19/11/2013 Vers. 1.1 3

1. Warranty................................................................................................................................................................5

2. Warnings................................................................................................................................................................5

3. Environmental Notes.............................................................................................................................................5

4. General Information...............................................................................................................................................6

4.1. Introduction...................................................................................................................................................6

4.2. Preparation Of The Station...........................................................................................................................6

4.3. Purpose.........................................................................................................................................................7

5. The ATF2 station...................................................................................................................................................8

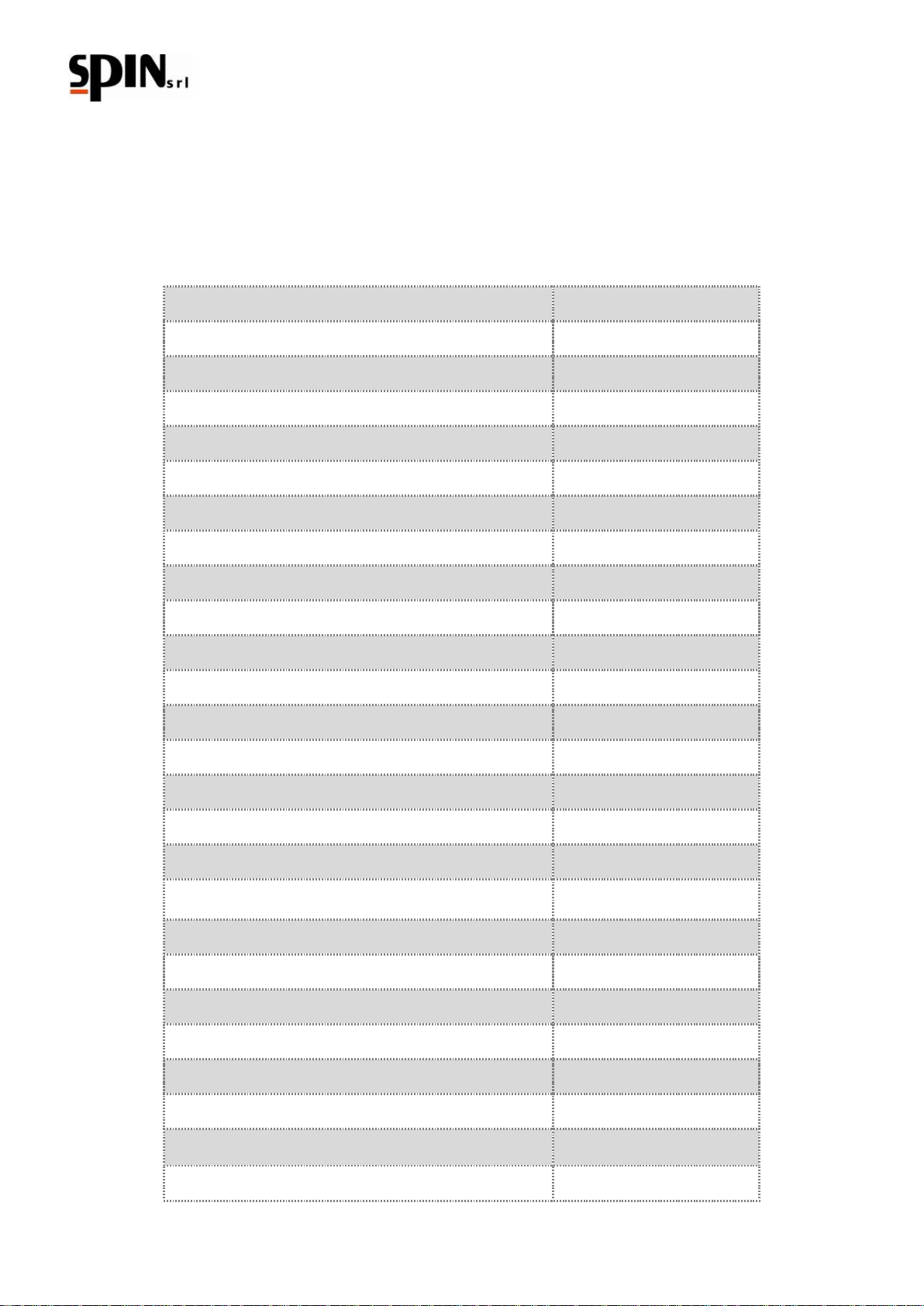

5.1. Technical features.........................................................................................................................................8

5.2. Components..................................................................................................................................................9

5.3. Control Panel and Display..........................................................................................................................11

5.4. Supplied Accessories .................................................................................................................................12

5.5. Products used.............................................................................................................................................13

6. Preparing the Car ................................................................................................................................................14

7. Preparing of the Station.......................................................................................................................................15

7.1. Preparing the oil..........................................................................................................................................15

7.2. Preparing the washing fluid ........................................................................................................................15

8. Connecting the station to the car.........................................................................................................................16

9. MANUAL procedure ............................................................................................................................................19

9.1. Inserting the washing fluid (A) ....................................................................................................................19

9.2. Washing (B)................................................................................................................................................19

9.3. Emptying of the cup for filter replacement and radiator cleaning (C) .........................................................20

9.3.1 Washing the radiator...............................................................................................................................21

9.4. Oil replacement in the converter (D)...........................................................................................................22

9.5. Inserting additive for transmission longevity...............................................................................................22

9.6. Resetting the circuit ....................................................................................................................................23

9.7. Level check.................................................................................................................................................23

10. AUTOMATIC Procedure......................................................................................................................................24

11. The DIPSTICK function.......................................................................................................................................25

12. Utility....................................................................................................................................................................27

12.1. Level........................................................................................................................................................27

12.2. Recirculation ...........................................................................................................................................27

12.3. Used oil drain..........................................................................................................................................27

12.4. Print.........................................................................................................................................................27

13. Setup ...................................................................................................................................................................28

13.1. Time/Date Setting ...................................................................................................................................28

13.2. LCD Setting.............................................................................................................................................28

MANUAL FOR USE AND MAINTENANCE