SpiderAlert SR-500 User manual

DE3211 3-11

SR

SRSR

SR-500

-500-500

-500, SR

, SR, SR

, SR-500

-500-500

-500 ER

ERER

ER

SpiderAlert Wireless Receiver Installation Instructions

1

11

1. INTRODUCTION

. INTRODUCTION. INTRODUCTION

. INTRODUCTION

SR-500 wireless receiver is as an interface unit between various

SpiderAlert wireless transmitters and the SpiderBus.

SR-500 ER is the extended range version of the SR-500. It has

the following features:

• Higher receiver sensitivity that enables longer communication

range.

• Improved receiver selectivity (narrower bandwidth) that

prevents reception of interfering signals from undesired

transmitters (whose frequencies are near the receiving

frequency).

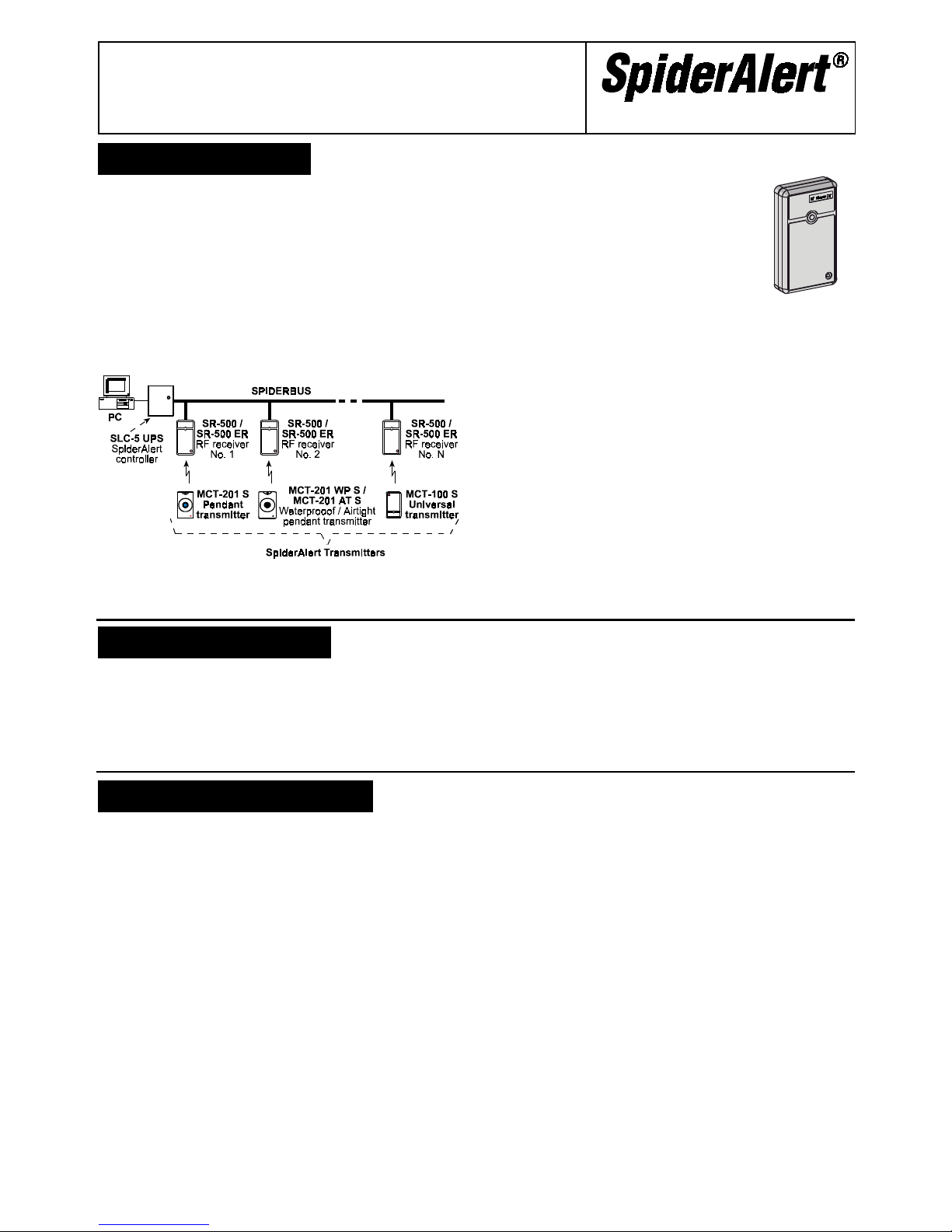

SR-500 (ER) receives RF signals from SpiderAlert transmitters

and relay the signals to the SpiderAlert Local Controller SLC-5

via the SpiderBus. All data collected by the SLC-5 is transferred

to the head end computer for further processing (see fig. 1-1).

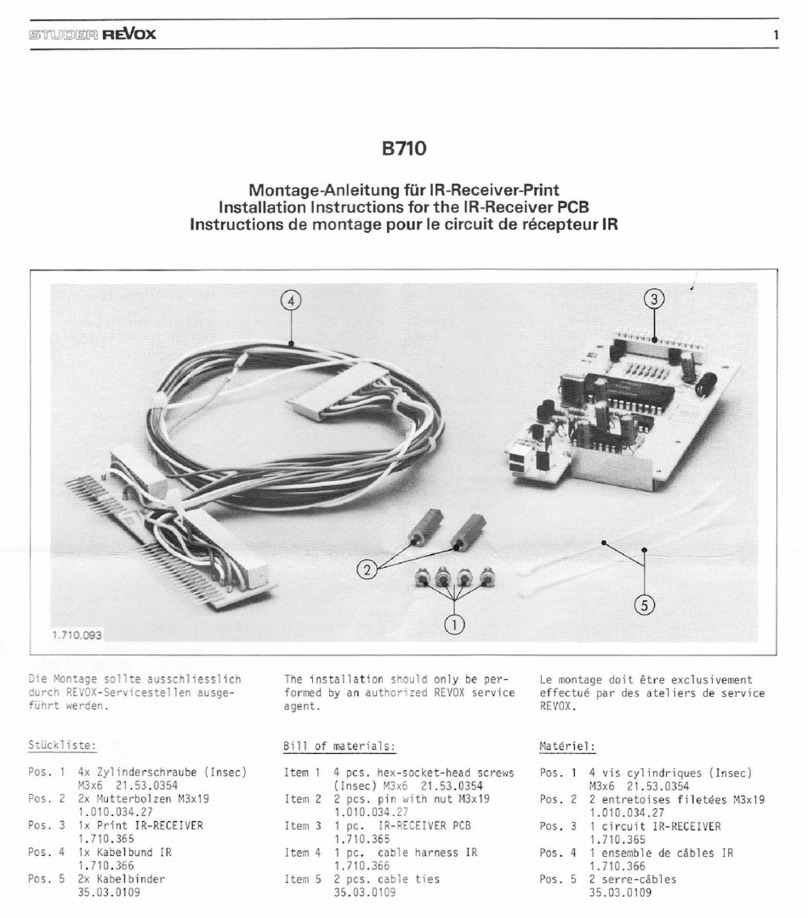

Figure 1-1. SR-500 (ER) in the SpiderAlert System

Each receiver has a factory-programmed, 8-bit ID number (in a

2-digit hexadecimal form) that is marked on top of its

microprocessor IC.

Attendance reports with the receiver ID

number are sent by each receiver to the

SLC-5 at regular intervals, thus permitting

continuous supervision over the entire

receiver network (see Para. 3-2).

SR-500 (ER) also responds to command

signals sent from the computer via the SLC-5

controller and SpiderBus. Each command

signal is addressed to a specific receiver, for

controlling one of its two output circuits.

Figure 1-2.

External View

This allows the attendant at the head end to control remote

equipment such as sirens, lights or automatic voice announcers,

that can be turned on and off by direct connection to receiver’s

output or via a relay.

The receiver can be remotely programmed from the SpiderAlert

main station - programming of the receiver ID number and the

duration of its outputs 1 and 2 signals in “pulse” operation mode.

The receiver is protected against tampering by an on board

tamper switch that is actuated upon removal of the front cover.

Once tampered with, the receiver sends out its ID code plus a

special tamper code to the head end computer.

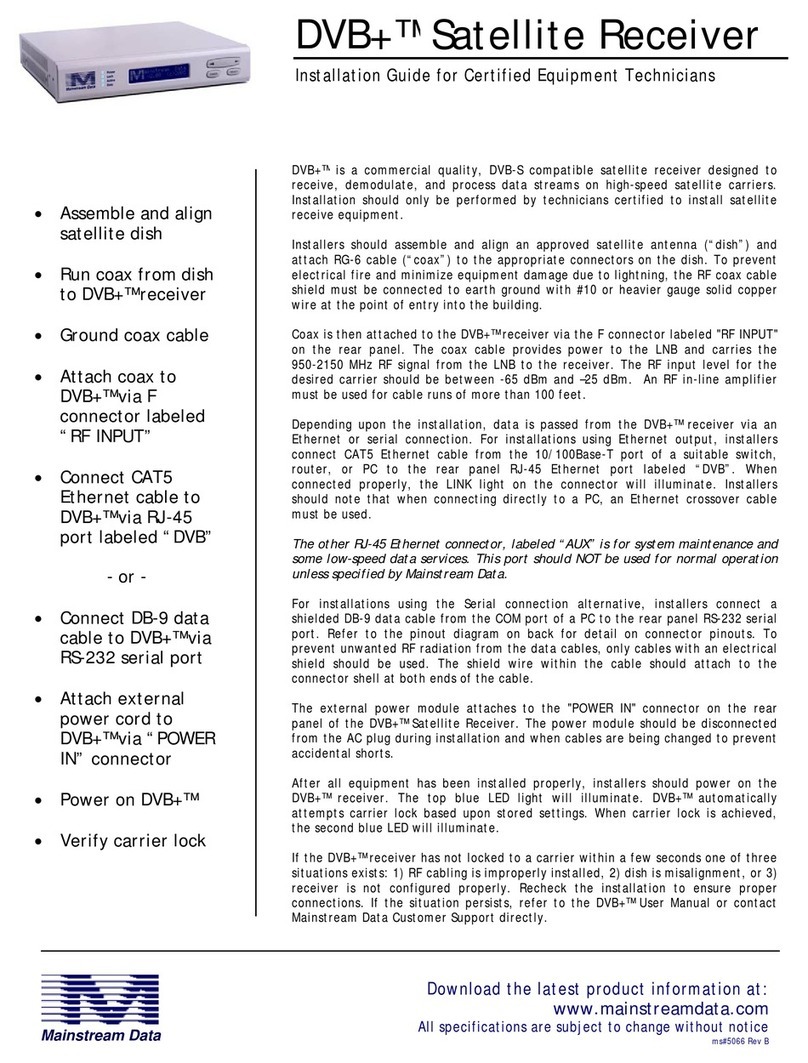

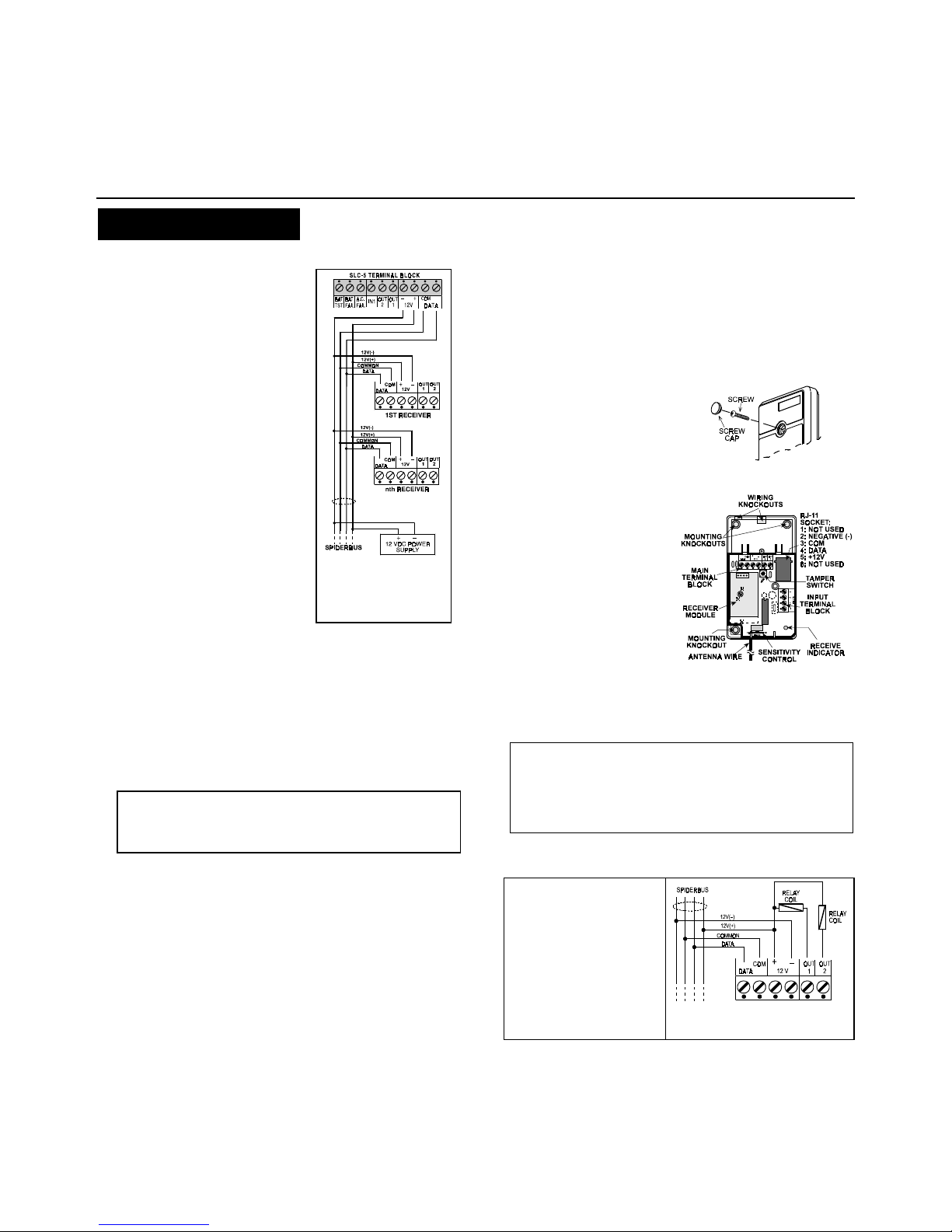

A sensitivity control (marked RANGE, see fig. 4.3) is provided on

the printed circuit board, to enable reception range adjustment.

A terminal block at the top (see fig. 4.3) provides a 4-wire

connection to the SpiderAlert bus and two output terminals for

controlling external devices (for details, refer to para. 3-3). A

right-hand side terminal block (fig. 4.3) provides 3 input terminals

for reporting local alarms (for details, refer to para. 3-4).

When a deliberate (or accidental) jamming signal is received, the

receiver sends a jamming alert message.

2

22

2. SPECIFICATIONS

. SPECIFICATIONS. SPECIFICATIONS

. SPECIFICATIONS

Operating Frequency (MHz): 315, 404, 418, 433.92 or other

frequencies according to local requirements.

Receiver ID Code: 1 of 255 possible codes, factory programmed

Data Transfer to Bus: Serial, software controlled.

Operating Voltage Range: 10 - 16 VDC.

Number and type of Inputs: 3, Normally closed (NC)

Number of Outputs: 2

Open Collector Output Current Sinking Capability: 100 mA.

Current Consumption @ 13.6 V:

SR-500: 7.2 mA (Standby), 8.8 mA (in operation)

SR-500 ER: 37 mA (standby), 39 mA (in operation)

Operating Temperature Range: 0°C to 49°C (32°F to 120°F).

Dimensions (H x W x D): 110 x 63 x 25 mm (4-5/16 x2-1/2 x 1 in.)

Weight: SR-500 - 80g (2.8 oz.), SR-500 ER - 78g (2.75 oz.)

3

33

3.

..

. OPERATION ROUTINE

OPERATION ROUTINEOPERATION ROUTINE

OPERATION ROUTINE

3.1 Message Handling

When a coded message is received from SpiderAlert transmitter,

the receiver registers it and checks whether the bus is busy. If so,

the receiver pauses to prevent collision of its message with other

messages, and then tries again. If the bus is free, the receiver

reports the transmitter's ID code, be it 12-bit or 24-bit,

accompanied by its own 8-bit ID number.

Once the message is received by the SLC-5, an "acknowledge"

signal is returned to the receiver, causing it to stop sending the

data. If there is no response from SLC-5, the receiver will keep

sending the data repeatedly, until SLC-5 returns an

acknowledgement. The receiver will not be free to receive new

coded transmissions until it gets this acknowledgement.

A special on-board LED lights upon reception of a valid RF

signal. It will remain illuminated while the receiver is engaged in

sending the message via the data bus or while the receiver is

waiting for an acknowledge signal from SLC-5. The LED turns off

5 seconds after reception of acknowledge signal from the SLC-5.

3.2 Supervision Method

The receiver is programmed to send out periodic attendance

messages. An attendance message consists of the receiver's ID

number and a special test code identifying the message as an

attendance report. Once the SpiderAlert network is powered up,

all receivers on the bus go through the first cycle of attendance

reports. The SLC-5 automatically "learns" the participating units'

ID numbers, registers their IDs and creates a supervision list.

After the first reporting cycle, the SLC-5 will expect regular

attendance reports from each unit on its list.

Attendance reports received at regular (correct) intervals are

acknowledged by the SLC-5 but not displayed by the head end

computer. However, attendance reports received for the first time

or after a break in communication between the receiver and the

SLC-5 will be displayed on the head end computer screen.

If an attendance report from a specific receiver fails to come in

within 4 minutes from the last report, a warning appears on the

computer's monitor. If attendance reports from a certain receiver

or from a group of receivers stop, the reason might be SpiderBus

discontinuity (an "open" bus), receiver failure or sabotage.

3-12 DE3211

3.3 Output Control

The SR-500 (ER) provides two output terminals (OUT1 and

OUT2). These terminals, that are of the open-collector type, are

under control of the head-end software - they can be activated

(pulled LOW) and deactivated manually or by automatic computer

command. Each output may be used to sound an alarm, to switch

lights on and off, to open a door controlled by an electrical door

strike, or for many other tasks. Since each open collector output

can not sink more than 100 mA, an interface relay might be

required for operating external devices, as shown in Figure 4-4.

3.4 Reporting Local Alarms

The SR-500 (ER) provides 3 input terminals with a common

ground return on a separate terminal block. The input circuits,

which are of the normally closed type, may be connected to

motion, smoke or glass break detectors in the immediate vicinity

of the unit for reporting local alarms via the SLC-5 to the

head-end computer. The computer software identifies the

receiver that sent out the alarm signal and the specific input of

origin. Consecutively, a suitable message appears on the

computer's monitor and the alarm is registered in the event log.

4

44

4. INSTALLATION

. INSTALLATION. INSTALLATION

. INSTALLATION

4.1 Preliminary Survey

Taking into account that the coverage

areas of individual receivers should

overlap a little, to prevent creation of

"dead" spots in-between neighbouring

units. It is therefore recommended to

conduct a survey of the installation

site as follows:

A. Prepare a test equipment set

consisting of an SLC-5, several

SR-500(ER) receivers, a power

supply unit, a 4-lead cable reel

and at least one type of

transmitter.

Note: Make sure the sensitivity

control in each receiver is set

halfway between MAX. and MIN.

Depress the tamper switch lever

and capture it in this position with

masking tape.

B. Place the SLC-5 in a convenient

location and temporarily deploy a

few receivers at "strategic"

reception points throughout the

coverage area.

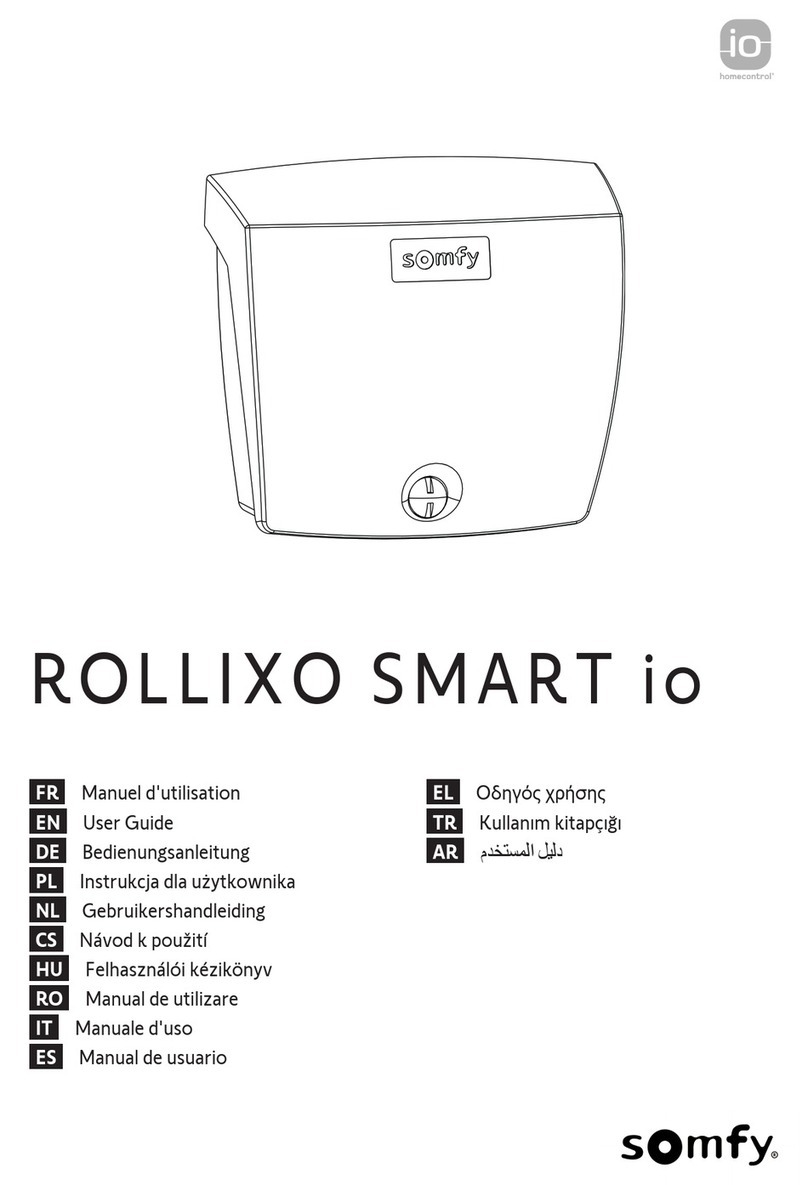

Figure 4-1.

Temporary Bus

C. Use the 4-lead cable to form a temporary bus that inter

connects all receiver units and SLC-5, as shown in Fig. 4-1

(also refer to Para. 5-1, Steps A and B). The cable may be

put down on the floor, following the shortest possible path.

D. Power up the test equipment using the 12 VDC power supply

or a 12 V battery (see Figure 4-1).

E. Operate a SpiderAlert transmitter in various locations within

the receiver's expected coverage area to test the reception

range. Reception is verified when the LED lights steadily in

response to each transmission, until the SLC-5 acknowledges

the message.

IMPORTANT: Remember that different transmitter models

have different power outputs. It is therefore advisable to

make this test with all transmitter models likely to be used in

the vicinity of the tested receiver.

F. If "dead" or marginal reception areas are discovered:

• Move the receiver to a point where reception is better.

• Rotate the sensitivity control towards MAX to increase the

receiver's sensitivity.

• Move the neighboring receiver closer, to bridge the

reception gap.

G. If the receiver is picking up transmissions made in a

neighboring area:

• Move the receiver away from the neighbouring area to

decrease the coverage overlap.

• Rotate the sensitivity control towards MIN to decrease the

receiver's sensitivity.

• Coil the antenna wire (use a small screwdriver's stem for

forming the coil) to reduce the reception range.

H. Repeat Steps E through G above for all other receivers.

Make a list of the chosen locations and indicate special

requirements (sensitivity control position, coiled antenna, etc.).

Note: To determine the point from which an alert transmission

was made with greater accuracy, dual technology (RF/IR)

receivers and transmitters should be used. This especially

applies to multi-story buildings.

4.2 Mechanical Mounting

Note: If it is necessary to install the receiver in a metal

enclosure, let the antenna wire out through a hole or a slot in the

metal enclosure, and test the reception ability very carefully.

A. Open the receiver box.

B. Open the two mounting

knockouts in the base.

C. Hold the base, against the

mounting surface, with the

antenna wire hanging

down.

D. Mark points for drilling, put

the unit aside and drill the

mounting holes. Attach the

unit to the mounting surface

using two screws and wall

anchors (if required).

Knockouts that serve as

wiring outlets are provided

at the top of the base.

SR-500(ER) may be connected

to the SpiderBus via 4

terminals (Fig. 4-4) or via

telephone type RJ-11

connector.

Figure 4.2 Cover Removal

Figure 4.3 Internal View

4.3 Terminal Block Wiring

A. Connect the data wires of the bus to the DATA terminals on

the receiver's terminal block.

CAUTION! One of the data terminals is marked COM,

indicating connection to the common (negative) lead of the

data bus. The other terminal marked DATA must be

connected to the second lead of the data bus. As long as the

data bus is free, the data lead is kept HIGH by a pull-up

resistor in the SLC-5 Local Control Unit.

B. Connect the power supply bus wires to the 12 V(+) and (–)

terminals.

Caution: Make sure not to reverse the bus wires!

Attention! With a large

number of receivers on the

bus, individual power

supplies may be used for

each group of receivers.

Refer to Para. 4-4 in SLC-5

installation manual

(D-7115-0), where several

examples are given for

power supply distribution

along the bus.

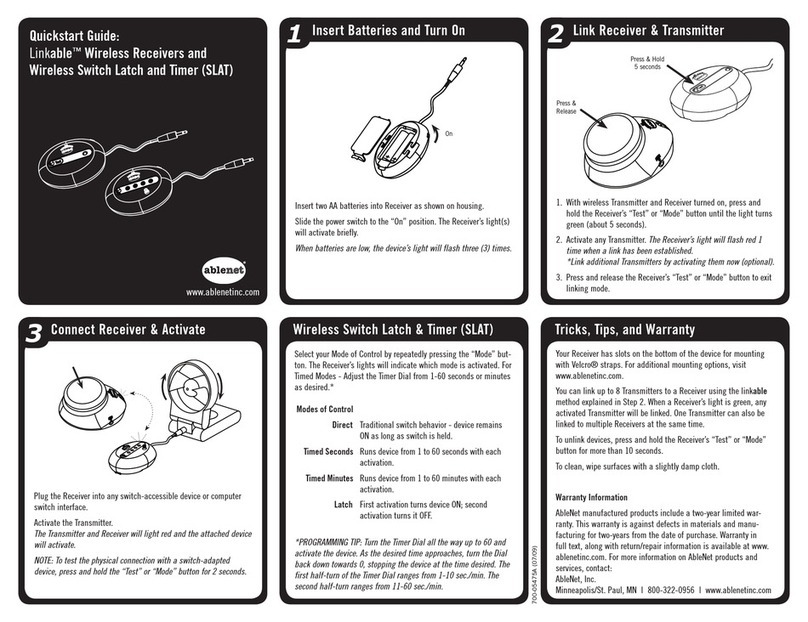

Figure 4-4. Bus, Power and

Output Terminal Block Wiring

Auxiliary power supply PS-2 and bus repeater SRP-51 are

available for long buses (refer to installation manuals).

C. Either output terminal is suitable for operating a low-current

12VDC buzzer, an LED, or an auxiliary relay that draws less

than 100 mA current. In case of a relay, connect its operating

DE3211 3-13

coil across the OUT1 and 12 V(+) or OUT2 and 12 V(+)

terminals (as shown in Figure 4-4).

Relays connected to OUT1 and OUT2 will pull in by manually

entered or automatic command received from the head end

computer. Relay contacts may be wired to open or close

doors, to control lighting fixtures, to sound an alarm, to switch

a wireless transmitters or CCTV on and off, etc.

D. If you wish to report up to 3

kinds of local alarms to the

head-end computer, connect

normally closed (N.C.) sensor

contacts across the alarm

inputs and the ground (–)

terminal, as shown in Fig. 4-5. Figure 4-5. Input

Terminal Block Wiring

Remember: Unused inputs should be bridged to the ground

terminal with a short jumper wire, or else they will constantly

initiate an alarm.

4.4 Bus Connection via RJ-11

If you prefer the quick attach/detach feature of telephone-type

connectors, you can wire the SpiderAlert bus to the receiver

using the on-board TELCO socket. The 4-pin mating plug

required is designated RJ-11 and commonly called "TELCO plug"

(see Figure 4-6). Prepare the following items:

• An appropriate length of a 4-lead color-coded modular cable,

for producing a patch cord between the bus port of the

SR-500(ER) and the bus junction box (see Figure 4-6).

• Two 4-position RJ-11 plugs, to terminate the above mentioned

patch cord.

• A crimping tool for 4-position RJ-11 plugs.

Figure 4-6. RJ-11 plug

A. Identify the bus 4 wires and connect them to the numbered

terminals within the junction box, maintaining the order

required for correct patching.

B. Prepare RJ-11-

to-RJ-11 patch cord,

long enough to

bridge the distance

between the bus

junction box and

SR-500(ER). Make

sure a "one-for-one"

configuration is

obtained - pin 2 is

connected to pin 2,

pin 3 to pin 3, etc.

Figure 4-7. Bus Connection via a

Junction Box

4.5 Final Calibration and Test

IMPORTANT! Before testing, verify that the SLC-5 Local

Control unit is active. If the SLC-5 is inactive, any receiver

sending a message to it will become "hung up" indefinitely, until

the message is acknowledged.

Having conducted a preliminary survey as instructed in Para. 4-1,

and having mounted receivers at the chosen locations, a final

test is only needed to make sure that the system functions well at

the outer edges of the coverage area.

A. Make sure the sensitivity control in each receiver is set as

determined during the preliminary survey. Also coil the

antenna wire wherever necessary according to your "special

requirement" list. Leave receiver covers off for the time being.

B. Temporarily disconnect all receivers from the bus by

disengaging the RJ-11 plugs.

C. Reconnect the receivers one by one. The head-end computer

should register an "attendance report" and a "tamper alert",

but the receiver's LED will light only once - while sending the

tamper alert.

D. Operate a SpiderAlert transmitter in various locations within

the receiver's coverage area to test the reception range,

beginning at the outer edges of the area to be covered.

Reception is verified when the LED lights steadily in response

to each transmission, until the SLC-5 acknowledges the

message. Readjust the sensitivity if necessary.

IMPORTANT: Do not leave the installation site before

verifying reliable reception all through the expected

coverage area.

5. PERIODIC INSPECTION

The supervision feature of the SpiderAlert system allows the

monitoring personnel to detect a disconnected data bus or a

receiver that fails to perform its data transfer duties.

This supervision, however, does not cover the RF communication

part of the process. If the receiver's RF section malfunctions, the

receiver will continue to send out regular attendance reports, but

will not be able to receive wireless transmissions. For this reason,

the system manager should make provisions for testing the

system periodically without alarming the monitoring personnel, as

suggested in Para. 5-1 below. Individual transmitter holders

(system users) should test their transmitters periodically without

involving the monitoring personnel. This can be carried out as

suggested in Para. 5-2. below.

5.1 Testing by the System Manager

To ensure unfailing operation of the system, the system manager

is advised to act as follows:

A. Define one or several transmitters as test units and ask the

monitoring personnel to link a test message to these

transmitters' ID numbers in the computer's data base.

Transmissions received from these test transmitters will be

registered in the on-screen event log but will not be

considered an alert.

B. Use a test transmitter to test all receivers at least once a

week by initiating a transmission in the coverage area of each

receiver. Watch the receiver's LED light in response to your

transmission and go off once the message is acknowledged.

C. Check the monitoring station event log and verify that all test

transmissions were duly registered by the system's computer.

D. Call the installation company and report any receiver that

failed to send a message to the computer.

5.2 Testing by Individual Users

Any SpiderAlert site may be easily equipped for transmitter tests

by individual users:

A. Create a special test station, well away from the coverage

area of all other receivers.

B. Define a receiver as a test unit, install it inside a metal box,

set its sensitivity control to MIN. and coil its wire antenna

tightly around the stem of a small screwdriver.

C. Drill a small hole in the metal box and insert a green LED into

the hole. Wire the LED with 1k½ resistor in series across the

test unit's OUT1 and 12 V+ terminals. The computer can be

programmed to respond to messages received from the test

unit by momentary activation of output No. 1 of the test unit.

D. Ask the monitoring station personnel to link a test message to

the test unit's ID number in the computer's data base. Any

message collected from this receiver will thereby be

considered a test message.

E. Inform all users of the test station, and instruct them to test

their transmitters periodically at close range. Green LED

momentary illumination, in response to each transmission,

serves as an assurance that the test has been successful.

3-14 DE3211

6. MISCELLANEOUS COMMENTS

6.1 Product Limitations

The SpiderAlert wireless system is very reliable and is tested to

high standards. However, due to low transmitting power and

limited range (required by FCC and other regulating authorities),

there are some limitations to be considered:

A. Receivers may be blocked by radio signals near their

operating frequencies, regardless of digital code used.

B. Receiver can only respond to one transmitted signal at a time.

C. Wireless equipment should be tested regularly to determine

whether there are sources of interference and to protect

against faults.

6.2 Standard Compliance

A. The user is cautioned that changes or modifications to the

unit, not expressly approved by Visonetix Ltd., could void the

user's FCC or other authority to operate the equipment.

B. The 315 MHz model of this device complies with Part 15 of

the FCC Rules and RSS-210 of Industry and Science

Canada. Operation is subject to the following two conditions:

(1) This device may not cause harmful interference, and (2)

this device must accept any interference received, including

interference that may cause undesirable operation.

C. 418 MHz and 433.92 MHz receiver’s models comply with CE

requirements for Europe and bear CE mark and certification.

Appendix A. Heated Enclosure for Cold Regions

Whenever SR-500 (ER) is installed outdoors in cold regions, it

becomes necessary to protect the sensitive electronics from exposure

to temperatures below 0°C (32°F). The enclosure available for this

purpose is Carlon model CJ-863, in which a heater kit is installed (see

Figure A-1).

Mount the SR-500(ER) within the heated enclosure as follows:

1. Use some hot glue or double sided tape to attach the receiver box

to the cover, as shown.

2. Bend the antenna wire and fix it to the cover, using some hot glue.

Install the heated enclosure and complete the wiring as follows:

1. Mount the fully equipped enclosure on the wall.

2. Wire the receiver as instructed in Section 4 of this manual.

3. Connect 24 VAC / 1.7A transformer to heating element terminals.

Note: When using 18 AWG wire, do not exceed 30m (100 ft) wire

length between the AC transformer and the heating element.

When using 12 AWG wire, do not exceed 90m (300ft) wire length.

Figure A-1. Internal Construction of the Heated Enclosure

4. Test the receiver according to para. 5.

5. Shut the heated enclosure tight and test reception range again.

WARRANTY

Visonetix Ltd., and its affiliates, (hereinafter collectively referred to as "the

Manufacturer") warrants its products (hereinafter referred to as "the Product”) to be free

of defects in materials and workmanship under normal operating conditions and use for

a period of one year from the date of shipment by the Manufacturer. The Manufacturer's

obligations shall be limited within the warranty period, at its option, to repair or to replace

the defective Product or any defective component or part thereof. To exercise this

warranty, the product must be returned to the manufacturer freight prepaid and insured.

This warranty does not apply to repairs or replacement caused by improper installation,

Product misuse, failure to follow installation or operating instructions, alteration, abuse,

accident, tampering, repair by anyone other than the Manufacturer, external causes, and

failure to perform required preventive maintenance. This warranty also does not apply to

any products, accessories, or attachments used in conjunction with the Product,

including batteries, which shall be covered solely by their own warranties, if any. The

Manufacturer shall not be liable for any damage or loss whatsoever, whether directly,

indirectly, incidentally, consequentially or otherwise, resulting from a malfunction of the

Product due to products, accessories, or attachments of others, including batteries, used

in conjunction with the Product.

THE MANUFACTURER MAKES NO EXPRESS WARRANTIES EXCEPT THOSE

STATED IN THIS STATEMENT. THE MANUFACTURER DISCLAIMS ALL OTHER

WARRANTIES, EXPRESS OR IMPLIED, INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE. THE MANUFACTURER’S SOLE RESPONSIBILITY FOR WARRANTY

CLAIMS IS LIMITED TO REPAIR OR TO REPLACE AS SET FORTH IN THIS

STATEMENT.

The Manufacturer shall have no liability for any death, personal injury, property damage,

or other loss whether direct, indirect, incidental, consequential, or otherwise, based on a

claim that the Product failed to function. However, if the Manufacturer is held liable,

whether directly or indirectly, for any loss or damage arising under this limited warranty

or otherwise, regardless of cause or origin, the Manufacturer's maximum liability shall be

limited to the purchase price of the Product, which shall be fixed as liquidated damages

and not as a penalty, and shall be the complete and exclusive liability of the

Manufacturer.

The Manufacturer shall not, under any circumstances whatsoever, be liable for any

inaccuracy, error of judgment, default, or negligence of the Manufacturer, its employees,

officers, agents, or any other party, or of the purchaser or user, arising from any

assistance or communication of any kind regarding the configuration, design, installation,

or creation of security system involving the Product, that being the responsibility of the

purchaser or user.

If the Manufacturer is unable to make such repair or replacement, the Manufacturer’s

entire liability shall be limited to the cost of a reasonable substitute product.

The Manufacturer shall not be responsible for any dismantling, installation, reinstallation,

purchasing, shipping, insurance, or any similar charges.

The Manufacturer shall have no liability for any damages, including without limitation, any

direct, indirect, incidental, special, or consequential damages, expenses, costs, profits, lost

savings or earnings, or other damages arising out of the use of the Product or the removal,

installation, reinstallation, repair or replacement of the Product or any related events. In the

event that there is any liability against the Manufacturer, such liability shall be limited to the

purchase price of the Product which amount shall be fixed as liquidated damages.

The purchaser and user understand that this Product may be compromised or circumvented

by intentional acts; that the Product will not in all cases prevent death, personal injury,

property damage, or other loss resulting from burglary, robbery, fire or other causes; and

that the Product will not in all cases provide adequate warning or protection. The purchaser

and user also understand that a properly installed and maintained alarm may reduce the risk

of events such as burglary, robbery, and fire without warning, but it is not insurance or a

guarantee that such events will not occur or that there will be no death, personal injury,

property damage, or other loss as a result of such events.

By purchasing the Product, the purchaser and user shall defend, indemnify and hold the

Manufacturer, its officers, directors, affiliates, subsidiaries, agents, servants, employees,

and authorized representatives harmless from and against any and all claims, suits, costs,

damages, and judgments incurred, claimed, or sustained whether for death, personal injury,

property damage, or otherwise, because of or in any way related to the configuration,

design, installation, or creation of a security system involving the Product, and the use, sale,

distribution, and installation of the Product, including payment of any and all attorney’s fees,

costs, and expenses incurred as a result of any such events.

The purchaser or user should follow the Product installation and operation instructions and

test the Product and the entire system at least once each week. For various reasons,

including but not limited to changes in environmental conditions, electric, electronic, or

electromagnetic disruptions, and tampering, the Product may not perform as expected. The

purchaser and user are advised to take all necessary precautions for the protection and

safety of persons and property.

This statement provides certain legal rights. Other rights may vary by state or country.

Under certain circumstances, some states or countries may not allow exclusion or limitation

of incidental or consequential damages or implied warranties, so the above exclusions may

not apply under those circumstances and in those states or countries.

The Manufacturer reserves the right to modify this statement at any time, in its sole

discretion without notice to any purchaser or user. However, this statement shall not be

modified or varied except by the Manufacturer in writing, and the Manufacturer does not

authorize any single individual to act on its behalf to modify or vary this statement.

Any questions about this statement should be directed to the Manufacturer.

VISONETIX LTD. (ISRAEL): P.O.B 22020 TEL-AVIV 61220 ISRAEL. PHONE: (972-3) 645-6890, FAX: (972-3) 645-6891

VISONIC SYSTEMS INC. (U.S.A.): 10 NORTHWOOD DRIVE, BLOOMFIELD CT. 06002-1911. PHONE: (860) 242-9945, (800) 874-3989 FAX: (860) 242-0191

VISONIC LTD. (UK): UNIT 1, STRATTON PARK, DUNTON LANE, BIGGLESWADE, BEDS. SG18 8QS. PHONE: (01767) 600857 FAX: (01767) 601098

VISONETIX LTD. 1999 SR-500, SR-500 ER D-3211-0, NEW: DE3211- (REV. 5, 12/99)

This manual suits for next models

1

Table of contents