SpinCore Technologies PulseBlasterESR-PRO-200-cPCI User manual

PulseBlasterESR-PRO-200-cPCI

http://www.spincore.com 2 2017/01/24

© 2000-2017 SpinCore Technologies, Inc. All rights reserved.

SpinCore Technologies, Inc. reserves the right to make changes to the prod ct(s) or information herein witho t notice. P lseBlasterESR-PRO-

200-cPCI™, P lseBlaster™, SpinCore, and the SpinCore Technologies, Inc. logos are trademarks of SpinCore Technologies, Inc. All other

trademarks are the property of their respective owners.

SpinCore Technologies, Inc. makes every effort to verify the correct operation of the eq ipment. This eq ipment version is not intended for

se in a system in which the fail re of a SpinCore device will threaten the safety of eq ipment or person(s).

Congratulations and thank you for choosing a design from

SpinCore Technologies Inc.

We appreciate your business!

At SpinCore we aim to fully support the needs of our customers. If you

are in need of assistance please contact us and we will strive to provide

the necessary support.

PulseBlasterESR-PRO-200-cPCI

Table of Contents

I. Introduction ........................................................................................ 5

II. Device Description and Specifications .......................................... 6

Device Overview ................................................................................................................... 6

System Architecture ........................................................................................................ 6

Output Signals ................................................................................................................. 6

Timing Characteristics ..................................................................................................... 7

Instruction Set (Flow Control) ..................................................................................... 7

On- oard Clock ............................................................................................................... 7

Device Memory ................................................................................................................ 7

External Inputs ................................................................................................................. 7

Summary ............................................................................................................................... 8

Output Signals ................................................................................................................. 8

Timing Characteristics ..................................................................................................... 8

Instruction Set (Program Flow) ....................................................................................... 8

On- oard Clock ............................................................................................................... 8

Device Memory ................................................................................................................ 8

External Input Specifications ........................................................................................... 8

III.Installation ......................................................................................... 9

Installing the PulseBlasterESR-PRO-200-cPCI ................................................................. 9

IV. Programming PulseBlaster Devices ........................................... 10

Introduction ........................................................................................................................ 10

Programming Paradigm .................................................................................................... 10

PulseBlaster Interpreter ..................................................................................................... 11

PulseBlaster.NET ................................................................................................................ 12

MATLAB GUI ....................................................................................................................... 13

LabVIEW Extensions ......................................................................................................... 14

C/C++ Programming .......................................................................................................... 15

http://www.spincore.com 3 2017/01/24

PulseBlasterESR-PRO-200-cPCI

V. Connecting to PulseBlaster Devices ............................................ 16

Connector Information ...................................................................................................... 16

NC Header Connectors ............................................................................................... 16

IDC Headers .................................................................................................................. 17

HWTrig/Reset Header ................................................................................................... 19

VI. Related Products and Accessories ............................................ 21

VI.Contact Information ....................................................................... 22

I.Document Information ..................................................................... 22

http://www.spincore.com 4 2017/01/24

PulseBlasterESR-PRO-200-cPCI

I. Introduction

The P lseBlasterESR-PRO-200-cPCI is a programmable m ltichannel p lse/delay generator in the

CompactPCI form factor. This device is capable of generating p lses and delays with d ration ranging from 5 ns

to 2.3 x 107 seconds (260 days). The P lseBlasterESR-PRO-200-cPCI feat res o tp ts on BNC connectors and

IDC headers, highly flexible program flow control, and can accommodate p lse programs containing p to 4096

instr ctions (if more instr ctions are necessary, please contact SpinCore Technologies, Inc. for more information).

The P lseBlasterESR-PRO-200-cPCI is capable of generating complex o tp t p lse seq ences feat ring

very short and very long p lses and delays in the same seq ence. P lses/delays can be as short as one clock

cycle, to as long as 252 clock cycles. Regardless of the p lse/delay length, timing resol tion is only one clock

cycle.

The intelligence of the P lseBlasterESR-PRO-200-cPCI comes from its proprietary P lseBlaster processor

core. Unlike general-p rpose processors, the P lseBlaster processor core feat res a highly optimized instr ction

set designed for timing applications. A niq e feat re of the P lseBlaster processor core is the ser can vary the

exec tion time of instr ctions.

User interaction with the P lseBlasterESR-PRO-200-cPCI can be accomplished in several different ways.

Many Graphical User Interfaces (GUI) are offered by SpinCore Technologies that allow a ser with little to no

programming experience to create, edit, save and r n p lse programs. Development environments like

LabVIEW, MATLAB, and C/C++, are s pported by sing the SpinAPI package, a dedicated Application

Programming Interface (API) package. The SpinAPI package can be sed with most Windows programming

environments and can be sed with other operating systems, incl ding Lin x. Software for the P lseBlasterESR-

PRO-200-cPCI is available on o r website: http://www.spincore.com/s pport/.

http://www.spincore.com 5 2017/01/24

PulseBlasterESR-PRO-200-cPCI

II. Device Description and Specifications

Device Overview

System Architecture

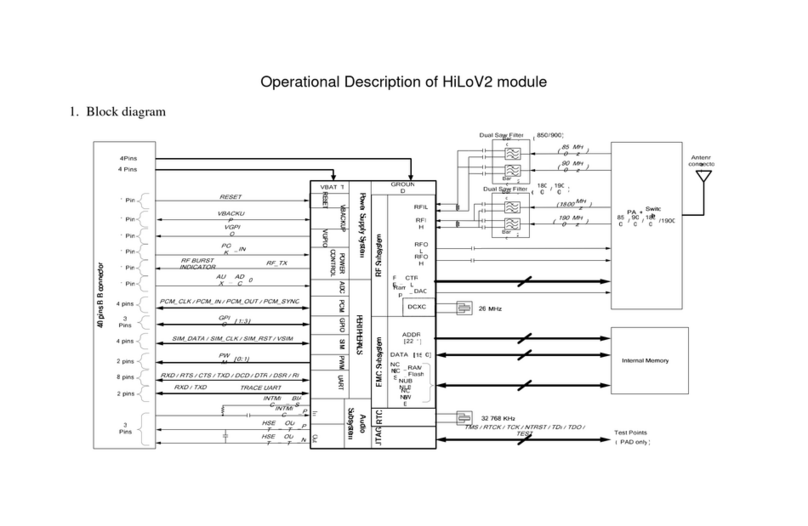

The major b ilding blocks of the P lseBlaster processor core are the SRAM memory, the microcontroller

core ( PC), the integrated b s controller (IBC), the co nter, and the o tp t b ffers. All components are

located on a single silicon chip, making the design a System-on-a-Chip (SOC). User control of the device is

provided thro gh the integrated b s controller (IBC) sing the CompactPCI b s. The fig re below shows the

block diagram of the P lseBlaster processor core.

Output Signals

P lse seq ences are o tp t digitally sing 3.3 V Low Voltage TTL (LVTTL). If the channel is on, then the

device will o tp t 3.3 V nterminated, and if the channel is off, the device will o tp t 0.0 V, nterminated.

Each channel is capable of delivering p to 25 mA per channel. If more o tp t c rrent is necessary, the

individ al channels can be driven in parallel.

O tp ts are available on BNC connectors and IDC headers. The BNC connectors are impedance

matched to 50 Ω and are located on the mo nting bracket. All o tp ts are available on IDC headers located

http://www.spincore.com 6 2017/01/24

Figure 1: Block Diagram of the P lseBlaster processor core. All the components

are placed on a single silicon chip, making the design a System-on-a-

Programmable-Chip (SOPC). The clock oscillator signal is derived from an on-chip

PLL circ it typically sing a 50 MHz on-board reference clock.

CompactPCI bus

PulseBlasterESR-PRO-200-cPCI

on the board's s rface. Stat s bits are also available on IDC headers, allowing the ser or an external device

to monitor the stat s of the P lseBlaster device. For more information abo t the connections available,

please see “V. Connecting to P lseBlaster Devices.”

Timing Characteristics

The innovative architect re of the P lseBlaster processor core allows p lses/delays to be as short as one

clock cycle (5 ns) and last p to 252 clock cycles (260 days). Regardless of the timing d ration sed, the

timing resol tion is one clock cycle. A program can have both long and short p lses/delays in the same

program, and both will be acc rate to a single clock cycle.

Instruction Set Flow Control)

The P lseBlaster devices feat res a set of commands for highly flexible program flow control. The

specialized microcontroller allows for programs to incl de branches, s bro tines, and loops p to 8 nested

levels deep. These commands allow the ser to perform repetitio s events with ease.

Instr ction exec tion time can be set by the ser. The minim m instr ction exec tion time is five clock

cycles (25 ns), and the maxim m is 252 clock cycles (260 days). To create p lses with d ration shorter than

five clock cycles, the Short P lse Feat re will need to be sed. The Short P lse Feat re allows p lse

d ration to be as short as one clock cycle (5 ns); however, at least five clock cycles are still req ired for the

P lseBlaster processor core to process the instr ction. For more information abo t P lseBlaster processor

core architect re, please see the “Instr ction Set Architect re” of Using SpinAPI in C/C++ in P lseBlaster

Programming, fo nd at: http://www.spincore.com/s pport/spinapi/ sing_spin_api_pb.shtml.

On-Board Clock

The P lseBlaster device accepts an on-board 50 MHz oscillator. The on-board oscillator's freq ency is

internally m ltiplied to 200 MHz by sing a Phase-Locked Loop (PLL). The device can be externally clocked

by removing the oscillator and attaching an eq ivalent external so rce to the oscillator mo nt. The

P lseBlaster device does not have on-board termination for the clock inp t signal. Applying less than 0.0 V or

more than 3.3 V to the clock inp t pins will damage the P lseBlaster device.

CAUTION: Incorrectly attaching an external clock source will damage the Pulse lasterESR-PRO-200-

cPCI. Contact SpinCore Technologies, Inc. if you would like information on how to use an external clock

source.

Device Memory

The memory will hold p to 4096 instr ctions. Programs do not need to fill the memory; they can be as

short as desired. If larger device memory is req ired, please contact SpinCore Technologies, Inc.

http://www.spincore.com 7 2017/01/24

PulseBlasterESR-PRO-200-cPCI

External Inputs

The P lseBlaster device has 2 external inp ts for device control: HW_Trig and HW_Reset. If HW_Trig is

activated, then the device will start r nning the program (the P lseBlaster device m st be programmed first).

If HW_Reset is activated, then the device will be stopped. The two separate lines combine the convenience

of triggering (e.g., in cardiac gating) with the safety of a "stop/reset" line. External inp ts are described f rther

in “V. Connecting to P lseBlaster Devices.”

http://www.spincore.com 8 2017/01/24

PulseBlasterESR-PRO-200-cPCI

Summary

Output Signals

4 bracket-mo nted BNC connectors, impedance matched to 50 Ω. 3.3 V LVTTL.

21 individ ally controlled digital o tp t signals on IDC headers. 3.3 V LVTTL.

25 mA o tp t c rrent per o tp t line.

4 stat s o tp ts on IDC header.

Timing Characteristics

Shortest p lse/delay: 1 clock cycle (5.0 ns).

Longest p lse/delay: 252 clock cycles (260 days).

P lse resol tion: 1 clock cycle (5.0 ns), regardless of p lse length.

Instruction Set Program Flow)

User-programmable instr ction exec tion time.

S bro tines can be nested p to 8 levels deep.

Loops can be nested p to 8 levels deep.

20-bit loop co nters (maxim m of 1,048,576 repetitions).

Branch range incl des the entire memory.

Latency after trigger (WAIT state) – 8 clock cycle latency (40 ns at 200 MHz), adj stable to 20

seconds in d ration.

External trigger and reset provide external control of the P lseBlaster device.

On-Board Clock

50 MHz on-board oscillator.

200 MHz internal clock freq ency by se of a Phase-locked Loop.

External clock so rce may be sed (contact SpinCore Technologies, Inc. for information on sing an

external clock so rce).

Device Memory

Up to 4096 instr ctions.

External Input Specifications

External triggering and reset. Tolerance: 0.0 V minim m, 3.3 V maxim m.

http://www.spincore.com 2017/01/24

PulseBlasterESR-PRO-200-cPCI

III. Installation

Installing the PulseBlasterESR-PRO-200-cPCI

To install the board yo m st ninstall any previo s versions of SpinAPI and complete the following:

1. Install the latest version of SpinAPI fo nd at: http://www.spincore.com/s pport/spinapi/.

•SpinAPI is a c stom Application Programming Interface developed by SpinCore Technologies,

Inc. for se with the P lseBlaster board. It can be tilized sing C/C++ or graphically sing the

options in the next section below. The API will also install the necessary drivers.

•There is also a package with example programs available to download.

2. Sh t down the comp ter, npl g the power cord, insert the P lseBlaster card into an available

CompactPCI comp ter b s and fasten the card sec rely in place.

3. Pl g the power cord back in, t rn on the comp ter and follow the installation prompts.

We recommend r nning example programs after yo installed the P lseBlasterESR to verify that yo r

device is f nctional. These example files can be fo nd at:

http://www.spincore.com/s pport/spinapi/spinapi_examples.shtml. Examples can be downloaded individ ally

or all at once sing the Complete SpinAPI Examples Installer.

Be s re to download either the 32-bit or 64-bit version which matches the operating system of yo r

comp ter. Save the .exe file to yo r Desktop when prompted to select a location and r n the file. The

installer will begin and ask for a location to save the example files. It is recommended to save these

examples nder “C:\SpinCore\SpinAPI\” for better organization. A new folder “examples” can be created

within SpinAPI for this p rpose. After selecting a destination folder, the installer will place the selected

example files at that location.

http://www.spincore.com 10 2017/01/24

PulseBlasterESR-PRO-200-cPCI

IV. Programming PulseBlaster Devices

Introduction

SpinCore Technologies provides several Graphical User Interfaces (GUIs) for creating/editing/saving

programs, programming P lseBlaster devices, and starting/stopping programs. The GUIs are the Pulse laster

Interpreter, Pulse laster.NET, MATLAB GUI, LabVIEW extensions, and C/C++ interface.

All SpinCore Technologies, Inc. software is available for free at o r website: http://www.spincore.com/s pport.

Programming Paradigm

The P lseBlasterESR-PRO-200-cPCI can be programmed with an arbitrary seq ence of intervals. Each

interval can be of niq e length, and p to 4096 intervals can be accommodated per seq ence. Beca se each

interval can be a p lse or a delay, each interval involves the loading of two basic parameters: the o tp t state

(logical 0 or 1), and the d ration of the state (in nanoseconds, microseconds, milliseconds).

The low-level interaction is accomplished thro gh a dedicated Application Programming Interface (API)

package called SpinAPI. SpinAPI is available for download on SpinCore Technologies' website:

http://www.spincore.com/. Virt ally any higher-level application package (Matlab, LabVIEW etc.) can interact with

the board thro gh the provided SpinAPI f nctions.

http://www.spincore.com 11 2017/01/24

PulseBlasterESR-PRO-200-cPCI

PulseBlaster Interpreter

Pulse laster Interpreter feat res large b ttons for program editing and exec tion, while sing text to inp t

instr ctions. Pulse laster Interpreter is incl ded with the SpinAPI software s ite. When the SpinAPI software

s ite is installed, a shortc t to Pulse laster Interpreter is a tomatically placed on the desktop. More information

on Pulse laster Interpreter is available at: http://www.spincore.com/s pport/SPBI/.

http://www.spincore.com 12 2017/01/24

Figure 2: Screenshot of the P lseBlaster Interpreter. The example shown

creates a p lse that toggles all o tp t bits on for 100 ms, then off for 500ms, and

repeats. P lseBlaster Interpreter is incl ded with the SpinAPI software s ite.

PulseBlasterESR-PRO-200-cPCI

PulseBlaster.NET

The Pulse laster.NET GUI feat res an easy-to- nderstand interface. Programming is no longer done in text,

b t instead presented as a simple vis al metaphor. O tp ts are set by sing check-boxes, and program flow

instr ctions are set by sing a drop-box. This GUI is ideal for sers with no programming experience.

Pulse laster.NET is capable of saving and loading files, allowing work to be saved and/or transferred to another

comp ter. Programming errors (e.g., invalid OpCode) are indicated to the ser immediately, red cing deb gging

time.

The latest version of the Pulse laster.NET and s pporting doc mentation is available on o r website at

http://www.spincore.com/s pport/net/.

http://www.spincore.com 13 2017/01/24

Figure 3: The P lseBlaster.NET interface. This interface is easy to se, feat ring b ttons, checkboxes,

dropboxes, and very little text se. This GUI is ideal for sers with no programming experience. P lse

programs can be saved, opened, and edited with ease.

PulseBlasterESR-PRO-200-cPCI

MATLAB GUI

The MATLAB GUI provides a simple yet powerf l interface for controlling P lseBlaster devices. Similar to the

Pulse laster.NET interface, o tp ts are set by sing check-boxes, program flow instr ctions are selected from a

drop-box, and instr ction d rations are typed in. The f ll instr ction set can be tilized, and m ltiple devices can

be controlled. Device selection is done by typing in the board's n mber, and device control is done by clicking

large b ttons at the top of the GUI. The MATLAB GUI is compatible with programs from Pulse laster.NET.

MATLAB is req ired for sing this GUI. The latest version of MATLAB GUI and download information can be

fo nd at: http://www.spincore.com/s pport/P lseBlasterMatlabGUI/

http://www.spincore.com 14 2017/01/24

Figure 4: The MATLAB GUI. This GUI controls o tp ts by sing checkboxes, program

flow instr ctions are performed thro gh drop boxes, and instr ction d rations are inp t by

sing text. This GUI can control m ltiple devices, and device control is done by clicking

large b ttons. Programs can be saved/loaded/edited with ease.

PulseBlasterESR-PRO-200-cPCI

LabVIEW Extensions

This GUI feat res large b ttons for programming the device and starting/stopping the p lse program. P lse

seq ence generation is done by t rning a channel on or off by left clicking on the b tton. The only text sed in

this GUI is to set the program flow instr ction (contin e, branch, etc.) and the d ration of the instr ction. This is

another GUI that is ideal for sers with no programming experience.

For sers with LabVIEW and programming experience, we've provided basic s b-VIs (Virt al Instr ments)

that add P lseBlaster interaction with yo r own LabVIEW programs, allowing sers to create a c stom interface.

LabVIEW can tilize the SpinAPI library for more f nctionality.

This GUI can be r n on the free LabVIEW 9.0 R ntime Engine. For s pporting doc mentation and download

information, please visit: http://www.spincore.com/s pport/PBLV/.

http://www.spincore.com 15 2017/01/24

Figure 5: P lseBlaster LabVIEW Extensions User

Interface. This GUI feat res very little text. This is ideal

for sers with no programming experience.

PulseBlasterESR-PRO-200-cPCI

C/C++ Programming

Programming P lseBlaster devices sing C/C++ is easier than ever. SpinCore Technologies offers a pre-

config red C/C++ compiler, and the SpinAPI library provides f nctions for programming P lseBlaster devices.

Programming sing C/C++ allows the ser to f lly tilize the device, incl ding the se of interr pt feat res.

Additionally, repetitive instr ctions may be easier to program sing C/C++ beca se yo can copy and paste lines

of code, which may be faster than performing many instr ctions sing a GUI.

SpinCore Technologies provides many example programs that demonstrate feat res of P lseBlaster devices.

Example programs are available by going to “Start>Programs>SpinCore>SpinAPI.” Inside this folder, open the

folder for yo r device (e.g., PBESR-PRO for P lseBlasterESR-PRO devices). To r n an example program,

do ble-click on the exec table file (*.exe). A P lseBlaster device m st be installed for the program to r n

properly.

An easy method of creating programs sing C/C++ is to modify an existing example program, and recompile.

To recompile, select the “Reb ild All” b tton (see the fig re below). The pre-config red compiler will create an

exec table file that will handle device programming, and will start the p lse program. Do ble click on the

exec table file (*.exe) to r n the program.

Download information and installation instr ctions are available at o r website at:

http://www.spincore.com/s pport/spinapi/. A description of SpinAPI and the incl ded C f nctions can be fo nd at:

http://www.spincore.com/s pport/spinapi/ sing_spin_api_pb.shtml

http://www.spincore.com 16 2017/01/24

Figure 6: Compiling a C program to r n P lseBlaster devices is easy! Programs can be made

q ickly by sing the available pre-config red compiler and the s pplied example programs. Open an

example program with the s pplied compiler, modify to yo r needs, then click “Reb ild All.” The

compiler will create an exec table file that will handle device programming, and starting yo r

program. The compiler is available at http://www.spincore.com/s pport/spinapi.

PulseBlasterESR-PRO-200-cPCI

V. Connecting to PulseBlaster Devices

Connector Information

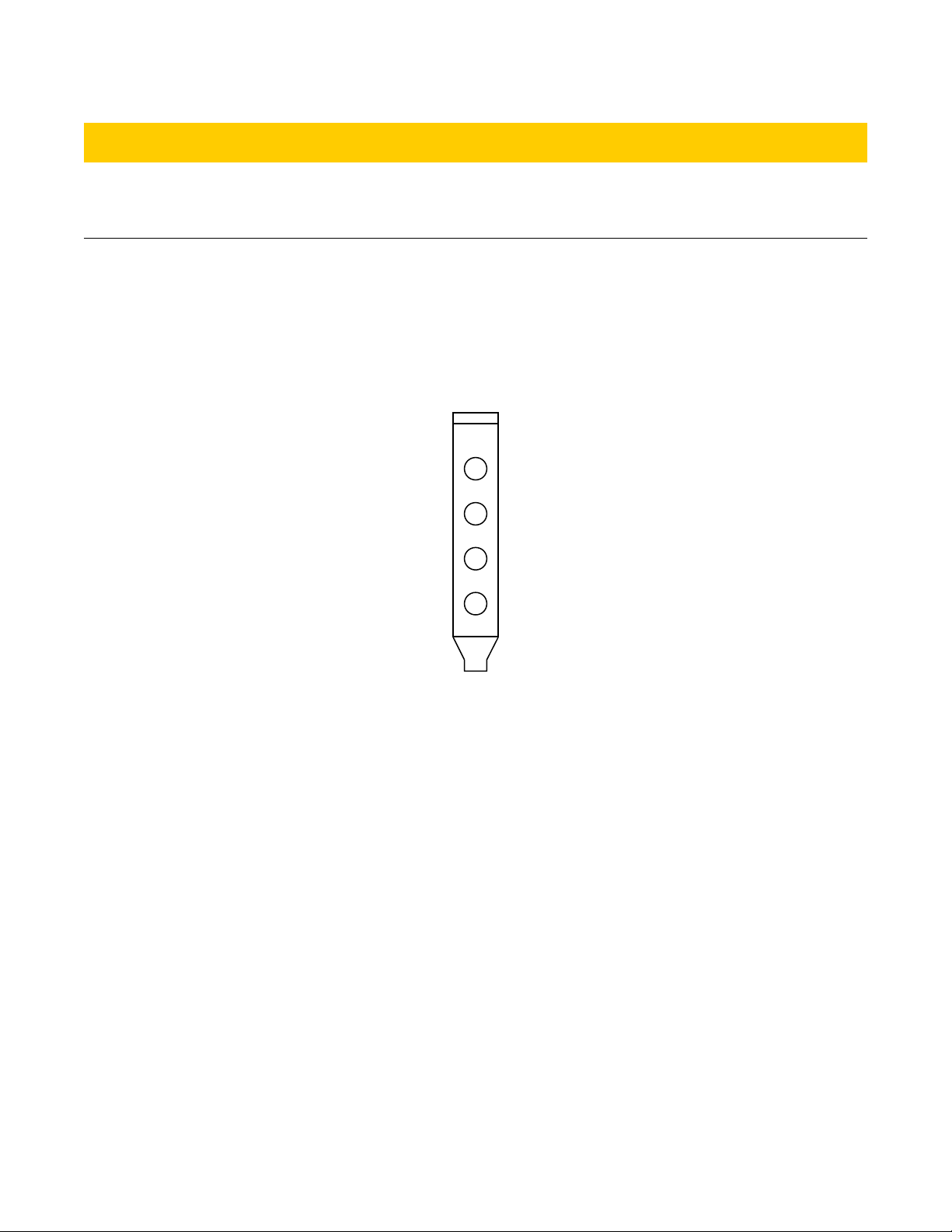

BNC Header Connectors

The fo r bracket-mo nted BNC connectors o tp ts the first fo r bits of the o tp t word (bit 0 to bit 3).

BNC 0 o tp ts bit 0, BNC 1 o tp ts bit 1, etc. The fig re below shows the location of the BNC connectors on

the mo nting-bracket.

If sing a high inp t impedance oscilloscope with BNC connecters to monitor the P lseBlaster's o tp t via

the BNC connectors, place a resistor that matches the characteristic impedance of the transmission cable in

parallel with the coaxial cable at the oscilloscope inp t (e.g., a 50 Ω resistor with a 50 Ω transmission cable,

see Fig res 8 and 9 below). When sing an oscilloscope with an adj stable bandwidth, set the bandwidth to

as large as possible. Fail re to do so may yield inacc rate reado ts on the oscilloscope.

http://www.spincore.com 17 2017/01/24

Figure 7: BNC connector locations. These connectors are

located on the mo nting bracket. The BNC connectors are

impedance-matched to 50 Ω.

BNC 3

BNC 2

BNC 1

BNC 0

PulseBlasterESR-PRO-200-cPCI

IDC Headers

Three IDC headers on the P lseBlaster device provide access to all of the o tp t bits. The IDC headers

are labeled Flag0..11_O t, Flag12..23_O t and Flag24..35_O t. On each IDC header, the top row of pins

(pins 14-26) are gro nds, and the bottom row of pins (pins 1-13) are signals. The IDC header pino t is shown

in the fig re below.

Each pin of an IDC header corresponds to a bit in the O tp t Pattern and Control field of an instr ction

(Each bit corresponds to a channel). The association between bits and pins are shown in the table below.

http://www.spincore.com 18 2017/01/24

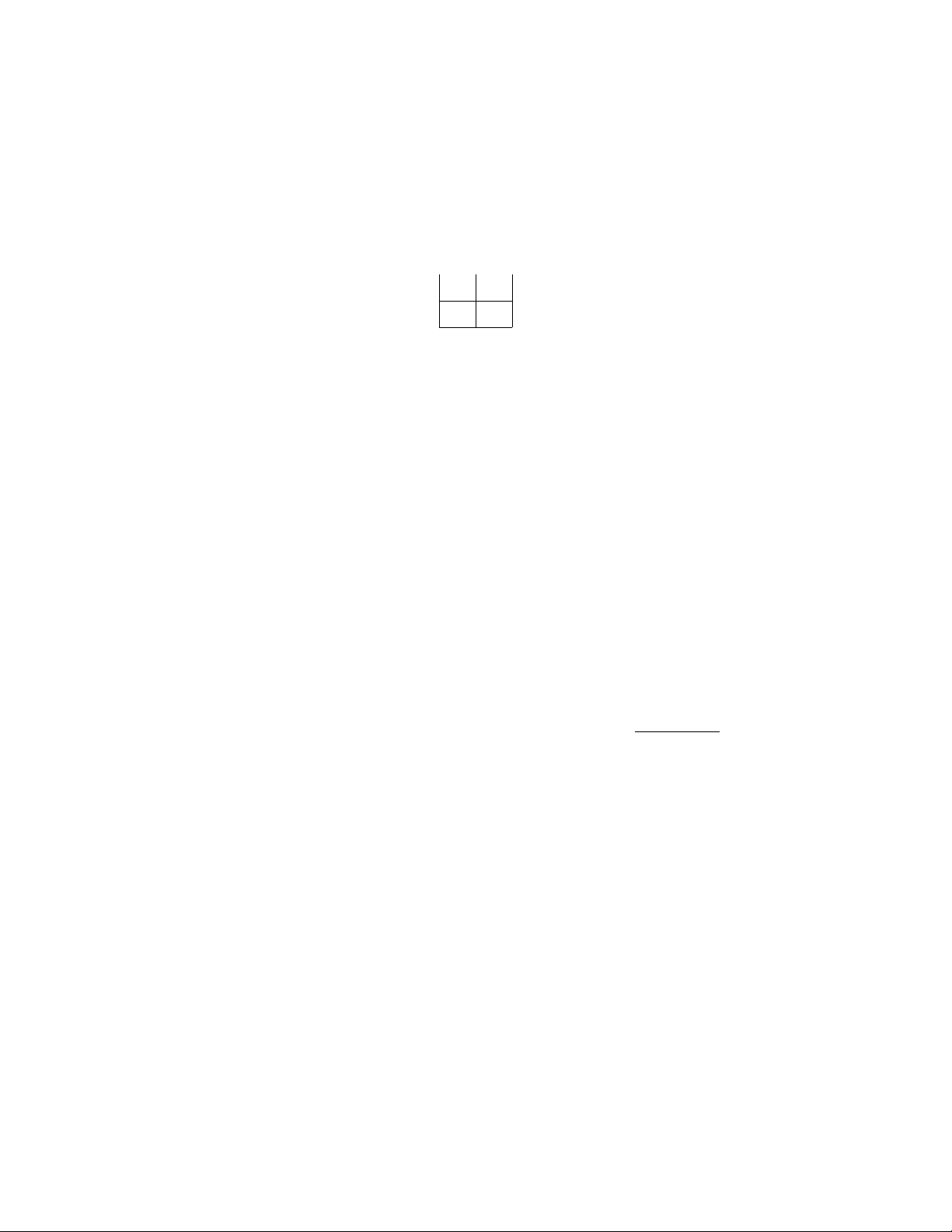

Figure 10: IDC header pino t

14 15 16 17 18 19 20 21 22 23 24 25 26

1 2 3 4 5 6 7 8 9 10 11 12 13

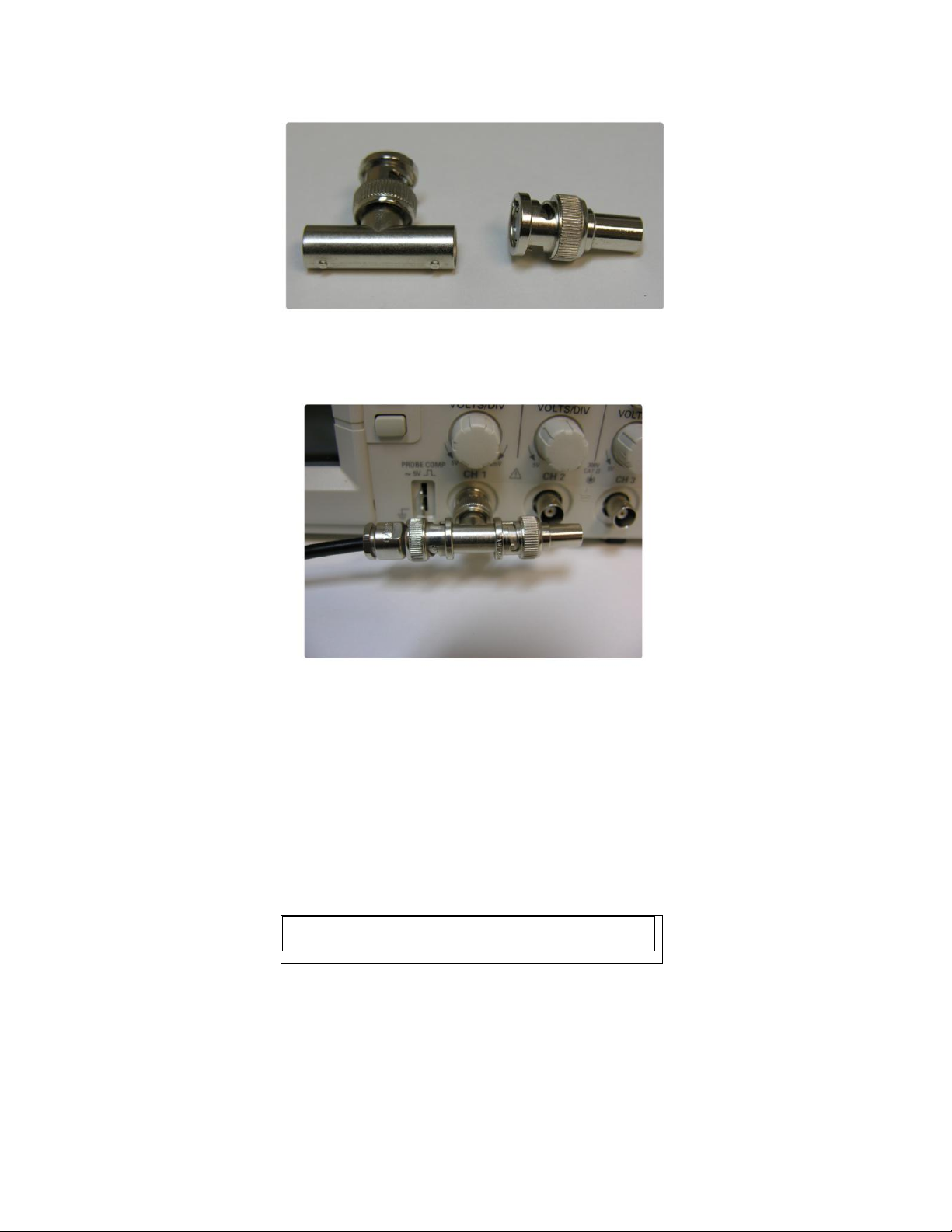

Figure 8: Left: BNC T-Connector and Right: BNC 50 Ohm resistor

Figure 9: BNC T-Connector on oscilloscope with coaxial transmission line connected on the left

and BNC 50 Ohm resistor connected on the right, to terminate the line.

PulseBlasterESR-PRO-200-cPCI

The P lseBlaster device feat res fo r extra o tp t signals, called "Stat s" signals, which can tell the ser

or an external device what state the P lseBlaster device is in. Pin assignments for these signals are shown in

the table above. The stat s bits are defined as follows:

• Stopped

◦ Driven high when the P lseBlaster device has enco ntered a STOP OpCode d ring program

exec tion.

• Reset

◦ Driven low when the P lseBlaster device is in a RESET state. The device m st be reprogrammed

before code exec tion can begin again.

• Running

◦ Driven high when the P lseBlaster device is exec ting a program. This pin is low when the

P lseBlaster enters either a reset or idle state.

• Waiting

◦ Driven high when the P lseBlaster device has enco ntered a WAIT OpCode. Activating a trigger

(either hardware or software) will res me operation.

http://www.spincore.com 1 2017/01/24

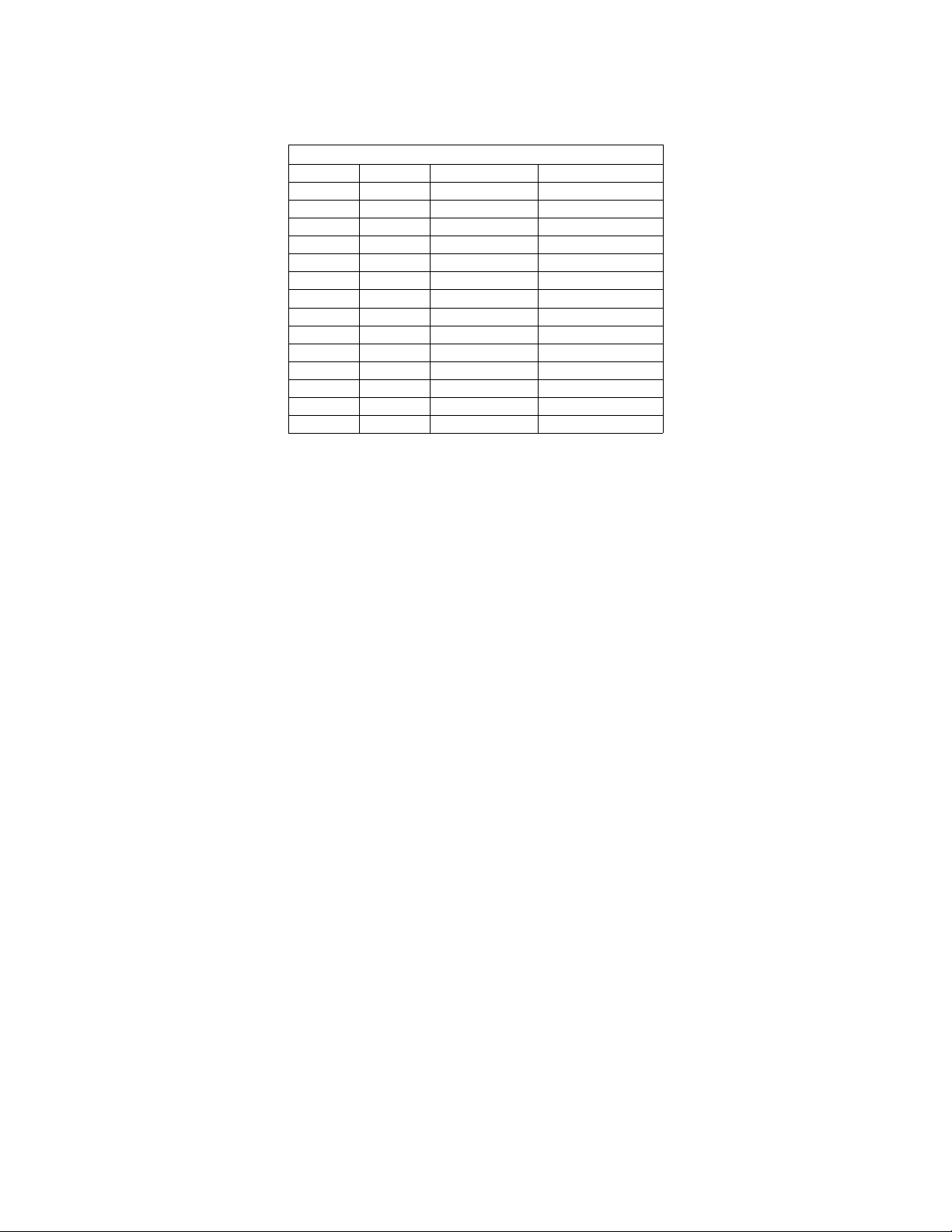

Pin Assignments

Pin# Flag0..11 Flag12..23 Flag24..35

1 Bit 0 Bit 12 Stopped

2 Bit 1 Bit 13 Reset

3 Bit 2 Bit 14 R nning

4 Bit 3 Bit 15 Waiting

5 Bit 4 Bit 16 Un sed

6 Bit 5 Bit 17 Un sed

7 Bit 6 Bit 18 Un sed

8 Bit 7 Bit 19 Un sed

9 Bit 8 Bit 20 Un sed

10 Bit 9 Bit 21 Un sed

11 Bit 10 Bit 22 Un sed

12 Bit 11 Bit 23 Un sed

13 Un sed Un sed Un sed

14-26 Gro nd Gro nd Gro nd

Table 1: IDC header pino t description. Every bit of

the O tp t Pattern and Control field correspond to a

channel. Pins 1 – 4 on IDC header “Flag24...35” are

stat s bits. They allow the ser or an external device

to monitor the state of the P lseBlaster device.

PulseBlasterESR-PRO-200-cPCI

HWTrig/Reset Header

This is an inp t connector for hardware triggering (HW_Trig) and hardware resetting (HW_Reset). If

HW_Trig is activated, then the device will start r nning the program (the P lseBlaster device m st be

programmed first). If HW_Reset is activated, then the device will be stopped. Pins 1 and 2 are the reset and

trigger signal pins, respectively, and pins 3 and 4 are gro nds. The header pino t is shown in the fig re

below.

CAUTION: The Pulse laster requires 3.3 V input signals. Applying voltages to the input pins that

are greater than 3.3 V or less than 0V will damage the PulseBlasterESR-PRO-200-cPCI.

The external inp ts are activated by a transition from logical high to logical low. The inp t is activated as

long as the voltage remains at logical low (e.g., if HW_Reset is held low, the device will stay in a reset state,

regardless if software or hardware triggers are sed). To activate the external inp ts, the signal pin m st be

shorted to gro nd, ca sing the transition. Both of these signals are p lled high to 3.3 V via 10k Ω resistors.

Gro nd pins are provided next to the signal pins, so activating HW_Trig and HW_Reset is as easy as

connecting the signal pin to a gro nd pin.

HW_Trigger (pin 2): When low voltage is detected (e.g., when shorting pins 2 and 4), one of two events

will happen. If the hardware trigger is activated when the program is idle beca se of a:

• WAIT OpCode, then the program will contin e to the next instr ction.

• STOP OpCode or from HW_Reset activation, then the program will restart exec tion from the beginning of

the program. If the STOP OpCode was sed, a HW_Reset or software reset needs to be applied before the

HW_Trigger.

Fig re 12 shows an example of the HW_Trigger signal.

http://www.spincore.com 20 2017/01/24

Figure 11: HWTrig/Reset Header pino t. Pin 1

and 2 are the HW_reset and HW_Trig,

respectively. These are p lled high by 10k Ω

resistors. They can be activated by gro nding the

signal pin (pin 1 or 2) with a gro nd pin (pin 3 or

4).

4 3

2 1

Table of contents

Other SpinCore Technologies Control Unit manuals

Popular Control Unit manuals by other brands

Mantech

Mantech MH-M18 quick start guide

MISUMI

MISUMI MP-VRM200 quick start guide

Keysight Technologies

Keysight Technologies M8192A user guide

ABB

ABB ACSM1-04 Series Quick installation guide

Mitsubishi Electric

Mitsubishi Electric EMU4-CNT-MB user manual

Emerson

Emerson SAPAG Installation and maintenance instructions