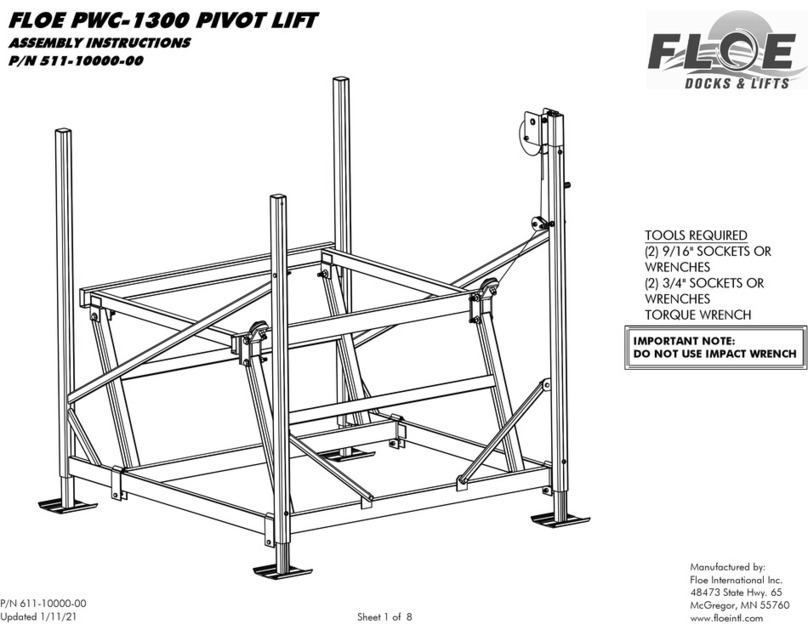

SPIDER SC1500 User manual

Property of SafeWorks LLC. This information is proprietary and may not be copied or reproduced without written consent of SafeWorks LLC.Swing Stage Checklist 705997-1 Rev C

Checklist for Operating Swing Stages on Wind Turbine Exteriors

√Read the Code of Safe Practices prior to using platform.

√ ReadthehoistOperational Manual prior to using platform.

√ PerformtheHoist Daily Inspections prior to using the platform.

√ ReadtheGenerator Requirements on the Checklist prior to using platform.

√ Verifytotalplatformweightandliveloaddoesnotexceedhoist’sratedload.

√ Whende-riggingthesecondarywirerope,toremovethesecondarywireropefromthehoist,pushthe

primaryinletguidetothesidetoreleasethesecondarysafetybrake.

√ Verifythatfallarrestsystemsdonotallowtheworkertofalla

distance greater than 6 feet.

√ Knowthemaximumwindspeedallowedforexteriorwork

inthewindfarm.Carryananemometertomeasurewind

speed.Donotworkinunsafewindorweatherconditions.

√ Ensuretaglinesaresecuredtostructuraluprightsof

platform. (1)

√ Verifyfallarrestanchorboltsaretightenedto150ft-lbsof

torque. (2)

√ Keepthedeckcleartoeliminatetriphazards.Usework

bucketstostorematerialsoutsidethedeck/platformarea.

√ Verifykellumgripsonpowersupplyareattachedproperlyto

stirrup.

WARNINGS

√ Topreventdamagetoequipment,de-rigplatformduring

severeweatherconditions.

√ Inspectwireropesforkinks,brokenwiresorbirdcagingprior

to rigging.

√ Donotoverloadtheplatform.Conrmthatweightofthe

totalequipmentincludingworkers,tools,wireropes,power

cordandaccessoriesdoesnotexceedhoistratedload.

√ Verifyallrollersonstirrupmastturnfreelyandthatthereare

nosignsofexcessivewear.(3)

√ Donotdrill,cut,removepartsfromormodifytheplatform.

Ifyouneedsomethingdifferentontheplatform,call

SPIDERat877-774-3370forassistance.

√ Ifhoistisnotoperatingproperly,readtheoperationmanualfortroubleshootinghelp.

Primary (red)

Secondary ( grey)

2 (2x)

1 (4x)

√ Fallarrestanchorhastwoconnectionpoints;one

peroperator.Theseconnectionpointsaretobe

usedwithashock-absorbinglanyard.(4)

√ Verifythelifelineisproperlyattachedtothe

platformatthetoprailbumperplate.Thelifeline

isusedtostabilizetheplatformonthebladeor

tower.Toreleaselifelinefromropegrab,pull

ropetowardsropegrabandthenreleasecam.

(5)

√ Verifythesupportisinplaceandboltsare

secure. (6)

√ Verifythehoistnameplateinformationmeetsthe

requirementsforvoltagesuppliedtothehoistand

capacityratingsoftheplatform.(7)

√ Verifythestoragebucketisproperlyattachedto

theplatformanddrainholesinthebucketare

freefromdebris.Toremoveorrelocatethe

storagebucket,pullthespring-loadedpinto

disengage it from the platform. (8)

√ Verifythehoistlanyardisattachedtothehoist

carryinghandleandthestirrupasshownin

detailed picture to secure hoist in the upright

position. (9)

√ Verifytherollerbumpersaresecuredtothe

platform.Verifytherollerbumpersturnfreely

and are in good condition. (10)

√ Verifythehitchpinsareinstalledandaresecured

withahairpin.(11)

4 (2x)

9

5

10 (6x)

8

7

3

11

11 (2x)

6

Property of SafeWorks LLC. This information is proprietary and may not be copied or reproduced without written consent of SafeWorks LLC.Swing Stage Checklist 705997-1 Rev C

SpiderrecommendsthefollowinggeneratorsforusewithitsSC1000andSC1500electrictractionhoistsrunningon

110VACand208VACsingle-phase60Hz,and208VAC3-phase60Hz.

HoistModel PartNumber HoistCapacityinlbs VoltageAC AmperagePhase MinimumKWperhoist*

SC1500 9015,9016 1500 208 9.9 1 6

SC1500 9035,9036 1500 208 6.9 3 6

*Whenusing3hoistsormoreonaplatform,consultSpiderproductsupportat+1(206)394-5319forpropergensetratings.

Theserecommendedgensetratingsaretheminimumrecommendedbasedonintermittentplatformmovement(lessthan10

minutesofcontinuousupwardtravel)andstandardambientconditions.

Usingalargercapacitygeneratorisalwaysacceptable,andisadvisedifanyofthefollowingarepresent:

• Ambienttemperatureover100°F

• Relativehumidityover50%

• Siteelevationabovethan5000feet

• Cordlengthover250feet,wheretransformerisnotused.

• Runningthehoistscontinuouslyformorethantenminutes

IMPORTANT:Verifythevoltageoperatingrangeofthehoistbeforepluggingitintothegenerator.Voltagethatistoohighortoo

lowwilldamageahoist,causingworkdelaysandexpensiverepairs.Consultthehoistoperator’smanualbeforeyoustart.Use

abuckorboosttransformertoadjustoutputvoltageofthegeneratortomeetthehoist’sspeciedvoltage.Verifythatthetrans-

formeriswiredforthedesiredbuckorboostfunction.

Key Term What you need to know:

Portable Engine- Anengine-drivengeneratoror‘genset’.Engineconvertsfuelintomechanicalpower;

Generator set generatorconvertsmechanicalpowerintoelectricalpower.

Fuel Eitherdieseloil,gasoline,naturalgasorpropanevapor.

Governor Adjuststheenginethrottlepositiontomaintainenginespeedandoutputfrequencyasloadschange.

Voltage Regulator Controlstheoutputvoltageastheloadchanges.Usuallynotadjustableonportableunits.

Frequency (Hz) ThenumberoftimespersecondtheACvoltageandcurrentgofrommaximumtominimum

andbacktomaximum.

Directlycontrolledbytheenginespeed

DeterminesthespeedofanACmotordrivenbythegenset

Ambient conditions Theairtemperature,humidityandelevationabovesealevelusedtorategensets

Generator ratings Theamountofpoweragensetcanproduceoveralengthoftimewithoutdamage

Intermittentrating:Thehighestoutputavailableforashortperiodoftime

Standbyrating:Forusewhenutilitiesgoout,runningnomorethan60hoursayear

Continuousrating:Powerlevelproducedcontinuously,mustbeasteadyload

Primerating:Forusewhengensetisprimarysourceofpower,running24hoursadayunder

varyingloads.

!! Increased air temperature, humidity and elevation reduces the engine power output,

and the generator output power ratings

Contact Spider at 877-774-3370

Generator Size Recommendations

& Operations Overview

Inverters AnelectronicdevicethatconvertsDCelectricalpowerintoACelectricalpower.

InvertergeneratorsuseaDCgeneratorconnectedtoaninvertercreatingACpower.

Typicallyquieter,weighless,uselessfuel.

Limitedpoweroutputandeasilydamagedbysuddenloadsurges.

3-Phase Power Electricalpowerprovidedbythegridin3phases,orseparatelines.Usedforequipmentwithhigh

startup loads

Single-Phase PowerUsedformosttoolsanddevices.Oneofthethreecircuitscomingfromthegrid.

Startup/Run Factor Powerrequiredwhenanelectricalmotorisstartedwithaloadalreadyappliedtoit

(suchasahoistsupportingaplatform).

Powerrequiredforascaffoldhoistmotorcanbe3timestherunpower.

Power Cord Connectsthegensetandmotor,includesplug(male)andsocket(female)connectoratends.

Orientationofconnectorpinsandsockets(xtox,ytoy,etc)oneachwiremustbecorrectorthevoltage

and/orphasewillbeincorrect

TROUBLESHOOTING POOR HOIST PERFORMANCE AND DAMAGE DUE TO:

.

Low Engine Speed/ Outputfrequencymeasuredwithamulti-meteratthepoweroutletorendofthepowercordmust

Output Frequency measurebetween58and62Hz.Ifyougetadifferentreading,consulttheoperator’smanualor

contactthegenset’sauthorizedserviceprovider

Checktoseeifthegensetissetin“energysaver”mode.Thismodeidlestheengineuntilaloadis

appliedtoit.Thehighstartuploadsofahoistmotorcandamagethegensetwheninthismode,

andalsothehoistmotor.Keepthegensetinfullrunmode.

Incorrect Voltage Ifoutputvoltageatthegensetgaugepanelormeasuredwithamulti-meteratthegensetoutletis

lessthantheratedhoistvoltagewithnoload,donotusethegensettopowerthehoist.Checkthe

gensetoperator’smanualforhowtoadjusttheoutputvoltageorcontactthegen-set’sauthorized

serviceprovider.

Ifthevoltageattheoppositeendofthecordislessthantheratedhoistvoltageornovoltageis

measured,checkforincorrectsocket/plugalignmentinthecord,plugandsocket.

Orientationofconnectorpinsandsockets(xtox,ytoy,etc)oneachwiremustbecorrectorthevoltage

and/orphasewillbeincorrect

Low Fuel Level Lowfuelsupplyaffectsthegen-setspeed,causingvoltageandpowersurgesthatcandamagethehoist.

Consultthegensetoperator’smanualsforfuelconsumptionratesandmakesureenoughfuelis

availablefortheoperatingshift.

Consultthegensetoperator’smanualsafetyconsiderationsduringrefuelingandonre-startingafter

refueling

Intake, Exhaust and Restrictingthegensetairintake,exhaustorcoolingsystemswillresultinlowpoweroutput,overheating

Cooling System anddamage.Thegensetmustbeinanopenspacewithplentyofroomaroundittodrawinairandlet

Blockage exhaustgasesleavethearea.

AlwaysfollowOperator’sManualsinstructions,dailyoperationstests,andtroubleshootingsteps.

ContactSpiderat877-774-3370formoreassistance.

Contact Spider at 877-774-3370

Other manuals for SC1500

1

This manual suits for next models

4

Other SPIDER Lifting System manuals

Popular Lifting System manuals by other brands

probst

probst VACUUM-HANDY VH-1/25 operating instructions

Aqua Creek Products

Aqua Creek Products Pro Pool-XR manual

AMGO

AMGO Hydraulics PRO-12ASX Installation and service manual

FACAL

FACAL ALUMITO STANDARD User and maintenance guide

SCANCLIMBER

SCANCLIMBER LT500 instruction manual

RITE-HITE

RITE-HITE Mechanical Dock Leveler Hydraulic Conversion Installation & owner's manual