Eelectron AD84C01KNX User manual

AD84C01KNXFI000030101_HANDBOOK_EN.DOCX

AD84C01KNX - ANALOG / DIGITAL MODULE Handbook

Eel ect r on Sp A, Vi a Mon t everd i 6 ,

I-20025 Legnano (MI), Italia

Tel: +39 03 31.5008 02 Fax:+39 03 31.564826

E-mail:info@eelectron.com Web:www.eelectron.com

C.F. e P.IVA 11666 76 0159

Tr ib u n ale d i M il an o 3 59 15 7-8760-07

CCIAA M i lan o 1 48 549

1/27

Product Hand book

AD84C01KNX

Analog / Digital Module 8 Input / 4 led Out put

Docum ent

Version: 1.1

Date:

31/01/2019

AD84C01KNXFI000030101_HANDBOOK_EN.DOCX

AD84C01KNX - ANALOG / DIGITAL MODULE Handbook

Eel ect r on Sp A, Vi a M on t everd i 6,

I-20025 Legnano (MI), Italia

Tel: +39 03 31.5008 02 Fax:+39 03 31.564826

E-mail:info@eelectron.com Web:www.eelectron.com

C.F. e P.IVA 11666760159

Tr ib u n ale d i M il an o 3 59 15 7-8760-07

CCIAA M i lan o 1 48 549

2/27

INDEX

1. Gen eral int rod uct ion ......................................................................................................................................................................... 5

2. Prod u ct overview ................................................................................................................................................................................. 5

3. Installat ion instructions .................................................................................................................................................................. 6

4. Param et ri Gen erali.............................................................................................................................................................................. 6

5. Inp ut s configurat ion .......................................................................................................................................................................... 6

6. Digital inputs.......................................................................................................................................................................................... 7

Activation on press.................................................................................................................................................................................... 7

Activation on press / release ............................................................................................................................................................... 7

Activation on short and long press................................................................................................................................................ 7

Dim m ing ........................................................................................................................................................................................................... 8

Sh u t t er an d Bl in d s ..................................................................................................................................................................................... 8

Sc en e ................................................................................................................................................................................................................... 8

Com m an d s seq u en c es............................................................................................................................................................................ 9

Com m an d seq u en ces (1 b i t )............................................................................................................................................................... 9

Input count er (pulse counter)......................................................................................................................................................... 10

Set RGB color.............................................................................................................................................................................................. 10

MUR / DND ................................................................................................................................................................................................... 10

Loo p am on g val ues ................................................................................................................................................................................ 10

7. Led ou t p ut ............................................................................................................................................................................................. 11

8. Analog inputs...................................................................................................................................................................................... 11

Tem p er at u r e sen so r description............................................................................................................................................... 11

Tem p er at u r e sen so r parameters.............................................................................................................................................. 12

9. Th erm ost at Fu n ct ion ..................................................................................................................................................................... 12

Set p o i n t Set t i n g s ..................................................................................................................................................................................... 12

SETPOINT Ob ject .................................................................................................................................................................................... 12

HVAC MODE obj. (switched heat / cool).................................................................................................................................. 12

HVAC MODE obj. (autom atic heat / cool) ............................................................................................................................... 13

SETPOINT COMFORT, STANDBY, ECONOMY......................................................................................................................... 13

COM FORT Ob ject ..................................................................................................................................................................................... 13

WINDOW CONTACT Object .............................................................................................................................................................. 13

SETPOINT ADJUSTMENT ob ject .................................................................................................................................................... 14

KNX probe tem perature obj............................................................................................................................................................ 14

ACTUAL SETPOINT ob ject .................................................................................................................................................................. 14

Tw o p o in t s on /o ff ..................................................................................................................................................................................... 14

Int egral p rop ort ion al cont rol PW M ............................................................................................................................................. 15

Integral proport ional cont r. continuous................................................................................................................................... 15

Fan co il o n /off ............................................................................................................................................................................................. 15

Manage valve independently .......................................................................................................................................................... 17

Fan coil con t rol PI.................................................................................................................................................................................... 17

Additional valve ........................................................................................................................................................................................ 17

Additional valve 6 ways....................................................................................................................................................................... 18

Force fan coi l sp eed ............................................................................................................................................................................... 18

Vent ilation m ode ..................................................................................................................................................................................... 18

Tem p er at u r e p r ob e f ai lu r e / o u t of r an g e m easu r em en t ............................................................................................. 19

Tem p erature alarm object ................................................................................................................................................................ 19

AD84C01KNXFI000030101_HANDBOOK_EN.DOCX

AD84C01KNX - ANALOG / DIGITAL MODULE Handbook

Eel ect r on Sp A, Vi a M on t everd i 6,

I-20025 Legnano (MI), Italia

Tel: +39 03 31.5008 02 Fax:+39 03 31.564826

E-mail:info@eelectron.com Web:www.eelectron.com

C.F. e P.IVA 11666760159

Tr ib u n ale d i M il an o 3 59 15 7-8760-07

CCIAA M i lan o 1 48 549

3/27

10. Th er m ost at b eh avi ou r o n b u s fail u re, r ec overy an d d ow n l oad ...................................................................... 20

Behaviour on bus voltage failure .................................................................................................................................................. 20

Behaviour on bus voltage recovery ............................................................................................................................................. 20

Behaviour on ETS Dow nload ........................................................................................................................................................... 20

11. Log ics........................................................................................................................................................................................................ 20

12. Virtual holder ...................................................................................................................................................................................... 22

How it works............................................................................................................................................................................................... 22

Com m u n i cat i on Ob j ect s..................................................................................................................................................................... 23

Param et ers Gen eral ............................................................................................................................................................................ 23

Param et ers Rem ot e in p ut s............................................................................................................................................................ 24

Rem ot e Sen sor In p ut s (Glob al Enable)..................................................................................................................................... 25

13. Wrong application download.................................................................................................................................................. 25

AD84C01KNXFI000030101_HANDBOOK_EN.DOCX

AD84C01KNX - ANALOG / DIGITAL MODULE Handbook

Eel ect r on Sp A, Vi a M on t everd i 6,

I-20025 Legnano (MI), Italia

Tel: +39 03 31.5008 02 Fax:+39 03 31.564826

E-mail:info@eelectron.com Web:www.eelectron.com

C.F. e P.IVA 11666760159

Tr ib u n ale d i M il an o 3 59 15 7-8760-07

CCIAA M i lan o 1 48 549

4/27

Any inform ation inside this m anual can be changed w ithout advice.

Th is h an d b o ok c an b e d ow n l oad freel y f rom t h e website:

www.eelectron.com

Exclusion of liab ilit y:

Despite checking that the contents of this docum ent m atch the hardw are and softw are, deviations cannot be

com pletely excluded. We therefore cannot accept any liability for this.

Any necessary corrections will be incorporated into newer versions of this m anual.

Sym b o l for rel evan t in form at ion

Sym b o l for w ar n in g

DISPOSAL : Th e cro ssed -out bin sym bol on the equipm ent or packaging m eans the product m ust not be

included w ith other general w aste at the end of its working life. The user m ust take the worn product to a sorted

waste centre,or return it to the retailer when purchasing a new one. An efficient sorted waste collection for the

environm entally friendly disposal of t he used device, or its subsequent recycling, helps avoid the potential

negative effects on the environm ent and people s h eal t h , an d en co urages t h e re-use and/or recycling of the

construction m aterials

AD84C01KNXFI000030101_HANDBOOK_EN.DOCX

AD84C01KNX - ANALOG / DIGITAL MODULE Handbook

Eel ect r on Sp A, Vi a M on t everd i 6,

I-20025 Legnano (MI), Italia

Tel: +39 03 31.5008 02 Fax:+39 03 31.564826

E-mail:info@eelectron.com Web:www.eelectron.com

C.F. e P.IVA 11666760159

Tr ib u n ale d i M il an o 3 59 15 7-8760-07

CCIAA M i lan o 1 48 549

5/27

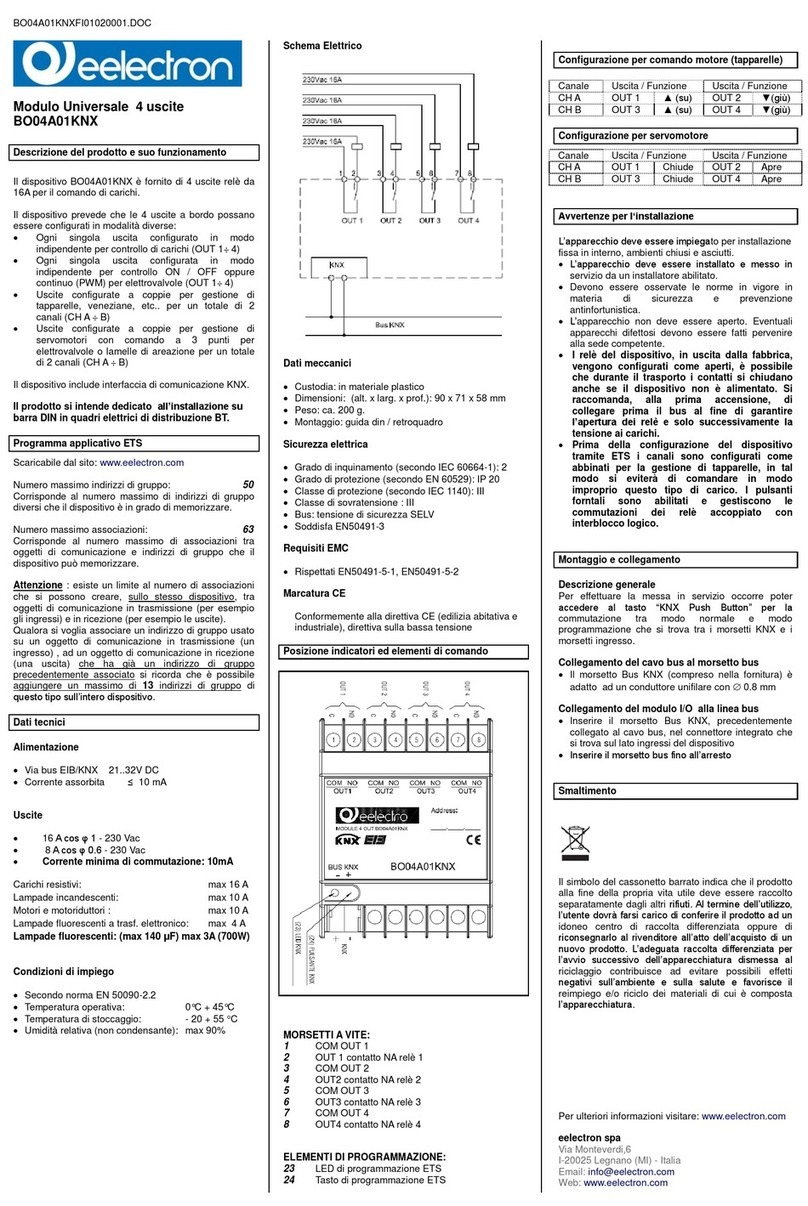

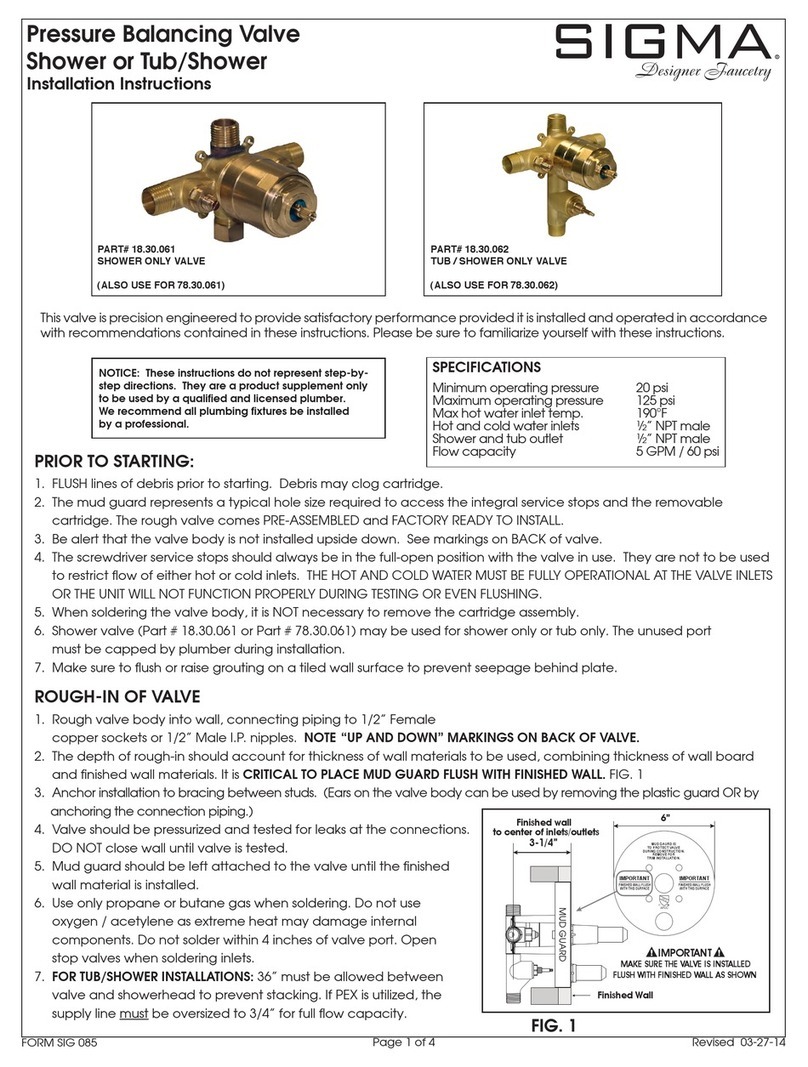

1. Gen er al i n t r o d u c t i o n

Th i s m an u al i s intended for use by KNX® installers

and describes functions and param eters of the

AD84C01KNX m odule and how you can change

set t in gs an d co n figu rat i on s u sin g t h e ETS soft w ar e

tool.

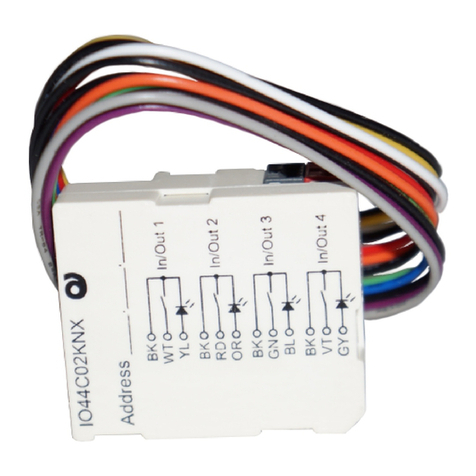

Th e AD84C01KN X d evice is a in w al l m od u le w it h 8

inputs and 4 LED outputs.

The 8 inputs are for dry contacts (free from

potential); inputs from 1 to 4 are digital, inputs 5 to

8 can be configured as digital or analogical to

interface NTC tem perature probes (code eelectron

TS01A0 1A CC or TS01B0 1A CC).

Th e o u t p u t s can d r ive l ow vo lt age LEDs; use high

efficiency LED code eelectron LD00A01ACC (blue) or

LD00A1 1A CC (w h it e).

Th e A D 84 C01 KN X m o d u l e i s d esi g n ed f o r u se i n

domestic and building installations (eg offices,

hotels, private homes, etc.).

2. Prod uct overview

Main functions digital inputs 1 ÷ 8

Digital inputs can be connected to buttons or

sw i t c h es an d c an b e u sed fo r:

1-bit commands: loads activation / deactivation

com m ands (ON / OFF / TOGGLE) with short

pressure or with long and short pressure

differentiation

1 byte com m ands (0-255 or HVAC com m ands or

% value com m ands).

Sen d in g lon g ac t io n t el eg ram s t o t h e sam e sh o rt

action address or to a d ifferent group address

Com m an d s fo r cyclic sen d in g

Seq u en ces (3 c om m an d s t h at m i x 1 b i t / 1 b yt e

objects) with different group addresses - in short

and long press m ode or in sw it ching m ode

Dim m er m anagem ent (w ith single button or

with double button)

Roller shu t t ers an d b lin d s m anagem en t (w it h

sin g le b u t t o n o r w i t h d ou b le b u t t on )

Con t ro l seq u en ces w it h 1 b it t o m an ag e

sw it ch in g on / o ff ligh t s or rows of lights

Input count ers (only input s from 1 to 4)

RGB color set t in g w it h fixed value (short

pressure) or color change (long pressure); 1 byte

datapoint or 3 byte selectable

MUR / DND (Make Up Room - / Do Not Disturb),

function with built-in logics

Loop function between values to send step by

st ep a seq u en c e o f val u es of 1 byte

Main functions analog input si 5 ÷ 8

Inputs 5 to 8 can b e configured as analogue for t he

connection of NTC tem perature probes

It is possib le t o en able 4 com plet e t herm ost ats

modules; each thermostat module manages 2

st ages w it h in t egrat ed PI con t roller for d rivin g

heating and cooling equipment, valves, 2 and 4 pipe

fan coils, etc..

NTC probes :

For NTC t em p er at u re p r ob e t h e fol low in g eelect ron

code accessories m ust be used:

TS01A01A CC (fro m -20°C to +100°C)

TS01B01A CC (fro m -50°C to +60°C)

NTC probes main functions:

Con fig u red as t em p er at u re sen sors (4 sen so rs) -

main functions:

2 different tem perature thresholds to activate

alarm s / w arnings w it h 1 bit telegram s

En able / disable alarm s / alerts via 1-bit objects

Con fig u red as t h erm ost at s (4 thermostats) - main

functions:

Different Control Algorithm s: 2-point on / off;

PW M; con t in uou s con t rol / Fan Coil con t rol

Different m odes of operation m ode setting:

Autom atic HVAC / HVAC Manual / Setpoint

Additional com m and for 2nd st ag e

management

Window contact m anagem ent

Additional external probe (optional)

AD84C01KNXFI000030101_HANDBOOK_EN.DOCX

AD84C01KNX - ANALOG / DIGITAL MODULE Handbook

Eel ect r on Sp A, Vi a M on t everd i 6,

I-20025 Legnano (MI), Italia

Tel: +39 03 31.5008 02 Fax:+39 03 31.564826

E-mail:info@eelectron.com Web:www.eelectron.com

C.F. e P.IVA 11666760159

Tr ib u n ale d i M il an o 3 59 15 7-8760-07

CCIAA M i lan o 1 48 549

6/27

Logic function and Virt ual Hold er function

Th e d evice in c lu d es so m e log ic fun ct io n s an d a

logic for the autom atic detection of the presence in

room called "Virtual Holder"

Logics main functions

2 input object and 1 out put obj for every logic

Delay, retransm ission of telegram s

NOT / AND / OR / NAND / NOR / XOR / XNOR

Bit to Byte conversion

Byte to Bit conversion

1,2,4 Bytes Threshold

Free exp ressio n s w it h 4 in p ut o b ject s and 1 out

object

3. Inst allat ion inst ruct ions

Th e d evice m ay b e u sed f or p erm an en t in d oor

installations in dry locations within w all box

mounts.

WARNING

Device m ust be installed keeping a m inim um

distance of 4 mm between electrical power line

(m ain s) an d in p u t c ables or red / black bus cable.

Th e d evice m u st n o t b e con n ect ed t o 230V

cables

Th e p r evai li n g saf et y r u les m u st b e h eed ed .

Th e d evice m u st b e m o un t ed an d com m ission ed

by an authorized installer.

Th e ap p l icab le saf et y an d accid en t p r even t ion

regulations m ust be observed.

Th e d evic e m u st n o t b e op en ed . An y fau lt y

devices should be returned to manufacturer.

For p lan n in g an d co n st ru ct ion of el ect ric

installations, the relevant guidelines, regulations

and st andards of t he respective count ry are to be

considered.

KNX bus allow s you to rem otely send com m ands

to the system actuators. Always make sure that

the execution of remote commands do not lead

to hazardous situations, and that the user always

has a warning about which commands can be

activated rem otely.

Fo r f u r t h er i n f or m at i on p l ease vi sit :

www.eelectron.com

4. Param et ri Gen erali

KNX PARAMETER

SETTINGS

Delay on Pow er-up

5 ÷ 15 seconds

Th rou g h t h is p aram et er i s p ossib le t o set t h e d el ay of

transmission of telegrams after a power on by selecting

the time by which the device is allowed to send

telegrams.

In large syst em s aft er a pow er failure or shutdow n this

delay avoids to generate excessive traffic on the bus,

causing slow perform ance or a transmission block.

If there are different devices req uiring send ing telegram s

on the bus after a reset, these delays m ust be

programmed to prevent traffic congestion during the

initialization phase.

Th e i n p u t d et ect i on an d t he values of objects are

updated at the end of the transmission delay time

At the end of ETS program m ing the device behaves like

after a pow er on.

Virtual holder

disabled / enabled

By setting this param eter, you can enable a "virtual

holder", that is, a logical function that autom atically

recognizes the presence of a person in a room . This

feature can be used in hotel or sim ilar installations and

requires connection to other devices.

En ab l e alarm ob j . i np . <x >

disabled / enabled

By setting this param eter, a 1-bit communication object

is show n which is used to signal a m alfunction related to

the temperature sensor.

5. Inp ut s configurat ion

Inputs 1 to 4 are digital, while inputs 5 to 8 can be

configured as digital or analogical to interface NTC

temperature p rob es.

AD84C01KNXFI000030101_HANDBOOK_EN.DOCX

AD84C01KNX - ANALOG / DIGITAL MODULE Handbook

Eel ect r on Sp A, Vi a M on t everd i 6,

I-20025 Legnano (MI), Italia

Tel: +39 03 31.5008 02 Fax:+39 03 31.564826

E-mail:info@eelectron.com Web:www.eelectron.com

C.F. e P.IVA 11666760159

Tr ib u n ale d i M il an o 3 59 15 7-8760-07

CCIAA M i lan o 1 48 549

7/27

6. Digit al input s

With DIGITAL INPUT con figu rat ion each in d ivid u al

input can be configured to perform one of the

following functions:

Activation on press

Activation on press / release

Activation on short and long press

Dim m ing

Sh u t t er an d b l in ds

Scen e

Com m an d seq u en ces (sh o rt an d lon g p r ess)

Com m an d seq u en ces (t o gg l e f u n ct i on )

Com m an d seq u en ces 1 b i t

Input count er (pulse count er)

Set RGB c olo r

MUR/DND function

Loo p am on g val ues

Activation on press

on press" allow s you to configure the

sen d i n g of telegram s when the button is pressed;

device can also be configured to send periodic

messageswith repetition period.

KNX PARAMETER

SETTINGS

Telegram Associat ed

1 bit / 1 byte

It is possib le to send 1 b it or 1 b yte object s

Co n f i g u r at i o n s f or 1 b it object :

On

Off

To g g l e

Co n f igu rat i on s f o r 1 b y t e o b j ect :

Value 0-255 (g en er ic sig n ed in t )

Value 0-100% (scal in g valu e in st ep s o f 5 %)

HVAC Mode (DPT_HVACMod e 20.102)

KNX PARAMETER

SETTINGS

Cy cl i c sending w hen

button pressed

Never

0.3 sec.

0.4 sec.

0.5 sec.

0.8 sec

1.0 sec.

1.2 sec.

1.5 sec.

2.0 sec.

3.0 sec.

5.0 sec.

8.0 sec.

10 sec.

As long as the button is pressed, the telegram w ith

sel ec t ed size an d val u e is sen t cyc lic al ly; t h is

parameters defines the time interval between two

sen d ings

Activation on press / release

on press / release " allow s you to

configure the sending of telegram s when the

button is pressed and when it is released.

KNX PARAMETER

SETTINGS

Co m m u n i c at i o n o b j ec t

on release

disabled / enabled

if enabled, this param eter displays an additional

com m unication object (<Button x> Release Action) that

is transm itted on the release event, this object can be

associat ed w it h a group address other than the one

that sends the value associated with the pressure.

Activation on short and long press

Th e d iff eren t d u rat i on b et w een sh ort an d l on g p r ess

is defined by the param eter "Minim um tim e long

You can set t o sen d a t elegram s w it h different

values on short and long press or decide to send

com m ands only on one of this events.

AD84C01KNXFI000030101_HANDBOOK_EN.DOCX

AD84C01KNX - ANALOG / DIGITAL MODULE Handbook

Eel ect r on Sp A, Vi a M on t everd i 6,

I-20025 Legnano (MI), Italia

Tel: +39 03 31.5008 02 Fax:+39 03 31.564826

E-mail:info@eelectron.com Web:www.eelectron.com

C.F. e P.IVA 11666760159

Tr ib u n ale d i M il an o 3 59 15 7-8760-07

CCIAA M i lan o 1 48 549

8/27

When button is pressed then counting time starts; if

t h e b u t t on is released b efore t im e exceed s TPL

time, device executes the command associated

with the event of "short press" and if, on the

con t rary, TPL t im eout exp ires an d b ut t on is st ill

pressed then the command associated with the

Th e p aram et er s an d m od e of t ran sm ission o f

telegrams can be managed through "activation on

long and short press" are the same set with the

configuration "Activation of press / release " except

for the function of cyclic sending that is not

provided here.

Dim m ing

control a light dim mer using short and long pressof

the buttons.

Each b u t t on u ses 2 com m u nicat ion ob ject s:

1 bit dim ension for ON /OFF com m and associated

to short press operation

4 bit dim ension for brightness regulation associated

to long press operation

Param et er "Min im u

darker behaviour and step of each long press

action.

Sh u t t er an d Bl in d s

le

to control Roller Shutters or Blinds using short and

long press of the buttons.

Each in p u t u ses 2 co m m u n icat i on ob j ect s:

1 b it d im en sion for STEP /STOP com m an d

associated to short press operat ion

1 bit d im ension for UP / DOWN com m and

associated to long press operation

associated to long press act ion.

Scen e

button for scene management: learn and recall

scen e com m an d s.

Th ese d if feren t b eh avi ou r (r ecall an d learn ) ar e

performed through two different actions (short and

long press) of the button.

Learn scen e on long p ress act ion is en ab led b y a

parameter; "Min im um

set t h e m i n im u m d u r at i on o f l o n g p r ess.

KNX PARAMETER

SETTINGS

Scen e N u m b er

Num ber of the scene:

0 ÷ 63

Th is p aram et er set s t h e val ue of t h e scen e you in t en d

to learn / recall (one per channel).

Rem em b er t h at ou t p ut d evices (i.e. actuators, et c.)

generally can m anage several scenes, each identified

by a value (that varies from 0 to 63); therefore is

im portant to set this param eter correctly and

matching the number set on the actuators.

St o re sc en e o n l o n g

press

disabled / enabled

If d isable, long p ress act ion is ignored and no t elegram

is sent to the bus; if enable on long press action a learn

scen e t el eg ram i s sen t t o t h e b u s.

AD84C01KNXFI000030101_HANDBOOK_EN.DOCX

AD84C01KNX - ANALOG / DIGITAL MODULE Handbook

Eel ect r on Sp A, Vi a M on t everd i 6,

I-20025 Legnano (MI), Italia

Tel: +39 03 31.5008 02 Fax:+39 03 31.564826

E-mail:info@eelectron.com Web:www.eelectron.com

C.F. e P.IVA 11666760159

Tr ib u n ale d i M il an o 3 59 15 7-8760-07

CCIAA M i lan o 1 48 549

9/27

Object enable scene

learning from bus

disabled / enabled

If t his param et er is enabled you have a com m unication

object (size = 1 bit) in order to enable / disable runtim e

When this object receives a telegram "1" then the

function associated to the long press of the button

(sen d t h e t el eg ram st orage scenario) is enab led, w h en

with the long pressisnot sent.

Com m an d s seq u en ces

Th is fu n ct i on al low s yo u t o assoc iat e t o sh o rt an d

long press, sequences of different com m ands on the

bus.

For each b u t t on this function is available for short

and long press or as toggle function.

Th e seq u en ce con sist s o f 2 o r 3 com m an d s w h ich

can each be sized as 1 bit or 1 byte.

Once defined the num ber of elem ents in the

seq u en c e (2 o r 3 ) an d t h ei r size (1 -bit / 1 byte), you

can associate different com m ands to each elem ent

of the sequence or decide to send com m ands only

on one of the two events.

Th e w ait in g t im e b et w een a c om m an d an d t h e n ext

is fixed in 1 second.

Each ob j ec t com m u n icat i on can b e con n ect ed t o a

different group address.

For exam p l e it is p ossib le t o d ef in e a seq u en ce:

obj

dimension

sh or t p ress

(op erat ion 1)

long press

(op erat ion 2)

A

1 bit

ON

( t o act u at ors)

OFF

(t o act u at ors)

B

1 byte

100%

(t o a d im m er)

0%

(t o a d im m er)

C

1 byte

COMFORT

(t o a thermostat)

ECONOMY

(t o a t h erm ost at )

Command sequences (1 bit)

Th is f u n ct ion al lo w s yo u t o sen d seq u en c es o f 1 -bit

com m ands to m ultiple objects. The sequence can

be defined on 2 or 3 objects. Each time the

sw it ch /b u t t on connected to the input is pressed,

the next step of the defined sequence is sent.

KNX PARAMETER

SETTINGS

Num ber of objetcs

2, 3

Th i s p aram et er d ef in es t h e n u m b er of 1 -bit objects

that will be visible and will send values 0 or 1 on the

bus

Num ber of steps in the

seq uence

2 ÷ 8

Indicates the number of steps of which the sequence is

made up.

Lon g p ress t i rest art

seq uence

disabled/enab led

Allow s to associate to a long pressure of the

sw i t ch /b u t t on con nect ed t o in p u t c h an n el an ac t io n of

restart of the sequence.

Restart function

Restart an d sen d first

Sen d l on g st ep an d

restart

AD84C01KNXFI000030101_HANDBOOK_EN.DOCX

AD84C01KNX - ANALOG / DIGITAL MODULE Handbook

Eel ect r on Sp A, Vi a M on t everd i 6,

I-20025 Legnano (MI), Italia

Tel: +39 03 31.5008 02 Fax:+39 03 31.564826

E-mail:info@eelectron.com Web:www.eelectron.com

C.F. e P.IVA 11666760159

Tr ib u n ale d i M il an o 3 59 15 7-8760-07

CCIAA M i lan o 1 48 549

10/27

Rest ar t and sen d f irst

Th e l on g p r ess d et erm in es t h e sen d in g o f st ep 1

Sen d l o n g st ep an d r est ar t

Th e l on g p ress d et erm in es t h e sen d in g of t h e n ext st ep

and brings the sequence to the initial step .

Sen d only changed

objects

disabled/enabled

Th is p aram et er d ef in es w h et h er, in t h e t ran sit ion fro m

one step to the next, all values associated with single-

bit objects or only those that change are to be sent.

Value step <x>

On and off com binations

on 2 or 3 1-bit objects

Determ ines the com bination associated with a

seq u en c e u si n g 2 o r 3 1 -bit objects.

Input count er (pulse counter)

Using the Input Counter function it is possible to

count the pulses of a contact connected to the

input. It is possible to define the size of the counter

(1,2 or 4 Byt es), t h e in it ial valu e an d t h e fin al value.

It is possible t o associate t he send ing of a value w ith

1 bit or 1 byte each tim e the counter reaches the

final value (overflow). the counter can be reset by an

writing on a dedicated 1-bit object.

Using t he "Condition of increase count er"

parameter, you choose whether to count only the

rising, falling or both edges.

Th e p aram et er "So ft w are filt er freq u en cy " al l ow s t o

manage a software filter that allows to count 2

pulses too close each other as a single impulse; this

is necessary w hen the contact connected to the

input has a debounce for a certain tim e.

Set RGB col or

Th is fu n ct io n al low s yo u t o associat e a sh ort p ress of

the button to a command on the bus in order to set

a RGB color. The "RGB object type" p aram eter

defines whether the command is sent with a single

3-byte object or 3x1-byte objects. It is also possible

to enable a feature associated with a long press that

allow s t o change t he color w hich is sent w ith a

sh ort press. During long press the color transition is

performed and at the t im e of release the selected

color is stored; this m eans that from now every tim e

a short press is done the new color is sent on the

bus. When the device is powered off and on the last

sel ec t ed co lo r i s k ep t in m em o ry. Th e "En ab l e

sen d in g c olor d u rin g t r an sit ion " op t ion allo w s you

to send all color transitions during long press so

that each color can be displayed on another device.

MUR / DND

Th i s f u n ct i on al lo w s yo u t o c on f ig u re a input to

sen d 1-bit commands with DND (do not disturb),

MUR (m ake up room ) or reset both signals -

according to t he sequence described below .

(co lu m n

defines which values are sent on the 2 x 1 bit

objects

cm d

Action

DND

MUR

Note

MUR

enab le

0

1

MUR

disable

-

0

MUR

toggle

MUR enable/disable alternate

DND

enab le

1

0

DND

disable

0

-

DND

toggle

DND enable/disable alternate

Loop

0

1

Loop am on g t h ese 3 set s

1

0

0

0

It is possible t o associate a color to each of t he 3

st at es (DND act ive, M UR act ive, M UR & DND n ot

on

the bus using a 3Byte Object DPT 232.600 RGB

value 3x(0..255)

Loop am on g values

With this function you can configure a button to

sen d a 1-byte value in sequence. The sequence is

com posed of a num ber of values between 3 and 9.

AD84C01KNXFI000030101_HANDBOOK_EN.DOCX

AD84C01KNX - ANALOG / DIGITAL MODULE Handbook

Eel ect r on Sp A, Vi a M on t everd i 6,

I-20025 Legnano (MI), Italia

Tel: +39 03 31.5008 02 Fax:+39 03 31.564826

E-mail:info@eelectron.com Web:www.eelectron.com

C.F. e P.IVA 11666760159

Tr ib u n ale d i M il an o 3 59 15 7-8760-07

CCIAA M i lan o 1 48 549

11/27

Each t im e a p ressure (or release accordin g t o t h e

"act ive ed ge" p arameter) is done a value is sent

following the order set in ETS: from the first (A) to

the last ( I).

Tw o ob ject are avail ab le:

<Input x> Loop Val u e Out p u t

1 byte 0..255| CW

Th is ob jec t is st o sen d t h e val ues o f t h e seq u en ce

< Input x> Loop Value Feedback:

1 byte 0..255| CRT

this object is to receive a value from the bus; if it

corresponds to a value set in the sequence it bring the

sam e t o t h e co rresp on d in g st ep .

7. Led output

Each output can be connected to a LED (see LED

eelect ron code LD00A01ACC / LD00A11ACC) and

configured as:

Always OFF

Led is OFF

Always ON

Led is ON

Bus controlled

Led i s l it o n o r o ff u p o n t h e

telegram receive from bus ; initial

st at e an d led b eh aviou r (f ixed o r

blink) can be configured

8. Analog inputs

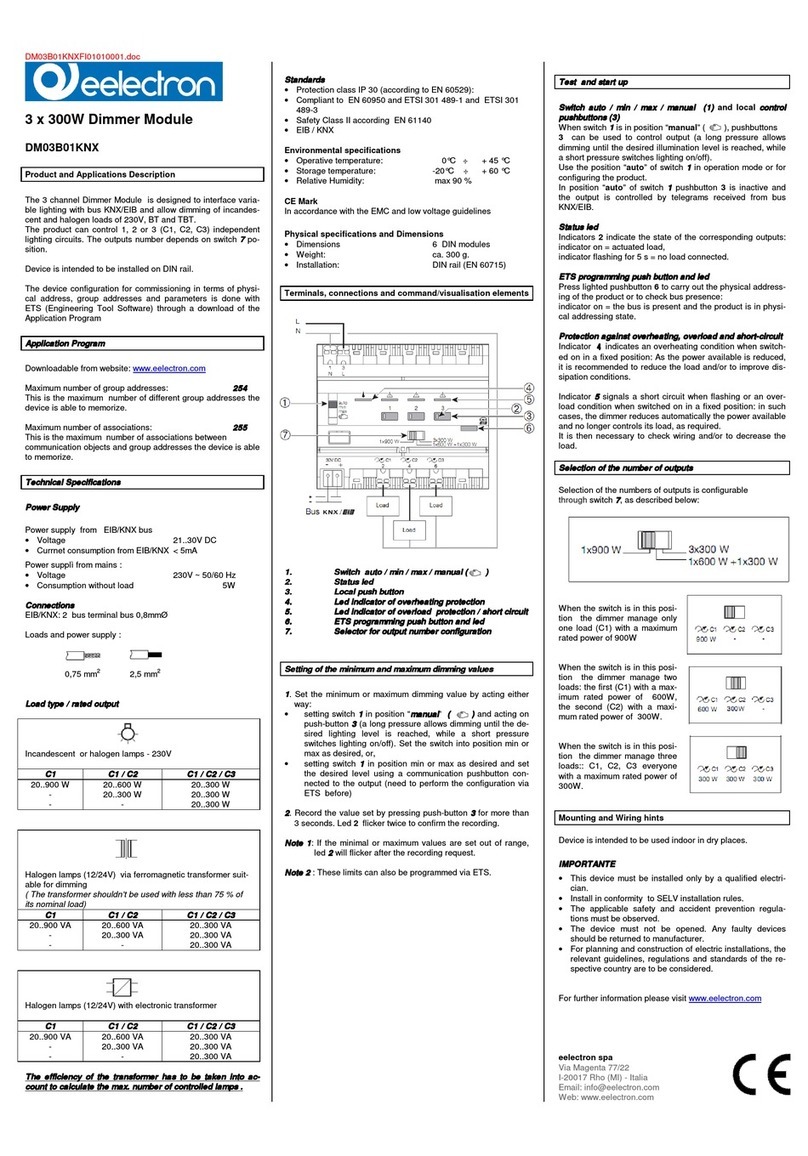

For in p u t s 5 , 6 , 7 and 8, i f c o n f i g u r e d a s an a l o g

inputs for tem perature probe, the NTC probes code

eelect ron m ust be used:

TS01A0 1A CC (d a -20°C a +100°C)

TS01B0 1A CC (d a -50°C a +60°C)

twisted

cable)

At each input it is possib le t o asso ciat e t h e

Tem p er at u r e Sen sor function or the Th er m o st at

function

TS01A 01ACC

Dim ensions in m illim etres

NTC resistance tolerance: ± 3%

Measure range -20°C ÷ +100°C

Cab le: 2 w ire single insulation

Cab l e co lo u r: Black

NTC colour: Black

Warning:

keep at least 6 mm from all live parts

TS01B01ACC

D1 = 9 m m D2 = 4 m m L2 = 49 m m L1 = 1250 m m

NTC resistance tolerance: ± 2%

Measure range -50°C ÷ +60°C

Cab le: 2 w ire double insulation

Cab l e co lo u r: White

NTC colour: White

Warning:

keep at least 3 m m from all live parts

Tem p er at ure sen sor description

Using the "tem perature probe" m odule it is possible

(b y con n ect in g t h e NTC p robe) t o m easure t h e

temperature and send ON / OFF commands.

Th e o b ject s availab le are as follow s:

AD84C01KNXFI000030101_HANDBOOK_EN.DOCX

AD84C01KNX - ANALOG / DIGITAL MODULE Handbook

Eel ect r on Sp A, Vi a M on t everd i 6,

I-20025 Legnano (MI), Italia

Tel: +39 03 31.5008 02 Fax:+39 03 31.564826

E-mail:info@eelectron.com Web:www.eelectron.com

C.F. e P.IVA 11666760159

Tr ib u n ale d i M il an o 3 59 15 7-8760-07

CCIAA M i lan o 1 48 549

12/27

<Tem p e r a t u r e x > A c t u al Te m p .

2 byt es | CRT

Sen d t em p er at u re m easu rem en t i n °C o n var iat io n an d / or

cyclically.

<Tem p er at u r e x > K N X p r o b e Te m p .

2 byt es | CW

Th e m easu rem en t o f an o t h er p rob e i s r eceived via KN X

<Pr o b e x > Se t p o i n t Upper

2 byt es | CW

Receives t h e u p p er set p oin t via KNX b u s

< Pr o b e x > Te l eg r am U p p e r

1 bit | CRT

Sen d On , Of f o r n ot h i n g w h en g o in g u p or d o w n t h e set

upper threshold

< Pr o b e x > Se t p o i n t Lo w e r

2 byt es | CW

Receives t h e lo w er set p oin t via KNX b u s

< Pr o be x>Telegram Lower

1 bit | CRT

Sen d On

< Pr o b e x > En a b l e In p u t

1 bit | CW

En ab les or d isab les t h e send in g of on / off t eleg ram s

Tem p er at ure sen sor parameters

KNX PARAMETER

SETTINGS

Activation telegram

Teleg ram 0

Teleg ram 1

Definisce quale v

telegrammi on/off di soglia.

St at e af t er d ow n l oad

disabled/enabled

Defines whether the sending of on / off telegram s is

enab led or disabled after dow nload ing.

Hysteresis

0.5°C 1.0°C

2.0°C 5.0°C

Defines the hysteresis value to be applied on the high and

low thresholds

Upper set point value

-20°C ÷ +100°C TS01A01ACC

-50°C ÷ +60°C TS01B01ACC

Low er set p o in t value

-20°C ÷ +100°C TS01A01ACC

-50°C ÷ +60°C TS01B01ACC

Telegram w hen valu e is

above setpoint

off / on / nothing

Telegram w hen valu e is

below set p oin t

off / on / nothing

Cy cl i c sen d i n g t i m e o f

telegrams

No cyclic send 30 m in

1 hour 2 hours

9. Th er m ost at Fu n ct i on

Th e t em p er at u re function can be configured as a

thermostat to control the temperature of a room or

area by driving heat ing or cooling equipm ent / air

conditioning fan coils / valves or through

com m ands on / off to heating /cooling elem ents

su ch as rad iat ors, h eat p u m p s, sp lit , et c. ..

Set p o in t val u es (i n clu d i n g SETPOINT MODE)

from the bus are accepted in a range from

10°C to 50°C

Set p o in t Set tings

Th e con t rol set p oin t can b e ch an ged b y b u s in t w o

different ways, via one of these objects:

HVAC Mode

SETPOINT Mod e

Th e r ig h t p o licy t o ad o p t d ep en d f ro m t h e d evic e

that acts as a master, a tim e therm ostat, a control

panel or a SW supervisor. Here the list of object for

changing the active m ode or setpoint value by bus.

SETPOINT Ob j ect

When "Thermostat control mode" parameter is

select ed w it h t h e valu e SETPOINT MODE, ob ject

HVAC Mode is n o lon g er visib le.

Each t im e t h e t h erm ost at receives a valu e on ob ject

SETPOINT MODE ( 2 b yt e size), it is u sed as set p oin t

for tem perature control.

HVAC MODE obj. (sw it ched heat / cool)

Using the HVAC MODE object (size 1 byte), it is

possible to set the t herm ost at in one of the

following m odes: OFF; ECONOMY; STANDBY;

COM FORT; each m o d e is associat ed w it h a set p oin t

set b y an ETS p aram et er .

AD84C01KNXFI000030101_HANDBOOK_EN.DOCX

AD84C01KNX - ANALOG / DIGITAL MODULE Handbook

Eel ect r on Sp A, Vi a M on t everd i 6,

I-20025 Legnano (MI), Italia

Tel: +39 03 31.5008 02 Fax:+39 03 31.564826

E-mail:info@eelectron.com Web:www.eelectron.com

C.F. e P.IVA 11666760159

Tr ib u n ale d i M il an o 3 59 15 7-8760-07

CCIAA M i lan o 1 48 549

13/27

OFF m ode is associat ed w ith the antifreeze set point

in heating m ode and at the high tem perature

protection set point in cooling mode.

HVAC MODE obj. (autom atic heat / cool)

Th er m ost at

control m ode

the switching from heating to cooling mode and

vice versa is aut om at ic. With t his set ting it is

necessary to set an insensitive zone as in param eter

Dead zone

Whenever tem perature becomes greater than :

Set p o in t com f ort h eat i n g + (Dead Ban d / 2)

active

control is cooling; when tem perature becom es less

than:

Set p o in t co m f or t co ol in g - (Dead Band / 2)

active cont rol is heating.

SETPOINT COMFORT,STA NDBY,ECONOMY

Th ese 2 b yt e o b ject s are u sed t o set t h e set p o int

values for COMFORT, STAND-BY, ECONOMY m ode.

Whenever change, the setpoint are in saved in

memory.

After dow nload these setpoint are reset to values

according t o ETS param et er; on pow er up t hese

object are set according to last values before power

down.

Use these com m unication object s to

change current setpoint for every HVAC

Mode according to the current active control

(heating or cooling)

KNX PARAMETER

SETTINGS

Action to execute for

set p oint

modify relative

modify absolute

If you set this p aram et er to " modify relative ", t h e

thermostat will take into account the new value set but

will still consider the setpoint set in ETS as a reference to

determine the allowed variation range (± 1, ± 2, ± 3, .. );

choosing instead the value "absolute change" also this

range will be recalculated.

COM FORT Ob j ect

COM FORT ob ject (1 b it size) is visib le on ly w h en

"Therm ost at control m ode" parameter is selected

with the value HVACMODE.

When a telegram "1" is received thermostat goes in

COM FORT m o d e (it ap p lies f or b ot h h eat in g an d

cooling)

On receipt of a telegram "0", t herm ostat returns t o

the mode set by HVAC MODE object.

COM FORT m od e can be set also with tim ing: after a

time set by a parameter thermostat returns in the

previous mode.

KNX PARAMETER

SETTINGS

Com fort Ob ject

Tim e lim it ed

Tim e u nl im it ed

Com fort Overw rit e Tim e

1.. 255 (m inutes)

WINDOW CONTACT Object

Th is ob ject , i f enabled , has higher priority than

HVAC MODE, SETPOINT MODE, COMFORT ob ject s.

Heat protection (Off)

Econ om y Cooling

St an d b y Co ol in g

Co m f ort Co ol in g

DEAD BAND

Co m f ort H eat in g

St an d b y Heating

Econ om y H eat in g

Antifreeze (Off)

SETPO IN T

HVAC

MODE

COMF STBY ECO OFF

COOLIN G

HEATING

AD84C01KNXFI000030101_HANDBOOK_EN.DOCX

AD84C01KNX - ANALOG / DIGITAL MODULE Handbook

Eel ect r on Sp A, Vi a M on t everd i 6,

I-20025 Legnano (MI), Italia

Tel: +39 03 31.5008 02 Fax:+39 03 31.564826

E-mail:info@eelectron.com Web:www.eelectron.com

C.F. e P.IVA 11666760159

Tr ib u n ale d i M il an o 3 59 15 7-8760-07

CCIAA M i lan o 1 48 549

14/27

When a telegram is received ("0" or "1") on the

com m unication object WINDOW CONTACT

thermostat enters a power saving mode:

BUILDING PROTECTION (if run ning in HVAC MODE)

or Set p o in t antifreeze /high temperature protection

(if run n ing in SETPOINT MODE)

If the t elegram received ind icates t hat t he w indow

is opened, therm ostat change its m ode or setpoint

after 1 m inut e from t he recep tion of t he telegram .

When it receive a telegram corresponding to state

alw ays w it h a d elay of 1 m inut e . The value of

SETPOINT ADJUSTMENT (if en ab led ) is alw ays

restored.

SETPOINT A DJUSTMENT ob j ect

The ob ject SETPOINT ADJUSTMENT allow s you t o

temporarily change the setpoint value used by the

thermostat applying an offset to the current value.

If the t herm ostat is operating in "HVAC MODE" t he

offset value is applied from the tim e of receipt of a

valid t eleg ram on ob ject SETPOINT ADJUSTMENT

until this value does not change, even in case of

change of the active m ode (Com fort and Standby);

when device enters Econ om y m od e this value can

delta setpointon HVAC economy). Entering Building

Prot ect ion mode the value of ob ject SETPOINT

ADJUSTMENT is forced to 0.

Sim ilarly, if t h e t h erm ost at is op erat in g in SETPOINT

MODE the offset value is applied also when the

set p o in t valu e received o n t h is ob j ect ch an g es.

KNX probe tem perature obj.

It is possible to enab le the reading of a second

ext ernal probe w hich send s t he m easurem ent d ata

to the thermostat via the communication object

ADDITIONAL TEMPERATURE of size 2 b yt es.

Su r v ei l l an c e t i m e f o r

KNX probe

10..255 (m in)

Whenever the thermostat receive a valid data from

KNX probe it consider this value in the calculation of

the measured temperature and reset the internal time

(m on it orin g t im e).

If KNX p robe is enabled the monitoring

time is used to check if the additional

temperature sensor periodically sends valid data to

the thermostat. This mechanism avoids to consider

as valid som e data which can be old hours or days,

for exam ple if the additional sensor should fail or

the thermostat could not receive data for long time.

It is st r on g ly reco m m en d ed to set a value

for surveillance tim e of the additional sensor

more than twice of the period set for the cyclical

sen d i n g of t h e ad d i t io n al sen so r.

ACTUAL SETPOINT object

The ACTUAL SETPOINT ob ject sen d t h e set p oint in

use and is sent every time:

Th e val u e o f HVA C m o d e object changes

The valu e BASE SETPOINT ch an ges

Th e valu e of SETPOINT ADJUSTMENT ob j ect

changes

After download

One m inute after pow er on

Tw o p o in t s on/of f

control heating or cooling elem ents that can be

controlled by switching on and off of the same

elem ent s, radiators, under floor heating w ith on-off

valves, boilers, et c. ..

When the thermostat switches to "winter m ode"

(h eat m od e) sen d s a o ff com m an d on ob ject

ON/OFF COOLING and operates the cont rol only

through the object ON/OFF HEATING (the object

ON/OFF COOLING is t herefore not updated anym ore

until it returns in "cooling mode").

AD84C01KNXFI000030101_HANDBOOK_EN.DOCX

AD84C01KNX - ANALOG / DIGITAL MODULE Handbook

Eel ect r on Sp A, Vi a M on t everd i 6,

I-20025 Legnano (MI), Italia

Tel: +39 03 31.5008 02 Fax:+39 03 31.564826

E-mail:info@eelectron.com Web:www.eelectron.com

C.F. e P.IVA 11666760159

Tr ib u n ale d i M il an o 3 59 15 7-8760-07

CCIAA M i lan o 1 48 549

15/27

Th erefor e in t h e t ran sit ion from " w int er" t o

HEATING com m ands and activates the control

through the object ON/OFF COOLING

on/off control in heating m ode:

on/off control in cooling m ode:

Int egral prop ort ional control PW M

Integral proportional cont rol w it h PW M is an

algorithm that reduces the effects of hysteresis

around the set point value by adjusting t he controls

on the values ranging from 0% to 100% where 0%

Once a cycle tim e is defined the therm ost at sets the

actuator t o ON for a fraction of the cycle tim e and

OFF for the rem aining part. Driving t he actuator

with the control value of 80% means that it isactive

(i.e., ON) for 80% of cycle t im e an d OFF for t h e

rem aining 20%

KNX PARAMETER

SETTINGS

Cycl e t i m e (TCp )

10, 20, 30, 60 m in

It defines the time interval.

Prop ort ion al b and (Bp)

1, 2, 3, 4, 5 °C

Th e p rop o rt io nal b an d BP is a ran ge of t em p erat u res

-

mode, within this interval thermostat controls the

tem perature using the proportional algorithm; outside It

drives actuator always in ON or OFF.

When temperature is inside this range device wait the

end of the cycle tim e before calculat ing the duty cycle

of the next cycle.

When tem perature is outsid e of this range : b elow

-

cooling m ode it starts a new cycle as soon as

tem perature enters the Bp

Int egrat ion t im e (Ti)

5 .. 250 m in

Defines the integration tim e

Int egral prop ort ional contr. co n t i n u o u s

control w it h PW M

parameters. This mode uses a 1 byte object (%

value) to send the com m and on t he bus .

Fan coil on /of f

Fan co il is a d evi ce t h at c ontrols the flow of cooling

/ heating liquid driving a valve (2-pipe fan coil) or

two valves (4-pipe fan coil).

Liq u id exch an ges h eat /co ol w it h t h e en viro n m en t

through a ventilation system controlled by a fan.

Th e fan is d riven b y an en g in e t h at t yp ically has 3

windingsthat can be enabled at 3 distinct speeds.

TARGET SETPOINT

TARGET SETPOIN T + DIFFEREN TIAL

TH E M EA SURED TEM PERA TURE DECREA SES

BELOW THE VALUE OF SETPOINT

TH ERM OSTA T SEN DS A ON COM M AND

TH E M EASURED TEM PERA TURE RISE A BO VE

THE VALUE OF SETPOIN T + DIFFERENTIAL:

TH ERM OSTA T SEN DS A O FF COM M A N D

REGULATION DIFFERENTIAL

TARGET SETPOIN T - DIFFERENTIAL

TARGET SETPOIN T

TH E TEM PERATU RE M EA SURE IS DO WN UN DER

THE SETPOINT VALUE - DIFFERENTIAL:

TH E TH ERM OSTA T SEN DS A COM M A ND O FF

TH E M EA SURED TEM PERA TURE RISE A BOVE

THE VALUE OF SETPOINT:

TH ERM OSTA T SEN DS A ON COM M A ND

REGULATION DIFFERENTIAL

DIFFERENTIAL

AD84C01KNXFI000030101_HANDBOOK_EN.DOCX

AD84C01KNX - ANALOG / DIGITAL MODULE Handbook

Eel ect r on Sp A, Vi a M on t everd i 6,

I-20025 Legnano (MI), Italia

Tel: +39 03 31.5008 02 Fax:+39 03 31.564826

E-mail:info@eelectron.com Web:www.eelectron.com

C.F. e P.IVA 11666760159

Tr ib u n ale d i M il an o 3 59 15 7-8760-07

CCIAA M i lan o 1 48 549

16/27

Con t rol logic for a 3 sp eed fan coil in heating:

When tem perature increasing

When tem perature decreasing

Where:

Tsp : Tar g et set p o i n t t em p er at u r e

TdrV1SP : r e g ulation differential in heating for V1-SP

TdrV1V2 : r e g u l a t i o n d i f f e r en t i a l i n h e at i n g f o r V 1-V2

TdrV2V3 : r e g u l a t i o n d i f f e r e n t i a l i n h e at i n g f o r V2 -V3

Con t rol logic for a 3 sp eed fan coil in cooling:

When tem perature decreasing

When tem perature increasing

Where:

Tsp : Tar g et set p o i n t t em p er at u r e

TdrV1SP : r e g u l at i o n differential in cooling for V1-SP

TdrV1V2 : r e g u l a t i o n d i f f e r en t i a l i n cooling for V1-V2

TdrV2V3 : r e g u l a t i o n d i f f e r e n t i a l i n cooling for V2-V3

VALVE ON

VALVE OFF

V2 ACTIVE

V1 ACTIVE

V1 ACTIVE

VENTILATION OFF

V3 ACTIVE

REGULATION DIFFERENTIAL: V1-SP

TEMP. SP Tsp

REGULATION DIFFERENTIAL: V1-V2

REGULATION DIFFERENTIAL: V2-V3

TEMP. SP TdrV1V2 Td rV2V3

TEMP. SP + Td rV1SP

TEMP. SP - Td r V1V2

VALVE ON

VALVE OFF

V2 ACTIVE

V3 ACTIVE

V1 ACTIVE

VENTILATION OFF

V1 ACTIVE

TEMP. SP + Td r V1V2 + TdrV2V3

TEMP. SP + Td r V1V2

TEMP. SP Tsp

TEMP. SP - Td r V1SP

REGULATION DIFFERENTIAL: V1-SP

REGULATION DIFFERENTIAL: V1-V2

REGULATION DIFFERENTIAL: V2-V3

VALVE ON

VALVE OFF

V2 ACTIVE

V3 ACTIVE

V1 ACTIVE

VENTILATION OFF

TEMP. SP Tsp

VENTILATION OFF

REGULATION DIFFERENTIAL: V1-SP

REGULATION DIFFERENTIAL: V1-V2

REGULATION DIFFERENTIAL: V2-V3

TEMP. SP + Td r V1V2 + TdrV2V3

TEMP. SP + Td r V1V2

TEMP. SP - Td r V1SP

VALVE ON

VALVE OFF

V2 ACTIVE

V1 ACTIVE

TEMP. SP TdrV1V2 Td rV2V3

VENTILA TION OFF

TEMP. SP + Td rV1SP

V3 ACTIVE

TEMP. SP - Td r V1V2

TEMP. SP Tsp

VENTILATION OFF

REGULATION DIFFERENTIAL: V1-SP

REGULATION DIFFERENTIAL: V1-V2

REGULATION DIFFERENTIAL: V2-V3

AD84C01KNXFI000030101_HANDBOOK_EN.DOCX

AD84C01KNX - ANALOG / DIGITAL MODULE Handbook

Eel ect r on Sp A, Vi a M on t everd i 6,

I-20025 Legnano (MI), Italia

Tel: +39 03 31.5008 02 Fax:+39 03 31.564826

E-mail:info@eelectron.com Web:www.eelectron.com

C.F. e P.IVA 11666760159

Tr ib u n ale d i M il an o 3 59 15 7-8760-07

CCIAA M i lan o 1 48 549

17/27

Manage valve independently

In Fan coil on / off m ode it is possible to have the

opening or closing of the valve independent from

sw it ch in g on or off t h e sp eed s by setting the

parameter "manage valve independently". This

makesvalve adjustment differentials visib l e and can

be set different from those set for speeds. The valve

can therefore be kept open even when the fans are

st op p ed .

Th e sh ad ed ar ea rep r esen t s t h e t em p erat u re r an ge

defined by the "heating control differential ON"

parameter in case of increasing tem perature.

When the temperature decreases, the "heating

control differential ON" param eter defines the valve

hysteresis.

Fan coil con t r ol PI

Log ic an d p aram et er s ar e t h e sam e u sed i n On /off

w it h PW M con t rol m od e; t h e d ifference is that now

the proportional value is sent to the bus via a 1 byte

object form at as a % value from 0% to 100%.

Th is m od e i s u sef ul t o con t rol fan coils (sel ect in g 2

or 4 pipes) or generic proportional actuators as

valve drivers only linking the 1 byte com m unication

object and avoiding to link the valve objects.

CONTINUOUS CONTROL ob ject

Th is 1 Byt e o b jec t sen d % c on t rol val u e t o act uat or.

Additional valve

In fan coil m ode it is p ossible, in 4 p ip es

syst em s t o en ab l e an ad d it io nal val ve ob ject.

Th is ob j ect is u sed w h en t h e t h erm ost at h as t o

manage 2 different system ,one in heating and one

in cooling .

Su p p ose t o h ave a syst em w h en f loo r h eat in g is

required in heating m ode and a 3 speed fan coil

syst em is req u ir ed in co olin g m o d e.

To m an ag e this system it is necessary to :

OFF cont rol>Enable

=c o o l i n g

coil ON OFF cont rol > Syst em

= 4 p i p e s

according to your system request

VALVE ON

V2 ACTIVE

V1 ACTIVE

V1 ACTIVE

VENTILATION OFF

OFF

V3 ACTIVE

TEMP. SP Tsp

VALVE OFF

V2 ACTIVE

VENTILATION OFF

V1 ACTIVE

VENTILATION OFF

V3 ACTIVE

TEMP. SP Tsp

VALVE ON

AD84C01KNXFI000030101_HANDBOOK_EN.DOCX

AD84C01KNX - ANALOG / DIGITAL MODULE Handbook

Eel ect r on Sp A, Vi a M on t everd i 6,

I-20025 Legnano (MI), Italia

Tel: +39 03 31.5008 02 Fax:+39 03 31.564826

E-mail:info@eelectron.com Web:www.eelectron.com

C.F. e P.IVA 11666760159

Tr ib u n ale d i M il an o 3 59 15 7-8760-07

CCIAA M i lan o 1 48 549

18/27

valve valve

cool heat

Additional valve 6 w ays

Th e ad d it io n al valve al so m an ag es com m an d s f or 6 -

way valves in which the control value from 0% to

100% defines both the percentage of valve opening

and the passage of hot or cold fluid.

KNX PARAMETER

SETTINGS

Percent age 100% cool

0% ÷ 30%

Value to be sent to bring the cold valve t o 100% op en

position [point A on the diagram]

Percent age 0% cool

23% ÷ 53%

Value to b e sent t o b ring the cold valve in closed

position (0% open) [point B of the diagram ]

Percent age 0% h eat

47% ÷ 77%

Value to b e sent t o b ring t he hot valve to the closed

position (0% open) [point C of the diagram]

Percent age 100% h eat

70% ÷ 100%

Value to b e sent to b ring th e hot valve to 100% open

position [point D on the diagram ]

Value to send for valve

fully closed

36% ÷ 66%

Value to be sent t o b ring b ot h t he cold and hot valves t o

the fully closed position. [area of the diagram between B

and C]

For t h e ad d it ion al valve, in 6 -way mode, it is

possible to d efine different control different ials

around the set point value as show n below :

Th is m ak es it p o ssib le t o ad j ust t h e o p en i n g an d

closing of the additional valve independently of the

sp eed con t rol (for exam p le, on ce t h e set p oin t h as

been exceeded, a maintenance action can be taken

keeping the valve open again without activating the

sp eed s)

KNX PARAMETER

SETTINGS

Regu lat ion d if f er en t i al

valve 0%

0°C ÷ 5 °C

Defines the width of the F-G bands for cooling and H-I

for heating

Regul at ion differential

valve 100%

0°C ÷ 5 °C

Defines the w idth of the E-F bands for cooling and I-L

for heating

Force f an coil sp eed

In fan coil operation (in 1-bit or 1-byte mode), you

can force the use of just one speed and bypass the

aut om atic speed selection. This mode is useful, for

exam ple, in sm all room s such as hotel room s, for

exam ple or in any case w here the fan speed m ay

bring noise. To activate forcing, you m ust act on the

1-bit object that sel ect s AUTO / MAN and then on

the object that activates the desired speed (3x1 1-

bit object or 1 object at 1-byte in% mode)

Ventilation m ode

When using fan coil, you can also activate "fan" or

"vent ilat ion " m od e. In t h is m od e, t h e fan coil w ill

100%

0%

100%

A

B

C

D

Value t o send

Set p o in t h eat i n g

E

Set p o i n t c o o l in g

F

G

H

I

L

Cool valve op en (100%)

Cool valve close (0% )

Heat valve close (0%)

Heat valve open (100%)

AD84C01KNXFI000030101_HANDBOOK_EN.DOCX

AD84C01KNX - ANALOG / DIGITAL MODULE Handbook

Eel ect r on Sp A, Vi a M on t everd i 6,

I-20025 Legnano (MI), Italia

Tel: +39 03 31.5008 02 Fax:+39 03 31.564826

E-mail:info@eelectron.com Web:www.eelectron.com

C.F. e P.IVA 11666760159

Tr ib u n ale d i M il an o 3 59 15 7-8760-07

CCIAA M i lan o 1 48 549

19/27

never turn off the fan even when, after reaching the

desired setpoint, the heat / cool valve closes. To

sel ect t h e fan sp eed used in ventilation m ode the

mode the ventilation stops when setpoint is

reached. It is also possible to m ake the "vent ilation"

mode alwaysactive without having to turn it on / off

via a com m unicat ion object.

2nd Stage Object

Th e 2n d St ag e ob ject is an ad d it ion al co n t ro l ob ject

for the regulation of a second heating or cooling

equipm ent; a 1-bit or 1-byte control can be set for

this object; if the control is a byte it is possible to set

PI con t rol (Prop ort ion al Int egral). Wit h t h e

"Ban d w id t h " p aram et er you set h ow m uch t h e

current setpoint is sh ift ed to manage the switching

on and off of the equipm ent controlled by the 2nd

st ag e ob ject . Fo r exam ple, if the setpoint is 20 ° C

and "Band w idt h" is set = 1 then the set point for the

part controlled by the 2nd stage object will be 20-1

= 1 9 ° C; v i c e v er sa i f "B a n d w i d t h " i s = -1 then the

2nd stage setpoint will be 20 - (- 1) = 20 + 1 = 21 ° C.

If the equipment controlled by 2nd Stage is

a 1,2 or 3-sp eed fan coil it is su gg est ed t o set t h e

2nd stage as 1 Byte and to send the control value %

in the logic called "proportional sp eed /fan co il

conversion" t o h ave 1 b it ou t pu t objects for the 3

sp eed s.

Tem perature probe failure / out of range

measurement

If the tem perature probe is disconnect ed or

in short circuit the control action is

interrupted and the controlled actuators are

sw it ch ed off.

Th e val u e o f t em p erat u r e sen t o n t h e b u s in

case of probe disconnection or short circuit or

for out of range m easured value is 0 °C

(accor d in g t o KNX DPT_Val ue_Tem p 9.001)

Tem p er at ure alar m ob ject

Alarm objects are available for each therm ostat and

for each tem perature probe; in case of probe failure

or out of range m easurem ent, a t elegram w it h value

"1" is sen t t o t h e b u s on a 1-bit communication

object; as soo n as t h e t em p erat u re sen sor is

operating again, the value "0" is transm itted.

To correct l y m an ag e t h e in t ern al o r rear sen so r or

KNX sen so r via bus, refer to the follow ing

configuration m odes:

CONFIGURA TION MODE 1

Only prob e connected to input

if the tem perature probe is disconnected or short-

circuited, the m onitoring action is interrupted and the

controlled actuators are deactivated.

probe / short circuit disconnection / out of range

measurement:

Obj "Tem p erat u re" is not sen d

Obj "Alarm " sen d "1"

CONFIGURA TION MODE 3

Only KNX tem perature via bus

Th e KN X p ro b e i s read c on si d er in g t h e last val u e

received on the Obj "KNX probe tem perature".

If the KNX probe value is out of range or t he

monitoring timeexpires:

Obj "Alarm " send "1" until KNX tem perature is

received again.

CONFIGURA TION MODE 3

Mix of probe connected to input and KNX

temperature via bus

Th e KN X p ro b e is read b y con sid erin g t h e l ast value

received on the OBJ "KNX tem perature probe".

Th e valu e of t h e t em p erat u re sen t on t h e b u s is t h e

weighted average between the values of the front

probe and KNX.

If the value of the KNX p robe is out of range or the

monitoring time expires without having received any

message, the thermostat starts by considering only

the other probe until it receives a new valid value

from the KNX probe; in this case the bus value is again

considered.

AD84C01KNXFI000030101_HANDBOOK_EN.DOCX

AD84C01KNX - ANALOG / DIGITAL MODULE Handbook

Eel ect r on Sp A, Vi a M on t everd i 6,

I-20025 Legnano (MI), Italia

Tel: +39 03 31.5008 02 Fax:+39 03 31.564826

E-mail:info@eelectron.com Web:www.eelectron.com

C.F. e P.IVA 11666760159

Tr ib u n ale d i M il an o 3 59 15 7-8760-07

CCIAA M i lan o 1 48 549

20/27

10. Th er m ost at behaviour on bus

failure, recovery and download

Behaviour on bus voltage failure

On failure of bus voltage no actions are executed by

the device; behaviour of controlled actuators m ust

be set using their own parameters.

Behaviour on bus voltage recovery

On bus voltage recovery all the com m unication

objects are set to 0 except for objects for w hich a

parameter is d ef in ed f or t h e in it ial val u e; t hermostat

keeps these values in m em ory and restore them

after recovery:

Heat / Cool m ode

HVAC Mode

Base Setpoint

Set p oin t A d just m en t

Force val u e in m an u al m o d e

Vent ilation

Con t ro l val u es (i.e. co m m an d s t o act uat or s) are

calculated using act ual setpoint and tem perature.

After power on device recalculates the

com m ands to actuators and switch them

on, if necessary, otherwise does not carry out any

action; you are recomm ended to set the behaviour

of actuator in order to switch the heating / cooling

equipm ent off aft er bus pow er on.

Behaviour on ETS Dow n load

s p ossib le t o set in it ial valu e of:

Heat / Cool m ode

HVAC Mode

Vent ilation

For ot h er com m unications objects t he behaviour is

identical to bus voltage recovery.

11. Logics

Th e l o g ic f u n c t i o n s ar e o r g an i ze d i n t o g r o u p s o f 3

objects: 2 inputs and 1 output, except the one

logic expression that will be described later.

The scheme of logics is as follow s:

Input s

Input datatypes can be bit, byte, float et c accord ing

to the selected logic.

IN1 is alw ays present. IN2 m aybe unused (or hidden

directly by ETS).

Delay

Th e l og ic ou t p u t can b e d el ayed acco rd in g t o t h e

ETS p aram et er, if a new value is received , t he out put

is overwritten and the delay reset.

Cy cl i c

Th e d el ayed ou t p u t can b e r et ran sm it t ed n t i m es

according to ETS param eters

Log ic f u n ct i on

Log ic funct ion t yp e is d efin ed b y an ETS p aram et er ;

here the list of functions:

FUNCTION NA ME

DESCRIPTION

Disabled

Th e l og ic b lock i s d isab led , n o

param eter / object is visible.

bit no transfer

Only delay and ret ransm ission.

IN1 is a bit .

IN2 is disabled.

OUT is a bit.

byte no transfer

Only delay and ret ransm ission.

IN1 is a byte.

IN2 is disabled.

OUT is a byt e.

bit NOT

OUT = NOT IN1

IN1 is a bit .

IN2 is disabled.

OUT is a bit .

LOGIC

FUN CTION

DELAY

CYCLIC

IN 1

IN 2

OUT

2

Table of contents

Other Eelectron Control Unit manuals

Popular Control Unit manuals by other brands

Lawler

Lawler NEPTUNE EMX 075 Installation & maintenance manual

Link

Link CAN-Lambda user manual

EST

EST SIGA-CRR Installation sheet

Keysight Technologies

Keysight Technologies M9101A Maintenance Guide

Yale

Yale Z-Wave Plus YRMZW2-US installation guide

Telit Wireless Solutions

Telit Wireless Solutions GE864 DUAL V2 Hardware user's guide