into the univer-

sal joint can degrade grease and cause universal joint dam-

age, which can result in separation of the driveline from the

vehicle.

WARNING: Incompatible greases that are applied to universal

joints and/or slip members can result in driveline failure and

can result in separation of the driveline from the vehicle.

WARNING: Hand tightening of grease zerk (nipple) fitting or

plugs is NOT recommended. Failure to torque grease zerk

(nipple) fittings to specifications can result in separation of

the driveline from the vehicle.

WARNING: Maximum grease gun pressure should not

exceed 60 psi. Excessive grease gun pressures may cause

seal damage.

CAUTION: In cold temperatures, be sure to drive the vehicle

immediately after lubrication. This activates the slip spline

and removes excess grease. Failure to do so could cause

excess grease to stiffen in the cold weather and force the plug

out. The end of the spline would then be open to collect con-

taminants and cause the spline to wear and/or seize.

CAUTION: All slip yoke and universal joint seals should be

completely purged.

WARNING

4

Inspection Procedures

Inspection Procedures

Inspection Procedures

Visually inspect all input and output end-fitting retaining nuts

or bolts for any gaps between mating surfaces. If gaps are

present, consult transmission, axle or transfer case original

equipment manufacturers' service and maintenance manuals

for proper fastener specifications.

Visually inspect for damaged bearing retainers or stamped

straps, loose bearing retainer bolts or strap bolts, loose com-

panion flange bolts and nuts, loose or missing spring tabs or

spring tab bolts, damaged tangs on end fittings, damaged or

missing snap rings, and rotating bearing cups.

If any of these situations are evident, replacement of the com-

ponents is necessary. Refer to the removal and installation

sections of this manual for proper replacement procedures.

Universal Joints

Note: The following procedures are to be performed prior to

any lubrication of universal joints or slip members. The

addition of lubricant can mask the looseness in a com-

ponet that is beginning to show wear and may be in

need of replacement.

1. Check for excessive looseness across the ends of

the universal joint bearing cup assemblies and trun-

nions. Take hold of the inboard yoke on the drive-

shaft with both hands. Try to move the yoke

vertically and horizontally.

There should be less than .006" (.15mm) movement

in the universal joint relative to the inboard or out-

board yokes. If looseness is greater than .006"

(.15mm), the universal joint kit may need to be

replaced.

Note: If the movement of the driveshaft is greater than .006",

the carrier assemblies input shaft and/or output shaft

ends play must be checked to make sure they are within

specification. Endplay readings that are out of specifica-

tion must be corrected before an accurate driveshaft

reading can be taken. Refer to the Input/Output Shaft

Endplay Inspection procedure.

Excessive looseness across ends of universal joint bearing

cup assemblies can cause imbalance or vibration in the

driveshaft assembly. Imbalance or vibration can cause

component wear, which can result in separation of the driv-

eline from the vehicle.

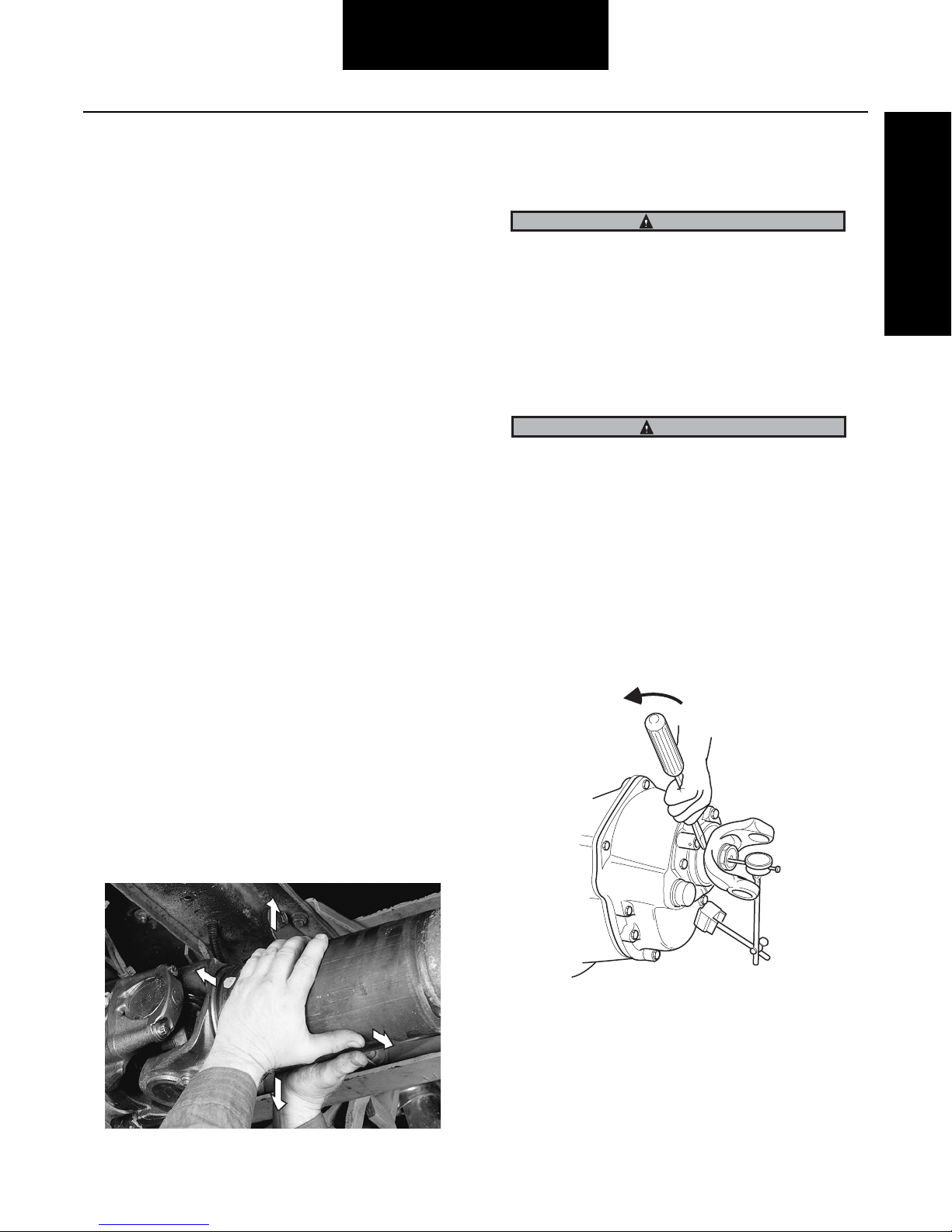

Check Input Shaft End-Play (Forward Axle)

a. Position dial indicator at yoke end of input shaft.

b. Push on input shaft and zero dial indicator.

c. Using pry bar, move input shaft axially and measure/

record end-play.

Add shims to increase end-play.

Note: Input and output shaft endplay specifications will vary

between model. Refer to manufacturer’s service manual

for correct endplay specifications.

IMPORTANT

WARNING

5

Inspection Procedures

Remove shim to decreased end-play.

Check Output Shaft End-Play (Forward Axle)

a. Position dial indicator at yoke end of input shaft.

b. Push on output shaft and zero dial indicator.

c. Using pry bar, move input shaft axially and measure/

record end-play.

Note: The output yoke can be installed when taking end-play

measurements.

d. Correct end-play for new assembly is .001" to .015".

Grease Zerk Inspection

Check for presence of all grease zerk fittings. Grease zerk fit-

tings should not be loose, fractured or missing.

- If grease zerk fitting is loose, tighten to required

specifications.

- If grease zerk fitting is fractured, replace grease zerk

fitting and tighten to required specifications.

- If grease zerk fitting is missing, the entire universal

joint kit needs to be replaced.

- If the plug is loose, tighten to required specifica-

tions.

- If a plug is missing or fractured, the entire universal

joint kit needs to be replaced.

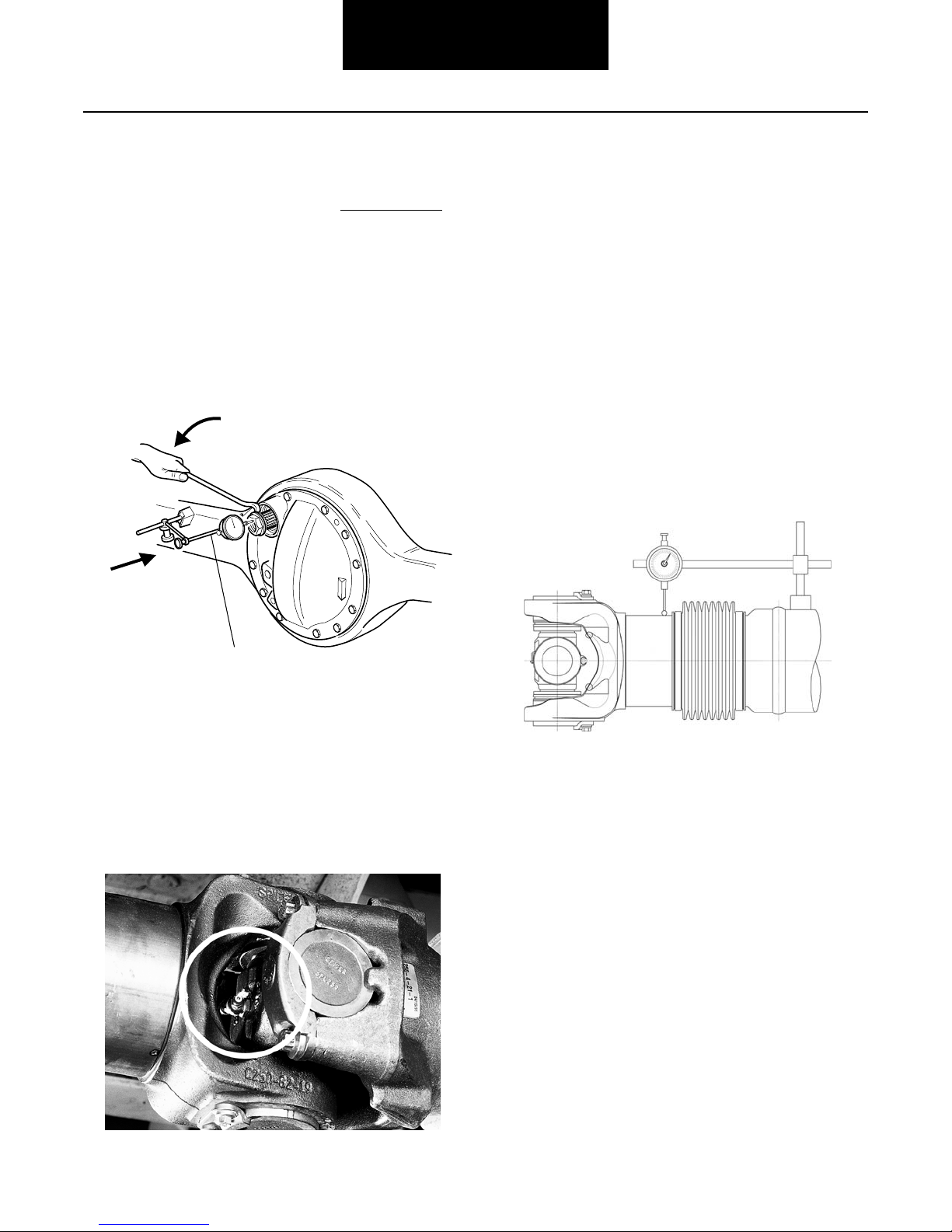

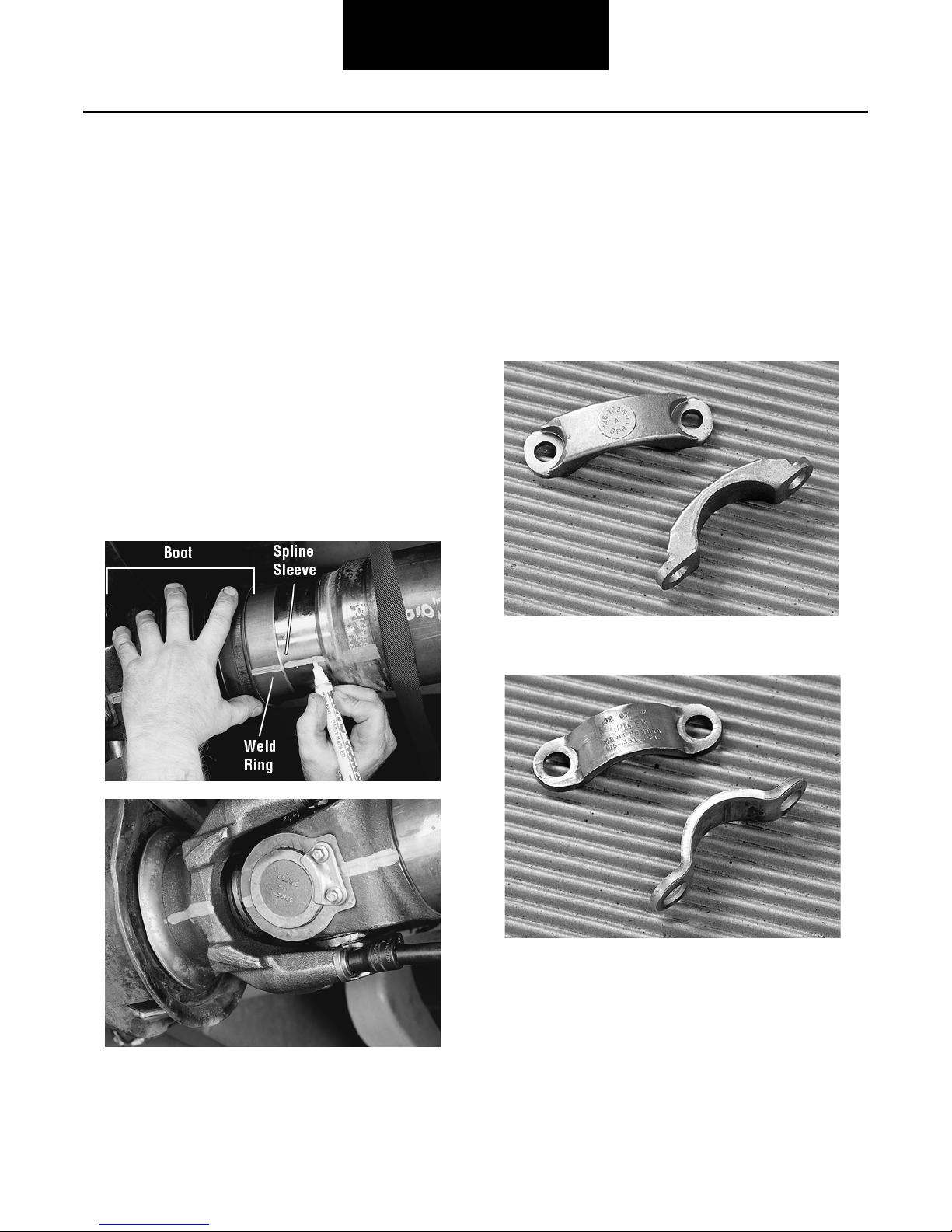

Slip Member Assembly Inspection

1. Check the slip member assembly for excessive radial

looseness. Using a dial indicator, take hold of the

tubing near the slip member with both hands and try

to move vertically, up and down relative to the

ground.

2. Arrange dial indicator with magnetic base one-quar-

ter inch (1/4") from the driveshaft’s tube weld. Dial

indicator should be firmly mounted on the tube so

that no movement of the dial indicator base is

allowed.

3. Extend dial indicator arm from the base, across the

slip member boot, allowing the dial indicator to con-

tact the yoke shaft tube one quarter inch (1/4") off

the opposite side of the boot from where the mag-

netic base is mounted. Dial indicator’s arm should be

running parallel to the driveshaft.

Measured end-play (Step 3) 0.015” – 0.015”

Desired end-play (New Parts) 0.003” to 0.007”

Remove shims to provide desired

end-play

0.012” to 0.008”

1

2

3

6

Inspection Procedures

Inspection Procedures

4. Apply effort perpendicular to shaft axis making note

of total indicator travel. Allowable indicator travel is

.000-.012 in.

Excessive radial looseness can cause imbalance or vibra-

tion in the driveshaft assembly. Imbalance or vibration can

cause component wear, which can result in separation of

the driveline from the vehicle.

5. For an inboard and outboard slip yoke assembly

design, check to be sure the slip yoke welch plug is

not loose, missing or damaged.

If any of these situations are evident, replacement of

the slip yoke and professional rebalancing of the

driveshaft is necessary.

6. Visually inspect for the presence of the grease zerk

fitting, if applicable, on the slip yoke.

a. If grease zerk fitting is loose, tighten to required

specifications. (See Table C.)

b. If grease zerk fitting is missing or fractured, the

slip members may need to be replaced.

7. Check the slip yoke seal. Make sure the seal is prop-

erly attached to the slip yoke and is not loose or

damaged.

Permanently Lubricated Style

Check the yoke shaft boot. Make sure the boot is properly

attached to the yoke shaft assembly and splined sleeve. Visu-

ally inspect for boot tears, punctures, loose clamps and clamp

damage.

If any of these situations are evident, replace damaged com-

ponents and measure slip joint movement.

WARNING

Table C - Slip Member Grease Zerk Fitting Specifications

Thread

Size

Zerk

Nm

Torque

IN. LB.

0.25"-28" 3.5-6.2 31-55

7

Inspection Procedures

Tubing Inspection

1. Check the driveshaft for bent or dented tubing. If

either of these situations is evident, replacement of

the complete driveshaft assembly or tube is neces-

sary.

2. Make certain there is no buildup of foreign material

on driveshaft.

If found, buildup should be removed carefully to

avoid damaging the driveshaft.

a. When removing dirt or mud, rinse with water.

b. When removing tar or undercoating, use min-

eral spirits or any appropriate solvent.

Center Bearings Inspection

1. Visually inspect all center bearings, end-fitting mid-

ship nuts for any gaps between the mating surfaces.

Note: Be sure to repeat steps 2 and 3 for all center bearing

end fittings for broken back and backlash.

2. Inspect the center bearing bracket bolts for loose-

ness.

Note: If looseness is evident, retighten center bearing bracket

bolts. Consult the vehicle manufacturers’ specifications

for proper bolt torque. Check the alignment of the

bracket before tightening the bolts. Bracket should not

be skewed.

3. Visually inspect the center bearing rubber cushion

for damage. Make sure the slingers are not rubbing

against the rubber cushion. Verify that the rubber

cushion is properly seated in the metal bracket.

8

Lubrication Warnings

Lubrication

Spicer Life Series™ Lubrication Warnings and Cautions

Before You Get Started

1. ALWAYS wear safety glasses when performing

maintenance or service. Failure to wear safety

glasses can result in personal injury and/or partial or

complete vision loss.

2. NEVER go under a vehicle while the engine is run-

ning. Be sure the vehicle's engine is off, and keys are

removed from ignition.

3. NEVER go under or work on a vehicle that is not on a

level or flat surface.

4. NEVER work on a driveshaft without blocking the

vehicle's wheels and releasing all parking brakes.

See warning below.

5. NEVER lift a vehicle without the appropriate weight-

rated, vehicle-support equipment.

6. NEVER REMOVE a driveshaft from the vehicle with-

out keeping the vehicle's transmission in neutral.

See above warning.

7. CAUTION – Spicer Life Series™ driveshaft assem-

blies can weigh in excess of 100 pounds (46 kilo-

grams). Be sure to use proper lifting techniques

when handling Spicer Life Series™ driveshafts. More

than one person may be needed when handling

driveshaft assemblies.

8. ALWAYS use support straps to prevent the drive-

shaft from falling out of vehicle during the removal

and installation process.

9. ALWAYS wear protective gloves when applying

grease to slip joints or other driveshaft components.

10. NEVER heat components or use sledgehammers or

floor jacks to remove the driveshaft from vehicle.

Note: For driveshaft applications that have pillow blocks,

dampers, parking brakes or retarders, refer to these

component manufacturers' or the original equipment

vehicle manufacturers' service manuals for proper pro-

cedures.

Failure to release all parking brakes and failure to place

transmission in neutral can result in torque being applied to

the driveshaft. Disconnecting a driveshaft with applied

torque can result in property damage, serious personal

injury or death.

Inadequate lubrication can cause driveline failure which

can result in separation of the driveline from the vehicle. A

separated driveline can result in property damage, serious

personal injury or death.

Incompatible lubricants/greases which are applied to uni-

versal joints and/or slip members, can result in failure of

the driveline and can result in separation of the driveline

from the vehicle.

To prevent serious eye injury, always wear safety glasses

when performing maintenance or service. Failure to wear

safety glasses could result in serious personal injury, and/

or partial or complete vision loss.

WARNING

9

Lubrication Procedures

Spicer Life Series™ Lubrication

ALWAYS use support straps to prevent the driveshaft from

falling out of the vehicle. Failure to use a support straps

can cause damage to the driveshaft or result in property

damage, serious personal injury or death.

DO NOT attach the support straps to fuel lines, oil lines,

brake lines, or wiring. DO NOT entangle fuel lines, oil

lines, brake lines or wiring in the support straps.

Lack of proper lubrication is one of the most common causes

of universal joint and slip member problems. When properly

applied, relubable Spicer Life Series™ universal joints which

are adequately relubricated at recommended intervals will

meet or exceed vehicle operation requirements.

Note: Spicer Life Series™ replacement universal joint kits

contain only enough grease to provide needle roller

bearing protection during storage. It is therefore neces-

sary to completely lubricate each replacement kit prior

to assembly into yokes.

Note: There are numerous instances when special lubrication

is required by vehicle specifications or customer

request. The lubrication recommendations listed in this

manual are prescribed by Spicer Driveshft Division engi-

neering. Any alternate lubricants, or lubrication proce-

dures, are the responsibility of the user.

Inadequate relubrication intervals and failure to properly lubri-

cate the universal joints will cause universal joint failures.

Proper relubrication flushes the universal joints, thus remov-

ing abrasive contaminants from the bearings. Relubable slip

members must also be adequately relubricated to prevent slip

member failure.

Inadequate relubrication can cause driveline failure which

can result in separation of the driveline from the vehicle.

Recommended Lubricants for Relubable

Universal Joints and Slip Members

Standard Application

Spicer recommends that the following requirements be met

for any lubricant that will be used to service most vehicular,

industrial and all auxiliary driveshaft applications.

Note: Refer to Dana information bulletin number J3295 for

additional grease specification guidelines.

Failure to use Dana recommended grease specification

may cause premature component wear and void warranty

coverage.

• Use a good quality E.P. (extreme pressure) grease

• Timkin Test Load – 50 lbs/23Kg minimum

• Meeting N.L.G.I. (National Lubricating Grease Insti-

tute), E.P., Grade 2 specifications

• Grease must have an operating range of +325ºF to -

10ºF (+163ºC to -23ºC)

Consult your local lubricant source for greases that meet

these specifications.

Incompatible lubricants/greases which are applied to uni-

versal joints and/or slip members, can result in failure of

the driveline and can result in separation of the driveline

from the vehicle.

Grease Compatibility

When greases made from different thickeners are mixed, the

mixture may result in lower service performance or physical

properties than either of the original component products.

This reduction in lubricant performance is called incompatibil-

ity. It may show up in any of several areas, such as:

1. Lower heat resistance;

2. Change in consistency, usually softening; or

3. Decrease in shear stability.

Mixtures which show none of these changes are considered

compatible. Incompatibility is not always caused by the thick-

ener, since each of the greases in the mixture is a complete

package—thickener, fluid, and additives.

Sometimes the thickener of one grease is incompatible with

the fluid or the additives present in the second grease. If the

mixture proves to be significantly softer, less shear stable, or

less heat resistant than the original grease, the mixture shall

be deemed incompatible.

WARNING

WARNING

CAUTION

WARNING

10

Lubrication Procedures

Lubrication Procedures

Incompatibility is best determined in service or in service-

related tests; it is not predictable. Certain thickener combina-

tions often have been found unsatisfactory and are generally

so recognized. These would include lithium and sodium

greases and organo-clay and most soap greases. Contact

your local lubricant supplier for grease compatibility infor-

mation.

To help reduce the effects of incompatible greases, make sure

to thoroughly purge all four bearing seals on each universal

joint with the new grease. Purge seals until the fresh grease is

visible on the outside of all four bearing seals.

It is recommended that all purged grease be wiped clean to

prevent discharge into the general environment.

Intervals for Relubable Universal Joints

Lubrication intervals vary depending on the service require-

ments and operating conditions of the vehicle or machine.

Table F, below, shows the recommended universal joint lubri-

cation intervals for various types of service.

City is defined as all applications that require a minimum of

90% of operation within city limits.

On-highway is defined as all applications requiring less than

10% of operating time on gravel, dirt or unpaved roads.

Off-highway is defined as all applications requiring more than

10% of operating time on gravel, dirt or unpaved roads.

Linehaul is defined as 100% of operation time on smooth

concrete or asphalt.

*Relubrication intervals for off-highway and industrial use

vary depending on the application and operating conditions.

In general, to obtain maximum life, relubrication on industrial

applications should occur every 500 hours for normal service

and every 250 hours for continuous service or severe envi-

ronmental conditions.

Universal Joints Lubrication

1. Use the recommended lubricant to purge all four

seals of each universal joint. This flushes abrasive

contaminants from each bearing assembly and

assures proper filling of all four bearings.

Note: Make sure fresh grease is evident at all universal joint

bearing seals.

Table F - Universal Joint Maximum Lubrication Intervals

SERIES CITY ON-HWY. LINEHAUL OFF-HWY.* INDUSTRIAL

SPL 100, 90,

70 & 55

8,000 Mi.

(12,800 Km.)

15,000 Mi.

(24,000 Km.)

15,000 Mi.

(24,000 Km.)

8,000 Mi.

(12,800 Km.)

500 Hrs.

or or or or

3 Months 3 Months 3 Months 3 Months

(which ever comes first) (which ever comes first) (which ever comes first) (which ever comes first)

SPL 250, 170

& 140

25,000 Mi.

(40,000 Km.)

100,000 Mi.

(160,000 Km.)

100,000 Mi.

(160,000 Km.)

25,000 Mi.

(40,000 Km.)

500 Hrs.

or or or or

3 Months 6 Months 6 Months 3 Months

(which ever comes first) (which ever comes first) (which ever comes first) (which ever comes first)

IMPORTANT

11

Lubrication Procedures

2. If any of the seals fail to purge, try to push the trun-

nion away from the bearing cup while applying

grease. On two side zerk fittings, try greasing from

the opposite side of the fitting.

Note: Due to sealing capability of the Spicer Life design, there

may be one or more bearing assembly seals that will not

purge.

3. If any bearing cup assemblies fail to purge, releasing

seal tension may be necessary.

Releasing Universal Joint Bearing Seal

Tension

Quick Disconnect™ Spring Tab Style

It will be necessary to have addtional bearing retainer or

stamped strap bolts and stamped straps in order to com-

plete the following instructions.

1. Utilizing a brass hammer and wearing safety glasses,

sharply strike inboard yoke on lug ear once to firmly

seat bearing against spring tab and relieve tension

across span. Rotate shaft 180 degrees and repeat

procedure on opposite lug ear.

2. Apply grease gun pressure and purge all four bear-

ings until fresh grease is seen at all four bearing

seals.

3. If striking lug ears does not cause purging, remove

and discard spring tab bolts and spring tabs.

4. With a marking stick, paint marker or other lelegible

device, mark all bearing positions in relation to yokes

and bearing retainers at the effected universal joint.

This assures proper reassembly of the driveshaft

into the vehicle, in its original position. See Warning

Below.

Reassembly of a driveline out of original phase can cause

vibration and failure of the driveline and attaching compo-

nents.

5. Working at the effected universal joint, support the

driveshaft with a support strap. Attach support

straps to frame rails or some structural part of the

vehicle.

6. Remove the bearing retainers and bolts at the

effected universal joint.

Note: New cold formed bearing retainers DO NOT need to

be replaced. Replace only if damaged.

IMPORTANT

Cold Formed Straps

(SPL 140, 170, 250)

WARNING

12

Lubrication Procedures

Lubrication Procedures

*Spicer bolts are specially heat-treated.

DO NOT substitute with inferior grade bolts.

7. It may be necessary to unseat bearing cup assem-

blies by tapping on yoke or bearing cup with a soft-

faced hammer. Once the bearing cup assemblies are

free, allow the driveshaft to rest on support strap.

8. Apply a c-clamp around the outboard bearings.

Apply grease gun pressure. Completely purge both

inboard bearings.

9. If bearings fail to purge, slightly loosen c-clamp and

reapply grease gun pressure until both outboard

bearings purge.

10. After all four bearings purge fresh grease, retighten

c-clamp to squeeze out excess grease and wipe

clean. This will ease installation of universal joint kit

back into yoke. Install universal joint kit in the yoke

using new bearing retainer bolts, and torque bolts to

the required specifications.

11. If the bearings still will not purge, complete replace-

ment of the universal joint kit is required. See

removal section of this manual for proper proce-

dures on removing Spicer Quick Disconnect™ style

driveshaft assemblies and spring tab style universal

joints.

Slip Joint Lubrication

Lubrication Procedure for Relubale Slip Members

1. Apply grease gun pressure to the lube fitting until

lubricant appears at the seal. Always use an E.P.,

Grade 2 specification, N.G.L.I grease on spline mem-

bers. Spicer recommends the same lubricant used

for universal joints.

Caution - In cold temperatures, be sure to activate

the slip member by driving the vehicle sufficiently to

cause displacement of the grease prior to its stiffen-

ing. Failure to do so could cause the excess lubri-

cant to stiffen in the cold weather and force the

welch plug out. The end of the spline would then be

open to collect contaminants and can result in drive-

line failure.

Stamped Straps

(SPL 55, 70, 100)

Bolt Specifications - Quick Disconnect™

Series Thread Size Head Size Bolt

Nm

Torque

Lb. Ft.

SPL 140 12mm - 1.25 12mm, 12

point

156-170 115-125

SPL 170 12mm - 1.25 12mm, 12

point

156-170 115-125

SPL 250 12mm - 1.25 12mm, 12

point

156-170 115-125

13

Lubrication Procedures

Lubrication for Center Bearings

All Spicer manufactured center bearings are permanently

lubricated. No attempt should be made to add or change

grease with the bearing itself.

14

Removal Warnings

Removal

Spicer Life Series™ Driveshaft Removal Warnings and Cautions

Before You Get Started

1. ALWAYS wear safety glasses when performing

maintenance or service. Failure to wear safety

glasses can result in personal injury and/or partial or

complete vision loss.

2. NEVER go under a vehicle while the engine is run-

ning. Be sure the vehicle's engine is off, and keys are

removed from ignition.

3. NEVER go under or work on a vehicle that is not on a

level or flat surface.

4. NEVER work on a driveshaft without blocking the

vehicle's wheels and releasing all parking brakes.

See warning below.

5. NEVER lift a vehicle without the appropriate weight-

rated, vehicle-support equipment.

6. NEVER REMOVE a driveshaft from the vehicle with-

out keeping the vehicle's transmission in neutral.

See above warning.

7. CAUTION – Spicer Life Series™ driveshaft assem-

blies can weigh in excess of 100 pounds (46 kilo-

grams). Be sure to use proper lifting techniques

when handling Spicer Life Series™ driveshafts. More

than one person may be needed when handling

driveshaft assemblies.

8. ALWAYS use support straps to prevent the drive-

shaft from falling out of vehicle during the removal

and installation process.

9. NEVER heat components or use sledgehammers or

floor jacks to remove the driveshaft from vehicle.

Note: For driveshaft applications that have pillow blocks,

dampers, parking brakes or retarders, refer to these

component manufacturers' or the original equipment

vehicle manufacturers' service manuals for proper pro-

cedures.

Reassembly of a driveline out of original phase can cause

vibration and failure of the driveline and attaching compo-

nents. Failure of a driveline can result in separation of

driveline from the vehicle, which can result in property

damage, serious personal injury or death.

Attaching or entangling support straps to fuel, oil or brake

lines or wiring can result in their damage. Damaged fuel,

oil or brake lines or wiring can result in failure of the vehi-

cle, which can result in property damage, serious personal

injury or death.

DO NOT reuse bearing retainer bolts, stamped straps,

stamped strap bolts, damaged bearing retainers, or use

inferior grade bolts. Reuse of bearing retainer bolts,

stamped straps, stamped strap bolts, damaged bearing

retainers or the use of inferior grade bolts can cause drive-

line failure, which can result in separation of driveline from

the vehicle. A separated driveline can result in property

damage, serious personal injury or death.

DO NOT deform yoke cross holes by removing excessive

metal. Raised metal or deformed yoke cross holes can be a

cause of cross and bearing failure, which can result in sep-

aration of driveline from vehicle. A separated driveline can

result in property damage, serious personal injury or death.

DO NOT reuse flange bolts, washers or nuts or use inferior

grade bolts. Reuse of flange bolts, washers or nuts or use

of inferior grade bolts can cause driveline failure, which

can result in separation of driveline from the vehicle. A

separated driveline can result in property damage, serious

personal injury or death.

Driveshaft assemblies can weigh in excess of 100 pounds

(46 kilograms). Make sure to use proper lifting techniques

when handling driveshafts. More than one person may be

needed when handling driveshaft assemblies.

Hand tightening of grease zerk fittings or plugs is NOT rec-

ommended. Grease zerk fittings or plugs will eventually

vibrate loose and fall out of journal. Prolonged operation

with missing grease zerk fittings or plugs allows contami-

nants into the universal joint. Invasion of contaminatns into

the universal joint can degrade the lubricant and cause uni-

versal joint damage, which can result in separation of the

driveline from the vehicle. A separated driveline can result

in property damage, serious personal injury or death.

WARNING

15

Driveshaft

Removal

Driveshaft Removal

Refer to the transmission, axle or transfer case original equip-

ment manufacturers’ service and maintenance manuals for

removal procedure.

Removal Procedures for Driveshaft Assem-

blies

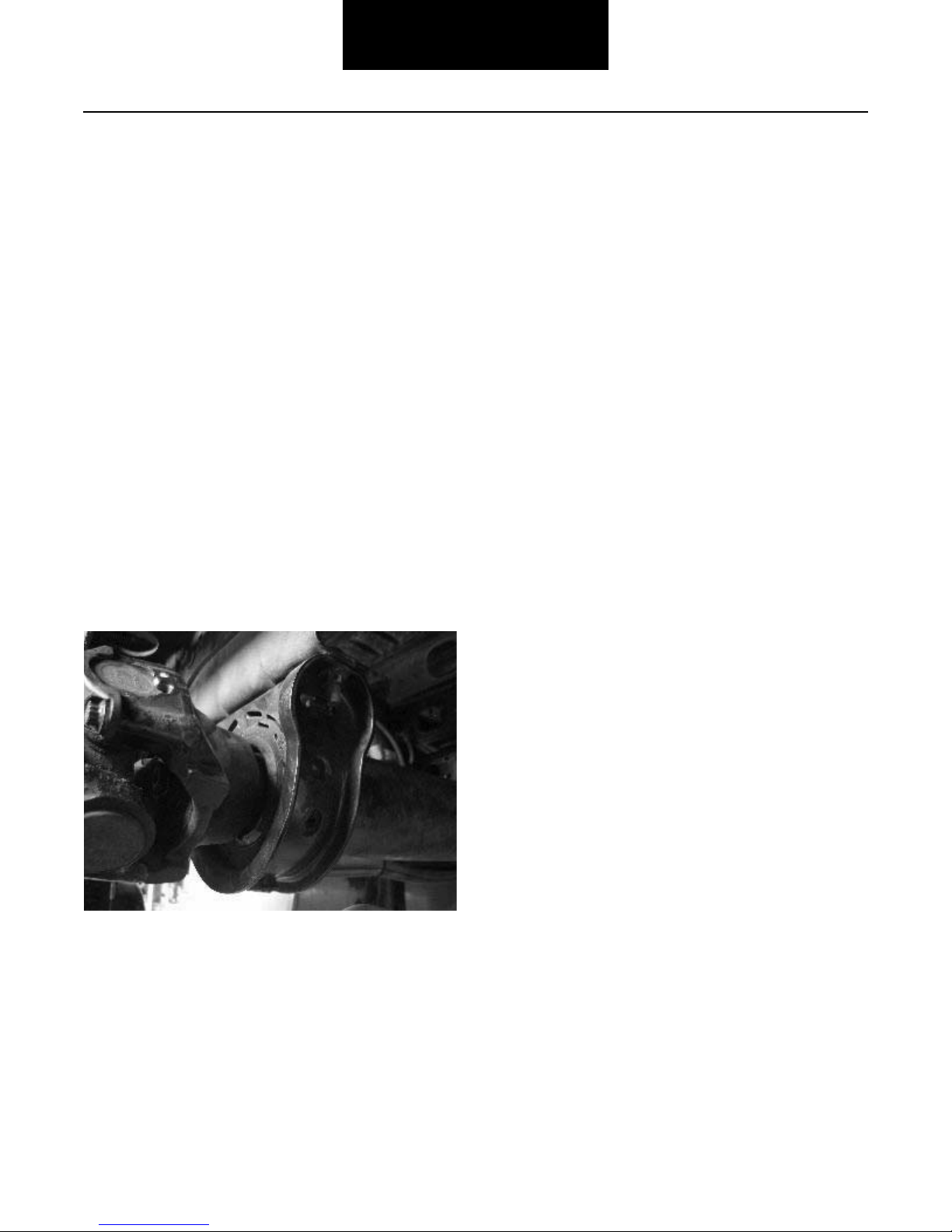

1. Mark Driveshaft ("Phasing Marks")

It is imperative to mark all the mating components of

a driveshaft, as illustrated below. Mark the driveshaft

with a marking stick, paint marker or other legible

marking device. In addition, be sure to mark all bear-

ing positions, spline positions, shaft locations and all

bearing retainers. This assures proper reassembly of

the driveshaft into the vehicle, in its original position.

2. Be sure to ALWAYS use support straps to prevent

the driveshaft from falling out of the vehicle.

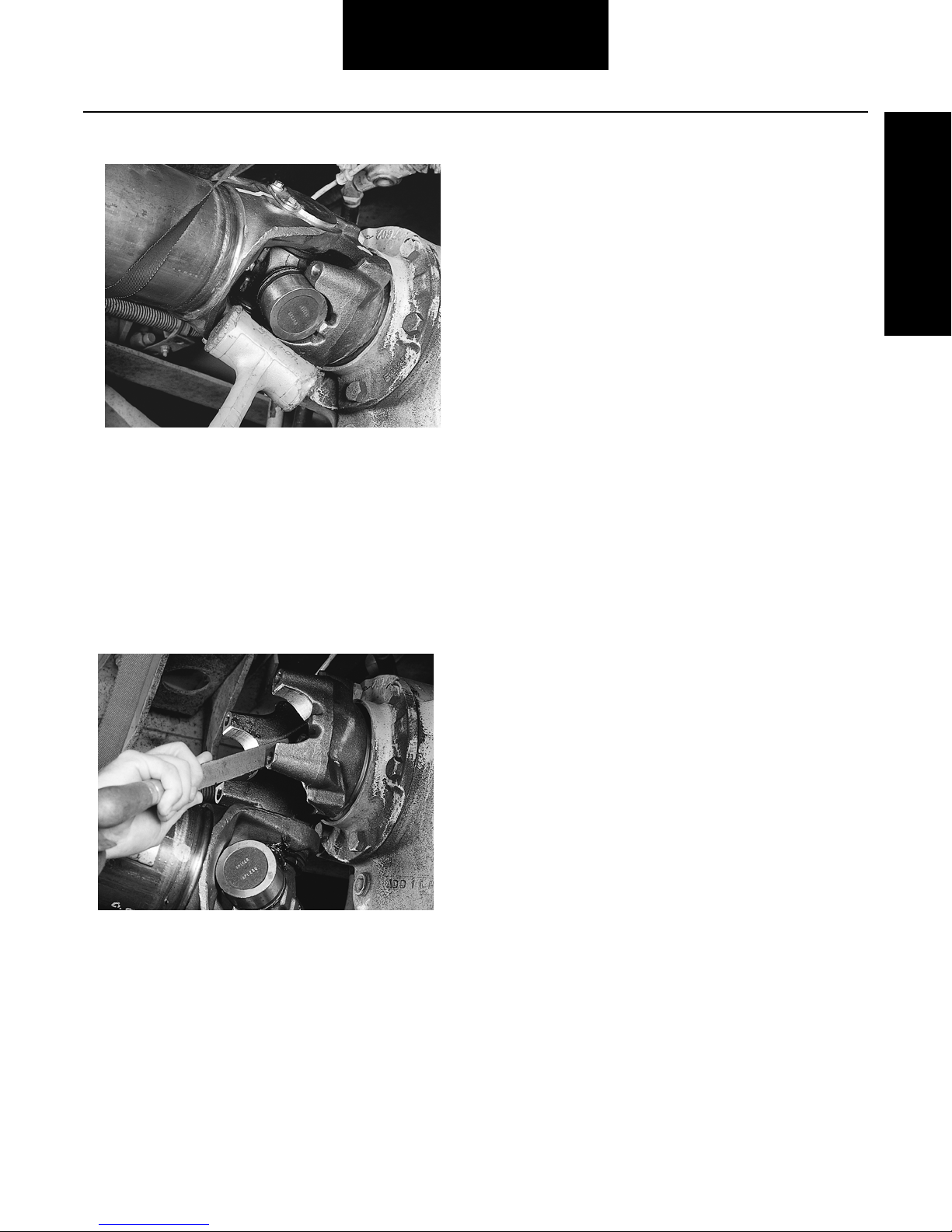

3. Remove the bearing retainers or stamped straps and

bolts at rear end. Discard bolts. Discard stamped

straps.

a. Cold Formed retainers CAN be reused if there is no

damage. If damaged, replace.

b. Stamped straps CANNOT be reused.

4. It may be necessary to unseat bearing cup assem-

blies by tapping on yoke or bearing cup with a soft-

faced hammer. Once the bearing cup assemblies are

free, collapse the driveshaft until both bearing

assemblies clear the open end yoke cross holes.

Allow the driveshaft to rest on support strap.

Cold Formed Straps

Stamped Straps

16

Driveshaft

Removal

5. Remove bearing retainers or stamped straps and

bolts at the front end.

6. Inspect all end yoke cross hole surfaces and bolt

hole threads for damage. If the bolt hole threads are

damaged, the yoke must be replaced.

7. Inspect for raised metal or fretting on open yoke

cross holes can be removed with a fine-toothed file

and/or emery cloth.

8. Inspect the end yoke cross holes for distortion and

damage.

Inspect Companion Flange/Flange Yokes

1. Inspect all flange bolt hole threads or through holes

for damage. If the bolt hole threads or through holes

are damaged, the flange must be replaced.

Note: For removal procedures for companion flanges, refer to

the original equipment manufacturers’ service and main-

tenance manuals. For removal procedures for flange

yokes, see removel of universal joints in this manual.

2. Inspect all flange faces for galling or damage. If

damaged, the flange must be replaced.

Grease Zerk Removal and Installation

Remove Grease Zerk Fitting or Plug

1. Tilt the universal joint kit or flange yoke and univer-

sal joint kit to allow access to effected grease zerk

fitting or plug. Using pliers or an open-ended

wrench, turn grease zerk fitting or plug counter-

clockwise until it is removed from the journal cross.

Discard the grease zerk fitting or plug.

Grease Zerk Fitting Only

Check for threads in the journal. If threads are

present, proceed to next step. If threads are not

present, replacement of universal joint is necessary.

2. Thoroughly wipe clean the grease zerk fitting or plug

threaded hole.

Install New Grease Zerk Fitting or Plug

3. Install new grease zerk fitting or plug. Tighten to

minimum 15 ft. lbs. (20 Nm). Then continue to turn

only until grease zerk fitting is correctly positioned.

Slip Member Assembly

Remove Grease Zerk Fitting

1. Using pliers or an open-ended wrench, turn grease

zerk fitting counter-clockwise until it is removed

from the slip yoke seal. Discard the grease zerk fit-

ting.

2. Thoroughly wipe clean the grease zerk fitting

threaded hole.

Install New Grease Zerk Fitting

3. Install new grease zerk fitting (Spicer part number

500174-1). Tighten to 31-55 in. lbs. (3.5-6.2 Nm).

Removal Procedure for Universal Joint Kits

Note: Refer to the Appendix for the recommended list of tools

for the following procedure.

Remove Universal Joint Kit(s)

17

Driveshaft

1. For Snap-Ring Style: Using snap-ring pliers,

remove all snap rings. If snap rings are severely cor-

roded or out-of-round, snap rings must be replaced.

1. For Quick Disconnect™ Style: Remove spring tab

bolts and discard, and remove outboard bearing cap

assemblies.

2. Make sure universal joints cross assembly is not

tilted in the yoke. Place bearing cup spacer onto the

base of the arbor press and under the yoke. If the

arbor is larger than the bearing cup diameter, a

smaller diameter push rod will be needed to avoid

damaging the yoke or bearing.

Snap-Ring Style

Quick Disconnect™ Style

Correct Positioning

Incorrect Positioning

Table of contents

Other Spicer Automobile Accessories manuals