Meritor Wabco 1000 Series Guide

TP-92116

Revised 8-98

TP-92116

16579/Meritor Revised 8-98

Printed in the USA © Copyright Meritor WABCO, 1998

Page 1

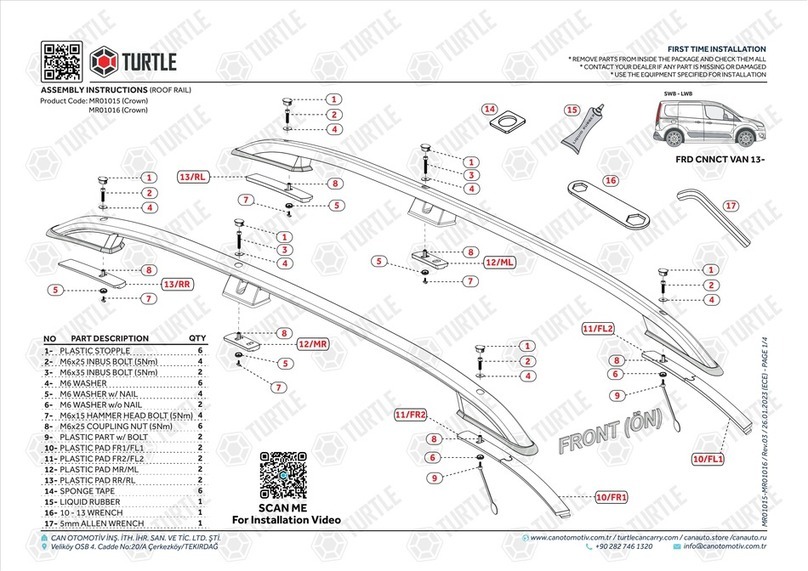

SERVICE PARTS

INSTRUCTIONS

Installing the

Meritor WABCO

System Saver 1000 and

1200 Series Air Dryers

For Use on Tractors, Trucks

and Buses with Air Brakes

Installation Requirements

1

2

3

4

5

M

E

R

I

T

O

R

W

A

C

O

P

/

N

4

3

4

1

0

0

3

1

0

0

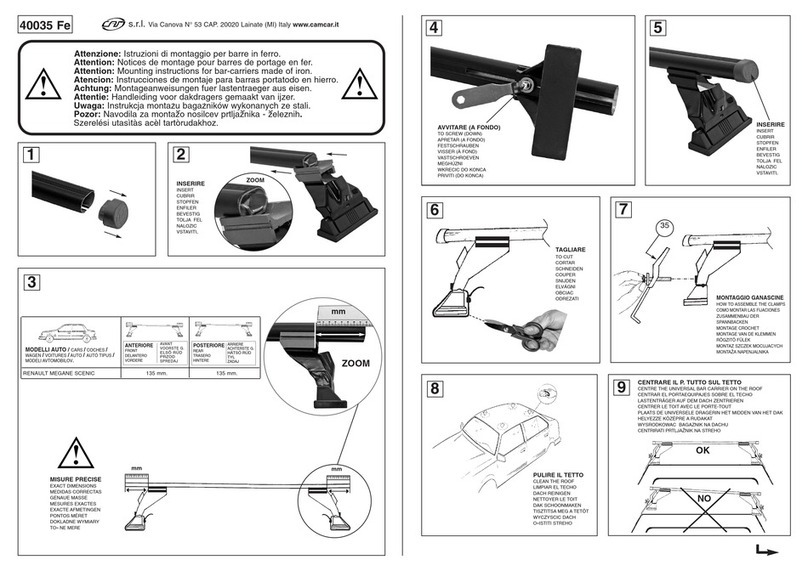

Item Qty. Description

1 1 12- or 24-Volt Air Dryer

2 3 Capscrew (1/2"-13 UNC – 2A x 1.375)

3 3 Lock Washer (1/8" thick)

4 1 Heater Power Harness

5 1 Pressure-Controlled Check Valve

TP-92116

Revised 8-98 16579/Meritor

Page 2

© Copyright Meritor WABCO, 1998 Printed in the USA

Service Notes

You must follow your company safety procedures when you install the System Saver 1000 and 1200 Series

air dryers. Meritor WABCO uses the following types of notes to give warning of possible safety problems

and to give information that will prevent damage to the air dryer.

WARNING

A warning indicates procedures that must be followed exactly. Serious personal injury can occur if the

procedure is not followed.

CAUTION

A caution indicates procedures that must be followed exactly. If the procedure is not followed, damage to

equipment or components can occur. Serious personal injury can also occur in addition to damaged or

malfunctioning equipment or components.

This symbol is used to indicate fasteners that must be tightened to a specific torque value.

NOTE

A note indicates an operation, procedure or instruction that is important for correct installation. A note

can also give information that will make installation quicker and easier.

Meritor WABCO System Saver Single Cartridge Air Dryer

Publications

MM34 Maintenance Manual

PB-96134 Parts Book

TP-9672 Air Dryer Application Guidelines

TP-9772 26” x 40” Troubleshooting Guide

Wall Chart

TP-97101 Troubleshooting Guide

(laminated card)

T-97105V Troubleshooting and Repair Video

(30 min.)

To order literature contact the Meritor Customer

Support Center at 800-535-5560.

Part Number Selection Guide (See page 3 for application information)

Series Voltage (100 Watts) Replacement Kit ID Tag Number

1200 Standard Application 12 volts R955205 432 413 001 0

1200 Standard Application 24 volts R955206 432 413 002 0

1200E Use with Holset E

Compressor 12 volts R955207 432 413 006 0

1200E Use with Holset E

Compressor 24 volts R955208 432 413 009 0

1200U Discharge Line

(Continuous Flow) Installation 12 volts R955210 432 413 007 0

1200U Discharge Line

(Continuous Flow) Unloader

Installation

24 volts R955211 432 413 021 0

TP-92116

16579/Meritor Revised 8-98

Printed in the USA © Copyright Meritor WABCO, 1998

Page 3

Introduction

This installation manual contains basic installation

instructions for standard air systems and

includes special instructions for installing the

Pressure-Controlled Check Valve (PCCV). It also

includes System Saver 1000 and 1200 air dryer

diagnostics. Read all instructions before

proceeding with your installation.

Application Information:

Cubic Feet per Minute (CFM) Less than 25 CFM

Normal Duty Cycle Less than 30%

Typical Compressor 2 Minutes or Less

Loaded Time

WARNINGS

To prevent serious eye injury, always wear

safe eye protection when you perform vehicle

maintenance or service.

Do not work around or under the vehicle

unless it is parked on a level surface. Use blocks to

keep the vehicle from moving. A moving vehicle

can cause serious personal injury and damage.

Remove all air from the air system before

servicing any component in the air system.

Pressurized air can cause serious personal injury.

Basic Installation Instructions

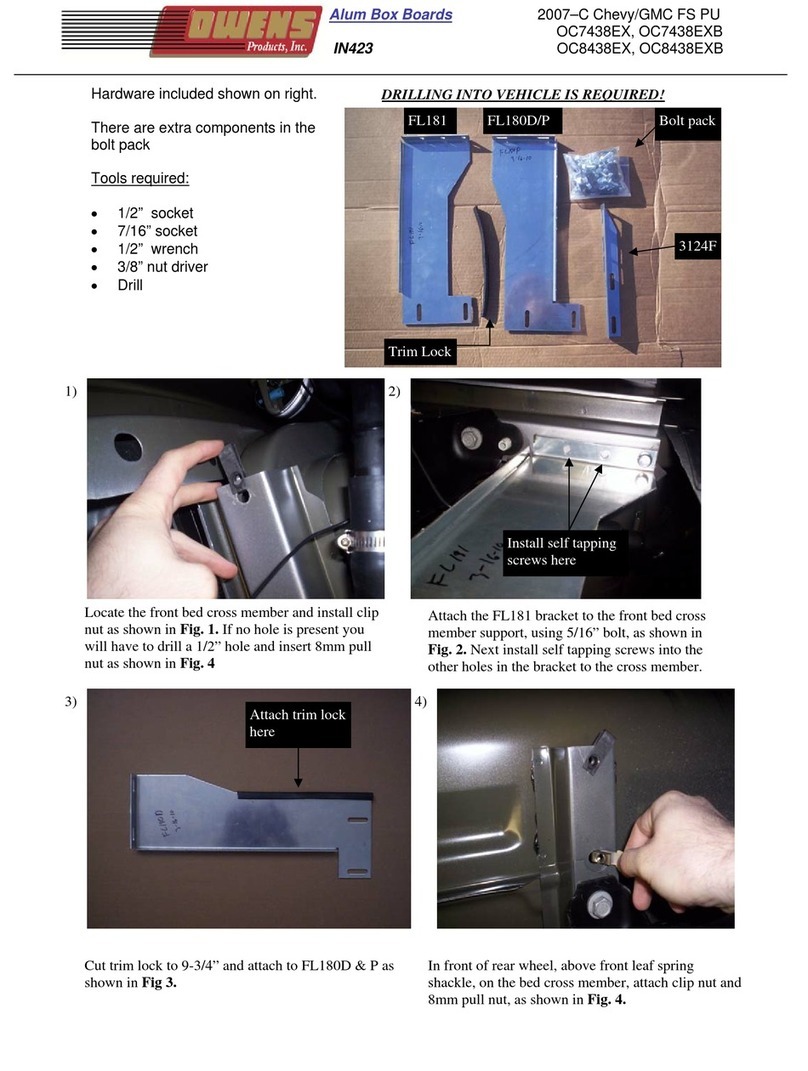

TYPICAL INSTALLATION FOR SYSTEM SAVER 1000 AND 1200 SERIES AIR DRYER

GOVERNOR COMPRESSOR

INTAKE LINE

UNLOADER

PORT

GOVERNOR

PORT

COMPRESSOR

DRYER INLET

COMPRESSOR

DISCHARGE

LINE PURGE VALVE

DRYER OUTLET

CHECK

VALVE SYSTEM

RESERVOIR

SYSTEM

RESERVOIR SYSTEM

RESERVOIR

SYSTEM

RESERVOIR

SUPPLY

(WET) TANK

PRESSURE-CONTROLLED

CHECK VALVE

TO BRAKE SYSTEM

TP-92116

Revised 8-98 16579/Meritor

Page 4

© Copyright Meritor WABCO, 1998 Printed in the USA

Mounting the Air Dryer

1. Park the vehicle on a level surface, stop the

engine, set the parking brake and block

the wheels.

2. Drain pressurized air from

all reservoirs

to

0 psi (0 bar). Open

all

draincocks to expel

collected water.

3. Inspect the vehicle for a suitable mounting

location that meets the following criteria. The

air dryer will operate most efficiently when you

follow these guidelines.

a. Mount the air dryer where cool air can flow

around it . . . but not directly in the vehicle

wind stream . . . and at least 12 inches away

from any heat source.

b. Mount the air dryer

LOWER

than the

compressor so that water in the delivery line

flows into the air dryer. There should be no

water traps (low points) in the line before or

after the air dryer.

c. Mount the air dryer in a vertical position or

within 30˚ of vertical, with the desiccant

cartridge at the top.

d. Allow at least two inches (51 mm) of

clearance above the top of the air dryer for

servicing the desiccant cartridge.

e. Mount the air dryer in a location where it is

not subject to direct splash or spray from

a wheel.

4. Apply the adhesive-backed template to the

selected location.

Figure 1

.

Figure 1

2.875" / 73 mm

2.063" / 52 mm

4.125" / 105 mm

Air Dryer Installation Template

TP-92116

16579/Meritor Revised 8-98

Printed in the USA © Copyright Meritor WABCO, 1998

Page 5

NOTE

Check the vehicle manufacturer’s specifications

before drilling into the frame member.

5. Drill 9/16-inch holes at each cross mark. Use a

mounting bracket, if necessary.

Figure 2 or 3

.

6. Mount the air dryer using the capscrews and

lock washers provided.

7. Tighten each capscrew to 22-30 lb-ft

(30-40 N

O

m).

Connecting the Air Lines

NOTE

Use pipe sealant or teflon tape on all air fittings.

NOTE

The reference to nylon tubing throughout this

manual refers to SAE J844 air brake nylon tubing.

1. Connect the delivery line from the compressor

to the air dryer inlet port (1/2" NPTF, marked

“1”) with 1/2-inch-ID minimum stainless-steel

braided teflon hose. The air dryer will operate

most efficiently when the following guidelines

are used.

a. The delivery line should follow a

DOWNHILL

route to the inlet port

(Figure 4),

free of kinks

and sags, which cause water traps.

b. Air temperature entering the dryer should

be less than 175˚F (79.5˚C). The delivery line

must be at least 6.0 feet (1.83 m), but most

vehicles require a greater length to achieve

this condition.

c. The delivery line should not exceed 20 feet

(6.1 m), or moisture within the line can

freeze, blocking air passage.

d. Insulate a delivery line with a length of over

10 feet (3.0 m).

Figure 2

Figure 3

Figure 4

TP-92116

Revised 8-98 16579/Meritor

Page 6

© Copyright Meritor WABCO, 1998 Printed in the USA

2. Connect the air dryer outlet port (1/2-inch

NPTF, marked “21”) to the inlet of the supply

(wet) tank with 1/2-inch or 5/8-inch nylon

tubing.

Figure 5

.

3. Connect the air governor unloader port to the

air dryer control port (1/4-inch NPTF, marked

“4”) with 1/4-inch or 3/8-inch nylon tubing.

Figure 6

.

4. Check all fittings for leaks before proceeding.

Connecting the Heater

The System Saver 1000 and 1200 Series air dryers

are available in 12- or 24-volt models; each has a

100-watt heater. Each kit contains a two-wire

harness which supplies power to the unit. Be sure

to select the correct power source for the air dryer

model. Using the wrong voltage can cause

malfunction and even damage the unit. Check

vehicle manufacturer specifications for exact

wiring information.

1. Connect one of the leads to a good vehicle

ground. Attach the other lead to a line that is

powered with the ignition in the run position,

and not powered with the ignition off. A

15-amp fuse is recommended for this line for

12 volts and 7.5 amps for 24 volts.

2. Press the male plug on the end of the power

cable into the receptacle on the side of the

dryer. Plug must be inserted until the latch

snaps over the tab on the mating connector.

Figure 7

.

3. Insulate and seal all electrical splices and

properly secure the harness.

Figure 5

Figure 6

Figure 7

TP-92116

16579/Meritor Revised 8-98

Printed in the USA © Copyright Meritor WABCO, 1998

Page 7

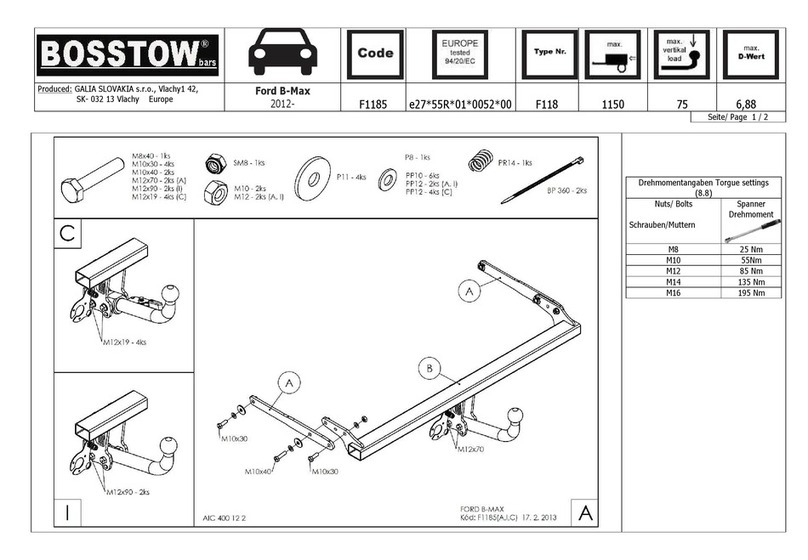

Determine the Correct

Pressure-Controlled Check Valve

(PCCV) Placement for the

System Saver 1000 and 1200 Series

Air Dryer

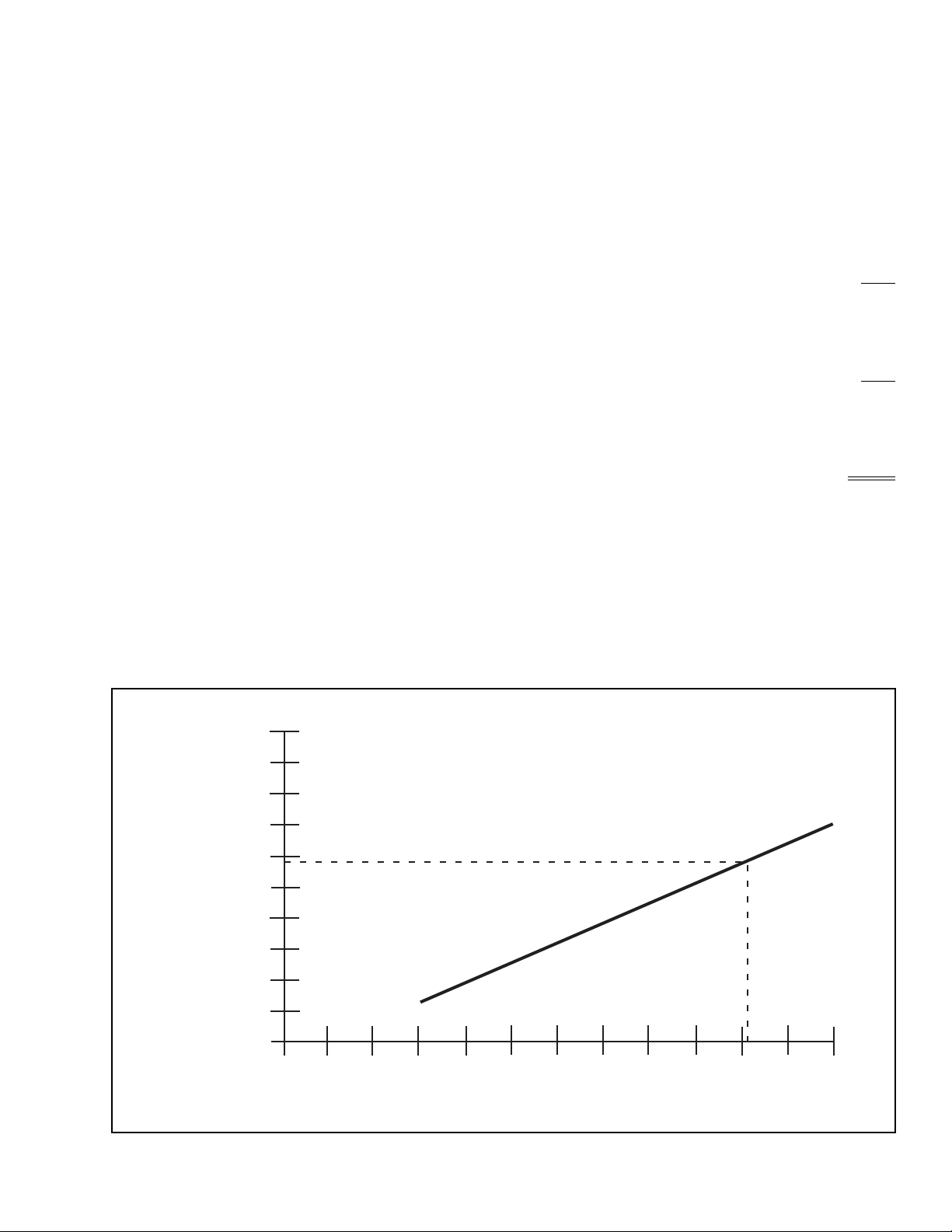

The regeneration volume is determined by how

much compressed air is pumped through the air

dryer during each compressor cycle. The following

chart shows the proper sizing of the system and

the volume of the reservoirs contributing to the

regeneration volume required for a given

installation. The “reservoirs contributing to

regeneration” will determine the placement of the

PCCV in the system. Since the air dryer will take

approximately 10 psi from the contributing

reservoirs, the volume for regeneration will be a

function of the reservoir sizes.

The “Total System Size” is the sum of all the air

tanks to be filled on all vehicles that the

compressor will be filling. For instance, if the

tractor has a total air system of 6000 in

3

(supply — 900 in

3

, primary 3200 in

3

, secondary

1900 in

3

) and it pulls a lead single trailer with

1400 in

3

, a single axle dolly with 1400 in

3

, and a

second single axle trailer with 1400 in

3

, the total

system size is 10,200 in

3

. Looking at the chart and

finding 10,200 in

3

at the bottom, reading up and

over shows the system needs 2856 in

3

of reservoir

volume contributing to regeneration. From this

volume,

≈

10 psi would be taken for regeneration.

In this case, installing the PCCV on the primary

tank gives adequate regeneration volume (supply

900 in

3

+ primary 3200 in

3

= 4100 in

3

).

Figure 8

.

Formula for Total System Size

Use the formula below to compute total

system size.

r

Total System Size = Sum of all reservoir tanks

an air compressor must service in the vehicle’s

air system

.

Example:

(IN

3

)

r

Supply (Wet) Tank 900

Primary Reservoir Tank 3200

Secondary Reservoir Tank 1900

Tractor’s Total Air System 6000

(IN

3

)

r

Lead Single Axle Trailer 1400

Single Axle Dolly 1400

Second Single Axle Trailer 1400

Total Load Pulled: 4200

r

Total Combination Vehicle

System Size (IN

3

)

The Air Compressor

Must Service 6000 + 4200 = 10,200

Figure 8

5000

4000

3000

2000

1000

0

Total reservoir volume — in3

0 5000 10,000

Volume of reservoirs contributing

to regeneration — in3

TP-92116

Revised 8-98 16579/Meritor

Page 8

© Copyright Meritor WABCO, 1998 Printed in the USA

Installing the Pressure-Controlled

Check Valve (PCCV)

NOTE

The pressure-controlled check valve replaces the

one-way check valve on either the secondary or

primary service reservoir. Use pipe sealant or

teflon tape on all air fittings.

1. Identify the appropriate service reservoir (see

above) and locate the one-way check valve at

the inlet. This reservoir is fed by the supply

(wet) tank and typically supplies air to the front

brakes and air-operated accessories. For more

information about the PCCV, please refer to

TP-9672,

Air Dryer Application Guidelines

.

NOTE

If the one-way check valve is internal or otherwise

inaccessible, locate the check valve on the

primary reservoir.

2. Remove and

discard

the one-way check valve

from the reservoir.

NOTE

The arrow located on the face plate of the PCCV

must point

TOWARD

the reservoir. Figure 9

.

3. Install the pressure-controlled check valve in

place of the check valve you discarded. If space

is limited, you can use a 45˚ or 90˚ pipe fitting.

4. Reconnect the supply line from the supply

(wet) tank to the inlet of the PCCV. Reroute or

shorten the air hose as necessary.

Check the Vehicle’s Air System for

an Alcohol Evaporator

NOTE

Typically, an alcohol evaporator will be installed in

the line between the air dryer and the supply (wet)

tank. Common installations are on the truck’s

firewall, on a frame rail and behind the cab.

However, an alcohol evaporator can also be found

at other locations.

1. Check the vehicle’s air system to determine if

an alcohol evaporator is installed.

2. If an alcohol evaporator is installed in the air

system, check for a bypass line connected to

the evaporator, as illustrated in

Figure 10

.

CAUTION

If a check valve is installed in the bypass line, the

air dryer will not function properly. Damage to the

system can result.

3. If a bypass line is connected to the evaporator,

check to see if a check valve is installed in the

bypass line. If check valve is installed:

a. remove the check valve from the

bypass line,

b. remove the bypass line and

c. replace the bypass line with 1/4-inch

nylon line.

4. If there is no bypass line installed at the alcohol

evaporator, install one using 1/4-inch nylon

line.

Figure 10

.

Figure 9

M

E

R

I

T

O

R

W

A

C

O

P

/

N

4

3

4

1

0

0

3

1

0

0

Figure 10

BYPASS LINE

LINE TO

SUPPLY TANK

ALCOHOL

EVAPORATOR

1/4"

NYLON

LINE

LINE TO

AIR DRYER

TP-92116

16579/Meritor Revised 8-98

Printed in the USA © Copyright Meritor WABCO, 1998

Page 9

Testing the System Saver 1000 and

1200 Series Air Dryers

1. Close the drain cocks on all reservoirs.

2. Start the vehicle. Wait for the air system to

reach full operating pressure.

3. If the air dryer exhausts air for 10-20 seconds

after the governor cuts out, it is

working correctly.

4. Apply vehicle brakes several times until the

compressor cuts in.

5. If the air dryer exhausts air for 10-20 seconds

after the compressor cuts out, it is

working correctly.

NOTE

One of the air pressure gauges on the vehicle

instrument panel will decrease by approximately

10 psi when the compressor cuts out and the air

dryer purges. This decrease is normal for the

System Saver 1000 and 1200 Series air dryers.

If the gauge does not decrease, recheck the

plumbing to ensure proper placement of the

pressure-controlled check valve.

Final Checks

1. Start the vehicle. Wait for the air system to

reach full operating pressure. When the

compressor cuts out, listen to the air dryer.

If either of the following conditions exist,

refer to Meritor WABCO Maintenance

Manual No. 34,

System Saver 1000 and 1200

Series Air Dryers

.

a. The air dryer continues to exhaust air for

longer than 30 seconds.

b. The air dryer does not exhaust air after

initial decompression.

2. Shut engine

OFF

. Apply a soap solution to each

connection that contains pressurized air:

a. If soap bubbles do not appear, connections

are sealed properly.

b. If soap bubbles appear:

r

Drain all reservoirs.

r

Remove leaking connection.

r

Inspect for damaged threads or cracks;

replace as necessary.

r

Apply pipe sealant or teflon tape to the

connection.

r

Repeat process.

TP-92116

Revised 8-98 16579/Meritor

Page 10

© Copyright Meritor WABCO, 1998 Printed in the USA

TP-92116

16579/Meritor Revised 8-98

Printed in the USA © Copyright Meritor WABCO, 1998 Page 11

System Saver 1000 and 1200 Series Air Dryers Diagnostics

Condition Possible Cause Solution

Dryer leaks from purge

valve during compressor

loaded cycle. The leak

may cause excessive

compressor cycling or

prevent the system from

building air pressure.

Purge valve frozen open (cold weather

operation).

Debris under purge valve seat, such as particles

from fittings or air inlet line.

Purge valve washer installed upside-down.

Wrong air line connected to dryer port 4

(unloader port).

Purge valve snap ring not fully seated in groove.

Check heater. Repair/replace if necessary. Make

sure governor to dryer port 4 line is free of water/oil.

Removeandinspectpurgevalveandcleanwater/oil

from top of piston.

Disassemble and clean purge valve.

Remove cartridge and clean dryer sump area.

Ensure lip on aluminum washer faces down, away

from dryer.

Verify correct air line installation and correct as

needed.

Seat snap ring fully into groove.

Slight leak from purge

valve.Afterseveralhours,

the supply tank may be

empty.

Outlet check valve not seating or regeneration

valve not shutting off regeneration airflow. Remove, inspect, and clean outlet check valve and

regeneration valve diaphragm. Replace if worn or

damaged.

Regeneration cycle too

long (more than

30 seconds),

accompanied by loss of

pressure in the supply

tank.

Outlet check valve not seating.

Regenerationvalvenotshuttingoffregeneration

airflow.

Inspect and replace outlet check valve as needed.

Replace regeneration valve.

Regeneration cycle too

short (less than 10

seconds).

High air system demands during compressor

unloaded cycle.

Pressure-controlled check valve not installed in

system or not working properly.

One-way check valve installed in system

reservoir instead of, or with, pressure-controlled

check valve.

Regeneration valve not working.

Air governor not working properly.

Increase air system capacity or reduce air demands.

Check and replace pressure-controlled check valve

as needed.

Remove one-way check valve. Make sure pressure-

controlled check valve is installed correctly.

Remove regeneration valve and clean oil from

diaphragm. If no oil or other contaminants are

present, replace regeneration valve assembly.

Inspect per manufacturer’s instructions and repair/

replace as needed.

Noregenerationcycle.No

airflow from purge valve

after initial purge blast

(dryer decompression).

Air dryer not connected to supply tank or

connections reversed at dryer.

Regeneration valve not working.

One-way check valve installed in supply tank.

Alcohol evaporator installed between dryer and

supply tank.

Verify proper dryer installation per system diagram.

Replace regeneration valve.

Remove one-way check valve.

Install bypass line around evaporator or remove

evaporator from system.

Air dryer purges too

often, perhaps as

frequently as every

15seconds, accompanied

by excessive cycling of

the compressor.

Leak in line between governor and dryer port 4.

Leak in line between supply tank and governor.

Excessive air system leaks.

Excessive air system demands.

Outlet check valve not sealing.

Regeneration valve not shutting off properly.

Air governor has less than 16 psi range.

Leaking air compressor unloader(s).

Repair air line.

Repair air line.

Repair leaks.

Increase air system capacity or reduce air demand.

Inspect and replace outlet check valve as needed.

Replace regeneration valve.

Replace air governor.

Inspect compressor. Repair/replace per

manufacturer’s instructions.

Air dryer does not purge

when compressor

unloads (no blast of air

from purge valve).

Air line between governor and air dryer port 4

kinked or plugged.

Purge valve stuck closed.

Air governor not working properly.

Cut-out pressure never achieved by air

compressor.

Repair air line.

Replace purge valve.

Inspect air governor. Repair/replace per

manufacturer’s instructions.

Check for air leaks in system and repair as needed.

If no leaks in system, check compressor output.

Repair/replace per manufacturer’s instructions.

Air flows out of purge

valve entire time

compressor is unloaded.

Turbo cut-off valve not sealing. Replace turbo cut-off valve.

Meritor WABCO

Vehicle Control Systems

2135 West Maple Road

Troy, MI 48084 U.S.A.

800-535-5560

www.meritorauto.com

Information contained in this publication was in effect at the time the publication was approved for

printing and is subject to change without notice or liability. Meritor WABCO reserves the right to

revise the information presented or discontinue the production of parts described at any time.

© Copyright 1998

Meritor WABCO

All Rights Reserved Printed in the USA

Please Recycle

TP-92116

Revised 8-98

16579/Meritor

Rapid “spitting” of air

from purge valve in small

amounts. Frequency

varies with engine speed.

Holset E-Type compressor used, but non-1200E

dryer installed.

Compressor not completely unloading when

cut-out pressure is reached.

Replace air dryer with a System Saver 1200E air

dryer.

Inspect compressor. Repair/replace per

manufacturer’s instructions.

Air leak at turbo cut-off

valvevent.Holeburnedin

piston.

Temperature of air coming into dryer is too high

– not enough cooling takes place before dryer

inlet.

Move dryer farther from compressor. Add

additional compressor discharge line before air

dryer. Add cooling coil or heat exchanger before air

dryer.

NOTE: Inlet air temperature must not exceed 175°F.

Air leak at turbo cut-off

valve vent. Lip seal installed upside-down on piston. Lip

must face UP (towards dryer).

Valve bore worn excessively.

Install lip seal correctly.

Inspect valve bore for wear. If a new turbo cut-off

valve does not seal in a clean, lubricated bore,

replace the air dryer.

Air dryer frozen (water

collecting in base of dryer

is freezing).

No electrical power to heater connector.

Low voltage to heater connector.

Heater assembly not working.

Wrong voltage air dryer used; i.e., 12-volt air

dryer used in a 24-volt system.

Check for a blown fuse. Repair heater circuit.

NOTE: There must be power to the heater

connector the entire time the vehicle’s ignition is

“on.”

Repair cause of low voltage, such as poor electrical

ground, bad connections, corroded wire splices,

etc.

Replace heater assembly.

Replace with correct voltage air dryer.

No air pressure build-up

in system. Air dryer not plumbed correctly (connections

reversed).

Wrong air line connected to dryer port 4.

Air governor not working properly.

Air system leaks, such as compressor discharge

line, air dryer, reservoirs, brake or suspension

valves, etc.

Air dryer leaks from purge valve.

Ensure compressor discharge line is plumbed to air

dryer port 1, and air dryer port 21 is connected to

vehicle’s supply tank.

Ensure dryer port 4 line is connected to the “UNL”

port of the air governor.

Inspect governor per manufacturer’s instructions.

Repair or replace as needed.

Locate leak(s) and repair.

See purge valve conditions listed in this chart.

Water in tanks; often

following aftermarket

installation or when dryer

is a replacement for a

competitive brand.

Pressure-controlled check valve not installed in

correct tank or not installed at all.

Pressure-controlled check valve properly

installed, but one-way check valve not removed.

Installpressure-controlled checkvalve in secondary

tank.

Remove one-way check valve so that only the

pressure-controlled check valve is installed

between the secondary tank and supply tank.

Water, oil, or sludge in air

system tanks. Desiccant contaminated with oil.

Holset E-type compressor used, but non-1200E

dryer installed.

Replace desiccant. Inspect compressor per

manufacturer’s instructions.

Replace air dryer with a System Saver 1200E air

dryer.

Water in system tanks,

everything else checks

out okay.

Dryer not suitable for application. Review application guidelines. For assistance, call

Meritor Customer Support Center at

1-800-535-5560.

System Saver 1000 and 1200 Series Air Dryers Diagnostics (Continued)

Condition Possible Cause Solution

This manual suits for next models

1

Table of contents

Other Meritor Wabco Automobile Accessories manuals

Popular Automobile Accessories manuals by other brands

Cruz

Cruz Evo Rack Alu A23-140 Assembly instructions

Schaudt

Schaudt CSV 416 operating instructions

ARKSEN

ARKSEN 002-AU-19CC owner's manual

Classic Accessories

Classic Accessories StormPro RainProof Instructions & Care

Subaru

Subaru H001ssC800 installation instructions

Connects2

Connects2 Vision CAM-4 user manual