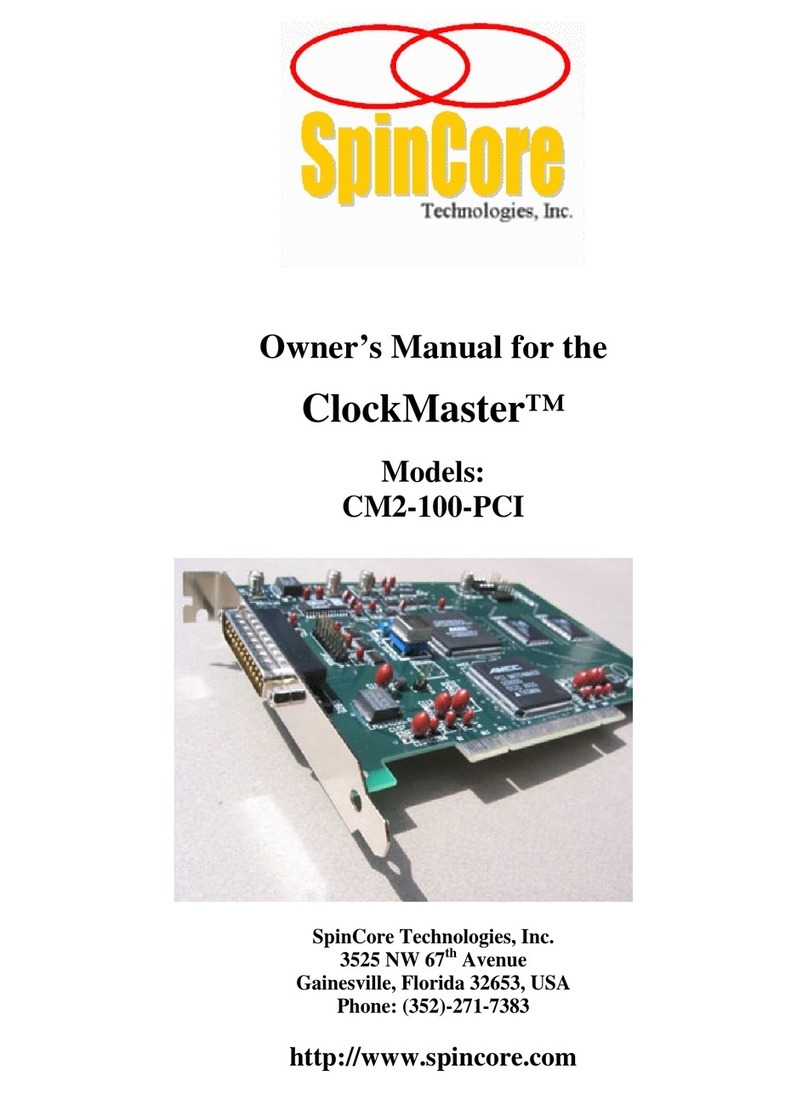

SpinCore Technologies PulseBlaster DDS-III User manual

PulseBlasterDDS™

Model DDS-III

(PCI Board SP3)

Owner’s Manual

SpinCore Technolo ies, Inc.

http://www.spincore.com

PulseBlasterDDS

Con ratulations and thank you for choosin a desi n from

SpinCore Technolo ies, Inc.

We appreciate your business!

At SpinCore we try to fully support the needs of our customers. If you

are in need of assistance, please contact us and we will strive to

provide the necessary support.

© 2000-2004 SpinCore Technologies, Inc. All rights reserved.

SpinCore Technologies, Inc. reserves the right to make changes to the product s) or information herein without notice.

PulseBlasterDDS™, PulseBlaster™, SpinCore, and the SpinCore Technologies, Inc. logos are trademarks of SpinCore

Technologies, Inc. All other trademarks are the property of their respective owners.

SpinCore Technologies, Inc. makes every effort to verify the correct operation of the equipment. This equipment version is not

intended for use in a system in which the failure of a SpinCore device will threaten the safety of equipment or person s).

9/20/20052

www.spincore.com

PulseBlasterDDS

Table of Contents

I. Introduction

...................................................................................................................... 5

Product Overview ................................................................................................... 5

Board Architecture ................................................................................................. 6

Block Diagram .................................................................................................... 6

Output signals..................................................................................................... 6

Timing characteristics......................................................................................... 7

Phase Coherent Switching.................................................................................. 7

Instruction set...................................................................................................... 7

External triggering .............................................................................................. 7

Status eadback................................................................................................. 7

Summary............................................................................................................. 7

Specifications.......................................................................................................... 8

DDS Specifications ............................................................................................ 8

TTL Specifications.............................................................................................. 8

Common Parameters (DDS and TTL Specifications)......................................... 8

Pulse Program Control Flow (Common)............................................................. 8

II. Installation

...................................................................................................................... 9

Installin the PulseBlasterDDS Driver................................................................... 9

For Windows XP...................................................................................................... 9

Initializin Control of the PulseBlasterDDS........................................................ 10

III. Pro rammin the PulseBlasterDDS

.................................................................................................................... 11

Instruction Set Architecture.................................................................................. 11

Machine-Word Definition................................................................................... 11

Breakdown of 80-bit Instruction Word............................................................... 11

Usin C Functions to Pro ram the PulseBlasterDDS........................................ 13

Example Use of C Functions............................................................................ 15

IV. Connectin to the PulseBlasterDDS Board

.................................................................................................................... 17

Connector Information.......................................................................................... 17

SMA Connectors labeled DAC_OUT_0, DAC_OUT_1, and DAC_OUT_2.......17

9/20/20053

www.spincore.com

PulseBlasterDDS

DB-25 - TTL Output Signal Bits........................................................................ 17

IDC Connector Status - Pin Assignments......................................................... 18

Header JP100................................................................................................... 18

SMA Connector labeled “SMA0”....................................................................... 18

SMA Connector labeled “SMA400”................................................................... 18

Appendix I: Sample C pro ram

.................................................................................................................... 19

Example Pro ram.................................................................................................. 19

Appendix II: Pro rammin the PulseBlasterDDS Usin Direct Outputs.

22

Usin DLL Functions to Send Instructions......................................................... 22

Building Instructions Using the DLL Functions................................................. 22

Pro rammin Information..................................................................................... 22

Example Pro ram.................................................................................................. 24

Contact Information

.................................................................................................................... 27

9/20/20054

www.spincore.com

PulseBlasterDDS

I. Introduction

Product Overview

The PulseBlasterDDS series of Intelligent Pattern and Waveform Generation boards from SpinCore

Technologies, Inc., couples SpinCore’s unique Intelligent Pattern Generation processor core, dubbed

PulseBlaster, with Direct Digital Synthesis DDS) for use in system control and pulse generation.

The PulseBlaster’s state-of-the-art timing processor core provides all the necessary timing control

signals required for overall system control and pulse synchronization. By adding DDS features,

PulseBlasterDDS can now provide not only digital TTL) but also analog output signals, meeting high-

performance and high-precision complex excitation/stimuli needs of demanding users.

PulseBlasterDDS provides users the ability to control their systems through the generation of fully

synchronized digital and analog) excitation pulses from a small form factor PC board, providing users a

compelling price/performance proposition unmatched by any other device on the market today. Figure 1

presents sample capabilities of the board.

Fi ure 1: Sample PulseBlasterDDS output capabilities

9/20/20055

www.spincore.com

PulseBlasterDDS

Board Architecture

Block Diagram

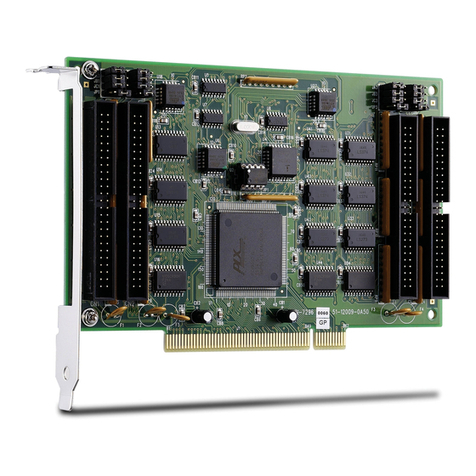

Figure 2 presents the general architecture of the PulseBlasterDDS system. The two major building

blocks are the DDS Core and the Pulse Programming and Timing Processor Core PP Core). The

DDS Core contains a numerically controlled oscillator and has 16 programmable frequency registers

that are under the pulse program control. Prior to gating, the DDS signal can be phase offset by one of

two sets of 16 programmable phase registers. The PP Core controls the timing of the gating pulses

and provides the necessary control signals for frequency and phase registers. The DDS and PP cores

have been integrated onto a single silicon chip. High performance DAC chips and high current output

amplifiers complement the design. User control to the system is provided through the host-

programming interface over the PCI bus.

Fi ure 2: PulseBlasterDDS board architecture

Output signals

The PulseBlasterDDS comes with three analog output channels configured to output radio-frequency

RF/IF) pulses, and 10 digital output signal lines one of the output lines has a dual use and

functions as a phase reset for the DDS generator). The frequency and phase of the RF pulses generated

by the DDS are under the control of the user and are specified through software programming. The phase

of the numerically controlled oscillator can be reset on demand within the pulse program.

PulseBlasterDDS provides the ability to gate the output of the DDS channels allowing for independent

pulsed RF operation. With digital sampling rate of 100 MHz max. reference clock frequency), the

maximum theoretical output frequency is 50 MHz the Nyquist Theorem). 1 The analog output signal is

available on an on-board SMA connector. The output impedance of the analog signal is 50-ohms. There

are no interpolating filters on board.

1 Note that the usefulness of a waveform with two samples per period is limited, and, depending on applications,

practical considerations would often call for more than two samples per period.

9/20/2005

DAC

RF

Outputs

(SMA)

Phase0-15 Gate

Numerically

Conrolled

Oscillator

DAC

Gate

Phase0-15

Freq0-15

Reference Clock

Oscillator

Precision Timing Processor Output and Control Register

TTL

Outputs

(DB-25)

SRAM

Host Programming Interface

User Control PulseBlasterDDS-III

© 2004 SpinCore Technologies, Inc.

http://www.spincore.com

Gate DAC

DDS Core

Pulse Timing

Core

Tx

Rx

www.spincore.com

PulseBlasterDDS

The 10 individually controlled digital TTL/CMOS) output bits are capable of delivering ±25 mA per

bit and have an output voltage of 3.3V. These signals are available on the PC bracket-mounted DB-25

connector. Setting output bit 10 high via the output control word also resets the phase of the RF

waveforms for phase coherent switching, and can be used to generate a constant voltage on the

DACs.

Timing characteristics

PulseBlasterDDS’s timing controller can accept either an internal on-board) crystal oscillator or

an external frequency source of up to 100 MHz. The innovative architecture of the timing controller

allows the processing of either simple timing instructions delays of up to 232 = 4,294,967,296 clock

cycles), or double-length timing instructions up to 252 clock cycles long – nearly 2 years with a 100

MHz clock!). Regardless of the type of timing instruction, the timing resolution remains constant for

any delay – just one clock period e.g., 10 ns for a 100 MHz clock).

The timing controller has a very short minimum delay cycle – only nine clock periods. This

translates to a 90 ns minimum pulse/delay/update with a 100 MHz clock.

Phase Coherent Switching

The board allows for phase continuous and/or phase coherent switching. In addition, the DDS

can be reset to zero whenever a new RF pulse is started. Consult the explanation of the flags

parameter to the pb_inst instruction on page 12 for implementing the phase reset.

Instruction set

PulseBlasterDDS’ design features a set of commands for highly flexible program flow control. The

micro-programmed controller allows for programs to include branches, subroutines, and loops at up to

8 nested levels – all this to assist the user in creating dense pulse programs that cycle through

repetitious events, especially useful in numerous multidimensional spectroscopy and imaging

applications.

External triggering

PulseBlasterDDS can be triggered and/or reset externally via dedicated hardware lines. The two

separate lines combine the convenience of triggering e.g., in cardiac gating) with the safety of the

"stop/reset" line. The required control signals are “active low” or short to ground).

Status Read ack

The status of the program can be read in hardware or software. The hardware status output

signals consist of five IDC connector pins labeled “Status”. The same output can be read through

software using C. See section IV Connecting to the PulseBlaster Board, page 16) for more detail

about the hardware lines and section III Programming the PulseBlaster, page 11) for more detail

about the C function status_readback ).

Summary

PulseBlasterDDS is a versatile, high-performance pulse/pattern TTL and RF/IF generator

operating at speeds of up to 100 MHz and capable of generating pulses/delays/intervals ranging from

90 ns to over 2 years per instruction. It can accommodate pulse programs with highly flexible control

commands of up to 32k program words. Its high-current output logic bits are independently controlled

with a voltage of 3.3 V. The output impedance of the analog channel is 50-ohms.

9/20/20057

www.spincore.com

PulseBlasterDDS

Specifications

DDS Specifications

•100 MHz reference clock oscillator other frequencies available upon request)

•0.047 Hz frequency resolution 32 bits)

•16 loadable frequency registers for agile frequency modulation/switching/selection 32 bits

each)

•Two sets of 16 loadable phase-offset registers for agile phase modulation/switching/selection

12 bits each)

•0.09° phase resolution 12 bits)

•40 ns phase switching latency

•40 ns frequency switching latency phase continuous)

•phase coherent switching

•10 dBm RF output power

•50 ohm output impedance

•SMA connectors

•30 MHz 3dB bandwidth

•RF Output capable of outputting DC at programmed output level using phase offset)

TTL Specifications

•10 individually controlled digital output lines TTL levels; one of the output lines has a dual use

and functions as a phase reset for the DDS generator)

•variable pulses/delays for every TTL line

•25 mA output current per TTL line

•output lines can be combined to increase the max. output current

Common Parameters (DDS and TTL Specifications)

•90 ns shortest pulse/interval per instruction

•2 years longest pulse/interval per instruction

•10 ns pulse/interval resolution

•RF and TTL pulses are synchronized

•32k max. memory space

•external triggering and reset – TTL levels

Pulse Program Control Flow (Common)

•loops, nested 8 levels deep

•20 bit loop counters max. 1,048,576 repetitions)

•subroutines, nested 8 levels deep

•wait for trigger - 80 ns latency, adjustable to 2 years in duration

•Approximately 2 MHz max. re-triggering frequency based on the latency of the WAIT opcode)

9/20/20058

www.spincore.com

PulseBlasterDDS

II. Installation

Installin the PulseBlasterDDS Driver

1. Go to http://www.pulseblaster.com/CD/PulseBlasterDDS/PCI/SP3 and download sp3.zip.

2. Unzip the files to their own directory.

3. Turn off your computer.

4. Insert the PulseBlasterDDS board into an empty PCI slot. Secure the bracket firmly with a screw.

5. Turn on your computer.

For Windows XP

6. After booting, the “Found New Hardware Wizard” should appear. Choose “Install from a list or specific

location” and click Next

7. Choose “Include this location in the search” and browse to the directory you unzipped the drivers to.

Click next.

9/20/20059

www.spincore.com

PulseBlasterDDS

8. While windows installs the driver, a “Files Needed” dialog may pop up. Choose the directory you

unzipped the drivers to, and click ok.

9. When finished, you should see this window.

NOTE: On some systems after you install your PulseBlasterDDS board you may need to run “Install.bat”

located in the “post_installation_files.zip” file located at

http://www.pulseblaster.com/CD/PulseBlasterDDS/PCI/SP3/old_version/post_installation_files.zip

in order for your board to work.

You are now ready to control the PulseBlasterDDS board

Initializin Control of the PulseBlasterDDS

3. Run the included “SP3_Test.exe”.

If equipped with a 100 MHz reference clock oscillator, the board should now output a 6.250MHz sine

wave on the SMA connectors labeled “DAC_OUT_0”, “DAC_OUT_1”, and “DAC_OUT_2”. The 10

TTL output lines should toggle every second.

The PulseBlasterDDS oard is now ready for use!

9/20/200510

www.spincore.com

PulseBlasterDDS

III. Pro rammin the PulseBlasterDDS

Instruction Set Architecture

Machine-Word Definition

The PulseBlaster pulse timing and control processor implements an 80-bit wide Very Long

Instruction Word VLIW) architecture. The VLIW memory words have specific bits/fields dedicated to

specific purposes, and every word should be viewed as a single instruction of the micro-controller.

The maximum number of instructions that can be loaded to on-board memory is 32k. The execution

time of instructions can be varied and is under self) control by one of the fields of the instruction word

– the shortest being five clock cycles for 512 memory-word models) and the longest being 2^52 clock

cycles. All instructions have the same format and bit length, and all bit fields have to be filled. Figure

3 shows the fields and bit definitions of the 80-bit instruction word.

Bit Definitions for the 80-bit Instruction Word (VLIW)

Output/Control Word | Data Field | OP Code | Delay Count

(24 bits) (20 bits) (4 bits) (32 bits)

Fi ure 3: Bit definitions of the 80-bit instruction/memory word

Breakdown of 80- it Instruction Word

The 80-bit VLIW is broken up into 4 sections

1. Output Pattern and Control Word - 24 bits

2. Data Field - 20 bits

3. OP Code - 4 bits

4. Delay Count - 32 bits

Output Pattern and Control Word

Please refer to Table 1, next page, for output pattern and control bit assignments of the 24-bit

output/control word.

9/20/200511

www.spincore.com

PulseBlasterDDS

Bit # Function Bit # Function

23 Selects Frequency Register bit 3) 11 Selects Phase Register for SMA connectors

labeled DAC_OUT_2 and DAC_OUT_0 bit 0)

22 Selects Frequency Register bit 2) 10 Output Enable for SMA connectors labeled

DAC_OUT_1 and DAC_OUT_0 0 = on, 1 = off)

21 Selects Frequency Register bit 1) 9 RF phase reset for phase coherent switching,

also routed to Output Connector DB25 pin 19

20 Selects Frequency Register bit 0) 8 Output Connector DB25 pin 7

19 Selects Phase Register for SMA connector

labeled DAC_OUT_1 bit 3) 7 Output Connector DB25 pin 8

18 Selects Phase Register for SMA connector

labeled DAC_OUT_1 bit 2) 6 Output Connector DB25 pin 21

17 Selects Phase Register for SMA connector

labeled DAC_OUT_1 bit 1) 5 Output Connector DB25 pin 22

16 Selects Phase Register for SMA connector

labeled DAC_OUT_1 bit 0) 4 Output Connector DB25 pin 10

15 Output Enable for SMA connector labeled

DAC_OUT_2 0 = on, 1 = off) 3 Output Connector DB25 pin 11

14 Selects Phase Register for SMA connectors

labeled DAC_OUT_2 and DAC_OUT_0 bit 3) 2 Output Connector DB25 pin 24

13 Selects Phase Register for SMA connectors

labeled DAC_OUT_2 and DAC_OUT_0 bit 2) 1 Output Connector DB25 pin 25

12 Selects Phase Register for SMA connectors

labeled DAC_OUT_2 and DAC_OUT_0 bit 1) 0 Output Connector DB25 pin 13

Table 1: Output Pattern and Control Word Bits

Data Field and Op Code

Please refer to Table 2 for information on the available operational codes OpCode) and the

associated data field functions the data field's function is dependent on the Op Code)

Op Code Instruction Data Field Function

0 CONTINUE Ignored Program execution continues to next instruction

1 STOP Ignored Stop execution of program *Note all TTL values remain

from previous instruction, and analog outputs turn off)

2 LOOP

Number of desired loops.

This value must be greater

than or equal to 1.

Specify beginning of a loop. Execution continues to next

instruction. Data used to specify number of loops

3 END_LOOP Address of beginning of

loop

Specify end of a loop. Execution returns to begging of

loop and decrements loop counter.

4 JSR Address of first subroutine

instruction Program execution jumps to beginning of a subroutine

5 RTS Ignored Program execution returns to instruction after JSR was

called

6 BRANCH Address of next instruction Program execution continues at specified instruction

7 LONG_DELAY

Number of desired loops.

This value must be greater

than or equal to 2.

For long interval instructions. Data field specifies a

multiplier of the delay field. Execution continues to next

instruction

8 WAIT Ignored

Program execution stops and waits for software or

hardware trigger. Execution continues to next instruction

after receipt of trigger. The latency is equal to the delay

value entered in the WAIT instruction line plus a fixed

delay of 6 clock cycles.

Table 2: Op Code and Data Field Description

Delay Count

9/20/200512

www.spincore.com

PulseBlasterDDS

The value of the Delay Count field a 32-bit value) determines how long the current instruction should

be executed. The allowed minimum value of this field is 0x6 for the 32k memory models. The timing

controller has a fixed delay of three clock cycles and the value that one enters into the Delay Count field

should account for this inherent delay.

Usin C Functions to Pro ram the PulseBlasterDDS

A series of functions have been written to control the board and facilitate the construction of pulse

program instructions. The functions also allow the programmer to set the DDS frequency and phase

registers.

In order to use these functions, the DLL pbd03pc.dll), the library file pbd03pc.lib), the header files

pbd03pc.h and pbdfuncs.h), and source file pbdfuncs.cpp) must be in the working directory of your C

compiler2.

int pb_init();

Initializes PulseBlasterDDS board. Needs to be called before calling any functions using the

PulseBlasterDDS. Returns a negative number on an error or 0 on success.

int pb_close();

Releases PulseBlasterDDS board. Needs to be called as last command in pulse program.

Returns a negative number on an error or 0 on success.

void set_clock(double clock_fre );

Used to set the clock frequency of the board. The variable clock_frequency is specified in MHz

when no units are entered. Valid units are MHz, kHz, and Hz. The default clock value is 50MHz.

You only need to call this function if you are not using a 50MHz board.

int start_programming(int device);

Used to initialize the system to receive programming information. It accepts a parameter

referencing the target for the instructions. Valid values for device are PULSE_PROGRAM,

FREQ_REGS, PHASE_REGS_0, and PHASE_REGS_1. PHASE_REGS_0 programs the phase

registers for the DDS output on SMA connectors labeled DAC_OUT_0 and DAC_OUT_2.

PHASE_REGS_1 programs the phase registers for the DDS output on SMA connector labeled

DAC_OUT_1. The function returns a 0 on success or a negative number on an error.

int set_fre (double fre );

Used to set the values in the frequency registers. Should only be called after start_programming

FREQ_REGS) has been called. Registers are programmed one at a time, starting at 0 and

incrementing each time this function is called. It accepts the value for the frequency register with

a default unit of MHz. Valid units are MHz, kHz, Hz. It returns a 0 on success or a negative

number on an error.

int set_phase(double phase);

Used to set the values in the phase registers. Should only be called after start_programming

PHASE_REGS_0) or start_programming PHASE_REGS_1) has been called. Registers are

programmed one at a time, starting at 0 and incrementing each time this function is called. It

accepts the value for the phase register in degrees. It returns a 0 on success or a negative

number on an error.

int pb_inst(int fre , int phase_SMA_1, int tx_output_enable,

int phase_SMA_0, int rx_output_enable, int flags, int inst,

2 These functions and library files have been generated and tested with the MS Visual Studio environment. Support and updated

functions/DLLs for other environments may be provided upon request if available.

9/20/200513

www.spincore.com

PulseBlasterDDS

int inst_data, double length);

Used to send one instruction of the pulse program. Should only be called after

start_programming PULSE_PROGRAM) has been called. It returns a negative number on an

error, or the instruction number upon success. If the function returns –99, an invalid parameter

was passed to the function. Instructions are numbered starting at 0.

int freq – Selects the frequency register to be used. Valid range is from 0 to 16

int phase_SMA_1 – Selects the phase register to be used from the phase registers programmed

using start_programming PHASE_REG_1). This is the DDS output on SMA connector labeled

DAC_OUT_1. Valid range is from 0 to 16

int tx_output_enable – Determines whether analog output is generating a sinusoid or is at

ground for TX output on SMA connector labeled DAC_OUT_2. Valid values are

TX_ANALOG_ON and TX_ANALOG_OFF

int phase_SMA_0 – Selects the phase register to be used from the phase registers programmed

using start_programming PHASE_REG_0). This is the DDS output on SMA connectors labeled

DAC_OUT_0 and DAC_OUT_2. Valid range is from 0 to 16

int rx_output_enable – Determines whether analog output is generating a sinusoid or is at

ground for RX output on SMA connectors labeled DAC_OUT_0 and DAC_OUT_1. Valid values

are RX_ANALOG_ON and RX_ANALOG_OFF

int fla s – determines state of each TTL output bit. Valid values are 0x0 to 0x3FF. For example,

0x010 would correspond to bit 5 being on and all other bits being off. Bit 10, corresponding to

hexadecimal value 0x200, is used to reset the phase of the numerically controlled oscillator. This

results in phase coherent switching. The numerical oscillator will pause for the length of the

instruction, resulting in a constant voltage at the DAC. The voltage level depends on the value of

the phase register in use.

int inst – determines which type of instruction is to be executed. Please see Table 2 for details.

int inst_data – data to be used with the previous inst field. Please see Table 2 for details.

double len th – duration of this pulse program instruction, specified in ns.

This function has been overloaded to accommodate TTL-only programs. When using the shorter

version of the function, the RF channel has its output set to ground. The overloaded form follow:

TTL Only:

int pb_inst(int fla s, int inst, int inst_data, double len th);

int stop_programming();

Used to tell that programming the board is complete. Board execution cannot start until this

command is received. It returns a 0 on success or a negative number on an error.

int start_pb();

Once board has been programmed, this instruction will start execution of pulse program. It

returns a 0 on success or a negative number on an error.

int stop_pb();

Stops output of board. Analog output will return to ground, and TTL outputs will remain in the

state they were in when stop command was received. It returns a 0 on success or a negative

number on an error.

9/20/200514

www.spincore.com

PulseBlasterDDS

int status_readback();

Reads the status of the board and returns an integer whose bit representation corresponds to the

status signals described in section IV. Bit zero is stopped; bit one is reset; bit two is running; bit

three is waiting.

Example Use of C Functions

// Example1.cpp

//

// SpinCore Technologies, nc.

// May 2004

// http://www.spincore.com

//

// The following program code uses C Functions from 'pbdfuncs' to

// generate and execute a pulse sequence on the PulseBlasterDDS board.

// Be sure to include the DLL (pbd03pc.dll), the library file

// (pbd03pc.lib), the header files (pbd03pc.h and pbdfuncs.h), and source

// file (pbdfuncs.cpp) in the working directory of your C compiler .

#include "pbdfuncs.h"

#include "pbdfuncs.cpp"

#include "PBD03PC.h"

#include <stdio.h>

void main(void)

{

int start;

// Locates & nitializes the PulseBlasterDDS Board

pb_init();

// Set Because the Board Operates at 100MHz

set_clock(100);

// Prepare the Board to Receive Freqeuncy Values

start_programming(FREQ_REGS);

// Load Frequency Register 0

set_freq(1.054);

// Load Frequency Register 1

set_freq(2);

// Prepare the Board to Receive TX Phase Values

start_programming(PHASE_REGS_1);

// Load Phase Register 0

set_phase(0);

// Load Phase Register 1

set_phase(90);

// Prepare the Board to Receive RX Phase Values

start_programming(PHASE_REGS_0);

// Load Phase Register 0

set_phase(0);

// Load Phase Register 1

set_phase(180);

// Prepare the Board to Receive pulse program instructions

start_programming(PULSE_PROGRAM);

// nstruction 0 - Continue to instruction 1 in 2us

//Freq Reg 0, Phase Reg 1 for DAC_OUT_1, DDS TX Output ON, Phase Reg 0 for

//DAC_OUT_0 and DAC_OUT_2, DDS RX Output ON, Flags = 0x3FF, OPCODE = CONT NUE

start = pb_inst(0, 1, TX_ANALOG_ON, 0, RX_ANALOG_ON, 0x3FF, CONT NUE, 0, 2*us);

// nstruction 1 - Continue to instruction 2 in 4us

//Freq Reg 0, Phase Reg 1 for DAC_OUT_1, DDS TX Output OFF, Phase Reg 0 for

//DAC_OUT_0 and DAC_OUT_2, DDS RX Output ON, Flags = 0x000, OPCODE = CONT NUE

9/20/200515

www.spincore.com

PulseBlasterDDS

pb_inst(0, 1, TX_ANALOG_OFF, 0, RX_ANALOG_ON, 0x000, CONT NUE, 0, 4*us);

// nstruction 2 - Branch to "start" ( nstruction 0) in 2us

//Freq Reg 0, Phase Reg 1 for DAC_OUT_1, DDS TX Output ON, Phase Reg 0 for

//DAC_OUT_0 and DAC_OUT_2, DDS RX Output ON, Flags = 0x000, OPCODE = BRANCH

pb_inst(0, 1, TX_ANALOG_ON, 0, RX_ANALOG_ON, 0x000, BRANCH, start, 2*us);

// Finished Sending nstructions

stop_programming();

// Run the Program

start_pb();

// Release Control of the PulseBlasterDDS Board

pb_close();

}

A more complex program using C Functions is provided in Appendix I.

9/20/20051

www.spincore.com

PulseBlasterDDS

IV. Connectin to the PulseBlasterDDS Board

Connector Information

SMA Connectors la eled DAC_OUT_0, DAC_OUT_1, and DAC_OUT_2

Outputs DDS signals generated by the user’s Program. The output impedance is 50 ohms.

Output power is approximately 10 dBm. Figure 4 is a portion of figure 2 that illustrates which RF output

corresponds to which SMA connector.

Figure 4: SMA Connectors

DB-25 - TTL Output Signal Bits

Outputs TTL signals generated by the user’s Program. Please consult the table below for bit

assignments.

Pin Assignments

Pin# Bit# Pin# Bit#

1 GND 14 GND

2 Reserved 15 Reserved

3 GND 16 Reserved

4 Reserved 17 GND

5 Reserved 18 Reserved

6 GND 19 9

7 8 20 GND

8 7 21 6

9 GND 22 5

10 4 23 GND

11 3 24 2

12 GND 25 1

13 0

Table 3: Output bits and signals of the PulseBlasterDDS board

9/20/200517

DAC

RF

Outputs (SMA)

Phase0-15 Gate

DAC

Gate

Phase0-15

Gate DAC

www.spincore.com

Tx

Rx

DAC OUT 2

DAC OUT 0

DAC OUT 1

PulseBlasterDDS

IDC Connector Status - Pin Assignments

The IDC connector labeled Status outputs TTL signals based on status of the user’s program.

Please consult the table below for pin assignments.

Pin Assignments

Pin# Pin#

1 Stopped 5 Running

2 GND 6 GND

3 Reset 7 Waiting

4 GND 8 GND

Table 4: Status signals of the PBDDS-III

The status pins correspond to the current state of the pulse program and are defined as follows:

Stopped – Driven high when the PulseBlaster device has encountered a STOP Op Code during program

execution and has entered a stopped state.

Reset – Driven high when the PulseBlaster device is in a RESET state and must be reprogrammed before

code execution can begin again.

Running – Driven high when the PulseBlaster device is executing a program. It is low when the

PulseBlaster enters either a reset or idle state.

Waiting – the PulseBlaster device has encountered a WAIT Op Code and is waiting for the next trigger

either hardware or software) to resume operation.

Header JP100

This is an input connector, for hardware triggering HW_Trigger) and resetting HW_Reset).

HW_Tri er is pulled high by default, and pin 1 is active pin 2 = GND). When a low state is

detected e.g., when shorting pins 1-2), it initiates code execution. This trigger will also restart

execution of a program from the beginning of the code if it is detected after the design has reached an

idle state. The idle state could have been created either by reaching the STOP Op Code of a

program, or by the detection of the HW_Reset signal. When the WAIT Op Code is used in the pulse

program, the HW_Trigger will cause the program to continue to the next instruction.

HW_Reset is pulled high by default, and pin 3 is active pin 4 = GND). It can be used to halt the

execution of a program by pulling it low e.g., by shorting pins 3-4). When the signal is pulled low

during the execution of a program, the controller resets itself back to the beginning of the program.

Program execution can be resumed by either a software start command or by a hardware trigger.

SMA Connector la eled “SMA0”

This SMA connector outputs the reference clock as a 3.3 V TTL signal, i.e., it generates positive-

only voltage. The output resembles a square wave if properly terminated. This signal can be

measured with an oscilloscope using either a high impedance probe at the SMA connector or a 50

ohm coaxial line that is terminated.

SMA Connector la eled “SMA400”

9/20/200518

www.spincore.com

PulseBlasterDDS

This SMA connector is used as an external clock input. Before attaching the external clock,

the internal clock must be removed from its socket. The internal clock’s orientation should be noted if

the internal clock is reconnected, it must be inserted in the same orientation or board damage may

occur). Also, the external clock must be a 3.3 V TTL signal. Another requirement is that a 50 ohm

resistor be soldered directly on the board on R401 pads or use a T connector with a 50 ohm terminator

connected directly to SMA400. Failure to follow the above requirements could result in damaging the

board.

Appendix I: Sample C pro ram

Example Pro ram

// Example2.cpp

//

// SpinCore Technologies, nc.

// May 2004

// http://www.spincore.com

//

// The following program code uses C Functions from 'pbdfuncts' to

// generate and execute a pulse sequence on the PulseBlasterDDS board.

// Be sure to include the DLL (pbd03pc.dll), the library file

// (pbd03pc.lib), the header files (pbd03pc.h and pbdfuncs.h), and source

// file (pbdfuncs.cpp) in the working directory of your C compiler .

#include "pbdfuncs.h"

#include "pbdfuncs.cpp"

#include "PBD03PC.h"

#include <stdio.h>

void main(void)

{

if (pb_init() != 0)

printf("--- Error nitializing PulseBlasterDDS ---\n");

// Check for proper initialization of PulseBlasterDDS

// Set clock frequency

set_clock(100);

// Start programming the frequency registers

start_programming(FREQ_REGS);

// Program the registers in order from 0 to 15

// Valid units are MHz, kHz, and Hz - default is MHz

9/20/200519

www.spincore.com

PulseBlasterDDS

set_freq(1*MHz); // Set register 0

set_freq(2*MHz); // Set register 1

set_freq(3*MHz); // Set register 2

set_freq(4*MHz); // Set register 3

set_freq(5*MHz); // Set register 4

set_freq(6*MHz); // Set register 5

set_freq(7*MHz); // Set register 6

set_freq(8*MHz); // Set register 7

set_freq(9*MHz); // Set register 8

set_freq(10*MHz); // Set register 9

set_freq(11*MHz); // Set register 10

set_freq(12*MHz); // Set register 11

set_freq(13*MHz); // Set register 12

set_freq(14*MHz); // Set register 13

set_freq(15*MHz); // Set register 14

set_freq(16*MHz); // Set register 15

// Start programming the phase registers for DAC_OUT_1

start_programming(PHASE_REGS_0);

// Program the registers in order from 0 to 15

// Units are in degrees

set_phase(0); // Set register 0

set_phase(22.5); // Set register 1

set_phase(45); // Set register 2

set_phase(67.5); // Set register 3

set_phase(90); // Set register 4

set_phase(112.5); // Set register 5

set_phase(135); // Set register 6

set_phase(157.5); // Set register 7

set_phase(180); // Set register 8

set_phase(202.5); // Set register 9

set_phase(225); // Set register 10

set_phase(247.5); // Set register 11

set_phase(270); // Set register 12

set_phase(292.5); // Set register 13

set_phase(315); // Set register 14

set_phase(337.5); // Set register 15

// Start programming the phase registers for DAC_OUT_0 and DAC_OUT_2

start_programming(PHASE_REGS_1);

// Program the registers in order from 0 to 15

// Units are in degrees

set_phase(0); // Set register 0

set_phase(22.5); // Set register 1

set_phase(45); // Set register 2

set_phase(67.5); // Set register 3

set_phase(90); // Set register 4

set_phase(112.5); // Set register 5

set_phase(135); // Set register 6

set_phase(157.5); // Set register 7

set_phase(180); // Set register 8

set_phase(202.5); // Set register 9

set_phase(225); // Set register 10

set_phase(247.5); // Set register 11

set_phase(270); // Set register 12

set_phase(292.5); // Set register 13

set_phase(315); // Set register 14

set_phase(337.5); // Set register 15

//Begin pulse program

start_programming(PULSE_PROGRAM);

9/20/200520

www.spincore.com

Table of contents

Other SpinCore Technologies PCI Card manuals

SpinCore Technologies

SpinCore Technologies RadioProcessor USB User manual

SpinCore Technologies

SpinCore Technologies RadioProcessor-G User manual

SpinCore Technologies

SpinCore Technologies ClockMaster CM2-100-PCI User manual

SpinCore Technologies

SpinCore Technologies PulseBlasterESR-PRO SP4B User manual

SpinCore Technologies

SpinCore Technologies PulseBlasterESR-PRO-II User manual

SpinCore Technologies

SpinCore Technologies PulseBlaster PB24-100-PCI User manual