PerTronix© thanks you for choosing JBA HEADERS, the best tting, highest

quality header on the market. In order to realize the full potential of our good

t, please read and understand these instructions completely prior to starting

work.

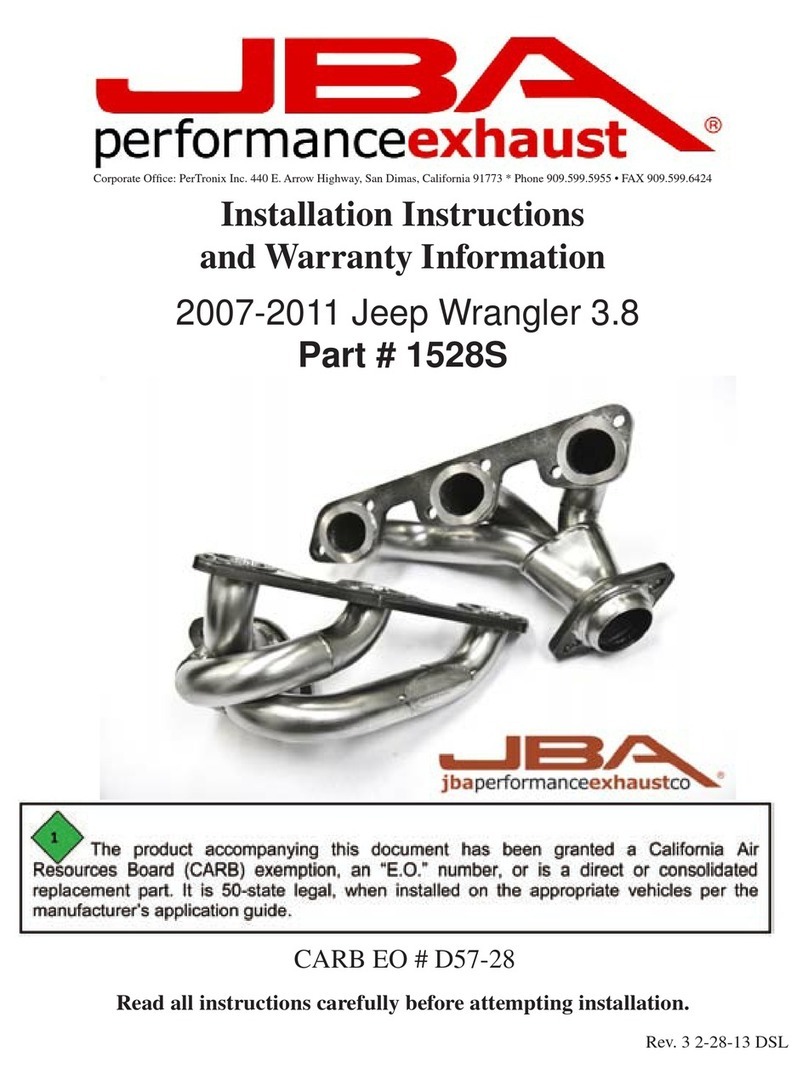

Check to make sure you received the proper parts for your application. The

header number will be stamped on the engine ange. If you are unsure you

have received the proper parts call before you start work.

Be sure to work safe! Whenever you work under the vehicle be sure that it

is located on level, solid ground and is supported by adequate safety stands!

Remember: Hot asphalt will not support most jack stands!

Many factors aect the installation of headers, some of which are broken or

aftermarket motor mounts, accidents that impact the conguration of the

frame, and/or the installation of dierent engines or aftermarket cylinder

heads.

Attention Customers breaking in new engines: Due to the extreme heat gener-

ated during the break-in process, the appearance of the ceramic coating may

be altered in certain areas. The protection characteristics and thermal barrier

properties of the coating is never compromised. It is recommended that a cast

iron manifold or old set of headers be used for this process.

Notice: The coating of these headers can be marred or scratched during instal-

lation. If the header needs to be returned and is damaged, you will be charged

for recoat.

JBA uses sealing beads on all its headers. We have found that when installed cor-

rectly,theraisedbeadaroundeachportincreasesthepressureexertedonthegasket

directly adjacent to the port and eectively prevents leaking gaskets. It is normal

for the ange to be raised o the cylinder head the thickness of the sealing bead.

It is important when installing the header, to install all bolts loosely, then tighten

evenly to ensure the at installation of the ange. The torque sequence from one

ange to another will vary, but generally every bolt on a header should be rst t

snug, starting from the inside of the ange working out, alternating from top to

bottom so that the bolt connects the ange to the manifold to the point where they

barely touch. Second, using the same inside-out pattern, tighten each bolt until

nished. This method will help prevent leakage and will give the user the best pos-

sible performance out of their pair of headers.